Professional Documents

Culture Documents

Pipe Pre-Test Checklist

Pipe Pre-Test Checklist

Uploaded by

jrod915Copyright:

Available Formats

You might also like

- UPDATED SPDC MEPSS PRICED COMM SCHEDULE - Buckets - 2B.2 - 2B.3 - 2B.4 - 2BDocument240 pagesUPDATED SPDC MEPSS PRICED COMM SCHEDULE - Buckets - 2B.2 - 2B.3 - 2B.4 - 2BChristopher OjoNo ratings yet

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriNo ratings yet

- Compliance Statement - PPR CopraxDocument1 pageCompliance Statement - PPR CopraxAhmed HelmyNo ratings yet

- Hydrotest Form 1Document2 pagesHydrotest Form 1jrod915No ratings yet

- 8-Piping Final InspectionDocument1 page8-Piping Final InspectionM.A.NNo ratings yet

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationYousuf KamalNo ratings yet

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthik100% (1)

- Method of Statement For Bus Duct InstallationDocument11 pagesMethod of Statement For Bus Duct InstallationMohd MuksinNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- Method Statement For Installation and Inspection of FirefightinDocument6 pagesMethod Statement For Installation and Inspection of FirefightinJAY ROD AWITNo ratings yet

- Technical Compliance Sheet Butterfly ValveDocument5 pagesTechnical Compliance Sheet Butterfly Valvebiswasdipankar05No ratings yet

- 2.FIT-UP & 3. Welding ReportDocument2 pages2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- Deepak Patil: Fire Fighting Description and WmsDocument5 pagesDeepak Patil: Fire Fighting Description and WmsDeepak PatilNo ratings yet

- Piping Spec: CS150 TFS 1021: Engineering StandardDocument4 pagesPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16No ratings yet

- Downloaded From Manuals Search EngineDocument50 pagesDownloaded From Manuals Search Enginemzmakba1No ratings yet

- New Senate Building Project: Method StatementDocument2 pagesNew Senate Building Project: Method Statementjerrick raulNo ratings yet

- Tubing Installation ProcedureDocument4 pagesTubing Installation ProcedurePutraArifWardhanaNo ratings yet

- Colour Coding To Pipelines (Ground Colour and Colour Bands)Document4 pagesColour Coding To Pipelines (Ground Colour and Colour Bands)Naizil Kareem100% (1)

- Hot+Water+Boilers+Pre Commissioning+Checklist+10 2021Document4 pagesHot+Water+Boilers+Pre Commissioning+Checklist+10 2021syukron36No ratings yet

- Method of Statement Virtual Gas PipelineDocument2 pagesMethod of Statement Virtual Gas PipelineMcLester Love ElinaNo ratings yet

- Test PackDocument38 pagesTest PackAbdülHak ÖZkara100% (1)

- Method Statement of Ipa-227 Piping WorksDocument5 pagesMethod Statement of Ipa-227 Piping WorksPramod kumarNo ratings yet

- Hoist Monorail Pre Commissioning ITPDocument7 pagesHoist Monorail Pre Commissioning ITPmetroroadNo ratings yet

- Tie in MosDocument2 pagesTie in MosAAISATNo ratings yet

- Job Card For Welders Qualification: Hi-TECH Engineering Corporation India Pvt. LTD., BaramatiDocument2 pagesJob Card For Welders Qualification: Hi-TECH Engineering Corporation India Pvt. LTD., Baramatig_sanchetiNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Statement HDPE PDFDocument1 pageStatement HDPE PDFshameemNo ratings yet

- Piping - Mapress Installation GuidelinesDocument144 pagesPiping - Mapress Installation GuidelinesPetru VladeanuNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- PC - EXHAUST FANS ID #'SDocument3 pagesPC - EXHAUST FANS ID #'SAbdul Mohid SheikhNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- BlastPainting Report R.1Document1 pageBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Fire Protection Pipes Method StatementDocument11 pagesFire Protection Pipes Method StatementEdmund YoongNo ratings yet

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- MQ SP M 4010 PDFDocument16 pagesMQ SP M 4010 PDFjaseelNo ratings yet

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoNo ratings yet

- Method Statement For Installation of VAV BoxDocument3 pagesMethod Statement For Installation of VAV BoxRamakrishnanNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- Checklist - Damper - Non Pressure Parts Drgs.Document2 pagesChecklist - Damper - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- 01-01-1865-D ELDS Technical Manual Iss13Document221 pages01-01-1865-D ELDS Technical Manual Iss13Alberyt099No ratings yet

- Process Plant Layout and Piping Design: Fundamentals ofDocument4 pagesProcess Plant Layout and Piping Design: Fundamentals ofSolakhudin Al Ayubi100% (1)

- Method Statement For DX AC UnitDocument28 pagesMethod Statement For DX AC UnitBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Shipping Storage and Preservation GuidelineDocument13 pagesShipping Storage and Preservation GuidelinePaul Gianmarco Melendez VasquezNo ratings yet

- Syarikat Kejuruteraan Sistematik Sendirian BerhadDocument3 pagesSyarikat Kejuruteraan Sistematik Sendirian BerhadPat Lim100% (1)

- Method of Statement For ROO ProjectDocument12 pagesMethod of Statement For ROO ProjectAmmar Alkindy100% (1)

- Scope of Works & BOQDocument3 pagesScope of Works & BOQmamahsen100% (2)

- Potter Flow SwitchDocument2 pagesPotter Flow SwitchWahyu Asyari MNo ratings yet

- AFT ChempakDocument2 pagesAFT ChempakbtjajadiNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Sprinklers PDFDocument43 pagesSprinklers PDFpil7194No ratings yet

- Cylinder Data Sheet (FM200 Gas Bottle) PDFDocument4 pagesCylinder Data Sheet (FM200 Gas Bottle) PDFKevin TsuiNo ratings yet

- Tai PresentationDocument43 pagesTai PresentationusamafalakNo ratings yet

- Installation, Testing & Flushing of Firefighting Piping System - Method Statement HQDocument20 pagesInstallation, Testing & Flushing of Firefighting Piping System - Method Statement HQvishwas salunkhe100% (1)

- ITR-B (Piping) Witness Joint1Document1 pageITR-B (Piping) Witness Joint1Momo ItachiNo ratings yet

- Edited - Flange Joint Assembly ChecklistDocument2 pagesEdited - Flange Joint Assembly ChecklistvivekkumarenzoNo ratings yet

- Post - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005Document1 pagePost - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005jrod915No ratings yet

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- WeldersDocument9 pagesWeldersjrod915No ratings yet

- EWO Drawing Weld # Weld Type Dia. Sch. Matl. Line Class Welder 1Document2 pagesEWO Drawing Weld # Weld Type Dia. Sch. Matl. Line Class Welder 1jrod915No ratings yet

- Price of Code Books For "R" Stamp and "PP" StampDocument1 pagePrice of Code Books For "R" Stamp and "PP" Stampjrod915No ratings yet

- Post - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005Document1 pagePost - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005jrod915No ratings yet

- Inspection Punch ListDocument2 pagesInspection Punch Listjrod915No ratings yet

- Requisition Form Requesition Number:: Date: Job NoDocument1 pageRequisition Form Requesition Number:: Date: Job Nojrod915No ratings yet

- Weld Count ReportDocument1 pageWeld Count Reportjrod915No ratings yet

- Welding RodDocument368 pagesWelding Rodjrod91586% (29)

- Time SheetDocument1 pageTime Sheetjrod915No ratings yet

- 01 General HSE RulesDocument7 pages01 General HSE Rulesjrod915No ratings yet

- QA QC Manual Final November 2010Document58 pagesQA QC Manual Final November 2010jrod915100% (2)

Pipe Pre-Test Checklist

Pipe Pre-Test Checklist

Uploaded by

jrod915Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Pre-Test Checklist

Pipe Pre-Test Checklist

Uploaded by

jrod915Copyright:

Available Formats

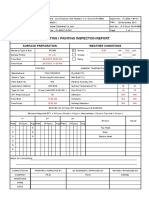

Test Package# J&L Rep.

F-004

PIPING & FITTINGS: All welding is complete Piping schedule, material and size is correct Piping is in proper location Piping has required clearances Fittings have correct ratings and are proper material Installation is straight and plumb or sloped per drawing Reducer orientation is correct Cold spring is per drawing VALVES: Check all valve tags for compliance with piping and material specifications Assure control, globe, angle and check valves have correct flow direction Valves should be in open position Direction of handles should be per ISO All vents and drains are installed including those required for testing SUPPORTS, GUIDES & ANCHORS: Properly installed per details All temporary erection supports have been removed Spring hangers chocked against movement Small bore supports installed per specification, in sufficient quantities and on location INSTRUMENTATION: Connections for instruments installed and isolated as required Orifice flange tap valves at correct angles, seal welded and jack screws in place Orifice flanges have correct meter runs, smooth bores; orifice plates removed All thermowells installed All reinforcing pads have weep holes BOLTS: Proper material and grade of bolt and nut installed Proper diameter and length installed Valves should be in open position Thread compound applied per Project requirements GASKETS: Proper type and material installed per piping material specifications Sized to match flange rating and fills bolt circle PIPING SPECIALTY ITEMS: Verify direction of flow for filters, strainers, traps and expansion joints Expansion joints have stops installed All blinds are sized correctly and installed as required by the drawing MECHANICAL EQUIPMENT: All equipment not included in test has been isolated / removed 1 OF 1

Y/N

You might also like

- UPDATED SPDC MEPSS PRICED COMM SCHEDULE - Buckets - 2B.2 - 2B.3 - 2B.4 - 2BDocument240 pagesUPDATED SPDC MEPSS PRICED COMM SCHEDULE - Buckets - 2B.2 - 2B.3 - 2B.4 - 2BChristopher OjoNo ratings yet

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriNo ratings yet

- Compliance Statement - PPR CopraxDocument1 pageCompliance Statement - PPR CopraxAhmed HelmyNo ratings yet

- Hydrotest Form 1Document2 pagesHydrotest Form 1jrod915No ratings yet

- 8-Piping Final InspectionDocument1 page8-Piping Final InspectionM.A.NNo ratings yet

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationYousuf KamalNo ratings yet

- RF Pad Test ReportDocument1 pageRF Pad Test ReportKarthik100% (1)

- Method of Statement For Bus Duct InstallationDocument11 pagesMethod of Statement For Bus Duct InstallationMohd MuksinNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- Method Statement For Installation and Inspection of FirefightinDocument6 pagesMethod Statement For Installation and Inspection of FirefightinJAY ROD AWITNo ratings yet

- Technical Compliance Sheet Butterfly ValveDocument5 pagesTechnical Compliance Sheet Butterfly Valvebiswasdipankar05No ratings yet

- 2.FIT-UP & 3. Welding ReportDocument2 pages2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- Deepak Patil: Fire Fighting Description and WmsDocument5 pagesDeepak Patil: Fire Fighting Description and WmsDeepak PatilNo ratings yet

- Piping Spec: CS150 TFS 1021: Engineering StandardDocument4 pagesPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16No ratings yet

- Downloaded From Manuals Search EngineDocument50 pagesDownloaded From Manuals Search Enginemzmakba1No ratings yet

- New Senate Building Project: Method StatementDocument2 pagesNew Senate Building Project: Method Statementjerrick raulNo ratings yet

- Tubing Installation ProcedureDocument4 pagesTubing Installation ProcedurePutraArifWardhanaNo ratings yet

- Colour Coding To Pipelines (Ground Colour and Colour Bands)Document4 pagesColour Coding To Pipelines (Ground Colour and Colour Bands)Naizil Kareem100% (1)

- Hot+Water+Boilers+Pre Commissioning+Checklist+10 2021Document4 pagesHot+Water+Boilers+Pre Commissioning+Checklist+10 2021syukron36No ratings yet

- Method of Statement Virtual Gas PipelineDocument2 pagesMethod of Statement Virtual Gas PipelineMcLester Love ElinaNo ratings yet

- Test PackDocument38 pagesTest PackAbdülHak ÖZkara100% (1)

- Method Statement of Ipa-227 Piping WorksDocument5 pagesMethod Statement of Ipa-227 Piping WorksPramod kumarNo ratings yet

- Hoist Monorail Pre Commissioning ITPDocument7 pagesHoist Monorail Pre Commissioning ITPmetroroadNo ratings yet

- Tie in MosDocument2 pagesTie in MosAAISATNo ratings yet

- Job Card For Welders Qualification: Hi-TECH Engineering Corporation India Pvt. LTD., BaramatiDocument2 pagesJob Card For Welders Qualification: Hi-TECH Engineering Corporation India Pvt. LTD., Baramatig_sanchetiNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Statement HDPE PDFDocument1 pageStatement HDPE PDFshameemNo ratings yet

- Piping - Mapress Installation GuidelinesDocument144 pagesPiping - Mapress Installation GuidelinesPetru VladeanuNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- PC - EXHAUST FANS ID #'SDocument3 pagesPC - EXHAUST FANS ID #'SAbdul Mohid SheikhNo ratings yet

- Client: Job No.: Job Title: Client's Job No.:: Company NameDocument13 pagesClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- BlastPainting Report R.1Document1 pageBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Fire Protection Pipes Method StatementDocument11 pagesFire Protection Pipes Method StatementEdmund YoongNo ratings yet

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- MQ SP M 4010 PDFDocument16 pagesMQ SP M 4010 PDFjaseelNo ratings yet

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoNo ratings yet

- Method Statement For Installation of VAV BoxDocument3 pagesMethod Statement For Installation of VAV BoxRamakrishnanNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- Checklist - Damper - Non Pressure Parts Drgs.Document2 pagesChecklist - Damper - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- 01-01-1865-D ELDS Technical Manual Iss13Document221 pages01-01-1865-D ELDS Technical Manual Iss13Alberyt099No ratings yet

- Process Plant Layout and Piping Design: Fundamentals ofDocument4 pagesProcess Plant Layout and Piping Design: Fundamentals ofSolakhudin Al Ayubi100% (1)

- Method Statement For DX AC UnitDocument28 pagesMethod Statement For DX AC UnitBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Shipping Storage and Preservation GuidelineDocument13 pagesShipping Storage and Preservation GuidelinePaul Gianmarco Melendez VasquezNo ratings yet

- Syarikat Kejuruteraan Sistematik Sendirian BerhadDocument3 pagesSyarikat Kejuruteraan Sistematik Sendirian BerhadPat Lim100% (1)

- Method of Statement For ROO ProjectDocument12 pagesMethod of Statement For ROO ProjectAmmar Alkindy100% (1)

- Scope of Works & BOQDocument3 pagesScope of Works & BOQmamahsen100% (2)

- Potter Flow SwitchDocument2 pagesPotter Flow SwitchWahyu Asyari MNo ratings yet

- AFT ChempakDocument2 pagesAFT ChempakbtjajadiNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Sprinklers PDFDocument43 pagesSprinklers PDFpil7194No ratings yet

- Cylinder Data Sheet (FM200 Gas Bottle) PDFDocument4 pagesCylinder Data Sheet (FM200 Gas Bottle) PDFKevin TsuiNo ratings yet

- Tai PresentationDocument43 pagesTai PresentationusamafalakNo ratings yet

- Installation, Testing & Flushing of Firefighting Piping System - Method Statement HQDocument20 pagesInstallation, Testing & Flushing of Firefighting Piping System - Method Statement HQvishwas salunkhe100% (1)

- ITR-B (Piping) Witness Joint1Document1 pageITR-B (Piping) Witness Joint1Momo ItachiNo ratings yet

- Edited - Flange Joint Assembly ChecklistDocument2 pagesEdited - Flange Joint Assembly ChecklistvivekkumarenzoNo ratings yet

- Post - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005Document1 pagePost - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005jrod915No ratings yet

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- Sprinkler System Installation ProcedureDocument3 pagesSprinkler System Installation ProcedureDong VanraNo ratings yet

- WeldersDocument9 pagesWeldersjrod915No ratings yet

- EWO Drawing Weld # Weld Type Dia. Sch. Matl. Line Class Welder 1Document2 pagesEWO Drawing Weld # Weld Type Dia. Sch. Matl. Line Class Welder 1jrod915No ratings yet

- Price of Code Books For "R" Stamp and "PP" StampDocument1 pagePrice of Code Books For "R" Stamp and "PP" Stampjrod915No ratings yet

- Post - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005Document1 pagePost - Test Checklist: J&L Rep. Test Pkg. # Yes / No Piping: F-005jrod915No ratings yet

- Inspection Punch ListDocument2 pagesInspection Punch Listjrod915No ratings yet

- Requisition Form Requesition Number:: Date: Job NoDocument1 pageRequisition Form Requesition Number:: Date: Job Nojrod915No ratings yet

- Weld Count ReportDocument1 pageWeld Count Reportjrod915No ratings yet

- Welding RodDocument368 pagesWelding Rodjrod91586% (29)

- Time SheetDocument1 pageTime Sheetjrod915No ratings yet

- 01 General HSE RulesDocument7 pages01 General HSE Rulesjrod915No ratings yet

- QA QC Manual Final November 2010Document58 pagesQA QC Manual Final November 2010jrod915100% (2)