Professional Documents

Culture Documents

Dolly Varden

Dolly Varden

Uploaded by

nongsamrongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dolly Varden

Dolly Varden

Uploaded by

nongsamrongCopyright:

Available Formats

BOAT BUILDER'S HANDBOOK 141

Strip boat that

can be built in

two lengths.

By WESTON FARMER

Craft Print Project No. 179

USE: Open utility outboard boat for fishing and general

use on lakes and rivers with a variety of outboard

engines.

LENGTH: 13' or 15' 6". AKERS will like the smooth lines of Dolly

BEAM: 4'2".

DEPTH: 20½" amidship.

WEIGHT OF HULL: 175 lbs. CAPACITY: 4 persons.

CONSTRUCTION: Strip planking and steam bent frames,

round bottom.

L Varden that scoots along with any outboard

in the under 7 hp class in choppy or smooth

water. Dolly is a strip boat fashioned like the

SPEEDS: 1½-2 hp about 6-7 mph. 5 hp, alternate firing, hundreds of similar boats built by craftsmen of

11 mph. 7 hp, 14 mph. the old school, and still being used because strip

COST: 13' hull $60. 15½' hull $65 (approx.). construction turns out a tight, durable, cheap and

easy-to-build boat that has real water kindliness

and handling ability. About $60 will pay for

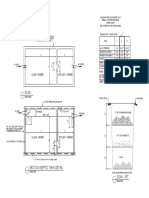

96"

45- 45" 76"

12" WL

54"

SHEER LINE 6" WL 32"

SHEER

SET OF LINES TO INSIDE OF PLANKING 1 2 " 1W A T E R L I N E

DOLLY VARDEN 6" WATERLINE

12" BUTTOCK

6" BUTTOCK

OF KEEL

TRANSOM #5 #4 #3 #2 #1 STEM

x 3" CHEEK PIECES

11" 13¼" SHEER

19¾" 22 SL 19 LINE

4" 13"

24" SL 18" WL

23 SL

20½" 22 20 17" 11½"

3" 23¾" 12" WL

20 18¼"17" 18" 21

15¼" 19½" 3 21¾" 17¾" 17" 19 13

19½" 13 8

3" 6" WL

17¼" 3" 5"

2½" 3¾"

x5 CHEEK PIECE 0

6" BU 12" BU. 6 BU 12 BU

TRANSOM & FRAME MOLD FRAME #5 MOLD FRAME #4 MOLD FRAME #3 MOLD FRAME #2 MOLD FRAME #1

142 BOAT BUILDER'S HANDBOOK

14" 60 48¼" 31¼" RABBETED STEM

SEAT SEAT SEAT SEAT

x12 x12 x12 FILLER

½"PLANKING

GUNWALE FEATHERS

AT STEM

HALF FRAMES SPACE BETWEEN

IN WAY OF STEM INWALE AND PLANKS

OAK K N E E

CEDAR F I L L E R BLOCK ROW LOCK x ½ RISER FOR SEATS

8"

SEAT RISER

10" 10"

KEEL

DETAIL OF TRANSOM KNEE HALF PLAN AND PROFILE VIEWS

GUNWALE INWALE FILLER

½"x GUNWALE

BRESTHOOK ½" PLYWOOD

CUT OFF STEM FASTEN UNDER INWALES

AFTER STEM

PLANKING

10" ½"

INWALES ½" x STEM RABBET

2½"

PLANKING

6½"

KEEL MATERIALS LIST—DOLLY V A R D E N

6"

RISER SHUTTER 15½-foot model

COPPER CLOUT NAILS 4½" No. of

STEM DIMENSIONS 6" Pieces Size and Material Use

EVERY OTHER STRAKE

1¾" OAK 14 1 x 6" x 16' rift sawn red cedar Planking strips

3½" 5" 3"

1½" 1 2 x 2" x 14' white oak Keel

2" 6" 1 2 x 8" x 4' white oak Stem and forefoot

LINE OF 8" 2 1 x 12" x 4' mahogany Transom

KEEL TOP 13½" 2 1¼ x 6" x 16' white or red oak

6" 35" (Should be wet or green) Frames

1 1 x 5" x 16' oak, mahogany or fir Wales and risers

1 1" redwood, fir or spruce as needed Thwarts and breasthook

Note: For 13-ft. model, cut two feet from strips, keel and wales

indicated above, as explained in the text.

materials to build either 13- or 15½-foot model

and if you can part with her, she'll market for

$225 to $350. 1x4 material which will reach to a convenient

Building Dolly Varden is a good way to get floor joist in the ceiling above (if you build in a

acquainted with the blessing of steam bending basement) or to rafters if in a garage. Erect

frames—long considered a bugaboo. Actually, a some stocks (short lengths of 2 x 4 ) spaced at

steam box is a cheap and effective "tool" and 2-foot intervals to raise the keel high enough for

anyone who can boil oatmeal can make a steam comfortable working room. The stocks in my

box say "Uncle." shop are tee'd to the floor, but ordinary 2 x 4

Either the 13- or 15½-foot models will ride posts, braced to a plank on the floor, will do.

safely on top of a car as you take off for your If you have a circular saw and a jointer, the

favorite fishing grounds. The 13-footer handles mill work necessary to cut and shape the strip

easier on the ground, but the fifteen is better in planking and frames will present no problem.

the water. There's only about $5 difference in Otherwise, take the cedar and oak to a sash and

costs—so take your choice and let's get started. door factory or to a well equipped lumber yard,

Lay out the molds on either scab lumber or and they will turn out the strips for you in a

cast off ¼ in. plywood, according to Fig. 1. The couple of hours.

molds merely serve to guide the shape of the Rip all the cedar boards to .625 x 6½ in. (Fig. 6).

strips. Since our keel is a straight line and the This will leave enough stock to get strong .437"

stealer or shutter planks which go onto the keel planed strips. Rip up the 1x5 in. 16-ft. oak

first determine the flow of the strips around the boards for frames into four ribbons a shy .875"

molds it is not strictly necessary to lay down wide, and re-saw these ribbons to divide the 1 in.

Dolly's lines. face two ways (Fig. 8). Then run these strips

The molds can be made from the dimensions through the planer, and if possible, rout the edges

with sufficient accuracy. Despite all you do, the round. They'll handle better if routed, but it's

planking will not follow the molds exactly. The not strictly necessary.

idea is to plank your hull using the molds as a Now, if you go to a mill, and want a thoroughly

close guide. In this 15½-ft. model, you'll find professional job of strip planking, I'd make a con-

mold No. 1, mold No. 3 and the transom will be cession to costs and to the possibility of turning

hard against the planking much of the time, while out that second boat for re-sale more easily by

molds Nos. 2, 4 and 5 merely guide the shape— investing in a shaper cutting head. I took this

that is, they maintain symmetry from side to side. shaper head and two sets of blank knives to a

With the molds done, attach them to a scab local tool works and had them ground to a ¾ in.

BOAT BUILDER'S HANDBOOK 143

STRIPS FOLLOW keel on the stocks (Fig.

HULL SHAPE 5). Assemble the tran-

SHINGLE NAIL som out of mahogany,

7d NAIL buttressed by white oak

cheek pieces (Fig. 9).

Glue and screw fasten

KEEL the cheek pieces of .625 or

SHUTTER OR 1ST STRIP ¾ in. oak to the transom.

STEALER The bevel on the bottom

STRIPS FOLLOW STEALER. edge of the transom is 20

degrees, fading around

PLANKING ASSEMBLY the turn of the bilge to

10 degrees top sides. If

DIMENSIONS OF SHUTTER OR you cut this on a band

STEALER PLANKS - MAKE 2 saw, set the table to 20

degrees, and cut the bot-

24" 24" 24" 24" 15" tom halfway up the turn

4" 4¼" 4 3¾

1 of the bilge. Then set

the table to 10 degrees,

to cut the top sides and

radius to produce a hollow and round edge to you can then fair off the bend by hand.

each strip plank. Hollow and round stripping is Erect this transom on the keel, using one No.

optional, but it pays off. I used it because the 16 x 3 in. screw from the keel into the cheek

commercial builders use it and the nails center piece, counterdrilled about 1 in. and plugged.

better, their heads are hidden without setting and Clamp or bolt the transom to the cant stock at

you can use casein glue on the strips to get a the stern end of the stocks.

perfectly tight boat that will not leak after long Fig. 2 shows the stem dimensions for the 15½-

auto trips. However, the original builders of the ft. boat. To build the stem for the 13-ft. boat,

Dolly Varden strip boat did not bother with hol-

low-and-round strips. They beveled their strips

on a jointer when bevels were called for. On part

of the hull, such as across the bottom and past

the turn of the bilge up along the topsides, hol-

low and round strip planks won't help much in

shaping the boat. But at the turn of the bilges,

you won't have to stop and bevel the strips and

work goes faster with hollow and round strip

planking. I used the hollow and round. But as

I say, you pays your money and you takes your

choice—

Use the shaper head, as shown in Fig. 7 to

cut hollows and rounds on the strip planks and

rounds on the frames. These operations complete Molds set up and failed in with light battens.

the mill work. On our boat this work was done

in a small cabinet factory in 2½ hours at a cost eliminate the lower horn end and land the knee

of $4. right on the keel, 2 ft. shorter. Mark out the

The white oak keel is rabbetted to just the rabbet and take a light chisel cut along the rab-

right depth for the stealer or shutter plank, and bet line. The rabbet itself is best cut as you pro-

should be cut smooth for a close fit. Set up the ceed with the planking, as the lay of each strip

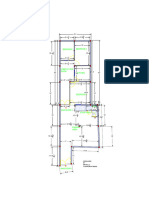

ELEVATION OF MOLD FRAME SET-UP

CANT PIECE 2x4 TO RAFTER 96" 4x4 POST

45" 45" 2x4s TO 76" TO RAFTERS

54" CUT STEM

½" 2" ¼" PLYWOOD MOLDS RAFTERS 32"-

#5 #4 #3 #2 #1 AFTER PLANKING

SHEER LINE 6½"

CUT RABBET AS

STOCK HULL IS PLANKED

6"

TRANSOM

CHEEK PIECES 2

TEMPORARY 3

NO KNEE NECESSARY ½"RABBET NAILS 8"

4 #18 FH 1x4 2"x2" KEEL 6" 35" 2" 7¼"

4" 20"

2x4 STOCK

80° 2x4

18" 24- 24" 24" 24" 24" 24" 24"

144 BOAT BUILDER'S HANDBOOK

MAKING PLANKING STRIPS Each planking strip should be edge-nailed to

PROM CEDAR BOARDS the one already laid in place about every 10 in.

with 7d galvanized nails. Pre-drill holes to pre-

6½" vent splitting and as they go in, mark the inboard

surface with a pencil. Then, later, when framing,

16' you can see where you have driven a nail. None

of the strips used in planking requires any severe

RIP BOARD warping and will lay in nicely. If you get an

PLANE STRIPS ROUND EDGES occasional "stinker," try the old boat builder's

¼" PLANE HOLLOW

dodge of wrapping the piece in a rag soaked with

hot water to allow you to get the twist.

When you complete the planking and before

¾"R ¾"R removing the molds, nail several 1 x 4 in. pieces,

ROUND called cross spalls, from one sheer plank edge

to the other to hold the shape of the boat. These

SHAPING DETAILS CUTTING- cross spalls are not removed until after the boat

CUTTING

HOLLOW is framed and the wales, seat risers and seats are

ROUND ¾"R installed. Otherwise, the boat will belly out and

lose shape.

¾"R You are now ready to frame the boat. Starting

at the transom end 5 in. from the transom land-

ing, and every 5 in. thereafter, mark the space

each frame will occupy using a thin .125" oak

CUTTING PLAN FOR OAK FRAMES batten. On every other plank strip as you go

forward, drill a pilot hole from inside to outside.

From the outside tap the 1¼ in. copper clout

1"

4" nails (available at boat shops) in these holes, to

save time when you're ready to fasten in the

frames. Using the marking batten, determine the

lengths of each frame. From your green ripped

oak strips cut the proper length frames, and

RIP BOARD number them with indelible pencil starting from

RIP STRIPS the transom with No. 1.

ROUND

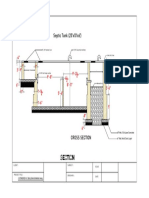

Now for a word about steaming. Any means of

¾"R getting the oak hot for fifteen minutes will do

EDGES

ROUND EDGES

plank will best show you how to bevel. Rabbet-

ing one strip at a time is simpler, easier, more

accurate and requires no more time.

Clamp the stem to the fore post on the stock

(Fig. 5) and bore two ¼ in. holes through the

horn end of the stem into the keel. Run through

two ¼ by 6 in. bronze, hanger strut bolts in

casein glue. Countersink outside the keel for the

heads. Locate the molds on the "backbone", toe

nailing the bottom of the molds at the proper

intervals from the stem post. Mold No. 5 divides

the distance between the transom and mold No. 4 Forward side of transom. Note cheek pieces and

on both the 13- and 15½-ft. models. Otherwise strip planks bedded in casein glue around edge.

there is absolutely no difference in the two boats,

as the heights are all the same.

Start the planking by putting in the shutter or

stealer planks (Fig. 3). Cut the first strips to

length and bend them around the shutter and

the molds. Use 3d or 4d galvanized shingle nails

to fasten the strips into the oak cheek pieces on

the transom, and 7d nails into the mahogany.

Two nails of each size per 1¼ in. strip will do

the job. Check the transom bevels frequently to

see they are fair. A touch with a chisel or plane

occasionally will keep them running fair. Nail

two 8d shingle nails per hood end in the forward Fort and starboard bottom strip planking applied

rabbet. Lay both ends of the strips in casein glue. around forefoot and up the stem.

BOAT BUILDER'S HANDBOOK 145

clamp the top edge to the sheer plank, and pro-

ceed to clinch nail the frame in place. All bevels

are pressed in, and when the frame is cold, it is

stiff; the devil himself couldn't pull the nails out.

When the frames are hot and ready to bend,

tack the center to the keel in position on the

marks. Overbend the frame, pull it back to the

sheer and clamp it. Set up a few 1¼ in. copper

clout nails in the bottom of the hull and around

the turn of the bilge. Go to the other side that

is now cooler, overbend, clamp and clinch nail

the whole works (Fig. 13). Return to your orig-

inal hot side and finish clinching. Set the copper

nail heads well below the outside surface to al-

low later planing or sanding over them.

Each strip of planking is edge-nailed in place. Strips

Saw off the frame ends and tack on the gun-

flow smoothly around molds. wales with galvanized nails, from inner plank

TWO METHODS OF OAK FRAME

HEATING OAK FOR STRIPS

FRAMES

STEAM FILLED

RAIN PIPE RAGS

4" PIPE FILLED

WITH BOILING

WATER

HOSE

RAGS

Frame positions are marked out by pencil with thin

batten at 5 in. centers. Spring batten from sheer to

sheer.

Cross spalls retain Dolly's

shape until wales, seats

and breasthook are in-

stalled and during planing.

face outboard. Put in the inner wales and the

seat risers with #10 x l½ in. fh screws, one in

every other frame.

An auto body bucking tool with handle helps in Shape and install the breasthook and the stern

clinching the 1¼ in. copper clout nails. knees. The seats are spaced as shown in Fig. 2.

Turn the hull over and plane with very light

the job. A pipe with boiling water or an old strokes any sharp edges. After smoothing with

rainspout with a tea-kettle and a rubber hose to a plane, sand off and paint. Set the nails at the

induce the steam will also do the trick. Steam rabbet transom ends of the plank strips and plug

bending is probably the most useful tool in boat the holes with putty mixed with varnish. One

building. A combination of moisture and heat final sanding and you're ready to paint. Try

does the trick. Oak to be bent is usually cut varnished wales, buff hull and green interior.

green and kept wet, but well soaked oak stock

will bend well if thoroughly saturated and heated.

Any oak can be bent permanently to unbeliev-

able shapes by a child after fifteen minutes of

steaming. The wetness of the wood allows heat

to penetrate the fiber more quickly.

With steam bending, you just wear a pair of

gloves, grab a hot frame out of the box, tack the

tenter down to the keel, bend the frame to shape,

You might also like

- Redwood Canoe PDFDocument6 pagesRedwood Canoe PDFpaulo_enpjNo ratings yet

- Benchmark Facade Acm MCM Evo Cad Details Horizontal NaDocument26 pagesBenchmark Facade Acm MCM Evo Cad Details Horizontal NajflNo ratings yet

- Pages From Hs 6097 Shop Order Rev eDocument1 pagePages From Hs 6097 Shop Order Rev ekennymagallanesNo ratings yet

- 37 Valley DetailDocument1 page37 Valley DetailAhmed Saber NassarNo ratings yet

- Column Detail PDFDocument1 pageColumn Detail PDFShubham KushwahaNo ratings yet

- Column Details PDFDocument1 pageColumn Details PDFShubham KushwahaNo ratings yet

- WTCPUA-Water Service Area Exhibit 1.20.15Document1 pageWTCPUA-Water Service Area Exhibit 1.20.15Anonymous Pb39klJNo ratings yet

- t.f- Brick Work Plan -09!01!24Document1 paget.f- Brick Work Plan -09!01!24infoNo ratings yet

- WatertowerplansDocument1 pageWatertowerplansJackSiedschlagNo ratings yet

- Lake D Askari 11: 2Nd Floor Plaza 85-Cca Block DD Commercial Phase 4 Dha Lahore PH# 0423-5694047, 0322-8083003Document13 pagesLake D Askari 11: 2Nd Floor Plaza 85-Cca Block DD Commercial Phase 4 Dha Lahore PH# 0423-5694047, 0322-8083003PrincE ZarTasHNo ratings yet

- Oil Storage Tank Foundation Design Spreadsheet 3Document1 pageOil Storage Tank Foundation Design Spreadsheet 3ronyNo ratings yet

- 59S-CS-518 - Steel Repair Details Sheet 2 of 5-Default - R3Document1 page59S-CS-518 - Steel Repair Details Sheet 2 of 5-Default - R3anandkc55No ratings yet

- CeilingdetailsDocument1 pageCeilingdetailsdolar buhaNo ratings yet

- Gas Pipe Point: Shoe Rack Shoe RackDocument6 pagesGas Pipe Point: Shoe Rack Shoe RackKrisai ComputersNo ratings yet

- Watcher Hut DrawingDocument1 pageWatcher Hut DrawingChinthakaNo ratings yet

- 1600 GalDocument1 page1600 GalZK KTNo ratings yet

- PRADEEP REDDY 80X55S-P-ModelDocument1 pagePRADEEP REDDY 80X55S-P-ModelNagaraj BNo ratings yet

- Gas Pipe Point: Shoe Rack Shoe RackDocument1 pageGas Pipe Point: Shoe Rack Shoe RackKrisai ComputersNo ratings yet

- Devils Tower Poster 2Document1 pageDevils Tower Poster 2Carlos ReNo ratings yet

- Ound Floor PlanDocument1 pageOund Floor PlansujanNo ratings yet

- Column and Beam DetailDocument1 pageColumn and Beam DetailManinder ChaudharyNo ratings yet

- PLAN3Document1 pagePLAN3Jassimar SinghNo ratings yet

- 4.5 Three Stage Oil-Grit Interceptor - 201804100736435698Document1 page4.5 Three Stage Oil-Grit Interceptor - 201804100736435698bladeliger22No ratings yet

- Ground Floor Plan: Lath Matchine Working Area 30'-6" X 38'-3" Open Playing Area 31'-3" X 60'-3"Document1 pageGround Floor Plan: Lath Matchine Working Area 30'-6" X 38'-3" Open Playing Area 31'-3" X 60'-3"amandeepNo ratings yet

- Ly 11Document1 pageLy 11amandeepNo ratings yet

- Septic Tank DetailsDocument1 pageSeptic Tank DetailsRohn J JacksonNo ratings yet

- St. Jude 2023 OKC Floor and Elevation PlanDocument3 pagesSt. Jude 2023 OKC Floor and Elevation PlanOKCFOXNo ratings yet

- JP 28-2-2019 Ground FloorDocument1 pageJP 28-2-2019 Ground Flooranon_291886663No ratings yet

- Straicase and Column and Footing Detail DRG: Slab TopDocument1 pageStraicase and Column and Footing Detail DRG: Slab TopSheetal HarapanahalliNo ratings yet

- Clipper Ships: Young AmericaDocument35 pagesClipper Ships: Young AmericaRafael Purgly100% (1)

- Schedule of Column Column No C1 C4 C5 C2 C3 C6 C7: Typical Column Footing (Sec.X:X)Document1 pageSchedule of Column Column No C1 C4 C5 C2 C3 C6 C7: Typical Column Footing (Sec.X:X)Dhairya ShahNo ratings yet

- Baraut FFDocument1 pageBaraut FFlakhanNo ratings yet

- Crockery UnitDocument1 pageCrockery Unitdeepthiraju.bNo ratings yet

- Ground Floor Plan E-1: 3' ProjectionDocument1 pageGround Floor Plan E-1: 3' ProjectionHammad SalahuddinNo ratings yet

- 25 Vented Ridge DetailDocument1 page25 Vented Ridge DetailAhmed Saber NassarNo ratings yet

- Stilt (D-169) Opt-9Document1 pageStilt (D-169) Opt-9skillblenderNo ratings yet

- RanahouseDocument1 pageRanahouseMuqabla ChannelNo ratings yet

- PLAN2Document1 pagePLAN2Jassimar SinghNo ratings yet

- Temple Wall 2Document1 pageTemple Wall 2AMAZE INTERIORNo ratings yet

- Proposed LandscapeDocument1 pageProposed LandscapeGunJan GKNo ratings yet

- Pride West Facing 2bhk 900 SQFT With Car ParkingDocument1 pagePride West Facing 2bhk 900 SQFT With Car Parkingsiddunani7569784978No ratings yet

- Birlal Sir Finall 2Document6 pagesBirlal Sir Finall 2nadimalam78692No ratings yet

- JCP-4-9 SeriesDocument1 pageJCP-4-9 SeriesAlban HysomemajNo ratings yet

- Main Door Canopy Section-DDocument1 pageMain Door Canopy Section-Dmanish318No ratings yet

- Designs: Architecture + Interior + Master PlanningDocument1 pageDesigns: Architecture + Interior + Master PlanningRavi ShankarNo ratings yet

- FF Rev G10 LabDocument1 pageFF Rev G10 LabGhulam MurtazaNo ratings yet

- NAKA ComDocument1 pageNAKA Comaniketkumar302139No ratings yet

- CascadaDocument24 pagesCascadacle.contruccionNo ratings yet

- 1/2" DN15 1/2" DN15: Nominal Size Nominal SizeDocument3 pages1/2" DN15 1/2" DN15: Nominal Size Nominal SizeoaperuchenaNo ratings yet

- Drawing 2Document1 pageDrawing 2HeintunzawNo ratings yet

- Trash Recycling Pad Receptacles TRP 1Document1 pageTrash Recycling Pad Receptacles TRP 1kmilo7darkNo ratings yet

- 1.6.13 Dripline Disposal Trench 945MIT 6 5 09Document1 page1.6.13 Dripline Disposal Trench 945MIT 6 5 09opulitheNo ratings yet

- Well Head 10 3/4" Casing: and AccessoriesDocument2 pagesWell Head 10 3/4" Casing: and AccessoriesHendra JurbonNo ratings yet

- OPTION 2Document1 pageOPTION 2Rohan MehtaNo ratings yet

- F51 518 VTFE 1500gpm 8x12aDocument1 pageF51 518 VTFE 1500gpm 8x12aJhon Anderson Rodriguez NietoNo ratings yet

- Plan Traffic BarrierDocument1 pagePlan Traffic BarrierAdnan NajemNo ratings yet

- Stilet Floor-03-07-23Document1 pageStilet Floor-03-07-23MUKESH RAJENDRANo ratings yet

- Main Door Canopy Section-CDocument1 pageMain Door Canopy Section-Cmanish318No ratings yet

- GC200 Picket RailDocument1 pageGC200 Picket RailArmando CarreñoNo ratings yet

- Plywood User's GuideDocument6 pagesPlywood User's Guidejindi100% (16)

- Multi SkiffDocument6 pagesMulti SkiffScaramagnao Miao BauNo ratings yet

- Perm 02Document24 pagesPerm 02api-3831626No ratings yet

- Agricultural Drawing and The Design of Farm StructuresDocument148 pagesAgricultural Drawing and The Design of Farm Structuresnongsamrong100% (8)

- Jon Boat PlansDocument3 pagesJon Boat Planslm13700100% (2)

- Happy Clam SkiffDocument11 pagesHappy Clam SkifffccfNo ratings yet

- A Boat That Anyone Can Build - Popular ScienceDocument5 pagesA Boat That Anyone Can Build - Popular ScienceFrancisco Costa NetoNo ratings yet