Professional Documents

Culture Documents

Polaris Hydraulic Gear Pump Catalog

Polaris Hydraulic Gear Pump Catalog

Uploaded by

btone911Copyright:

Available Formats

You might also like

- 58) TB.5801Document90 pages58) TB.5801Diego Ariel DominguezNo ratings yet

- H1 ManualDocument14 pagesH1 ManualJonatan Condo IbarraNo ratings yet

- Setting Up Serial DF1 Connection From A MicroLogix 1500 To A Quick Panel Via Quick DesignerDocument18 pagesSetting Up Serial DF1 Connection From A MicroLogix 1500 To A Quick Panel Via Quick Designercaasilva01No ratings yet

- Load Sensing: Series Pumps With ControlDocument10 pagesLoad Sensing: Series Pumps With ControlMiguel Angel Del Carpio Zuñiga100% (1)

- Piston SealsDocument149 pagesPiston SealspamururamuNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- JCB Trial Protocol PDFDocument3 pagesJCB Trial Protocol PDFRizvan QureshiNo ratings yet

- VP1 Service ParkerDocument16 pagesVP1 Service ParkerAdrian Alonso Bustos GonzalezNo ratings yet

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Document3 pages621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Jhonny RodriguezNo ratings yet

- Hydac Axial Piston Pump Ppv100m LQDocument32 pagesHydac Axial Piston Pump Ppv100m LQpeterNo ratings yet

- Ficha Tecnica Komatsu 400 - 7Document52 pagesFicha Tecnica Komatsu 400 - 7bariciado1No ratings yet

- Zenith-913 en PDFDocument4 pagesZenith-913 en PDFLucky TraderNo ratings yet

- Great Plains Parts Manual NTA-907 & NTA-3007Document170 pagesGreat Plains Parts Manual NTA-907 & NTA-3007a04205No ratings yet

- Main ReportDocument49 pagesMain Reportsandip bishal100% (1)

- IR Grease Pump Catalouge LM2250E-XX-B3-EnDocument4 pagesIR Grease Pump Catalouge LM2250E-XX-B3-Enankit.jhawarNo ratings yet

- Steering SystemsDocument48 pagesSteering SystemsOscar Coaquira FelicianoNo ratings yet

- Cat. Hy15-3502-R PDFDocument659 pagesCat. Hy15-3502-R PDFRuddy Ral100% (1)

- TTLA0561Document111 pagesTTLA0561Valourdos Lukas100% (1)

- Re92709 2015-12 PDFDocument12 pagesRe92709 2015-12 PDFnedim100% (1)

- STANDARD SPARE PARTS K3SP36C - REM-B ConnectDocument1 pageSTANDARD SPARE PARTS K3SP36C - REM-B ConnectJurandir100% (1)

- Amech Pump HydraulicDocument8 pagesAmech Pump HydraulicAmech100% (1)

- Gear PumpsDocument7 pagesGear PumpsPrince ShanNo ratings yet

- Product: Mini Hyd Excavator Model: 304E2 MINI HYD EXCAVATOR ME402271 Configuration: 304E2 Mini Hydraulic Excavator ME400001-UP (MACHINE) POWERED BY C2.4 EngineDocument2 pagesProduct: Mini Hyd Excavator Model: 304E2 MINI HYD EXCAVATOR ME402271 Configuration: 304E2 Mini Hydraulic Excavator ME400001-UP (MACHINE) POWERED BY C2.4 Engineevan100% (1)

- Stick Cylinder - Pala Hidraulica 6040FSDocument9 pagesStick Cylinder - Pala Hidraulica 6040FSAbel Jairo Santos CabelloNo ratings yet

- HYD CircuitDocument36 pagesHYD CircuitSumitomo Laos Sumitomo Laos100% (3)

- J-Gear Pumps CatalogueDocument21 pagesJ-Gear Pumps CatalogueturandotNo ratings yet

- Fuel Injection Pump Remove DelphiDocument4 pagesFuel Injection Pump Remove DelphiKhalid El SabroutyNo ratings yet

- Test Procedure (Margin Pressure and Load Sensing Pressure)Document10 pagesTest Procedure (Margin Pressure and Load Sensing Pressure)Halil KaraNo ratings yet

- Breaker Operator's and Services ManualDocument96 pagesBreaker Operator's and Services Manuallinuskotte100% (1)

- Xcentric RippeDocument84 pagesXcentric RippeChristopher LoAr100% (1)

- NACHI Full Catalog Small RevDocument468 pagesNACHI Full Catalog Small RevSombat MahamadNo ratings yet

- Profbreaker: Parts ListDocument47 pagesProfbreaker: Parts Listmurat HATONo ratings yet

- Geith - Acople Ec460bDocument25 pagesGeith - Acople Ec460bjrincon26No ratings yet

- 320D PDT ComparisonDocument22 pages320D PDT Comparisonlalo11715No ratings yet

- SM Pw170es-6k-962Document625 pagesSM Pw170es-6k-962Эрнест Бекиров100% (1)

- Hitachi Ex270 Engine Parts ManualDocument90 pagesHitachi Ex270 Engine Parts ManualJay Mechanic0% (1)

- LIT2319 R4 CH175 Service ManualDocument40 pagesLIT2319 R4 CH175 Service ManualAlfred HitchcockNo ratings yet

- 72 516 PDFDocument65 pages72 516 PDFJITENDRA KUMAR SHARMANo ratings yet

- Hy11-3353 CVG UkDocument36 pagesHy11-3353 CVG UkManuel Carvallo100% (1)

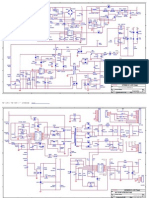

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Yancarlos Quispe AmayaNo ratings yet

- Aa2fm Model CodeDocument27 pagesAa2fm Model CodeCristianNo ratings yet

- Service Manual 300050007500 PermconDocument19 pagesService Manual 300050007500 PermconMiguel Angel Santos PintadoNo ratings yet

- 06 Steering PDFDocument33 pages06 Steering PDFDaniel NavasNo ratings yet

- 40Ω -10Ω Series Flow Control and ReliefDocument10 pages40Ω -10Ω Series Flow Control and ReliefMohamed FersiNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document13 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768julio cesarNo ratings yet

- Martillo Duraegon ManualDocument46 pagesMartillo Duraegon ManualJavier ChavezNo ratings yet

- Article - Technical - PDF (Como Inspeccionar Fallas en La Valvula EPPR)Document2 pagesArticle - Technical - PDF (Como Inspeccionar Fallas en La Valvula EPPR)Arbey GonzalezNo ratings yet

- Vane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Document5 pagesVane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Lucas CardosoNo ratings yet

- Relief Cartridge ValvesDocument16 pagesRelief Cartridge Valvesvivek_11111987100% (1)

- A10VO.3X - CANADA - Model A10V0 Piston Pump Manual PDFDocument23 pagesA10VO.3X - CANADA - Model A10V0 Piston Pump Manual PDFbee140676No ratings yet

- Selection Guide 2017 en HDDocument160 pagesSelection Guide 2017 en HDMaximiliano Dreyer100% (1)

- Ec 360 SpecDocument12 pagesEc 360 SpecYahdi AzzuhryNo ratings yet

- Troubleshooting BrookDocument52 pagesTroubleshooting Brookawangga putra maulanaNo ratings yet

- MINIPOWERPACK-Ver 6 0 PDFDocument208 pagesMINIPOWERPACK-Ver 6 0 PDFBruno CecattoNo ratings yet

- HMC 080Document12 pagesHMC 080Mohamed ElmakkyNo ratings yet

- Electro ValvulasDocument89 pagesElectro ValvulasJuan Domingo OrlandiniNo ratings yet

- Chapel Hydraulic ComponentsDocument76 pagesChapel Hydraulic ComponentsSaeed OsheeNo ratings yet

- Fluids Entry HBV Cetop 7 & 8 Series 101109Document12 pagesFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiNo ratings yet

- Motor Hidraulico Olbitrol EatonDocument36 pagesMotor Hidraulico Olbitrol EatonJaime JimenezNo ratings yet

- Pump Magnun SeriesDocument63 pagesPump Magnun SeriesDANIZACHNo ratings yet

- TruckDocument24 pagesTruckanup_nairNo ratings yet

- Pump Info ReferenceDocument42 pagesPump Info ReferenceingenieroNo ratings yet

- Opa381 PDFDocument19 pagesOpa381 PDFVictoria Guerrero100% (1)

- Diesel Edc 2Document14 pagesDiesel Edc 2DanielCostaXinaNo ratings yet

- 3.ISO Survey 2021 - Comparison With 2020 - Using Data From Providers Taking Part Both YearsDocument6 pages3.ISO Survey 2021 - Comparison With 2020 - Using Data From Providers Taking Part Both Yearsshirley servNo ratings yet

- Get Off To A Fast Start With Db2 V9 Purexml, Part 2Document16 pagesGet Off To A Fast Start With Db2 V9 Purexml, Part 2Ankur VermaNo ratings yet

- Domaci Programi VLC 12.01.2011Document4 pagesDomaci Programi VLC 12.01.2011acasfoxNo ratings yet

- Pipe Supports DesignDocument29 pagesPipe Supports Designkaruna100% (1)

- Peugeot 1007 Owners Manual 2007Document125 pagesPeugeot 1007 Owners Manual 2007Tester Quester100% (1)

- BG 45 - BS - 95 - PremiumLine - EN - 905 - 819 - 2Document24 pagesBG 45 - BS - 95 - PremiumLine - EN - 905 - 819 - 2Dilhara WickramaarachchiNo ratings yet

- Manual MIVII Voltage-Frequency RelayDocument231 pagesManual MIVII Voltage-Frequency RelayKiko OliveiraNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech-Access & Platforms For Portable Fire Protection System SAIC-B-2016Document1 pageSaudi Aramco Inspection Checklist: 1-Dec-06 Mech-Access & Platforms For Portable Fire Protection System SAIC-B-2016ரமேஷ் பாலக்காடுNo ratings yet

- 18 - Airtel Odisha Prepaid Tariff Plans PDFDocument4 pages18 - Airtel Odisha Prepaid Tariff Plans PDFNishant JainNo ratings yet

- IP Multicast With Applications To IPTV and Mobile DVB HDocument2 pagesIP Multicast With Applications To IPTV and Mobile DVB HPhương ThảoNo ratings yet

- B1 02s1266Document83 pagesB1 02s1266prp_manu4633No ratings yet

- Colbourne 2020Document9 pagesColbourne 2020Madheleyn del Carmen Alvarez ArmasNo ratings yet

- Esquema Pci Fonte Lc4055Document2 pagesEsquema Pci Fonte Lc4055heroncesarNo ratings yet

- B-75114en 02Document200 pagesB-75114en 02Sam eagle goodNo ratings yet

- SV09-ESG - Logging Geologist-SDL, I - Sample CatcherDocument4 pagesSV09-ESG - Logging Geologist-SDL, I - Sample CatcherTitoSootoNo ratings yet

- Gtu Me 2710209 Wireless Communication Dec 2014Document2 pagesGtu Me 2710209 Wireless Communication Dec 2014Mahesh RaghvaniNo ratings yet

- Array Cli PDFDocument398 pagesArray Cli PDFsanna agarwalNo ratings yet

- Old CrtoDocument7 pagesOld CrtoBertrand Lorente YanezNo ratings yet

- Voltage Drop Calc: 1Ph 2wire 1Ph 2wire Tap 1Ph 2wire LengthDocument13 pagesVoltage Drop Calc: 1Ph 2wire 1Ph 2wire Tap 1Ph 2wire LengthWilson PavãoNo ratings yet

- HYVA404 CTPT Analyzer Instruction Manual V1.3.19Document58 pagesHYVA404 CTPT Analyzer Instruction Manual V1.3.19Ricardo CardonaNo ratings yet

- Flat File ListingloaderDocument18 pagesFlat File Listingloaderrajiv6810% (1)

- Sni 03-3985-2000Document2 pagesSni 03-3985-2000ferry ferdiansyah pradana100% (1)

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINNo ratings yet

- EC 6802 Wireless Networks - BABU UNIT 1 & 2Document88 pagesEC 6802 Wireless Networks - BABU UNIT 1 & 2BABU MNo ratings yet

- Citrix SSLVPN CPS DeploymentGuideDocument48 pagesCitrix SSLVPN CPS DeploymentGuideforum4userNo ratings yet

- VSB 01 - 05 - National Code of Practice - Building Small Trailers PDFDocument39 pagesVSB 01 - 05 - National Code of Practice - Building Small Trailers PDFSergio RezendeNo ratings yet

Polaris Hydraulic Gear Pump Catalog

Polaris Hydraulic Gear Pump Catalog

Uploaded by

btone911Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polaris Hydraulic Gear Pump Catalog

Polaris Hydraulic Gear Pump Catalog

Uploaded by

btone911Copyright:

Available Formats

PL 02 T A

Replaces: PL 01 T A and PL 01 T E

Hydraulic gear pumps and motors

DISPLACEMENTS

From To 0.07 in3/rev (1.07 cm3/rev) 5.56 in3/rev (91.10 cm3/rev)

through bore aluminium body

PRESSURE

Max. Continuous Max. Intermittent Max. Peak 3770 psi (260 bar) 4060 psi (280 bar) 4350 psi (300 bar)

MAX. SPEED

4000 min-1

l Group 1, 2 and 3 with displacements from 0.07 in3/rev (1,07 cm3/rev) to 5.56 in3/rev (91.10 cm3/rev). l Drive shafts, mounting flanges and ports according to the international standards. l Combination of multiple pumps in standard version, common inlet and separated stages.

Edition: 02/07.2006

l Integrated outboard bearings for heavy duty application. l Many types of built-in valves.

POLARIS more than fifty years of Casappa experience in design and production of hydraulic components, characterized by large investments in research and development in order to propose new and personalized solutions to the market. Our use of CAD 3D in the developement of this generation permit us the 3D modelling and the virtual simulation of the behaviour of the components inserted in the hydraulic circuit. This means that the process will take less time and the quality of the products is better. Polaris pumps and motors are basically composed of a gear housing in aluminium alloy, two gear wheels supported by sleeve bearings and two end plates, the front and the rear cover, either in aluminium or in cast iron with excellent mechanical characteristics. Our success is based largely on the quality of our product. This guaranties the consistencies of the efficiencies and low level of noise emission during the life of our products.

*D0009604*

Polaris

INDEX

Section Page

FEATURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Replaces: 01/10.03 02/07.2006 Modification from former edition.

GENERAL DATA PUMPS AND MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 PUMPS PERFORMANCE CURVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 MOTORS PERFORMANCE CURVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 SINGLE UNITS DIMENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 MULTIPLE PUMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 MULTIPLE PUMPS DIMENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 VERSIONS (OUTBOARD BEARINGS FOR SHAFTS) . . . . . . . . . . . . . . . . . . . . . . . 46 DRIVE SHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 MOUNTING FLANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 CHANGING ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 VALVES AVAILABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

HOW TO ORDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

002

DCAT033-001

Polaris

FEATURES

Construction Mounting Line connection Direction of rotation (looking on drive shaft) Inlet pressure range for pumps External gear type pumps and motors EUROPEAN - SAE - GERMAN standard flanges Screw and flange Anti-clock (S) - clockwise (D) - reversible external drain (L - R) reversible internal drain (B) 10 44 psi [0,7 3 bar (abs.)] p 1 (continuous) max 73 psi (5 bar) Max back pressure for single rotation motors and reversible internal drain motors Max drain line pressure on the reversible rotation motors Max back pressure on the series motors (reversible motors external drain) Fluid temperature range Fluid p 2 (for 20 s) max 116 psi (8 bar) p 3 (for 8 s) max 218 psi (15 bar) 73 psi (5 bar) < p 1 (max continuous pressure) < 2175 psi (<150 bar) See table (1) Mineral oil based hydraulic fluids to ISO/DIN. For other fluids please consult our technical sales department. From 60 to 456 SSU [12 to 100 mm 2 /s (cSt)] recommended Viscosity range Filtering requirement Up to 3410 SSU [750 mm 2 /s (cSt)] permitted See table (2) page 4

Replaces: 01/10.03

Tab. 1

Type Fluid composition Max pressure psi - (bar) See page 3 Max speed min - 1 See page 3 Temperature F - (C) Min -13 (-25) -13 (-25) Max continuous 176 (80) 230 (110) Max peak 212 (100) 257 (125) Seals (l) N V Special shaft seals (u) D-H-C D

ISO/DIN

Mineral oil basedhydraulic fluid to ISO/DIN

( l ) N = Buna N (standard) - V = Viton (u)

Shaft seals max pressure and mounting scheme

D Standard shaft seal with wiper seal Max 44 psi (3 bar) Single rotation pumps H High pressure special shaft seal Max 363 psi (25 bar) C High pressure special shaft seal with wiper seal Max 363 psi (25 bar)

02/07.2006

Single rotation motors Reversible rotation pumps and motors

Max 44 psi (3 bar)

# Pressure could change in connection with shaft speed rotation.

For more information please consult our technical sales department.

DCAT033-002

002

Polaris

FEATURES

Filtration

Tab. 2

Working pressure psi (bar) Contamination class NAS 1638 Contamination class ISO 4406 Achieved with filter x (c) 75 D p < 2030 D p < (140) 10 21/19/16 25 m m 2030 < D p < 3045 (140) < D p < 210 9 20/18/15 10 m m D p > 3045 D p > (210) 8 19/17/14 10 m m

Casappa recommends to use its own production filters: Replaces: 01/10.03 Reversible rotation DCAT033-002 02/07.2006

General notes

Available with different inlet and outlet ports. For more information please consult our technical sales department.

Definition of rotation direction looking on the drive shaft

Anti-clock rotation

Clockwise rotation

Pressure definition

p1 Max. continuous pressure p2 Max. intermittent pressure p3 Max. peak pressure

002

Polaris

GENERAL DATA PUMPS AND MOTORS

Max. pressure Series Pump type PLP Motor type PLM in 3 /rev (cm 3 /rev) Displacement p1 p2 psi (bar) 3770 (260) 3770 (260) 3770 (260) 3770 (260) 3770 (260) 3625 (250) 3625 (250) 3335 (230) 3335 (230) 2610 (180) 2030 (140) 3625 (250) 3625 (250) 3625 (250) 3625 (250) 3625 (250) 3625 (250) 3625 (250) 3625 (250) 3625 (250) 2900 (200) 2900 (200) 2465 (170) 2465 (170) 1885 (130) 1885 (130) 3625 (250) 3625 (250) 3480 (240) 3480 (240) 3335 (230) 3045 (210) 2755 (190) 2465 (170) 2320 (160) 2175 (150) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 3915 (270) 3915 (270) 3625 (250) 3625 (250) 2900 (200) 2320 (160) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 4060 (280) 3190 (220) 3190 (220) 2755 (190) 2755 (190) 2175 (150) 2175 (150) 3915 (270) 3915 (270) 3770 (260) 3770 (260) 3625 (250) 3335 (230) 3045 (210) 2755 (190) 2465 (170) 2320 (160) 4205 (290) 4205 (290) 4205 (290) 4205 (290) 4205 (290) 4060 (280) 4060 (280) 3770 (260) 3770 (260) 3045 (210) 2465 (170) 4350 (300) 4350 (300) 4350 (300) 4350 (300) 4350 (300) 4350 (300) 4350 (300) 4350 (300) 4350 (300) 3480 (240) 3480 (240) 3045 (210) 3045 (210) 2465 (170) 2465 (170) 4060 (280) 4060 (280) 3915 (270) 3915 (270) 3770 (260) 3480 (240) 3190 (220) 2900 (200) 2610 (180) 2465 (170) 4000 4000 4000 4000 4000 4000 4000 3500 3500 3500 3500 4000 4000 4000 3500 3500 3500 3500 3500 3000 3000 3000 2500 2500 2000 2000 3000 3000 3000 3000 3000 2500 2500 2500 2200 2200 p3 min -1 650 650 650 650 650 650 650 650 650 650 650 600 600 600 600 600 600 600 500 500 500 500 500 500 500 500 350 350 350 350 350 350 350 350 350 350 Max. speed Min. speed

PL. 101 PL. 101,5 PL. 102 PL. 102,5 PL. 103,15 PL. 104 PL. 105 PL. 105,8 PL. 106,3 PL. 108 PL. 1010 PL. 204 PL. 206,3 PL. 207,2 PL. 208 PL. 209 PL. 2010,5 PL. 2011,2 PL. 2014 PL. 2016 PL. 2019 PL. 2020 PL 2024,5 PL. 2025 PL. 2027,8 PL. 2031,5 PL. 3022 PL. 3027 PL. 3034 PL. 3038 PL. 3043 PL. 3051 PL. 3061 PL. 3073 PL. 3082 PL. 3090

0.07 (1,07) 0.10 (1,60) 0.13 (2,13) 0.16 (2,67) 0.20 (3,34) 0.26 (4,27) 0.33 (5,34) 0.38 (6,20) 0.41 (6,67) 0.52 (8,51) 0.65 (10,67) 0.30 (4,95) 0.40 (6,61) 0.44 (7,29) 0.50 (8,26) 0.56 (9,17) 0.66 (10,9) 0.69 (11,23) 0.89 (14,53) 1.03 (16,85) 1.16 (19,09) 1.29 (21,14) 1.52 (24,84) 1.61 (26,42) 1.72 (28,21) 2.01 (33,03) 1.34 (21,99) 1.63 (26,70) 2.11 (34,55) 2.40 (39,27) 2.68 (43,98) 3.16 (51,83) 3.74 (61,26) 4.50 (73,82) 4.98 (81,68) 5.56 (91,10)

01/10.03

POLARIS 30

POLARIS 20

POLARIS 10

p1= Max. continuous pressure

p2= Max. intermittent pressure

p3= Max. peak pressure

The values in the table refer to unidirectional pumps and motors. Reversible pump and motors max pressures are 15% lower than those shown in table. For different working conditions please consult our sales department.

DCAT033-003

002

Polaris

GENERAL DATA PUMPS AND MOTORS

Q M P V n Dp

US gpm (l/min) lbf in (Nm) HP (kW) in3/rev (cm3/rev) min -1 psi (bar)

Flow Torque Power Displacement Speed Pressure

Efficiencies

Pumps hv= hv (V,Dp, n) hm= hm (V,Dp, n) ht = hv hm Volumetric efficiency Mechanical efficiency Overall efficiency ( 0,97) ( 0,88) ( 0,85) Motors ( 0,96) ( 0,85) ( 0,82)

DESIGN CALCULATIONS FOR PUMP Q= V(cm 3 /rev) h v n 10 -3 [l/min]

DESIGN CALCULATIONS FOR MOTOR V (cm 3 /rev) n 10 -3 hv D p (bar) V (cm 3 /rev) h m 62,83

Q=

[l/min]

M=

D p (bar) V (cm 3 /rev) 62,83 h m D p (bar) V (cm 3 /rev) n 600 1000 h t

[Nm] M=

[Nm]

P=

600 1000

[kW]

Note: Diagrams providing approximate selection data will be found on subsequent pages.

002

DCAT033-003

01/10.03

P=

[kW]

D p (bar) V (cm 3 /rev) n h t

Polaris

POLARIS 10 GEAR PUMPS PERFORMANCE CURVES

PLP 10

PLP 10

Each curve has been obtained at 122 F (50C), using oil with viscosity 168 SSU (36 cSt) at 104 F (40C) and at these pressures.

PLP 101 . . . . . 290-3770 psi (20-260 bar) PLP 102 . . . . . 290-3770 psi (20-260 bar) PLP 103,15 . . 290-3770 psi (20-260 bar) PLP 104 . . . . . 290-3625 psi (20-250 bar) PLP 105 . . . . . 290-3625 psi (20-250 bar) PLP 106,3 . . . 290-3335 psi (20-230 bar) PLP 108 . . . . . 290-2610 psi (20-180 bar) PLP 1010 . . . . 290-2030 psi (20-140 bar)

PLP 101,5 . . . 290-3770 psi (20-260 bar) PLP 102,5 . . . 290-3770 psi (20-260 bar) PLP 105,8 . . . 290-3335 psi (20-230 bar)

01/10.03 DCAT033-004

002

Polaris

POLARIS 10 GEAR PUMPS PERFORMANCE CURVES

PLP 101 PLP 101,5

PLP 10

PLP 102

PLP 102,5

002

DCAT033-004

01/10.03

Polaris

POLARIS 10 GEAR PUMPS PERFORMANCE CURVES

PLP 103,15 PLP 104

PLP 10

PLP 105

PLP 105,8

01/10.03 DCAT033-004

002

Polaris

POLARIS 10 GEAR PUMPS PERFORMANCE CURVES

PLP 106,3 PLP 108

PLP 10

PLP 1010

10

002

DCAT033-004

01/10.03

Polaris

POLARIS 20 GEAR PUMPS PERFORMANCE CURVES

PLP 20

PLP 20

Each curve has been obtained at 122 F (50C), using oil with viscosity 168 SSU (36 cSt) at 104 F (40C) and at these pressures.

PLP 204 . . . . . 290-3625 psi (20-250 bar) PLP 206,3 . . . 290-3625 psi (20-250 bar) PLP 208 . . . . . 290-3625 psi (20-250 bar) PLP 209 . . . . . 290-3625 psi (20-250 bar) PLP 2011,2 . . 290-3625 psi (20-250 bar) PLP 2014 . . . . 290-3625 psi (20-250 bar) PLP 2016 . . . . 290-3625 psi (20-250 bar) PLP 2020 . . . . 290-2900 psi (20-200 bar) PLP 2025 . . . . 290-2465 psi (20-170 bar) PLP 2031,5 . . 290-1885 psi (20-130 bar)

Ne

Di

sp

la

ce

en

ts

PLP 207,2 . . . 290-3625 psi (20-250 bar) PLP 2010,5 . . 290-3625 psi (20-250 bar) PLP 2019 . . . . 290-2900 psi (20-200 bar) PLP 2024,5 . . 290-2465 psi (20-170 bar) PLP 2027,8 . . 290-1885 psi (20-130 bar)

01/10.03 DCAT033-005

002

11

Polaris

POLARIS 20 GEAR PUMPS PERFORMANCE CURVES

PLP 204 PLP 206,3

PLP 20

PLP 207,2

PLP 208

12

002

DCAT033-005

01/10.03

Polaris

POLARIS 20 GEAR PUMPS PERFORMANCE CURVES

PLP 209 PLP 2010,5

PLP 20

PLP 2011,2

PLP 2014

01/10.03 DCAT033-005

002

13

Polaris

POLARIS 20 GEAR PUMPS PERFORMANCE CURVES

PLP 2016 PLP 2019

PLP 20

PLP 2020

PLP 2024,5

14

002

DCAT033-005

01/10.03

Polaris

POLARIS 20 GEAR PUMPS PERFORMANCE CURVES

PLP 2027,8 PLP 2025

PLP 20

PLP 2031,5

01/10.03 DCAT033-005

002

15

Polaris

POLARIS 30 GEAR PUMPS PERFORMANCE CURVES

PLP 30

PLP 30

Each curve has been obtained at 122 F (50C), using oil with viscosity 168 SSU (36 cSt) at 104 F (40C) and at these pressures.

PLP 3022 . . . . 290-3625 psi (20-250 bar) PLP 3027 . . . . 290-3625 psi (20-250 bar) PLP 3034 . . . . 290-3480 psi (20-240 bar) PLP 3038 . . . . 290-3480 psi (20-240 bar) PLP 3043 . . . . 290-3335 psi (20-230 bar) PLP 3051 . . . . 290-3045 psi (20-210 bar) PLP 3061 . . . . 290-2775 psi (20-190 bar) PLP 3073 . . . . 290-2465 psi (20-170 bar) PLP 3082 . . . . 290-2320 psi (20-160 bar) PLP 3090 . . . . 290-2175 psi (20-150 bar)

PLP 3022

PLP 3027

16

002

DCAT033-006

01/10.03

Polaris

POLARIS 30 GEAR PUMPS PERFORMANCE CURVES

PLP 3034 PLP 3038

PLP 30

PLP 3043

PLP 3051

01/10.03 DCAT033-006

002

17

Polaris

POLARIS 30 GEAR PUMPS PERFORMANCE CURVES

PLP 3061 PLP 3073

PLP 30

PLP 3082

PLP 3090

18

002

DCAT033-006

01/10.03

Polaris

POLARIS 10 GEAR MOTORS PERFORMANCE CURVES

PLM 10

PLM 10

Each curve has been obtained at 122 F (50C), using oil with viscosity 168 SSU (36 cSt) at 104 F (40C) and at these pressures.

PLM 101 . . . . 290-3770 psi (20-260 bar) PLM 102 . . . . 290-3770 psi (20-260 bar) PLM 103,15 . . 290-3770 psi (20-260 bar) PLM 104 . . . . 290-3625 psi (20-250 bar) PLM 105 . . . . 290-3625 psi (20-250 bar) PLM 106,3 . . . 290-3335 psi (20-230 bar) PLM 108 . . . . 290-2610 psi (20-180 bar) PLM 1010 . . . 290-2030 psi (20-140 bar)

PLM 101,5 . . . 290-3770 psi (20-260 bar) PLM 102,5 . . . 290-3770 psi (20-260 bar) PLM 105,8 . . . 290-3335 psi (20-230 bar)

01/10.03 DCAT033-007

002

19

Polaris

POLARIS 10 GEAR MOTORS PERFORMANCE CURVES

PLM 101 PLM 101,5

PLM 10

PLM 102

PLM 102,5

20

002

DCAT033-007

01/10.03

Polaris

POLARIS 10 GEAR MOTORS PERFORMANCE CURVES

PLM 103,15 PLM 104

PLM 10

PLM 105

PLM 105,8

01/10.03 DCAT033-007

002

21

Polaris

POLARIS 10 GEAR MOTORS PERFORMANCE CURVES

PLM 106,3 PLM 108

PLM 10

PLM 1010

22

002

DCAT033-007

01/10.03

Polaris

POLARIS 20 GEAR MOTORS PERFORMANCE CURVES

PLM 20

PLM 20

Each curve has been obtained at 122 F (50C), using oil with viscosity 168 SSU (36 cSt) at 104 F (40C) and at these pressures.

PLM 204 . . . . 290-3625 psi (20-250 bar) PLM 206,3 . . . 290-3625 psi (20-250 bar) PLM 208 . . . . 290-3625 psi (20-250 bar) PLM 209 . . . . 290-3625 psi (20-250 bar) PLM 2011,2 . . 290-3625 psi (20-250 bar) PLM 2014 . . . 290-3625 psi (20-250 bar) PLM 2016 . . . 290-3625 psi (20-250 bar) PLM 2020 . . . 290-2900 psi (20-200 bar) PLM 2025 . . . 290-2465 psi (20-170 bar) PLM 2031,5 . . 290-1885 psi (20-130 bar)

Ne

Di

sp

la

ce

en

ts

PLM 207,2 . . . 290-3625 psi (20-250 bar) PLM 2010,5 . . 290-3625 psi (20-250 bar) PLM 2019 . . . 290-2900 psi (20-200 bar) PLM 2024,5 . . 290-2465 psi (20-170 bar) PLM 2027,8 . . 290-1885 psi (20-130 bar)

01/10.03 DCAT033-008

002

23

Polaris

POLARIS 20 GEAR MOTORS PERFORMANCE CURVES

PLM 204 PLM 206,3

PLM 20

PLM 207,2

PLM 208

24

002

DCAT033-008

01/10.03

Polaris

POLARIS 20 GEAR MOTORS PERFORMANCE CURVES

PLM 209 PLM 2010,5

PLM 20

PLM 2011,2

PLM 2014

01/10.03 DCAT033-008

002

25

Polaris

POLARIS 20 GEAR MOTORS PERFORMANCE CURVES

PLM 2016 PLM 2019

PLM 20

PLM 2020

PLM 2024,5

26

002

DCAT033-008

01/10.03

Polaris

POLARIS 20 GEAR MOTORS PERFORMANCE CURVES

PLM 2025 PLM 2027,8

PLM 20

PLM 2031,5

01/10.03 DCAT033-008

002

27

Polaris

POLARIS 30 GEAR MOTORS PERFORMANCE CURVES

PLM 30

PLM 30

Each curve has been obtained at 122 F (50C), using oil with viscosity 168 SSU (36 cSt) at 104 F (40C) and at these pressures.

PLM 3022 PLM 3027 PLM 3034 PLM 3038 PLM 3043 PLM 3051 PLM 3061 PLM 3073 PLM 3082 PLM 3090

. . . 290-3625 psi (20-250 bar) . . . 290-3625 psi (20-250 bar) . . . 290-3480 psi (20-240 bar) . . . 290-3480 psi (20-240 bar) . . . 290-3335 psi (20-230 bar) . . . 290-3045 psi (20-210 bar) . . . 290-2775 psi (20-190 bar) . . . 290-2465 psi (20-170 bar) . . . 290-2320 psi (20-160 bar) . . . 290-2175 psi (20-150 bar)

PLM 3022

PLM 3027

28

002

DCAT033-009

01/10.03

Polaris

POLARIS 30 GEAR MOTORS PERFORMANCE CURVES

PLM 3034 PLM 3038

PLM 30

PLM 3043

PLM 3051

01/10.03 DCAT033-009

002

29

Polaris

POLARIS 30 GEAR MOTORS PERFORMANCE CURVES

PLM 3061 PLM 3073

PLM 30

PLM 3082

PLM 3090

30

002

DCAT033-009

01/10.03

Polaris

POLARIS 10

SINGLE UNITS SIDE PORTS

Replaces: 01/10.03

Reversible R

Single rotation S - D

Reversible B Mounting flange type version 0

Reversible L

X

mm (inch) 14 (0.5512) 14 (0.5512) 14 (0.5512) 14 (0.5512) 11,8 (0.4646) 17 (0.6693) 41 (1.6142) 41 (1.6142) 41 (1.6142) DRAIN PORT POSITION: L = Side * = Bottom DRIVE SHAFTS: see page 51 MOUNTING FLANGE: see page 57 59 Mounting flange material Screws tightening torque Nm (lbf in) For single rotation S - D and reversible rotation R the rear cover is available in cast iron and aluminium. For reversible rotation B and L the rear cover is available in aluminium only.

E1 E7 E8 B1 K2 S0 R8 R9 W9

Pump type Motor type

V

25

2,5

Aluminium Cast iron

(199 243)

A

mm (inch) 52,2 (2.0551) 53,8 (2.1181) 55,4 (2.1811) 57 (2.2441) 59 (2.3228) 61,8 (2.4331) 65 (2.5591) 67,6 (2.6614) 69 (2.7165) 74,5 (2.9331) 81 (3.1890)

B

mm (inch) 17,6 (0.6929) 18,4 (0.7244) 19,2 (0.7559) 20 (0.7874) 21 (0.8268) 22,4 (0.8819) 24 (0.9449) 25,3 (0.9961) 26 (1.0236) 28,75 (1.1319) 32 (1.2598)

C

mm (inch) 65,2 (2.5669) 66,8 (2.6299) 68,4 (2.6929) 70 (2.7559) 72 (2.8346) 74,8 (2.9449) 78 (3.0709) 80,6 (3.1732) 82 (3.2283) 87,5 (3.4449) 94 (3.7008)

D

mm (inch) 32,6 (1.2835) 33,4 (1.3150) 34,2 (1.3465) 35 (1.3780) 36 (1.4173) 37,4 (1.4724) 39 (1.5354) 40,3 (1.5866) 41 (1.6142) 43,75 (1.7224) 47 (1.8504)

PL. 101 PL. 101,5 PL. 102 PL. 102,5 PL. 103,15 PL. 104 PL. 105 PL. 105,8 PL. 106,3 PL. 108 PL. 1010 DCAT033-010

02/07.2006

002

31

Polaris

POLARIS 10

SINGLE UNITS REAR PORTS

Reversible R

Single rotation S - D and Reversible B

Mounting flange type version 0

X

mm (inch) 14 (0.5512) 14 (0.5512) 14 (0.5512) 14 (0.5512) 11,8 (0.4646) 17 (0.6693) 41 (1.6142) 41 (1.6142) 41 (1.6142)

Reversible L

E1 E7 E8 B1 K2 S0 R8 R9 W9

Pump type Motor type

The rear cover is available in aluminium only.

DRIVE SHAFTS: see page 51 MOUNTING FLANGE: see page 57 59

Mounting flange material

Screws tightening torque Nm (lbf in)

V

25

2,5

Aluminium Cast iron

(199 243)

A

mm (inch) 65,2 (2.5669) 66,8 (2.6299) 68,4 (2.6929) 70 (2.7559) 72 (2.8346) 74,8 (2.9449) 78 (3.0709) 80,6 (3.1732) 82 (3.2283) 87,5 (3.4449) 94 (3.7008)

B

mm (inch) 50,2 (1.9764) 51,8 (2.0394) 53,4 (2.0124) 55 (2.1654) 57 (2.2441) 59,8 (2.3543) 63 (2.4803) 65,6 (2.5827) 67 (2.6378) 72,5 (2.8543) 79 (3.1102)

PL. 101 PL. 101,5 PL. 102 PL. 102,5 PL. 103,15 PL. 104 PL. 105 PL. 105,8 PL. 106,3 PL. 108 PL. 1010 32

002

DCAT033-010

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 20

SINGLE UNITS SIDE PORTS

Replaces: 01/10.03

Reversible R

Single rotation S - D and Reversible B

Mounting flange type version 0

X

mm (inch) 18 (0.7087) 18,8 (0.7402) 16 (0.6299) 16 (0.6299) 17,7 (0.6969) 20 (0.7874) 20 (0.7874) 20 (0.7874) 20 (0.7874) 32,1 (1.2638) Reversible L For single rotation S - D, reversible rotation R and B the rear cover is available in cast iron and aluminium. For reversible rotation L the rear cover is available in aluminium only. DRAIN PORT POSITION: L = Side * = Bottom DRIVE SHAFTS: see page 52 54 MOUNTING FLANGE: see page 60 64 Mounting flange material Screws tightening torque Nm (lbf in)

E2 B2 B4 B5 B6 S1 S2 S9 S5 W8

Pump type Motor type

V

45 70

4,5 7

Aluminium Cast iron

(358 438) (558 682)

A

mm (inch) 75 (2.9528) 77,5 (3.0512) 78,5 (3.0905) 80 (3.1496) 81,3 (3.2008) 84 (3.3070) 84,5 (3.3268) 89,5 (3.5236) 93 (3.6614) 96,4 (3.7952) 99,5 (3.9173) 105,1 (4.1378) 107,5 (4.2323) 110,2 (4.3386) 117,5 (4.6260)

B

mm (inch) 25,75 (1.0138) 27 (1.0630) 27,5 (1.0826) 28,25 (1.1122) 28,9 (1.1378) 30,25 (1.1909) 30,5 (1.2008) 33 (1.2992) 34,75 (1.3681) 36,45 (1.4350) 38 (1.4961) 40,8 (1.6063) 42 (1.6535) 43,35 (1.7067) 47 (1.8504)

C

mm (inch) 86,5 (3.4055) 89 (3.5039) 90 (3.5433) 91,5 (3.6024) 92,8 (3.6535) 95,5 (3.7598) 96 (3.7795) 101 (3.9764) 104,5 (4.1142) 107,9 (4.2480) 111 (4.3701) 116,6 (4.5905) 119 (4.6850) 121,7 (4.7913) 129 (5.0787)

D

mm (inch) 43,25 (1.7028) 44,5 (1.7520) 45 (1.7716) 45,75 (1.8012) 46,4 (1.8268) 47,75 (1.8799) 48 (1.8898) 50,5 (1.9882) 52,25 (2.0571) 53,45 (2.1043) 55,5 (2.1850) 58,3 (2.2953) 59,5 (2.3425) 60,85 (2.3957) 64,5 (2.5394)

PL. 204 PL. 206,3 PL. 207,2 PL. 208 PL. 209 PL. 2010,5 PL. 2011,2 PL. 2014 PL. 2016 PL. 2019 PL. 2020 PL. 2024,5 PL. 2025 PL. 2027,8 PL. 2031,5 DCAT033-010

02/07.2006

002

33

Polaris

POLARIS 20

SINGLE UNITS REAR PORTS

Reversible R

Single rotation S - D e Reversible B

Mounting flange type version 0

X

mm (inch) 18 (0.7087) 18,8 (0.7402) 16 (0.6299) 16 (0.6299) 17,7 (0.6969) 20 (0.7874) 20 (0.7874) 20 (0.7874) 20 (0.7874) 32,1 (1.2638) Reversible L The rear cover is available in aluminium only. DRAIN PORT POSITION: L = Side * = Bottom DRIVE SHAFTS: see page 52 54 MOUNTING FLANGE: see page 60 64 Mounting flange material Screws tightening torque Nm (lbf in)

E2 B2 B4 B5 B6 S1 S2 S9 S5 W8

Pump type Motor type

V

45 70

4,5 7

Aluminium Cast iron

(358 438) (558 682)

A

mm (inch) 86,5 (3.4055) 89 (3.5039) 90 (3.5433) 91,5 (3.6024) 92,8 (3.6535) 95,5 (3.7598) 96 (3.7795) 101 (3.9764) 104,5 (4.1142) 107,9 (4.2480) 111 (4.3701) 116,6 (4.5905) 119 (4.6850) 121,7 (4.7913) 129 (5.0787)

B

mm (inch) 69 (2.71765) 71,5 (2.8150) 72,5 (2.8543) 74 (2.9134) 75,3 (2.9646) 78 (3.0708) 78,5 (3.0906) 83,5 (3.2784) 87 (3,4252) 89,9 (3.5393) 93,5 (3.6811) 99,1 (3.9016) 101,5 (3.9961) 104,2 (4.1024) 111,5 (4.3898)

PL. 204 PL. 206,3 PL. 207,2 PL. 208 PL. 209 PL. 2010,5 PL. 2011,2 PL. 2014 PL. 2016 PL. 2019 PL. 2020 PL. 2024,5 PL. 2025 PL. 2027,8 PL. 2031,5 34

002

DCAT033-010

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 30

SINGLE UNITS SIDE PORTS

Replaces: 01/10.03

Reversible R

Single rotation S - D

Mounting flange type version 0

X

mm (inch) 24 (0.945) 25 (0.984) 28 (1.102) 54 (2.1260) 20,8 (0.819)

The rear cover is available in cast iron only.

E3 E4 B3 S5 U3

DRIVE SHAFTS: see page 55 and page 56 MOUNTING FLANGE: see page 65 67

Mounting flange material

Screws tightening torque Nm (lbf in)

V

100

10

Cast iron

(797 974)

Pump type Motor type

A

mm (inch) 106 (4.1732) 109 (4.2913) 114 (4.4882) 117 (4.6063) 120 (4.7244) 125 (4.9212) 131 (5.1575) 139 (5.4724) 144 (5.6693) 150 (5.9055)

B

mm (inch) 39 (1.5354) 40,5 (1.5945) 43 (1.6929) 44,5 (1.7520) 46 (1.8110) 48,5 (1.9094) 51,5 (2.0276) 55,5 (2.1850) 58 (2.2835) 61 (2.4016)

PL. 3022 PL. 3027 PL. 3034 PL. 3038 PL. 3043 PL. 3051 PL. 3061 PL. 3073 PL. 3082 PL. 3090 DCAT033-010

02/07.2006

002

35

Polaris

MULTIPLE PUMPS

POLARIS series pumps can be coupled together in combination. Where the input power requirements of each section varies, that with the greater requirement must be at the drive shaft end, and progressively smaller to the rear. Features and performances are the same as the corresponding single pumps, but pressures must be limited by the transmissible torque of the drive and connecting shafts. To have appropriate data, use the formula below. The maximum rotational speed is that of the lowest rated speed of the single units incorporated. Available with common inlet and separated stages. For more information please consult our technical sales department.

M V Dp

lbf in (Nm) in3/rev (cm3/rev) psi (bar) ( 0,88)

Torque Displacement Pressure Mechanical efficiency

hm= hm (V,Dp, n)

M=

D p (bar) V (cm 3 /rev) 62,83 h m

[Nm]

DRIVE SHAFT SELECTION

The torque absorbed from the shaft of the first pump results from the sum of the torques due to all single stages. The achieved value must not exceed the maximum torque limit given for the shaft of the first pump. Diagrams providing approximate selection data will be found on page 37.

Let us consider a double pump PLP2014 + PLP204. If we suppose that we have to work with the first pump at a pressure of 2900 psi (200 bar) and the second pump at a pressure of 2175 psi (150 bar), the graph 2 shows that the torque absorbed by PLP2014 is 469 lbf in (53 Nm) and the PLP204 absorbs 115 lbf in (13 Nm) (acceptable value because it doesnt exceed the maximum drive shaft torque that is 973 lbf in (110 Nm), see page 39). The torque to be transmitted by the first drive shaft will thus be 469+115= 584 lbf in (53+13= 66 Nm), this value must not exceed the shafts maximum rated value.

36

002

DCAT033-011

01/10.03

Example

Polaris

ABSORBED TORQUE

PLP 30

PLP 20

PLP 20

3

Ne w di s

PLP 10

pl

ac

em

en

ts

01/10.03 DCAT033-011

002

37

Polaris

COMMON INLET - PORTS POSITION

IN IN

PLP

OUT

OUT

OUT

OUT

OUT

IN

IN

Reduced inlets provide overall systems savings by reducing the cost of redundant inlet hose and fittings. For other combinations please consult our sales department.

OUT

OUT

OUT

MULTIPLE PUMPS COMBINATION

PLP 10

V6 V7

Polaris 10/10 Polaris 10/10

STANDARD VERSION COMMON INLET VERSION

Front

Intermediate

Rear

88

MAX 30 Nm (266 lbf in)

88

MAX 30 Nm (266 lbf in)

38

002

DCAT033-011

02/07.2006

Replaces: 01/10.03

Polaris

MULTIPLE PUMPS COMBINATION

Polaris 20/20 Polaris 20/20

Front

PLP 20

S6 S7

Rear

STANDARD VERSION COMMON INLET VERSION

Intermediate

Replaces: 01/10.03

86

MAX 110 Nm (974 lbf in)

86

MAX 110 Nm (974 lbf in)

Polaris 20/20

Front

SEPARATED STAGES VERSION

Rear

Z6

86

MAX 110 Nm (974 lbf in)

Polaris 20/10 Polaris 20/10

STANDARD VERSION COMMON INLET VERSION

T6 T7

Front

Rear

51

MAX 30 Nm (266 lbf in)

02/07.2006

Polaris 20/10

Front

SEPARATED STAGES VERSION

Rear

Z6

51

MAX 30 Nm (266 lbf in)

DCAT033-011

002

39

Polaris

MULTIPLE PUMPS COMBINATION

Polaris 30/30 STANDARD VERSION

PLP 30

M6

Front

Intermediate

Rear

65

MAX 180 Nm (1593 lbf in)

65

MAX 180 Nm (1593 lbf in)

Polaris 30/20 Polaris 30/20

Front

STANDARD VERSION COMMON INLET VERSION

Rear

N6 N7

83

MAX 110 Nm (974 lbf in)

Polaris 30/20

Front

SEPARATED STAGES VERSION

Rear

Z6

83

MAX 110 Nm (974 lbf in)

40

002

DCAT033-011

02/07.2006

Replaces: 01/10.03

Polaris

PLP 30

Polaris 30/10 Polaris 30/10 Replaces: 01/10.03

Front

STANDARD VERSION COMMON INLET VERSION

Rear

Q6 Q7

52

MAX 30 Nm (266 lbf in)

02/07.2006 DCAT033-011

002

41

Polaris

POLARIS 10

MULTIPLE PUMPS

PLP 10/10

The rear cover is available in cast iron and aluminium.

DRIVE SHAFTS: see page 51 MOUNTING FLANGE: see page 57 59

Mounting flange material

Screws tightening torque Nm (lbf in)

V

25

2,5

Aluminium Cast iron

(199 243)

Pump type

A

mm (inch) 17,6 (0.6929) 18,4 (0.7244) 19,2 (0.7559) 20 (0.7874) 21 (0.8268) 22,4 (0.8819) 24 (0.9449) 25,3 (0.9961) 26 (1.0236) 28,75 (1.1319) 32 (1.2598)

Mounting flange type version 0

X

mm (inch) 14 (0.5512) 14 (0.5512) 14 (0.5512) 14 (0.5512) 11,8 (0.4646) 17 (0.6693) 41 (1.6142) 41 (1.6142) 41 (1.6142)

PLP 101 PLP 101,5 PLP 102 PLP 102,5 PLP 103,15 PLP 104 PLP 105 PLP 105,8 PLP 106,3 PLP 108 PLP 1010

E1 E7 E8 B1 K2 S0 R8 R9 W9

42

002

DCAT033-011

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 20

PLP 20/20

MULTIPLE PUMPS

PLP 20

Replaces: 01/10.03

Separated stages

PLP 20/10

Separated stages DRIVE SHAFTS: see page 52 54 MOUNTING FLANGE: see page 60 64 Mounting flange material Screws tightening torque Nm (lbf in) The rear cover is available in cast iron and aluminum.

Pump type

A

mm (inch) 25,75 (1.0138) 27 (1.0630) 27,5 (1.0826) 28,25 (1.1122) 28,9 (1.1378) 30,25 (1.1909) 30,5 (1.2008) 33 (1.2992) 34,75 (1.3681) 36,45 (1.4350) 38 (1.4961) 40,8 (1.6063) 42 (1.6535) 43,35 (1.7067) 47 (1.8504)

V

45 70

4,5 7

V1

25

2,5

Aluminium Cast iron

(358 438) (558 682)

(199 243)

PLP 204 PLP 206,3 PLP 207,2 PLP 208 PLP 209 PLP 2010,5 PLP 2011,2 PLP 2014 PLP 2016 PLP 2019 PLP 2020 PLP 2024,5 PLP 2025 PLP 2027,5 PLP 2031,5

Pump type

B

mm (inch) 17,6 (0.6929) 18,4 (0.7244) 19,2 (0.7559) 20 (0.7874) 21 (0.8268) 22,4 (0.8819) 24 (0.9449) 25,3 (0.9961) 26 (1.0236) 28,75 (1.1319) 32 (1.2598)

Mounting flange type version 0

X

mm (inch) 18 (0.7087) 18,8 (0.7402) 16 (0.6299) 16 (0.6299) 17,7 (0.6969) 20 (0.7874) 20 (0.7874) 20 (0.7874) 20 (0.7874) 32,1 (1.2638)

PLP 101 PLP 101,5 PLP 102 PLP 102,5 PLP 103,15 PLP 104 PLP 105 PLP 105,8 PLP 106,3 PLP 108 PLP 1010

E2 B2 B4 B5 B6 S1 S2 S9 S5 W8

02/07.2006

DCAT033-011

002

43

Polaris

POLARIS 30

PLP 30/30

MULTIPLE PUMPS

PLP 30

The rear cover is available in cast iron only.

PLP 30/20

Separated stages The rear cover is available in cast iron and aluminum.

PLP 30/10

The rear cover is available in cast iron and aluminum.

44

002

DCAT033-011

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 30

MULTIPLE PUMPS

PLP 30

Pump type

A

mm (inch) 39 (1.5354) 40,5 (1.5945) 43 (1.6929) 44,5 (1.7520) 46 (1.8110) 48,5 (1.9094) 51,5 (2.0276) 55,5 (2.1850) 58 (2.2835) 61 (2.4016)

Pump type

B

mm (inch) 25,75 (1.0138) 27 (1.0630) 27,5 (1.0826) 28,25 (1.1122) 28,9 (1.1378) 30,25 (1.1909) 30,5 (1.2008) 33 (1.2992) 34,75 (1.3681) 36,45 (1.4350) 38 (1.4961) 40,8 (1.6063) 42 (1.6535) 43,35 (1.7067) 47 (1.8504)

Pump type

C

mm (inch) 17,6 (0.6929) 18,4 (0.7244) 19,2 (0.7559) 20 (0.7874) 21 (0.8268) 22,4 (0.8819) 24 (0.9449) 25,3 (0.9961) 26 (1.0236) 28,75 (1.1319) 32 (1.2598)

PLP 3022 PLP 3027 PLP 3034 PLP 3038 PLP 3043 PLP 3051 PLP 3061 PLP 3073 PLP 3082 PLP 3090

PLP 204 PLP 206,3 PLP 207,2 PLP 208 PLP 209 PLP 2010,5 PLP 2011,2 PLP 2014 PLP 2016 PLP 2019 PLP 2020 PLP 2024,5 PLP 2025 PLP 2027,5 PLP 2031,5

PLP 101 PLP 101,5 PLP 102 PLP 102,5 PLP 103,15 PLP 104 PLP 105 PLP 105,8 PLP 106,3 PLP 108 PLP 1010

Replaces: 01/10.03

DRIVE SHAFTS: see page 55 and page 56 MOUNTING FLANGE: see page 65 67 Mounting flange type version 0

X

mm (inch) 24 (0.945) 25 (0.984) 28 (1.102) 54 (2.1260) 20,8 (0.819)

E3 E4 B3 S5 U3

02/07.2006

Mounting flange material

Screws tightening torque Nm (lbf in)

V

100

10

V1

45

4,5

V2

25

2,5

Aluminium Cast iron

(358 438)

(199 243)

(797 974)

DCAT033-011

002

45

Polaris

VERSIONS

For each version, the possible combination between drive shafts and mounting flanges are shown on pages 57 67. VERSION

Available for group: 10 20 30

VERSION

Available for group: 20

W8

VERSION

Available for group: 20

Version for applications without radial and axial load on the drive shaft.

VERSION

Available for group: 20

VERSION

Available for group: 20

VERSION

Available for group: 20

VERSION

Available for group: 20

VERSION

Available for group: 20

For the outboard bearing life expectancy, diagrams providing approximate selection data well be found on subsequent pages. For particular applications please consult our technical sales department. 46 002 DCAT033-012

01/10.03

Polaris

POLARIS 20

VERSION WITH OUTBOARD BEARING

X= Distance of the radial load result from the mounting flange [mm (in)].

Each curve has been obtained at: Lubricant oil ISO VG 46

W8

Replaces: 01/10.03

Temperature 60 C (140 F) Without or with very low axial load

Example

Fr Radial load X Speed Rating fatigue life 1915 N (430.88 lbf) 20 mm (0.7874 in) 2000 min -1 2000 h

02/07.2006 DCAT033-012

002

47

Polaris

POLARIS 20

VERSION WITH OUTBOARD BEARING

X= Distance of the radial load result from the mounting flange [mm (in)].

Each curve has been obtained at: Lubricant oil ISO VG 46 Temperature 60 C (140 F) Without or with very low axial load

4-6

Example

Fr Radial load X Speed Rating fatigue life 1850 N (416.25 lbf) 20 mm (0.7874 in) 2000 min -1 2000 h

48

002

DCAT033-012

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 20

VERSION WITH OUTBOARD BEARING

X= Distance of the radial load result from the mounting flange [mm (in)].

Each curve has been obtained at: Lubricant oil ISO VG 46

Replaces: 01/10.03

Temperature 60 C (140 F) Without or with very low axial load

Example

Fr Radial load X Speed Rating fatigue life 800 N (180 lbf) 20 mm (0.7874 in) 2000 min -1 2000 h

02/07.2006 DCAT033-012

002

49

Polaris

POLARIS 20

VERSION WITH OUTBOARD BEARING

X= Distance of the radial load result from the mounting flange [mm (in)].

Each curve has been obtained at: Lubricant oil ISO VG 46 Without or with very low axial load

7-8-9

Example

Fr Radial load X Speed Rating fatigue life 1858 N (524.25 lbf) 20 mm (0.787 in) 2000 min -1 2000 h

50

002

DCAT033-012

02/07.2006

Replaces: 01/10.03

Temperature 60 C (140 F)

Polaris

POLARIS 10

EUROPEAN TAPERED 1:8

Mounting face refer to flange code E1

DRIVE SHAFTS

81 EUROPEAN TAPERED 1:8

Mounting face refer to flange code E7

86

SAE AA SPLINE

Not available with size: 108 With flange: E1, E8, K2, S0 With flange: R8, R9 101,5 - 102,5 - 105,8

02

SAE AA STRAIGHT

Not available with size: 101,5 - 102,5 - 105,8 102,5 - 105,8

30

With flange: E7, B1, K2, R8, R9 With flange: S0

Mounting face refer to flange code R9

Mounting face refer to flange code S0

Ext. Involute Spline ANSI B92.1 with major diameter modified 9 teeth - 20/40 Pitch - 30 deg Flat Root - Side fit - Class 5

SAE STRAIGHT

Not available with size: 101,5 - 102,5 Mounting face refer to flange code R8

36

STRAIGHT

Not available with size: 105,8 Mounting face refer to flange code E8

29

01/10.03 DCAT033-013

002

51

Polaris

POLARIS 20

EUROPEAN TAPERED 1:8

Not available with size: 2010,5 - 2024,5 - 2027,8 Mounting face refer to flange code E2

DRIVE SHAFTS

82 GERMAN TAPERED 1:5

Not available with size: 207,2 - 2010,5 - 2019 - 2024,5 - 2027,8 - 2031,5 Mounting face refer to flanges code B4 and B5

54

GERMAN TAPERED 1:5

Mounting face refer to flange code B2

55

STRAIGHT

Not available with size:

46

Only for version 5 , 9 and W8 with outboard bearing

207,2 - 2010,5 - 2019 - 2024,5 - 2025 - 2027,8 - 2031,5 Mounting face refer to flange code E2

SAE A SPLINE

Not available with size: 2024,5 - 2027,8 Mounting face refer to flange code S1

03

SPLINE

Not available with size: 206,3 - 209 - 2010,5 - 2019 Mounting face refer to flange code S1

01

Ext. Involute Spline SAE J498B with major diameter modified 9 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

Ext. Involute Spline SAE J498B with major diameter modified 10 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

52

002

DCAT033-013

01/10.03

Polaris

POLARIS 20

SAE SPLINE

Not available with size: 207,2 - 2010,5 - 2019 - 2024,5 - 2027,8 Mounting face refer to flange code S1

DRIVE SHAFTS

07 SAE A STRAIGHT

Not available with size: 2010,5 - 2019 - 2024,5 - 2027,8 Mounting face refer to flange code S1

31

Ext. Involute Spline ANSI B92.1 with major diameter modified 11 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 5

STRAIGHT

Not available with size: 207,2 - 2019 - 2024,5 Mounting face refer to flange code S1

49

STRAIGHT

Not available with size: 207,2 - 2010,5 - 2019 - 2024,5 - 2027,8 Mounting face refer to flange code S1

50

SAE B SPLINE

Not available with size: 204 - 207,2 - 2010,5 - 2024,5 - 2027,8 Mounting face refer to flange code S5

04

SAE B STRAIGHT

Not available with size: 204 - 207,2 - 208 - 2010,5 - 2011,2 2019 - 2024,5 - 2027,8 Mounting face refer to flange code S5

32

01/10.03

Ext. Involute Spline SAE J498B with major diameter modified 13 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

DCAT033-013

002

53

Polaris

POLARIS 20

DIN 5482 SPLINE

Not available with size: 2010,5 - 2019 - 2024,5 - 2027,8 Mounting face refer to flange code B2

DRIVE SHAFTS

12 STRAIGHT

Only for version 6 with outboard bearing Available in 0 version only with size: 2020 Mounting face refer to flange code E2

48

Ext. Involute Spine B 17x14xe9 DIN 5482

STRAIGHT

Mounting face refer to flange code E2

B1

TANG

Not available with size: 207,2 - 2010,5 - 2019 - 2024,5 - 2027,8 Mounting face refer to flange code B6

95

Only for version 8 and 5 with outboard bearing

54

002

DCAT033-013

01/10.03

Polaris

POLARIS 30

EUROPEAN TAPERED 1:8

Not available with size: 3082 - 3090 Mounting face refer to flange code E3

DRIVE SHAFTS

83 EUROPEAN TAPERED 1:8

Not available with size: 3022 - 3027 - 3034 - 3038 Mounting face refer to flange code E4

84

GERMAN TAPERED 1:5

Not available with size: 3061 - 3073 - 3082 - 3090 Mounting face refer to flange code B3

56

STRAIGHT

Not available with size: 3082 - 3090 Mounting face refer to flange code E3

41

SAE B SPLINE

Not available with size: 3082 - 3090 Mounting face refer to flange code U3

A8

SAE BB SPLINE

Not available with size: 3022 - 3038 - 3082 - 3090 Mounting face refer to flange code U3

A5

01/10.03

Ext. Involute Spline SAE J498B with major diameter modified 13 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

Ext. Involute Spline SAE J498B with major diameter modified 15 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

DCAT033-013

002

55

Polaris

POLARIS 30

SAE B SPLINE

Mounting face refer to flange code S5

DRIVE SHAFTS

04 SAE BB SPLINE

Not available with size: 3090 Mounting face refer to flange code S5

05

Ext. Involute Spline SAE J498B with major diameter modified 13 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

Ext. Involute Spline SAE J498B with major diameter modified 15 teeth - 16/32 Pitch - 30 deg Flat Root - Side fit - Class 1

SAE B STRAIGHT

Mounting face refer to flange code S5

32

SAE BB STRAIGHT

Mounting face refer to flange code S5

33

56

002

DCAT033-013

01/10.03

Polaris

POLARIS 10

EUROPEAN

Material: cast iron and aluminium

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

E1 EUROPEAN

Material: cast iron and aluminium

E7

Replaces: 01/10.03

DRIVE SHAFTS

See page 51

DRIVE SHAFTS

See page 51

VERSIONS

See page 46

81 #

02 x

29 x

86 x

VERSIONS

See page 46

86 #

29 x

30 x

0

# Standard combination x Available combination

0

# Standard combination x Available combination

EUROPEAN

Material: cast iron and aluminium

E8

GERMAN 2 BOLTS

Material: aluminium

B1

02/07.2006

DRIVE SHAFTS

See page 51

DRIVE SHAFTS

See page 51

VERSIONS

See page 46

29 #

02 x

VERSIONS

See page 46

30 #

86 x

0

# Standard combination x Available combination

0

# Standard combination x Available combination

DCAT033-014

002

57

Polaris

POLARIS 10

GERMAN 4 BOLTS

Material: aluminium

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

K2 SAE "A-A" 2 BOLTS

Material: cast iron and aluminium

S0

DRIVE SHAFTS

See page 51

DRIVE SHAFTS

See page 51

VERSIONS

See page 46

02 x

30 x

VERSIONS

See page 46

30 #

02 x

86 x

0

# Standard combination x Available combination

0

# Standard combination x Available combination

SAE "A-A" 2-4 BOLTS

Material: cast iron

R9

SAE 2-4 BOLTS

Material: cast iron

R8

DRIVE SHAFTS

See page 51

DRIVE SHAFTS

See page 51

VERSIONS

See page 46

02 #

30 x

36 #

VERSIONS

See page 46

02 #

30 x

36 #

0

# Standard combination x Available combination

0

# Standard combination x Available combination

58

002

DCAT033-014

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 10

SAE 2 BOLTS

Material: cast iron

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

W9

Replaces: 01/10.03

DRIVE SHAFTS

See page 51

VERSIONS

See page 46

36 #

0

# Standard combination x Available combination

02/07.2006 DCAT033-014

002

59

Polaris

POLARIS 20

EUROPEAN

Material: cast iron and aluminium

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

E2

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 18 (0.7087) 55,4 (2.1811) 43,6 (1.7165) 55,4 (2.1811) 59,4 (2.3386) 59,4 (2.3386)

82 # # # #

46 #

B1

03 x

04 x

07 x

12 x

31 x

48 x

49 x x

50 x x

54 x x

0 4 5 6 7 8

x #

# Standard combination x Available combination

GERMAN

Material: cast iron and aluminium

B2

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 18,8 (0.7402) 44,4 (1.7480) 59,4 (1.7441)

12 #

54 # x

55

01 x

03 x x

31 x

46 x

49 x x

82 x x

0 5 9

x x

# Standard combination x Available combination

60

002

DCAT033-014

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 20

GERMAN 2 BOLTS

Material: cast iron and aluminium

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

B4

Replaces: 01/10.03

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 16 (0.63 41,6 (1.6378)

54 # x

03 x x

12 x

31 x

49 x x

54 x x

82 x x

0 5

# Standard combination x Available combination

GERMAN 2 BOLTS

Material: cast iron and aluminium

B5

02/07.2006

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 16 (0.63) 41,6 (1.6378)

54 # x

03 x x

12 x

31 x

49 x x

54 x x

82 x x

0 5

# Standard combination x Available combination

DCAT033-014

002

61

Polaris

POLARIS 20

GERMAN 4 BOLTS

Material: cast iron and aluminium

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

B6

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 17,7 (0.6968) 43,3 (1.747)

95 # x

07 x

12 x

0 5

# Standard combination x Available combination

SAE "A" 2 BOLTS

Material: cast iron and aluminium

S1

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 20 (0.787) 45,6 (1.7953)

01 #

03 # x

04 x

07 #

12 x

31 #

32 x

46 x

49 # x

50 x x

54 x x

82 x x

0 5

# Standard combination x Available combination

62

002

DCAT033-014

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 20

SAE "A" 2 BOLTS

Material: cast iron and aluminium

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

S2

Replaces: 01/10.03

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 20 (0.7874) 45,6 (1.7953)

01 #

03 # x

04 x

07 #

12 x

31 #

32 x

46 x

49 # x

50 x x

54 x x

82 x x

0 5

# Standard combination x Available combination

SAE "A" 2 BOLTS

Material: cast iron and aluminium

S9

02/07.2006

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 20 (0.7874) 45,6 (1.7953)

01 #

03 # x

04 x

07 #

12 x

31 #

32 x

46 x

49 # x

50 x x

54 x x

82 x x

0 5

# Standard combination x Available combination

DCAT033-014

002

63

Polaris

POLARIS 20

SAE "B" 2 BOLTS

Material: cast iron

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

S5

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 20 (0.7874) 45,6 (1.7953)

04 #

32 #

49 x x

0 5

# Standard combination x Available combination

GERMAN

Material: cast iron

W8

DRIVE SHAFTS

See page 52 54

VERSIONS

See page 46

A

mm (in) 32,1 (1.2638)

55 #

W8

# Standard combination x Available combination

64

002

DCAT033-014

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 30

EUROPEAN

Material: cast iron

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

E3

Replaces: 01/10.03

DRIVE SHAFTS

See page 55 e 56

VERSIONS

See page 46

83 #

41 #

04 x

05 x

32 x

33 x

A5 x

A8 x

0

# Standard combination x Available combination

EUROPEAN

Material: cast iron

E4

02/07.2006

DRIVE SHAFTS

See page 55 e 56

VERSIONS

See page 46

84 #

41 x

A5 x

A8 x

0

# Standard combination x Available combination

DCAT033-014

002

65

Polaris

POLARIS 30

GERMAN

Material: cast iron

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

B3

DRIVE SHAFTS

See page 55 e 56

VERSIONS

See page 46

56 #

83 x

A5 x

A8 x

0

# Standard combination x Available combination

SAE "B" 2 BOLTS

Material: cast iron

S5

DRIVE SHAFTS

See page 55 e 56

VERSIONS

See page 46

04 #

05 #

32 #

33 #

0

# Standard combination x Available combination

66

002

DCAT033-014

02/07.2006

Replaces: 01/10.03

Polaris

POLARIS 30

SAE "B" 2 BOLTS

Material: cast iron

MOUNTING FLANGES AND TABLE OF COMPATIBILITY

U3

Replaces: 01/10.03

DRIVE SHAFTS

See page 55 e 56

VERSIONS

See page 46

A5 #

A8 #

83 x

0

# Standard combination x Available combination

02/07.2006 DCAT033-014

002

67

Polaris

IN/OUT PORTS TYPE

SIDE PORTS PORTS TYPE Pump type Motor type German IN OUT BB BB BB BB BB BB BB BB BB BB BB BE BE BE BE BE BE BE BE BE BE BE BE BE BE BE BM BM BM BM BM BM BM BM BM BM BM OUT IN BA BA BA BA BA BA BA BA BA BA BA BC BC BC BC BC BC BC BC BC BC BC BC BC BC BC BL BL BL BL BL BL BL BL BL BL BL EA EA EA EA EA EA EA EB EB EB EB EB EB EB EB ED ED ED ED ED ED ED ED EF EF EF EA EA EA EA EA EA EA EA EA EA EA EA EA EA EA EB EB EB EB EB EB EB EB ED ED ED MA MA MA MA MA MA MA MB MB MB MB MC MC MC MC MB MC MC MD MD MD MD ME ME ME MF MA MA MA MA MA MA MA MA MA MA MA MB MB MB MB MA MB MB MC MC MC MC MD MD MD ME SA SA SA SA SA SA SA SB SB SB SB SC SC SC SC SB SC SC SD SD SD SD SE SE SE SF SA SA SA SA SA SA SA SA SA SA SA SB SB SB SB SA SB SB SC SC SC SC SD SD SD SE European IN OUT OUT IN Split SSM IN OUT OUT IN Split SSS IN OUT OUT IN Gas BSPP IN OUT GC GC GC GC GC GC GD GD GD GD GD GD GD GD GD GD GD GD GE GE GE GE GE GE GE GE GF GF GF GF GF GF GF GG GG GH GH OUT IN GC GC GC GC GC GC GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GF GF GF GF GF GF GF GF GF GG GG SAE ODT IN OUT OB OB OB OB OB OB OB OB OB OC OC OC OC OC OC OC OC OC OD OD OD OD OD OD OD OD OF OF OF OG OG OG OG OH OH OH OH OUT IN OA OA OA OA OA OA OA OA OA OB OB OC OC OC OC OC OC OC OC OC OC OC OC OC OC OC OD OD OD OF REAR PORTS Gas BSPP IN OUT GC GC GC GC GC GC GD GD GD GD GD GD GD GD GD GD GD GD GE GE GE GE GE GE GE GE OUT IN GC GC GC GC GC GC GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD GD SAE ODT IN OUT OB OB OB OB OB OB OB OB OB OB OB OC OC OC OC OC OC OC OD OD OD OD OD OD OD OD OUT IN OA OA OA OA OA OA OA OA OA OB OB OC OC OC OC OC OC OC OC OC OC OC OC OC OC OC

PL. 101 PL. 101,5 PL. 102 PL. 102,5 PL. 103,15 PL. 104 PL. 105 PL. 105,8 PL. 106,3 PL. 108 PL. 1010 PL. 204 PL. 206,3 PL. 207,2 PL. 208 PL. 209 PL. 2010,5 PL. 2011,2 PL. 2014 PL. 2016 PL. 2019 PL. 2020 PL. 2024,5 PL. 2025 PL. 2027,8 PL. 2031,5 PL. 3022 PL. 3027 PL. 3034 PL. 3038 PL. 3043 PL. 3046 PL. 3051 PL. 3061 PL. 3073 PL. 3082 PL. 3090

OF OF OG OG OG OG

68

002

DCAT033-015

01/10.03

OF

Polaris

EXTERNAL DRAIN PORTS

SIDE PORTS German GA TA GC European GB GC Split SSM GB GC Split SSS 03 OA Gas BSPP GA GB GC SAE ODT 03 03 OA REAR PORTS Gas BSPP GA GB SAE ODT 03 03

IN/OUT PORTS TYPE

PL. 10 PL. 20 PL. 30

DRAIN PORTS SIZES

Tightening torque for low pressure side port.

GAS STRAIGHT THREAD PORTS

British standard pipe parallel (55) conforms to UNI - ISO 228

BSPP

CODE

Nominal size

GA GB

1/8" 1/4"

mm mm mm mm (in) (in) (in) (in) 16,5 8,75 12 1 G 1/8 (0.6496) (0.3444) (0.4724) (0.0394)

Nm (lbf in) 5 +0,25 (44 46) 15 + 1 21,5 12 15 1,5 G 1/4 (0.8465) (0.4724) (0.5906) (0.0591) (133 142)

METRIC STRAIGHT THREAD PORTS ISO 6149

Metric thread ISO 60 conforms to ISO/R 262

METRIC

CODE

A

M 10x1

B

mm (in) 22 (0.8661)

C

mm (in) 9 (0.3543)

D

mm (in) 13 (0.5118)

E

mm (in) 0,5 (0.0197) Nm (lbf in) 10 + 0 , 5 (89 93)

TA

SAE STRAIGHT THREAD PORTS J514 01/10.03

American straight thread UNC-UNF 60 conforms to ANSI B 1.1

ODT

CODE

03

mm mm mm mm Nm (in) (in) (in) (in) (lbf in) 12 + 1 21 9,5 14 1 7/16"-20 UNF-2B (0.8267) (0.3740) (0.5512) (0.0394) (106 115)

Other drain ports are shown on subsequent pages.

DCAT033-015

002

69

Polaris

PORTS SIZES

Tightening torque for low pressure side port. Tightening torque for high pressure side port [values obtained at 5075 psi (350 bar)] For reversible rotation, please consult only the tightening torque for high pressure side port.

GERMAN FLANGED PORTS - 4 Bolts

Metric thread ISO 60 conforms to ISO/R 262

GERMAN

A

CODE mm (in) 8 (0.3150) 13 (0.5118) 15 (0.5906) 20 (0.7874) 19 (0.7480) 27 (1.0630)

B

mm (in) 30 (1.1811) 30 (1.1811) 35 (1.3780) 40 (1.5748) 55 (2.1654) 55 (2.1654)

C

Thread Depth mm (in) M6 12 (0.4724) M6 12 (0.4724) M 6 12 (0.4724) M 6 12 (0.4724) M8 18 (0.7087) M8 18 (0.7087) Nm (lbf in) 8 +0,5 (71 75) 8 +0,5 (71 75) 8 +0,5 (71 75) 15 + 1 (133 142) 20 + 1 (177 186) 15 + 1 (133 142) Nm (lbf in) 8 +0,5 (71 75) 8 +0,5 (71 75) 8 +0,5 (71 75) 15 + 1 (133 142) 20 + 1 (177 186) 20 + 1 (177 186)

BA BB BC BE BL BM

EUROPEAN FLANGED PORTS - 4 Bolts

Metric thread ISO 60 conforms to ISO/R 262

EUROPEAN

A

CODE mm (in) 13 (0.5118) 19 (0.7480) 27 (1.0630) 33 (1.2992)

B

mm (in) 30 (1.1811) 40 (1.5748) 51 (2.0079) 62 (2.4409)

C

Thread Depth mm (in) M 6 13 (0.5118) M 8 14 (0.5512) M 8 (u) 18 (0.7087) M 10 18 (0.7087) M 12 18 (0.7087) Nm (lbf in) 8 +0,5 (71 75) 15 + 1 (133 142) 15 + 1 ( u ) (133 142) 20 + 1 (177 186) 25 + 1 (221 230) Nm (lbf in) 8 +0,5 (71 75) 15 + 1 (133 142) 15 + 1 ( u ) (133 142) 30 + 2 , 5 (266 288) 50 + 2 , 5 (443 465)

EA EB ED EF

(u) For POLARIS 30

70

002

DCAT033-015

01/10.03

Polaris

PORTS SIZES

Tightening torque for low pressure side port. Tightening torque for high pressure side port [values obtained at 5075 psi (350 bar)] For reversible rotation, please consult only the tightening torque for high pressure side port.

SAE FLANGED PORTS J518 - Standard pressure series 3000 PSI

Metric thread ISO 60 conforms to ISO/R 262

SSM

A

CODE mm (in) 12,5 (0.4921)

B

mm (in) 38,1 (1.50))

C

mm (in) 17,5 (0.6890)

D

Thread Depth mm (in) M 8 14 (0.5512) M8 ( u ) 22 (0.8661) M 10 14 (0.5512) M 10 ( u ) 22 (0.8661) M 10 14 (0.5512) M 10 ( u ) 22 (0.8661) M 10 15 (0,5906) M 10 ( u ) 22 (0.8661) M 12 22 (0.8661) M 12 22 (0.8661) Nm (lbf in) 15 + 1 (133 142) 20 + 1 ( u ) (177 186) 20 + 1 (177 186) 20 + 1 ( u ) (177 186) 20 + 1 (177 186) 20 + 1 ( u ) (177 186) 20 + 1 (177 186) 20 + 1 ( u ) (177 186) 30 + 2 , 5 (266 288) 30 + 2 , 5 (266 288) Nm (lbf in) 15 + 1 (133 142) 20 + 1 ( u ) (177 186) 25 + 1 (266 288) 35 + 2 , 5 ( u ) (310 332) 25 + 1 (266 288) 35 + 2 , 5 ( u ) (310 332) 30 + 2 , 5 (266 288) 35 + 2 , 5 ( u ) (310 332) 60 + 5 (531 575) 60 + 5 (531 575)

MA

MB

19 (0.7480)

47,6 (1.8740)

22,2 (0.8740)

MC

25,4 (1.0000)

52,4 (2.0630)

26,2 (1.0315)

MD ME MF

30,5 (1.2008) 39,3 (1.5472) 51 (2.0079)

58,7 (2.3110) 69,8 (2.7480) 77,8 (3.0630)

30,2 (1.1890) 35,7 (1.4055) 42,9 (1.6890)

(u) For POLARIS 30

SAE FLANGED PORTS J518 - Standard pressure series 3000 PSI

American straight thread UNC-UNF 60 conforms to ANSI B 1.1

SSS

A

CODE mm (in)

B

mm (in)

C

mm (in)

D

Thread Depth mm (in) 5/16-18 UNC-2B 14 (0.5512) Nm (lbf in) 15 + 1 (133 142) 20 + 1 ( u ) (177 186) 20 + 1 (177 186) 20 + 1 ( u ) (177 186) 25 + 1 (221 230) 30 + 2 , 5 ( u ) (266 288) 45 + 2 , 5 (398 420) 70 + 5 (620 664) 70 + 5 (620 664)

SA

SB 01/10.03

SC SD SE SF

Nm (lbf in) 15 + 1 (133 142) 12,5 38,1 17,5 (0.4921) (1.50)) (0.6890) 5/16-18 UNC-2B ( u ) 20 + 1 ( u ) 22 (0.8661) (177 186) 20 + 1 3/8 - 16 UNC-2B 14 (0.5512) (177 186) 19 47,6 22,2 (0.7480) (1.8740) (0.8740) 3/8 - 16 UNC-2B ( u ) 30 + 2 , 5 ( u ) 22 (0.8661) (266 288) 20 + 1 3/8 - 16 UNC-2B 14 (0.5512) (177 186) 25,4 52,4 26,2 (1.0000) (2.0630) (1.0315) 3/8 - 16 UNC-2B ( u ) 20 + 1 ( u ) 22 (0.8661) (177 186) 20 + 1 30,5 58,7 30,2 7/16 - 14 UNC-2B (1.2008) (2.3110) (1.1890) 22 (0.8661) (177 186) 30 + 2 , 5 39,3 69,8 35,7 1/2 - 13 UNC-2B (1.5472) (2.7480) (1.4055) 22 (0.8661) (266 288) 30 + 2 , 5 ( u ) 51 77,8 42,9 1/2 - 13 UNC-2B (2.0079) (3.0630) (1.6890) 22 (0.8661) (266 288)

(u) For POLARIS 30

DCAT033-015

002

71

Polaris

PORTS SIZES

Tightening torque for low pressure side port. Tightening torque for high pressure side port [values obtained at 5075 psi (350 bar)] For reversible rotation, please consult only the tightening torque for high pressure side port.

GAS STRAIGHT THREAD PORTS

British standard pipe parallel (55) conforms to UNI - ISO 228

BSPP

CODE

Nominal size

B

mm (in) 30 (#) (1.1811)

C

mm (in) 15 (0.5906)

D

mm (in) 10 (#) (0.3937) 14 (0.5512) 14 (0.5512) 17 ( u ) (0.6693) 18 (0.7087) 18 (0.7086) 22 (0.8661) 24 (0.9448)

E

mm (in) 2 (#) (0.0787) Nm (lbf in) 15 + 1 (#) (133 142) 15 + 1 (133 142) 20 + 1 (177 186) 30 + 2 , 5 (266 288) 50 + 2 , 5 (443 465) 60 + 5 (531 575) 70 + 5 (620 664) Nm (lbf in) 25 + 1 (221 230) 50 + 2 , 5 (443 465) 90 + 5 (797 841) 130 + 1 0 (1151 1239) 170 + 1 0 (1505 1593) 210 + 1 5 (1859 1992)

GC

3/8"

G 3/8

GD GE GF GG GH

1/2"

G 1/2

19 (0.7480) 24,5 (0.9646) 30,5 (1.2008) 39 (1.5354) 45 (1.7716)

3/4" 1" 1" 1/4 1" 1/2

G 3/4 G 1 G 1 1/4 G 1 1/2

(#) Drain port (u) For POLARIS 20

72

002

DCAT033-015

02/07.2006

Replaces: 01/10.03

Polaris

PORTS SIZES

Tightening torque for low pressure side port. Tightening torque for high pressure side port [values obtained at 5075 psi (350 bar)] For reversible rotation, please consult only the tightening torque for high pressure side port.

SAE STRAIGHT THREAD PORTS J514

American straight thread UNC-UNF 60 conforms to ANSI B 1.1

ODT

CODE

Nominal size

B

mm (in) 26 (1.0236) 32 (1.2598) 35 (1.3780) 42 (1.6535) 49 (1.9291) 58 (2.2835) 65 (2.5591)

C

mm (in) 13 (0.5118) 17,5 (0.690) 20,5 (0.8071) 24,8 (0.9764) 30,5 (1.2008) 39,1 (1.5394) 45 (1.7717)

D

mm (in) 15 (0.5906) 15 (0.5906) 15 ( u ) (0.5906) 17 (0.6693) 20 (0.7874) 20 (0.7874) 20 (0.7874) 20 (0.7874)

E

mm (in) 1 (0.03934) 2 (#) (0.0787) 0,5 (0.0197) 0,5 (0.0197) 0,5 (0.0197) 0,5 (0.0197) 0,5 (0.0197) Nm (lbf in) 15 + 1 (133 142) 15 + 1 (#) (133 142) 20 + 1 (177 186) 30 + 2 , 5 (266 288) 40 + 2 , 5 (354 376) 60 + 5 (531 575) 70 + 5 (620 664) 100 + 5 (885 929) Nm (lbf in) 25 + 1 (221 230) 45 + 2 , 5 (398 420) 70 + 5 (620 664) 120 + 1 0 (1062 1151) 170 + 1 0 (1505 1593) 200 + 1 0 (1770 1858) 270 + 1 5 (2389 2522)

OA OB OC OD OF OG OH

3/8"

9/16" - 18 UNF - 2B

1/2"

3/4" - 16 UNF - 2B

5/8"

7/8" - 14 UNF - 2B

3/4" 1" 1" 1/4 1" 1/2

1 1/16" - 12 UNF - 2B 1 5/16" - 12 UNF - 2B 1 5/8" - 12 UNF - 2B 1 7/8" - 12 UNF - 2B

(#) Drain port (u) For POLARIS 10

01/10.03 DCAT033-015

002

73

Polaris

CHANGING ROTATION

Example of changing rotation: from PLP20 pump clockwise to counterclockwise To change rotation of Polaris unidirectional pumps and motors it is necessary to operate in the following way:

1 - Clean the pump externally with care. 2 - Loosen, and remove, the clamp bolts (1). 3 - Coat the sharp edges of the drive shaft (4) with adhesive tape and smear a layer of clean grease on the shaft end extension to avoid damaging the lip of the shaft seal when removing the mounting flange. 4 - Remove the mounting flange (2), taking care to keep the flange as straight as possible during removal. If the flange is stuck, tap around the edge with a fibre or rubber mallet in order to break away from the body. Ensure that while removing the front mounting flange, the drive shaft and other components remain in position. 5 - Ease the drive gear (4) up to facilitate removal the front plate (3), taking care that the precision ground surfaces do not become damaged, and remove the drive gear. 6 - Remove the driven gear (5) without overturning. The rear plate has not to be removed.

7 - Re-locate the driven gear (5) in the position previously occupied by the drive gear (4) 8 - Re-locate the drive gear (4) in the position previously occupied by the driven gear (5). 9 - Replace the front plate (3) in its original position.

10 - Gently wipe the machined surface of the mounting flange (2) and the body with a flat hand stone. 11 - Refit the front mounting flange (2) turned 180 from its original position. 12 - Refit the clamp bolts (1) with the washers and tighten in a crisscross pattern with the following torque value: 70 +5 Nm (620 664 lbf in) with cast iron cover. 45+5 Nm (398 443 lbf in) with one or both cover in aluminium. 13 - Check that the pump rotates freely when the drive shaft (4) is turned by hand. If not a pressure plate seal may be pinched. 14 - The pump is ready for installation with the original rotation reversed.

74

002

DCAT033-016

01/10.03

Polaris

INSTRUCTIONS

INSTALLATION

Pump The direction of rotation of single-rotation pumps must be the same as that of the drive shaft. Check that the coupling flange correctly aligns the transmission shaft and the pump shaft. Flexible couplings should be used (never rigid fittings) which will not generate an axial or radial load on the pump shaft. Motor The direction of rotation of single-rotation motors must match circuit connections. Check that the coupling flange correctly aligns the transmission shaft and the motor shaft. Flexible couplings should be used (never rigid fittings) wich will not generate an axial or radial load on the motor shaft.

Replaces: 01/10.03

TANK

Tank capacity must be sufficient for the systems operating conditions ( ~ 3 times the amount of oil in circulation) to avoid overheating of the fluid. A heat exchanger should be installed if necessary. The intake and return lines in the tank must be spaced apart (by inserting a vertical divider) to prevent the return-line oil from being taken up again immediately.

LINES

The lines must have a major diameter which is at least as large as the diameter of pump or motor ports, and must be perfectly sealed. To reduce loss of power, the lines should be as short as possible, reducing the sources of hydraulic resistance (elbow, throttling, gate valves, etc.) to a minimum. A length of flexible tubing is recommended to reduce the transmission of vibrations. All return lines must end below the minimum oil level, to prevent foaming. Before connecting the lines, remove any plugs and make sure that the lines are perfectly clean.

FILTERS

We recommend filtering the entire system flow. Filters on suction and return line must be fitted in according to the contamination class as indicated in the first pages of the catalogue. Casappa recommends to use its own production filters:

HYDRAULIC FLUID

Use hydraulic fluid conforming to ISO/DIN standards, having viscosity as specified in the first pages of the catalogue. Avoid using mixtures of different oils which could result in decomposition and reduction of the oils lubricating power.

STARTING UP

Check that all circuit connections are tight and that the entire system is completely clean. Insert the oil in the tank, using a filter. Bleed the circuit to assist in filling. Set the pressure relief valves to the lowest possible setting. Turn on the system for a few moments at minimum speed, then bleed the circuit again and check the level of oil in the tank. In the difference between pump or motor temperature and fluid temperature exceeds 50 F (10 C), rapidly switch the system on and off to heat it up gradually. Then gradually increase the pressure and speed of rotation until the pre-set operating levels as specified in the catalogue are attained.

02/07.2006

PERIODICAL CHECKS - MAINTENANCE

Keep the outside surface clean especially in the area of the drive shaft seal. In fact, abrasive powder can accelerate wear on the seal and cause leakage. Replace filters regularly to keep the fluid clean. The oil level must be checked and oil replaced periodically depending on the systems operating conditions.

DCAT033-016

002

75

Polaris

VALVE OPTIONS (u)

PRIORITY VALVE

Costant delivery and internal recirculation of excess flow.

MAX PRESSURE RELIEF VALVE

P1

VPEF..

Fixed setting with external drain.

P2

Costant delivery at controlled pressure. Internal recirculation of excess flow and drain valve.

VPIF..

Fixed setting with internal drain.

P3

Costant delivery at controlled pressure. Excess flow and drain valve must be connected to tank.

VPER..

Adjustable setting with external drain.

P4

Costant delivery and excess flow can both be used under load.

VPIR..

Adjustable setting with internal drain.

P5T

Costant delivery at controlled pressure with drain valve connected to tank. Excess flow can be used under load. Costant delivery. Excess flow at controlled pressure can be used under load. Internal recirculation of drain valve. Costant delivery at controlled pressure. Internal recirculation of valve drain. Excess flow can be used under load.

LOAD SENSING VALVE

...

Static.

P7

...

Dynamic.

P9

...

Dynamic with relief valve fitted on the main line.

ELECTRIC VALVE FOR MOTORS

By-pass valve normally closed with max. pressure relief valve and anti-cavitation valve. Dynamic with relief valve fitted on controlled line.