Professional Documents

Culture Documents

Plant QRQC Form

Plant QRQC Form

Uploaded by

Jordi PalomarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plant QRQC Form

Plant QRQC Form

Uploaded by

Jordi PalomarCopyright:

Available Formats

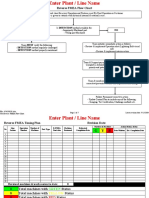

QRQC - 8D (Quick Response Quality Control)

Team: (D1) Date Opened: 5W / 2Hs 1st Problem Definition

What is the problem?

IS

IS NOT

Tracking Data

Part Number, Revision, & Part Name:

Steps

D1 to D3 1-24 hours

Milestone Review

D3: Quality Manager / Owner / Production Mgr. Definition of incident is clear ? NO YES

D2- Problem Description

Meeting Dates:

Why is it a ptoblem?

Affected Customer:

When the problem happened? When was the problem created?

Risks on similar processes, machines, plants?

D6: QRQC Owner: Production Mgr. / Logistic Mgr. / Quality Mgr. etc. Name/ Signature:

Who found the problem? Who created the problem?

Is there a safety risk? If yes, explain.

D4

D8: Responsible Mgr: Plant / Quality Mgr. / Production Mgr etc. Name/ Signature:

Where was the problem found? Where was the problem created?

Problem Statement: (Used for initiating the root cause analysis.

Shall define the following: Object (what is having the problem) & Defect (what is wrong or abnormal / undesirable)

How the problem was found ?

D5 to D8

How many? How Big?

Provide OK and NOK parts at the beginning of the analysis.

Re-occurrence:

YES

NO

Need to warn other plants/R&D?

YES

NO

D3 Temporary Countermeasures

Containment Actions

Responsible

ECD

ACD

Lot no.

Effective (Y/N)

New Risk Detected (Y/N)

Comments/ Conclusions

D4 Possible Cause & Root Cause

D4.1 Why did it escape? D4.2 Why was it made? D4.3 Why wasn't it prevented

Why 1:

Why 1:

Why 1:

Why 2:

Why 2:

Why 2:

Why 3:

Why 3:

Why 3:

Why 4:

Why 4:

Why 4:

Root Cause 1:

Root Cause 2:

Root Cause 3:

Root Cause 1:

Root Cause 2:

Root Cause 3:

Root Cause 1:

Root Cause 2:

Root Cause 3:

How were these root causes verified / validated? If you reject any of these root causes, why?

How were these root causes verified / validated? If you reject any of these root causes, why?

How were these root causes verified / validated? If you reject any of these root causes, why?

What data / evidence supports this event as the root cause? (Attach it) Example : Measurement, Sorting, Testing, etc.

What data / evidence supports this event as the root cause? (Attach it) Example : Measurement, Sorting, Testing, etc.

What data / evidence supports this event as the root cause? (Attach it) Example : Measurement, Sorting, Testing, etc.

D5 - Corrective Actions & D6 - Verify Results (Process, Machines, Standards, Hazard identification, risk assessment and determining controls)

Permanent Corrective Actions

Responsible

ECD

ACD

Lot no.

Effective (Y/N)

New Risk Detected (Y/N)

Verification Method

Verified by: & Date

D3 & D5. Indicators follow-up by date of Manufacture/ Occurrence / Action Implemented

D7 Prevent Recurrence

Who needs to be informed of the solution? How did you verify this will prevent recurrence? Was the corrective actions implemented on the similar products?

What did you change that will prevent recurrence of the root cause?

Was the Master FMEA (DFMEA/PFMEA) updated? If yes, list document number, if no explain why not?

Was the Master Control Plan, First piece inspection, operator instruction, maintenance plan, etc., updated? If yes, list document number, if no explain why not?

D8 - Congratulate the team

Was Lesson Learned Created? If yes list format of lesson & location, if no explain why not?

Explain how the lesson learned was shared with other facilities.

What went well in this investigation? / What did not go well?

Document No: 1033173 Rev. 1 Related Document to KSS064

You might also like

- QRQC / 8D Form: D 1. Description of The ProblemDocument5 pagesQRQC / 8D Form: D 1. Description of The ProblemDearRed FrankNo ratings yet

- QRQC - Quick Response To Quality ControlDocument49 pagesQRQC - Quick Response To Quality ControlKshitij Bhakoo100% (4)

- Training Module 8D QRCIDocument81 pagesTraining Module 8D QRCIMAPROLProjetos100% (6)

- 02 Q1 Rules Ref CardDocument23 pages02 Q1 Rules Ref CardAld Ov100% (1)

- AME Lean AssessmentDocument35 pagesAME Lean AssessmentNainerd Jing Jing100% (1)

- Copia de CQI 23Document47 pagesCopia de CQI 23giordanoNo ratings yet

- Stede Pdca-Ftatraining June2017Document82 pagesStede Pdca-Ftatraining June2017Riadh JellaliNo ratings yet

- QRQC Problem Solving TechniquesDocument1 pageQRQC Problem Solving TechniquesKristof MC100% (2)

- The 7QB of Production: FAS Training PresentationDocument50 pagesThe 7QB of Production: FAS Training Presentationcong da100% (1)

- Uk Vec Pdca QRQC PrésentationDocument149 pagesUk Vec Pdca QRQC Présentationmarsan1708100% (1)

- GM 1927-33 GM Global GP-12 Audit March 13, 2008Document8 pagesGM 1927-33 GM Global GP-12 Audit March 13, 2008Neumar NeumannNo ratings yet

- Appendix 25 VDA 6 3 Process AuditDocument12 pagesAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (2)

- FAU-S-DSG-2200 - PMCS Frame Work, Key Activities - V1 Mar 2016Document31 pagesFAU-S-DSG-2200 - PMCS Frame Work, Key Activities - V1 Mar 2016HammamiSalah100% (1)

- Reverse PFMEADocument5 pagesReverse PFMEASantosh BallalNo ratings yet

- Customer Complaints or Problems - Fast Response Tracking BoardDocument1 pageCustomer Complaints or Problems - Fast Response Tracking Boardsrinivigna100% (2)

- Booklet Learner 33774 Kit 2 Days ANPQP STD V3.2 Day2 ENDocument63 pagesBooklet Learner 33774 Kit 2 Days ANPQP STD V3.2 Day2 ENadrianNo ratings yet

- Fis-S-Lse-5280 (Faurecia)Document73 pagesFis-S-Lse-5280 (Faurecia)EdmarNo ratings yet

- QRQCDocument1 pageQRQCVirginia GrandoNo ratings yet

- UK VEC PDCA QRQC PrésentationDocument149 pagesUK VEC PDCA QRQC Présentationlaurasirbu100% (3)

- QRQC Training ProtocolDocument52 pagesQRQC Training ProtocolSudhagar P100% (1)

- 5S Kaizen Charter TemplateDocument4 pages5S Kaizen Charter TemplaterobinsonjamesonNo ratings yet

- Certificate CE PDFDocument1 pageCertificate CE PDFКонстантин КуприяновNo ratings yet

- QRQCDocument50 pagesQRQCPamfeel1100% (1)

- QRQC Training ModuleDocument37 pagesQRQC Training Modulemoez100% (2)

- Supplier QRQC ImplementationDocument21 pagesSupplier QRQC ImplementationChristopher GILL100% (1)

- Pokayoke 150112043214 Conversion Gate01Document82 pagesPokayoke 150112043214 Conversion Gate01pablo7890100% (1)

- Manual Alumno QRQC v2Document35 pagesManual Alumno QRQC v2Carlos AguilarNo ratings yet

- Sps0650en Poka YokeDocument8 pagesSps0650en Poka Yokepatima_sv4875No ratings yet

- QRQC PPTDocument10 pagesQRQC PPTNirmalya MishraNo ratings yet

- QRQC PresentationDocument17 pagesQRQC PresentationKristof MC100% (1)

- GM 1927-30 QSB AuditDocument38 pagesGM 1927-30 QSB Auditmanune01No ratings yet

- GP12Document18 pagesGP12bhushan911No ratings yet

- FaureciaDocument34 pagesFaureciaIonut Eduard100% (2)

- Presentation of The NSA: New Supplier AssessmentDocument35 pagesPresentation of The NSA: New Supplier AssessmentMojtaba MousaviNo ratings yet

- 5s TrainingDocument17 pages5s TrainingBonty MwashiNo ratings yet

- Lpa FormDocument2 pagesLpa FormEngineer100% (2)

- TPM 20guideline 20ver2Document20 pagesTPM 20guideline 20ver2Pedro SilvaNo ratings yet

- VSM PDFDocument52 pagesVSM PDFChip ChopNo ratings yet

- GP-12 Check SheetsDocument2 pagesGP-12 Check SheetsLam Nguyen100% (4)

- QRQCDocument1 pageQRQCmoez50% (2)

- Faurecia Supplier Requirements ManualDocument39 pagesFaurecia Supplier Requirements ManualJuan Egara100% (1)

- Apqp VolvoDocument7 pagesApqp Volvofdsa01No ratings yet

- 5S Support Functions FaureciaDocument21 pages5S Support Functions Faureciapedro_euNo ratings yet

- LPA - Layer Process Audit GuidelinesDocument23 pagesLPA - Layer Process Audit GuidelinesR J100% (2)

- QRQC Manual: Quick Response Quality ControlDocument36 pagesQRQC Manual: Quick Response Quality ControlCarlos Aguilar100% (1)

- Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Document2 pagesCore Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)skluxNo ratings yet

- Kobetsu Kaizen Pillar: Training Program OnDocument51 pagesKobetsu Kaizen Pillar: Training Program OnNeeraj SethyNo ratings yet

- Daimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta RisnerDocument23 pagesDaimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta Risneralberto100% (1)

- Standard Work Combination TablesDocument14 pagesStandard Work Combination Tablescoolpawan10No ratings yet

- Single Minute Exchange of DiesDocument11 pagesSingle Minute Exchange of DiesAhmed SamirNo ratings yet

- Layered AuditDocument38 pagesLayered AuditRajeshLSNo ratings yet

- 8D ReportDocument33 pages8D ReportvundavilliravindraNo ratings yet

- WCM BasicsDocument75 pagesWCM BasicsHrishikesh WaghNo ratings yet

- 02 - Fast Response - QIP V3Document85 pages02 - Fast Response - QIP V3HOSSIENNo ratings yet

- Poka Yoke Training MaterialDocument39 pagesPoka Yoke Training Materialnauli10100% (1)

- 5's TemplateDocument5 pages5's TemplatealamtareqNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- 1 - Training Activity MatrixDocument5 pages1 - Training Activity MatrixMashelet Valle33% (3)

- T3905-390-02 SG-Ins Lec ENDocument264 pagesT3905-390-02 SG-Ins Lec ENNanda KumarNo ratings yet

- Sheffield Linear System and Structural AnalysisDocument2 pagesSheffield Linear System and Structural AnalysisphilipyapNo ratings yet

- CK2 PreFIE LRW 9.2022Document9 pagesCK2 PreFIE LRW 9.2022tram29112712No ratings yet

- An KitDocument5 pagesAn KitKirti KumarNo ratings yet

- Huawei TechnologiesDocument9 pagesHuawei TechnologiesSai VasudevanNo ratings yet

- DIva Checkout DatalogicMagellan8200Document66 pagesDIva Checkout DatalogicMagellan8200ronex canadzNo ratings yet

- Sudan University of Science & TechnologyDocument3 pagesSudan University of Science & TechnologyMazin OmarNo ratings yet

- Future of Weather RadarDocument21 pagesFuture of Weather RadarWaheed Ali BangashNo ratings yet

- CSM6120 Introduction To Intelligent Systems: Informed SearchDocument58 pagesCSM6120 Introduction To Intelligent Systems: Informed SearchreemNo ratings yet

- Mcqs On Analog Modulation (Am FM) Am Radio Limits The Upper Modulating Frequency To 5 Khz. This Results in ADocument18 pagesMcqs On Analog Modulation (Am FM) Am Radio Limits The Upper Modulating Frequency To 5 Khz. This Results in AZynNo ratings yet

- Youlean Loudness Meter 2 MANUAL 2Document21 pagesYoulean Loudness Meter 2 MANUAL 2ddeivid359No ratings yet

- Birla Institute of Technology and Science, Pilani Pilani Campus Instruction DivisionDocument2 pagesBirla Institute of Technology and Science, Pilani Pilani Campus Instruction Divisiontourist101No ratings yet

- LTE OMC Functions IntroductionDocument46 pagesLTE OMC Functions IntroductionDativaNo ratings yet

- RSMSSB JEN Electrical SyllabusDocument2 pagesRSMSSB JEN Electrical Syllabusashwinivema1980No ratings yet

- Robust Control Scheme For Three-Phase Grid-Connected Inverters With LCL-filter Under Unbalanced and Distorted Grid ConditionsDocument9 pagesRobust Control Scheme For Three-Phase Grid-Connected Inverters With LCL-filter Under Unbalanced and Distorted Grid Conditionspradeep kumar sahuNo ratings yet

- Unit 6 QB UT2Document8 pagesUnit 6 QB UT2Hamza khanNo ratings yet

- Ambient IntelligenceDocument11 pagesAmbient Intelligenceravikishore1111No ratings yet

- Winplot TutorialDocument16 pagesWinplot TutorialRicardo MoGaNo ratings yet

- Dispatcher Server InstallationDocument128 pagesDispatcher Server InstallationЛариса ВоронинаNo ratings yet

- Transposition TechniquesDocument10 pagesTransposition TechniquesDharma ReddyNo ratings yet

- LC08 L2SP 118066 20130813 20200913 02 T1 MTLDocument7 pagesLC08 L2SP 118066 20130813 20200913 02 T1 MTLrehan pambudiNo ratings yet

- Birla Institute of TechnologyDocument2 pagesBirla Institute of TechnologyKushagra SinghNo ratings yet

- h248 Megaco eDocument56 pagesh248 Megaco emedamineNo ratings yet

- Unit 2. Complete The Answer The Questions of The Oral Quiz.Document3 pagesUnit 2. Complete The Answer The Questions of The Oral Quiz.Darwin TapuyoNo ratings yet

- H 046 010876 00 BeneVision CMS Service Manual R3 2.0Document162 pagesH 046 010876 00 BeneVision CMS Service Manual R3 2.0travieso112No ratings yet

- Rca Ss Hobby 1968Document6 pagesRca Ss Hobby 1968mundomusicalmeriaNo ratings yet

- Line Balancing & Worker Machine Process ChartDocument31 pagesLine Balancing & Worker Machine Process ChartDea Nabila100% (2)

- CH 08Document8 pagesCH 08kapil_arpitaNo ratings yet