Professional Documents

Culture Documents

Ekvivalenta Material

Ekvivalenta Material

Uploaded by

Loffegutt100%(1)100% found this document useful (1 vote)

4K views11 pagesMaterials

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMaterials

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

4K views11 pagesEkvivalenta Material

Ekvivalenta Material

Uploaded by

LoffeguttMaterials

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 11

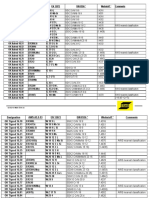

2004-12-17, G Grimfjrd, Progrim AB

MateriaIs - Swedish, EN and US standards

OId Swedish

SS 14-

Standard *)

Material

designation

(beteckning)

E

N

A

S

T

M

/

S

A

E

English language Swedish language Standard

Material

designation

Material

number

ASTM or SAE

standard

Material

designation

(814) D D C

Blackheart malleable cast iron. (Graphite

present as temper carbon). Typical yield

point 160 N/mm2.

Aducerjrn. GraIiten Irekommer som

temperkol (IinIrdelad) i strukturen, och inte

som Ijll (som i obehandlat jrn).

EN 1562 EN-JM 1110 EN-JM 1110 ASTM A47-84 ---

(1142) D D F Cold rolled sheed. Drawing quality. Kallvalsad tunnplt Ir pressning EN 10130 DC01 1.0330 ASTM A 366 A 366

(1142-32) D D F

Cold rolled sheed. Drawing quality.

"Standard" surIace quality, "normal" surIace

roughness.

Kallvalsad tunnplt Ir pressning SIS XXXX-

32 motsvarar ytkvalitet "A" (standard) och

ytrhet "m" (normal, dvs R

a

0.6-1.9 m).

Ytrhet "g" (semibright) har R

a

0.9

m.Ytrhet "r" (rough) motsvarar Ra~1.6

m.

EN 10130 DC01 Am 1.0330 ASTM A 366 A 366 Class 2 matte

(1142-42) D D F

Cold rolled sheed. Drawing quality. "Best"

surIace quality, "normal" surIace roughness.

Kallvalsad tunnplt Ir pressning. XXXX-42

motsvarar ytkvalitet "B" (bsta) och ytrhet

"m" (normal, dvs 0.6-1.9 m)

EN 10130 DC01 Bm 1.0330 ASTM A 366 A 366 Class 1 matte

11 44 H H, M F Cold rolled sheet. Kallvalsad tunnplt |EN 10 130| [DC02] [1.0330] [ASTM A 366] [A 366] 5

1146 D D F Cold rolled sheet. Kallvalsad tunnplt EN 10130 DC03 1.0347 ASTM A 619 A 619

(1147-32) D D F

Cold rolled sheed. Drawing quality. "Best"

surIace quality, "normal" surIace roughness.

Kallvalsad tunnplt Ir pressning. XXXX-32

motsvarar ytkvalitet "A" (standard) och

ytrhet "m" (normal, dvs 0.6-1.9 m).

EN 10130 DC04 Am 1.0338 ASTM A 620 A 620 Class 2 matte

(1300) D M

F

B

T

Structural carbon steel. Enklare konstruktionsstl. T ex Ir durkplt. EN 10 025A1 S185 1.0035

(1311) D P

F

B

T

Structural carbon steel. Enklare konstruktions-kolstl EN 10 025A1 S235JR 1.0037

ASTM A 283

(plate, no Charpy),

A284 (plate

+20C, bar,

profile)

Grade D 6

(1312-00) D P

F

B

T

Structural carbon steel. SpeciIy shape in

contract/drawing Ior correct ASTM

std/grade! See below.

Ordinrt konstruktionsstl. Speca Iormat Ir

att ge rtt ASTM/grade! Se nedan.

EN 10 025A1 S235JRG2 1.0038

ASTM A 36 (0C,

except tube),

A 501 (tube)

A 36 (except tube), A

501 (tube)

6 11

24

(1312-03) D D T

Structural steel tubing. SpeciIy heat

treatment in drawing/contract.

Konstruktionsrr. Speca vrmebehandling i

ritning/kontrakt, t ex "N". "H" str Ir

hlproIiler.

EN 10 210-1 S235JRH 1.0039 ASTM A 500 Grade A

Status vs.

foreign

standard

MateriaI type and properties

S

h

a

p

e

R

e

m

a

r

k

s European Standard **) American Standard **) Other

standard

or brand

name

2004-12-17, G Grimfjrd, Progrim AB

(1312-04) D D T

Structural steel tubing. SpeciIy hot or cold

Iorming by (EN standard), and heat

treatment (by "" addendum Iollowed by

letter) in drawing/contract.

Konstruktionsrr. Speca varm- eller

kallIormning med resp EN-standard, samt

vrmebehandling (med och bokstav) i

ritning/kontrakt.

EN 10 210-1 (hot

Iormed), 10219-1

(cold Iormed)

S235JRH 1.0039 ASTM A 500 Grade A

(1312-06) D M B

Structural steel, cold-drawn bar/rod. "Cold

drawn" speciIied by "+C" addendum.

Konstruktionsstl. Kalldragen stng.

"Kalldragning" specad med "+C".

EN 10 277-2 S235JRG2CC 1.0122

1325 M M B

Steel Ior screws, nuts and rivets, with good

deIormation capability suitable Ior cold

heading. Used also Ior hot Iorging oI nuts.

Yield point approx. 250 N/mm2.

Stl Ir skruvar, muttrar och nitar. Goda

kallstukningsegenskaper. Materialet anvnds

ven Ir varmsmidda muttrar.

(DIN 17111, U St

36, UQ St 36, U

St 38, UQ St 38)

|ASTM A 31 (rivets Ior

pressure steels), A 502

(rivets Ior building

structures)|

[A 31 (rivets for

pressure steels), A

502 (rivets for

building structures)]

1330-01 M P

F

,

B

Pressure vessel steel. Plate, strip, Ilat/round

bar. Normalized. SpeciIied properties at

elevated temperature. Re typically 235

N/mm2, Rm 360-480 N/mm2.

Tryckkrlsstl. Plt, band, platt- & rundstng.

Normaliserat. SpeciIicerade egenskaper vid

Irhjda temperaturer.

(EN 10 028-2) (P235GH)

Normalized only:

ASTM A 515 or 516

(NGS 113), ASTM A

285 (NGS 107)

Grade 55, Grade C

respectively

10

(1330-05) D P T

Seamless tubes Ior pressure purposes.

SpeciIy heat treatment in drawing/contract.

See also above.

Smlsa rr Ir tryckndaml. Speca

vrmebehandling i ritning/kontrakt. Se vidare

ovan.

EN 10 216-2

P235T2 or P235GH

CAT1

1.0345

Normalized only:

ASTM A 106

Grade B 10

(1330-06) D M T

Resistance welded tubes Ior pressure

purposes. Normalized. See also above.

Motstndssvetsade rr Ir tryckndaml.

Normaliserat. Se vidare ovan.

EN 10 217-2

P235TR2 or

P235GH CAT1

1.0345

(1330-15) D P T

Resistance welded tubes Ior pressure

purposes. Normalized. See also above.

Motstndssvetsade rr Ir tryckndaml.

Normaliserat. Se vidare ovan.

EN 10 216-2

P235T2 or P235GH

CAT2

1.0345 ASTM A 106

Grade 5 (only welded

tube, normalized)

10

(1330-16) D M T

Seamless tubes Ior pressure purposes.

Normalized. See also above.

Smlsa rr Ir tryckndaml. Normaliserat.

Se vidare ovan.

EN 10 217-2

P235TR2 or

P235GH CAT2

1.0345

(1412-00) D P

F

B

Structural steel. Plate, strip, bar. Hot rolled. Allmnt konstruktionsstl. Plt, stng. EN 10 025A1 S275JR (also tube) 1.0044

ASTM A 529, A 572

(no Charpy)

A 529 and Grade 42

respectively

6 11

25

(1412-03) D P T

Seamless hollow structural sections, hot

Iinished and cold Iormed respectively.

SpeciIy hot Iormed by "EN 10210" and cold

Iormed by "EN 10219", and iI any heat

treatment by "" and letter, in

drawing/contract.

Smlsa konstruktionsrr, varmvalsade eller

kallIormade. Ange varm- eller kallIormad

med "EN 10210" resp "EN10219", och

nskad vrmebehandling med "" och

bokstav, i ritning/kontrakt.

EN 10 210-1 (hot

Iinished) and EN

10 219 (cold

Iormed)

S275JOH 1.0149 ASTM A 618 Grade 6

(1412-04) D P T

Welded hollow structural sections, hot

Iinished and cold Iormed respectively.

SpeciIy hot Iormed by "EN 10210" and cold

Iormed by "EN 10219", and iI any heat

treatment by "" and letter, in

drawing/contract.

Svetsade konstruktionsrr, varmvalsade eller

kallIormade. Ange varm- eller kallIormad

med "EN 10210" resp "EN10219", och

nskad vrmebehandling med "" och

bokstav, i ritning/kontrakt.

EN 10 210-1 (hot

Iinished) and EN

10 219 (cold

Iormed)

S275JOH 1.0149

2004-12-17, G Grimfjrd, Progrim AB

(1414-00) D P

F

B

Structural steel. Plate, strip, bar. Hot rolled.

Allmnt konstruktionsstl. Plt, stng.

Obehandlat.

EN 10 025A1 S275J2G4 1.0145 ASTM A 573-89 Grade 70

11

27

(1414-01) D P

F

B

Structural steel. Plate, strip, bar.

Normalized.

Allmnt konstruktionsstl. Plt, stng.

Normaliserat.

EN 10 025A1 S275J2G4 1.0145 ASTM A 572, 573-89

Grade 42 and 70

respectively

11

1450

W

M

P

B

S

General engineering steel, C 0.22, Mn

0.70. Yield point 250 N/mm2. Possible to

carburize, but will get hard core in smaller

dimensions. Typically used Ior special

Iorgings (bolts, hot Iorged nuts and more).

Maskinstl. Tidigare specialstandard. Mjligt

att stthrda, men Ir hrd krna vid klena

dimensioner. Huvudsakligen avsett Ir

speciella smiden.

(1.0402, DIN C

22, Ck 22)

SAE 1025, 1026 9 12

1550 P P

F

B

T

S

General engineering steel, C 0.34, Mn

0.70. Hardenable, yet to a limited extent at

lower C and Mn and heavier sections. SS

1572 is better optimized Ior hardening!

Typically use also Ior bolts and hot Iorged

nuts

Vanligt anvnt maskinstl. Hrdbart, dock i

begrnsad omIattning vid lgre C, Mn och

vid grvre dimensioner. SS 1572 har bttre

avpassad sammansttning Ir hrdning.

EN 10 025A1 E295

1.0060,

except tube

SAE 1035 9 11

1550-00 P

F

B

T

S

As above, hot rolled Som ovan, varmvalsat EN 10 025A1 E295

1.0050,

except tube

11

1550-01 p

F

B

T

S

As above, normalized Som ovan, normaliserat EN 10 025A1 E295

1.0050,

except tube

11

1550-06

W

P

M B As above, cold drawn bar Som ovan, kalldragen stng |EN 10 277-2| |E295GCC| [1.0533] 13

(1572) D D

F

B

T

S Heat treatable engineering steel Ior

machining and use in automotive and

machine applications.

Hrdbart stl Ir bearbetning och anvndning

i bil- och maskinapplikationer.

EN 10 083-1 and

EU 83

respectively

C35E (bar, Ilat

products, Iorgings).

C36 (as above, but

Ior Ilame and

induction hardening)

1.1181

ASTM A 29 (bar),

A 519 (seamless

tube), A 513

(sheet, strip)

1034, 1035 and 1035

respectively

11

(1650-00) P P

F

B

T

S

General engineering steel, C 0.44, Mn

0.70. Heat treatable. Better hardenability

than SS 1550. Typically use also Ior bolts

and hot Iorged nuts. Good Iorgeability. Hot

rolled. SpeciIy delivery condition in

drawing/contract Ior USA.

Ocks oIta anvnt maskinstl. Bttre

hrdbarhet n 1550. Speca leveranstillstnd

(stng, etc) i ritning/kontrakt Ir USA.

EN 10 025A1 E335

1.0060,

except tube.

1044 or 1045 11

2004-12-17, G Grimfjrd, Progrim AB

( 1650-01) D P

F

B

T

S

Same as above. Normalized Normaliserat EN 10 025 E335

1.0060,

except tube.

See above 11

1650-06

W

P

P B Same as above. Cold machined condition. Kallbearbetat |EN 10 277-2| |E295GCC| [1.0543] See above 13

1655

F

B

T

S Heat treatable engineering steel Ior

machining and use in automotive and

machine applications.

Hrdbart stl Ir bearbetning och anvndning

i bil- och maskinapplikationer.

EN 10 025A1 E360

1.0070,

except tube

SAE 1055 11

(1672) D P

F

B

S

Heat treatable engineering Carbon steel Ior

machining and use in automotive, motor

and machine applications subject to higher

load and wear. Suitable Ior induction and

Ilame hardening. Can be Q&T treated.

Hrdbart maskinstl Ir bearbetning och

anvndning i bil-, motor- och

maskinapplikationer Ir strre pknningar

och slitage. Lmpligt att induktions- och

Ilamhrda. Gr att seghrda.

EN 10 083-1 and

EU 83

respectively

C45E (bar, Ilat

products, Iorgings).

C46 (as above, but

Ior Ilame and

induction hardening)

1.1191

ASTM A 29 (plate,

strip)

1045 11

1672-08 D M B

As above, but hot Iormed (not Q&T

treated).

Som ovan men varmbearbetat (ej seghrdat). As above As above As above

1672M D P B

As 1672, but S added Ior machinability

(Iree-cutting)

Som 1672 men S tillsatt Ir Iriskrande

egenskaper.

EN 10 277-5 C45RC (bar) 1.1201 SAE 1049 15

(1674) D P

F

B

S

Heat treatable engineering Carbon steel Ior

machining and use in automotive, motor

and machine applications, subject to higher

load or wear. Suitable Ior induction and

Ilame hardening. Can be Q&T treated.

Hrdbart maskinstl Ir bearbetning och

anvndning i bil-, motor- och

maskinapplikationer Ir strre pknningar

och slitage. Lmpligt att induktions- och

Ilamhrda. Gr att seghrda.

EN 10 083-1 and

EU 83

respectively

C50E (bar, Ilat

products, Iorgings).

2C55 (as above, but

Ior Ilame and

induction hardening)

ASTM A 29 (bar) 1050

1770 M D

F

s

B

W

Spring and surIace-hardening steel, C

0.70, Si 0.30, Mn 0.65. In

applications with normal demands on

Iatigue resistance Ior instance springs oI

thin and medium size.

Fjder- och ythrdande stl Ir normala

pknningar. T ex Ijdrar av klena och

medelgrova dimensioner.

ASTM A 682 (strip), A

29 (bar), A 713 (wire)

1074

(1770-03) D M W

See above. Drawn wire. See above. Dragen trd EN 10 270-2 VDC

1774 M D

F

s

B

W

Spring- and surIace-hardening steel, C

0.85, Si 0.30, Mn 0.65. Bar, wire

Fjder- och ythrdande stl Ir normala

pknningar. Stng, trd

ASTM A 682 (strip), A

29 (bar), A 713 (wire)

1084

(1774-04) D M W

See above. Drawn wire. Som ovan. Dragen trd EN 10 270-1 DM, SL or SM

(1774-05) D M W

See above. Drawn, patented wire. Som ovan. Dragen, patenterad trd. EN 10 270-1 DH or SH (1.1248)

[AS C 1065, ASTM

A 229]

(1914-00) D D B

Heavy-duty Iree-cutting steel, with lead. C

max 0.20, Mn 1.0. Pb.15-.35

Automatstl, blylegerat EN 10 087 11SMnPb30 1.0718 ASTM A 108 12L14

(1914-04) D M B

Same as above. Cold drawn bar, Q&T

treated.

Som ovan. Kalldragen stng, seghrdad. EN 10 277-3 11SMnPb30C 1.0718

2090 P P

B

W

S

Spring- and surIace hardening steel, C

0.56, Si 1.65, Mn 0.85. Bar, wire,

Iorging

Fjder- och ythrdande stl Ir rtt stora

pknningar, typ blad- och spiralIjdrar till

Iordon. Stng, trd

EU 89-71 (bar,

Ilat)

55Si7

ASTM A 29 (bar),

A 752 (wire)

9255

(2090-05) D M W

See above. Drawn wire. Som ovan. Dragen trd EN 10 270-2

VDSiCr, TDSiCr,

FDSiCr

2004-12-17, G Grimfjrd, Progrim AB

(2127) D M

B

S

Cementation steel. Similar to 1.7131 but

improved cutting properties by means oI

controlled S range. Typical use: Gear & link

components, bevels, plate- and cog wheels.

Stthrdningsstl. JmIrbart med 1.7131

men Irbttrad skrbarhet genom kontrollerat

S-haltintervall. Typiska applikationer:

Vxelldsdelar, styrinrttningar,

kardanknutar, axlar, bultar, tappar,...

EN 10 084 16MnCrS5 1.7139

2132

W

P

W P

F

B

T

S Micro alloyed Iine-grain treated structural

steel, C max .20, Si max .50, Mn max 1.60,

N .009-.020. Earlier experimental standard.

Mikrolegerat konstruktionsstl. Tidigare

Irsksnorm.

|EN 10 113-2| |E355KG| [1.0545] [ASTM A 633] [Grade C, D]

11

14

(2134-01) D P

F

B

Microalloyed Iine-grain treated structural

steel. Normalized.

Normaliserat. EN 10 113-2

S355N (earlier EU

113-E355KW,

withdrawn)

1.0545

ASTM A 633-90

(plate)

Grade C

11

26

(2134-03) D M T

Same as above, but aimed Ior constructional

seamless tubing. Toughness requirements.

Som ovan men smlsa, varmIormade,

normaliserade konstruktionsrr.

Slagseghetskrav.

EN 10 210-1 (hot

Iinished)

S355J2H 1.0539

(2134-04) D M T

Same as above but aimed Ior welded tubes

in hot Iormed, normalized material.

Toughness requirements.

Som ovan men i Iorm av svetsade rr av

varmbearbetat, normaliserat material.

Slagseghetskrav.

EN 10 210-1 (hot

Iinished), 10 219-

1 (cold Iormed)

S355J2H 1.0539

(2140) D M

F

B

Cold work "shrink-Iree" (tool) steel. Meets

high demands on Iorm stability during

hardening. Typical analysis C .90, Si .30,

Mn 1.20, Cr .50, W .50, V .10. Mostly oil-

hardened. Can be used Ior tools with sharp

contours, since small risk Ior hardening

cracks. Typical application: Tools Ior plate

pressing/stamping. Cutting, threading and

milling tools, reamers, calipers, plastic

moulds. This steel is typically delivered in a

soIt annealed condition

Kallarbetsstl, "krympIritt", d v s mycket god

mttbestndighet vid hrdning. Kan

anvndas Ir pressverktyg med skarpa hrn

eItersom risken Ir hrdsprickor r liten.

Typisk anvndning: Pltpressverktyg. Borr-,

skr-, Irs- och gngverktyg, Ir mttolkar,

mtrullar etc. Oljehrdas vanligen. Levereras

vanligen i mjukgldgat tillstnd. Motsvarar

Uddeholm Toolings kallarbetsstl "ARNE".

EN ISO 4957 95MnWCr5 1.2825

[AS O1, class 410.

ASTM A681-86. UNS

No. T31501]

2

2142

W

P

D

F

B

Microalloyed high tensile engineering steel.

Typical analysis C .18, Si .35, Mn 1.5, V

.08, N .009-.020 . Typical yield point

value 360-450 N/mm2 in normalized

condition. Has higher strength than 2172.

Mikrolegerat hghllIast stl, lmpligt Ir

seghrdning. UngeIrlig motsvarighet t ex

Ovako 280, normaliserat. Har hgre

hllIasthet n 2172.

EU 113 (earlier

standard, now

withdrawn). See

EN 10 113 Ior

substitution!

For instance S355N,

S420N or S460 N

depending on Re

requirements

Earlier E390KG

now withdrawn

ASTM A 572 Grade 60 2 11

(2172-00) D P

F

B

General engineering C-Mn-steel. No

toughness test. Hot rolled. Plate and bar.

Kol-manganstl, varmvalsat. Inga

slagseghetskrav. Obehandlat. Plt och stng

EN 10 025 S355JR 1.0045 ASTM A 572 Grade 50 6 11

(2172-03) D P T

Same, but supplied as seamless

constructional tubes. Untreated or heat

treated. SpeciIy in drawing/contract!

Som ovan, nen i Iorm av smlsa

konstruktionsrr. Speca typ av behandling i

ritning/kontrakt!

EN 10 210-1 (hot

Iinished), 10 219-

1 (cold Iormed)

S355J2H 1.0576 ASTM A 618 Grade 6 11

(2172-04) D P T Same, but supplied as welded tubes. Som ovan men svetsade rr

EN 10 210-1 (hot

Iinished), 10 219-

1 (cold Iormed)

S355J2H 1.0576 ASTM A 618 Grade 6 11

2004-12-17, G Grimfjrd, Progrim AB

2172-21 M D C

Steel casting. Normalized. Wall thickness

maximum 63 mm. Re min 290 N/mm2.

Stlgjutgods. Normaliserat. Vggtjocklek

max 63 mm. Re min 290 N/mm2.

|DIN 17 245| GS-C25 ASTM A 216-84 Grade WCC 16

(2174-00) D M

B

p

Similar to 2172, but toughness guarantee at -

20 C. Hot rolled.

Som 2172, men med slagseghetskrav vid -

20C. Varmvalsat, obehandlat

EN 10 025 S355J2G4 1.0577 [ASTM A 572] [Grade 50] 6 11

(2174-03) D M T

Same as above, but normalized, seamless

tubes.

Som ovan, men normaliserat, i Iorm av

smlsa rr.

EN 10 210-1 (hot

Iinished), 10 219-

1 (cold Iormed)

S355J2H 1.0576 [ASTM A 618] [Grade ] 6 11

(2174-04) D M T

Same as above, but welded tubes Irom

normalized material.

Som ovan, men som svetsade rr av

normaliserat material.

EN 10 210-1 (hot

Iinished), 10 219-

1 (cold Iormed)

S355J2H 1.0576 [ASTM A 618] [Grade ] 6 11

2190

W

M

M ?

High strength low alloyed C-Mn key steel,

typical analysis C .40, Si .30, Mn .50, N

.007 . High yield point 650 N/mm2, high

elasticity (350 N/mm2). Suitable Ior surIace

hardening, maintaining a core with extra

good toughness. Can in some cases be used

Ior disk springs or similar. Older, no longer

valid SS standard.

Stl mjligt att ythrda, med bibehllen

seghet i krnan.

|DIN 17 100, EN

10204-2.2|

|St 60-2 K|

|DIN W-Nr.

1.0542|

[ No equivalent, but

AS C1038 can

accomplish]. Please

check with suppliers!!

2 13

(2225) P P

F

B

T

S

Low alloyed Cr-Mo heat treatable high

strength (Q&T) steel. The QT condition has

typically Re 450-700, Rm 800-950 N/mm2.

Good weldability (all methods).

Machinability more diIIicult with increased

strength. Very good ductility in annealed

condition. Typical use: Axle arbors and

arms, turbine components, aircraIt engine

mounts. Vessels Ior high pressure hydrogen.

Also Ior cold extrusion.

Lglegerat seghrdningsstl hrdbart till

extra hg hllIasthet. ven Ir kallpressning.

Mycket god duktilitet i gldgat tillstnd. God

svetsbarhet.

EN 10 083-1

(except tube)

25CrMo4 or

25CrMo4QT

(speciIy which in

drawing/contract)

1.7218

ASTM A 29 (bar),

A 519 (seamless

tube), A 513

(welded tube), A

505 (plate).

[Check also with

ASTM A646

(premium quality

blooms and billets

for forging), ASTM

A788 (forgings)

and ASTM A921

(bars for forging)].

Grade 4130

(Warning! Check for

some differences in

steel composition)

6 11

2225M D M B

Same as above, although S in controlled

range Ior improved machining perIormance.

Som ovan. S i styrd halt Ir att ge bttre

bearbetnings- (Iriskrande) egenskaper.

EN 10 083-1, EN

10 277-5

25CrMo4 or

25CrMoS4C

respectively (speciIy

in draw-ing/contract)

1.7213

2225-23

Pr

O

O C

Steel casting, typical analysis C .25, Mn .6,

Cr 1.0, Mo .2 . Typical usage: Railway

materials. For applications with high creep

resistance requirements, and/or service at

elevated temperature.

Stlgjutgods Ir applikationer dr hg

hllIasthet och krypbestndighet krvs, ven

vid Irhjd temperatur.

prEN 10293-1, -2

and -3. Germany:

SE-WBI 510-77.

France: NF A 32-

054.

Finland: SFS 360-

1977

G25CrMo4 (prEN).

GS-25CrMo4

(Germany).

Z5CD4-M (France).

367 (Finland).

AISI SC4130, ASTM

LC2, WC6, WC9, C5;

ASTM A148, 488, 781,

802, 903, 915, 958;

ASTM A1001

(castings, heavy

sections)

AAR-MD,

SpeciIication

M-201-92.

2

9 11

2004-12-17, G Grimfjrd, Progrim AB

2230 P P

B

W

S

Micro-alloyed heat-treatable steel. Typical

analysis C .47-.55, Si .40, Mn 1.10, Cr

.90-1.20, V .10-.20 . Typically used Ior

automobile and drive components, exposed

to high wear, such as cog wheels, axles,

articulation components, arbors.

Mikrolegerat vrmebehandlingsstl, till

hgpknda komponenter som kugghjul,

drivutrustningar, lnkarmar, axlar,

styrinrttningar, lnkarmar.

EU 89-71 (bar,

wire, Ilat). Except

Iorgings.

51CrV4C

(conIorms with DIN

50CrV4)

1.8159

ASTM A 29 (bar),

A 231 (wire), A

752 (?). Check

also ASTM A60-49,

389-60T.

6150 6

2234 D P

B

S

Micro-alloyed heat-treatable steel. Typical

analysis C .30-.37, Si .40, Mn .80, Cr .90-

1.20, Mo .15-.30 . Typically used Ior

automobile and aircraIt components, Ior

high ductility, such as crankshaIts, axles,

arbors, tyres.

Mikrolegerat vrmebehandlingsstl, till

hgduktila komponenter i bilar och Ilygplan,

som vevstakar, lnkarmar, axlar, dckscord.

EN 10083-1 34CrNiMo4 1.7220 ASTM A 29 4135 6

(2244) D P

B

S

Low alloyed structural engineering steel,

suitable Ior hardening & tempering

Kan hrdas och seghrdas

EN 10 083-1 (bar,

Iorgings)

42CrMo4 1.7225

ASTM A 29 (bar),

A 519 (seamless

tube). Not for

forgings.

4140 6

(2244-04) D P B As above, Q&T. Som ovan men seghrdad

EN 10 083-1 (bar,

Iorgings)

42CrMo4QT 1.7225

ASTM A 29 (bar),

A 519 (seamless

tube). Not for

forgings.

4140 6 10

(2244M) D M B

As 2244. Normalized. Improved machining

properties by controlled S interval.

Som 2244 men med Irbttrade

skregenskaper (genom kontrollerat S

haltsintervall)

EN 10277-5 42CrMoS4C 1.7227

(2244-06) D M B See 2244 above. Cold worked. Som ovan, men kallbearbetat

EN 10 083-1 (bar,

Iorgings)

42CrMo4C 1.7225

ASTM A 29 (bar),

A 519 (seamless

tube). Not for

forgings.

4140 6 10

(2245) D M

B

S

High strength low alloyed steel Ior heat

treatment and cold extrusion. Typical

analysis C .38-.45, Si .15-.40, Mn .50-.80,

Cr .90-1.20, S .020-.035. High yield point

up to 800 N/mm2, high elasticity (typical

400 N/mm2). Suitable Ior surIace

hardening, maintaining a core with extra

good toughness. Typical use in automotive

suspension and steering components, axles.

Controlled S content Ior improved

machining properties.

HghllIast lglegerat stl Ir

vrmebehandling och kallpressning. Hg

hllIasthet och elasticitet. Typisk anvndning

i hjulupphngnings- och styrinrttning Ir

bilar. Kontrollerad S-halt Ir bttre

skregenskaper.

EN 10 083-1 (bar,

Iorgings)

41CrS4 1.7039

2004-12-17, G Grimfjrd, Progrim AB

(2321-02) D M

B

S

Stainless-/heat resisting Ierritic steel with

increased Cr content, 17 Ior improved

corrosion resistance and mechanical

properties. Annealed condition. Typical use:

Valves, springs.

17 rostIritt/vrmebestndigt stl.

Normaliserat tillstnd.

EN 10 088-3

(bar), 10250-4

(Iorging)

X17CrNi16-2A 1.4057+A [ASTM] [AS 431]

(2321-03) D P

B

S

As above, but in Q&T condition. Dito, seghrdat tillstnd

EN 10 088-3 (bar,

wire rod), 10250-

4 (Iorging)

X17CrNi16-2QT 1.4057+QT ASTM AS 431 17

(2324-02) D P

B

W

r

S

Stainless-/heat resisting 25Cr-1.5Mo-

5Ni-steel. Annealed condition

Mo-legerat 25Cr-5Ni-stl, gldgat tillstnd

EN 10 088-3

(bar), 10250-4

(Iorging)

X3CrNiMoN27-

5AT

1.4460+AT ASTM AS 329 17

(2331-02) D P

F

p

F

s

B

W

r

Stainless-/heat resisting 18Cr-8Ni-steel.

Annealed condition

18/8 stl, gldgat tillstnd

EN 10 088-2

(strip), -3 (bar,

rod), 10270-3

(spring wire)

X10CrNi18-8 1.4310+AT ASTM AS 302 17

(2331-06) D M

F

p

F

s

B

W

r

Same as above, but in cold-worked

condition

Som ovan men i kallbearbetat tillstnd

EN 10 088-2

(strip), -3 (bar,

rod), 10270-3

(spring wire)

X10CrNi18-8 1.4310+AT

(2333-02) D D

F

p

F

s

B

W

r

S

Stainless-/heat resisting 18Cr-10Ni-

steel. Austenitic. Annealed.

18 Cr, 10 Ni-stl. Gldgat tillstnd.

EN 10 088-2

(plate, strip),

-3 (bar, rod),

10 250-4

(Iorgings)

1.4301+AT ASTM A 240 AS 304 17

(2333-12) D D C Steel casting. Annealed and tempered. Stlgjutgods. Normaliserat.

EN 10 213-4, 10

283

GX5CrNi19-10AT 1.4308+AT ASTM A 743-85 CF-8

(2333-22) D D T Seamless tube. Smlsa rr. EN 10 216-5

X5CrNi18-10AT

CAT1

1.4301+AT

CAT1

ASTM A 213 (NGS

628), A 312 (NGS

675)

TP 304 18

(2333-23) D D T Welded tube. Svetsade rr. EN 10 217-7

X5CrNi18-10AT

CAT1

1.4301+AT

CAT1

ASTM A 249 (NGS

639), A 312 (NGS

675)

TP 304 18

(2333-24) D D T Seamless tube. Smlsa rr. EN 10 216-5

X5CrNi18-10AT

CAT2

1.4301+AT

CAT2

ASTM A 213 (NGS

628), A 312 (NGS

675)

TP 304 18

(2333-25) D D T Welded tube. Svetsade rr. EN 10 217-7

X5CrNi18-10AT

CAT2

1.4301+AT

CAT2

ASTM A 249 (NGS

639), A 312 (NGS

675)

TP 304 18

(2333-27) D D

B

S

Bar or Iorgings. Annealed & tempered. Stng eller smide. Gldgat.

EN 10 222-5

(Iorgings),

10 272 (bar)

X5CrNi18-10AT

CAT2

1.4301+AT

CAT2

ASTM A 479

TYPE 304L

(NGS 687)

18

(2333-28) D D

F

p

F

s

Stainless plate or strip. Annealed. RostIri plt eller band. Gldgat. EN 10 028-7 X5CrNi18-10AT 1.4301+AT ASTM A 240

TYPE 304

(NGS 635)

18

2346-02 P D

F

p

F

s

Stainless-/heat resisting 18Cr-10Ni-

steel, S-alloyed. Annealed condition

S-legerat 18/10-stl, gldgat tillstnd

EN 10 088-2

(plate, strip),

-3 (bar, rod)

X10CrNiS18-9

(plate, strip).

X10CrNiS18-9AT

(bar, rod)

1.4305+AT

(except tube

and forgings)

ASTM AS 303 (Se) 17

(2346-04) D M

B

W

r

Same as above, but cold-

rolled/machined/drawn

Som ovan men i kallbearbetat tillstnd

EN 10 088-3 (bar,

wire rod)

X10CrNiS18-

9C800 (bar, wire

rod)

1.4305+C800

2004-12-17, G Grimfjrd, Progrim AB

(2506) D P

F

B

B

r

B

w

S

H

Case hardening steel. 20NiCrMoS2-2 has a

typical composition C .20, Si .25, Mn .75,

Cr .50, Ni .60, Mo ..20 and S .020-.040

(controlled range Ior improved machining

perIormance).

Stthrdningsstl. Tidigare Eu-norm

20NiCrMo2 har kompletterats med

20NiCrMoS2-2 Ir att ge Irbttrade

bearbetningsprestanda.

EN 10 084,

EU 84

20NiCrMoS2-2 (Ilat,

bar, rod, wide bar,

Iorgings, semis)

1.6526

ASTM A 29 / SAE

(bar)

8620

(vs. 20NiCrMo2 or

20NiCrMo2-2)

19

20

(2511 and

2511M)

D M

F

B

B

r

B

w

S

H

Case hardening steel. 16NiCrS4 (complying

with earlier SS-2511M) has a typical

composition C .15, Si .25, Mn .90, Cr .80,

Ni 1.00 and S .020-.040 (controlled range

Ior improved machining perIormance).

Stthrdningsstl. Kontrollerat S-

haltsintervall Ir att ge Irbttrade

bearbetningsprestanda.

EN 10 084

16NiCrS4 (Ilat, bar,

rod, wide bar,

Iorgings, semis)

1.5715

(2523) D P

F

B

B

r

B

w

S

H

Case hardening steel. Typical composition

C .20, Si .25, Mn .90, Cr 1.00, Ni 1.20, Mo

.12. In the 10 084 standard, controlled S

content Ior improved machining properties.

Stthrdningsstl. I 10 084-varianten

kontrollerat S-intervall Ir bttre skrbarhet.

EN 10 084,

EU 84

17NiCrSMo6-4 (Ilat,

bar, rod, wide bar,

Iorging, semis),

17NiCrMo5 (Ilat,

bar, Iorging)

1.6569 AISI / SAE 4317 21

(2541) D P

F

B

B

r

B

w

S

H

Low alloyed structural engineering steel,

used Ior Q&T treatment.

Lgegerat konstruktionsstl, lmpligt Ir

seghrdning

EN 10083-1, EU

83

34CrNiMo6 1.6582 ASTM 4340 6

(2541-03) D P

F

B

B

r

B

w

S

H

Same as above, quenched & tempered Som ovan, seghrdat tillstnd See above See above See above See above See above 6

(2940) D M

B

S

Nitriding steel. composition C .42, Si .25,

Mn .70, Cr 1.70, Mo .30, Al 1.10 . Wear

and steam durable parts (working

temperature 350 up to 500 C). For highest

surIace hardness oI parts 100 mm diam.

Nitrerstl. Fr hgsta mjliga ythrdhet. Fr

hga slitage- och hllIasthetskrav. Anvnds t

ex i ngkraItanlggningar (temp upp till 500

C).

EN 10 085

41CrAlMo7-10

(older grade

41CrAlMo7, 1.8507)

1.8509

2672 D P

F

p

Hot rolled micro alloyed (Al, Nb, Ti, (V))

extra-high-tensile cold-Iorming steel, yield

point 650 N/mm2.

SS 2672-00 (?)

SSAB, Sweden.

Varmvalsat extra hghllIast

kallIormningsstl, Ir konstruktioner med

hg hllIasthet och lg vikt i kombination.

EN 10 149-2 S650MC ?

|ASTM A715-80, closer

to DOMEX 590 XPB|.

No exact similar

equivalent exists.

Please check this with

SSAB specialists, also

Ioreign sales oIIices, Ior

each speciIic design

case!!

Domex

650MC

2 4

11

2142 P P

B

T

High-tensile microalloyed steel. Typical

analysis C .18, SI .4, Mn 1.5, V .08.

Also very suitable Ior case hardening. Yield

point 450 N/mm2. Good weldability.

Ovako Steel, Sweden.

Mikrolegerat konstruktionsstl som ocks

lmpar sig vl Ir stthrdning.

EN 10 113-2 (S 420 N)

1.0045 (flat,

bar),

1.0576 (tube)

ASTM

Ovako

280 (SKF

280)

2 3

2004-12-17, G Grimfjrd, Progrim AB

Similar to 2172

/ 2142

D P

B

T

High-tensile microalloyed engineering steel,

with enhanced demands on Iorm stability

during hardening. Typical analysis C

0.2, Si .55, Mn 1.6, V .08. SoIt

annealed. Lower yield point than Ovako

280, 380 N/mm2, but with -20C toughness

guarantee.

Ovako Steel, Sweden.

Mikrolegerat konstruktionsstl med hga

krav p Iormstabilitet under hrdning. Med

slagseghetsgaranti.

EN 10 025A1 S355J2G3 1.0570 ASTM

[A 633 C close to but

no exact equivalent].

Please check with

Ovako for each

specific design case!!

Ovako

520 (SKF

520)

2

2106-01 (-N),

2107-01 (-NL1)

D P F

High tensile micro-alloyed pressure vessel

steel. Very good weldability. Yield point

350 N/mm2. C max .20, Mn max 1.60, Nb

max .04.

SSAB Oxelsund, Sweden EN 10 028-3

P355GH (Charpy at

0C), -N (-20C), -

NH (-20C), NL1 or

NL2 (-40 to -60 C).

1.0565

(P355NH),

1.0566

(P355NL1)

ASTM

A 737 B (N), A 537 C1

(NL1)

Ox 520

11

23

2624-03

(S690QL) and

2625-03

(S690QL1)

D P F

Extra-high-tensile structural steel, yield

point minimum 700 N/mm2, with very good

cold-Iorming and weldability properties.

Can be delivered with Charpy V-toughness

guarantee down to -60 C. Can be supplied

either Q or Q&T condition.

SSAB Oxelsund, Sweden

EN 10 137-1 and -

2

S690 Q (-20C),

S690 QL (-40 C),

S690 QL1 (-60C).

1.8931 (S690Q),

1.8928

(S690QL)

ASTM A 514 S (QL type)

WeIdox

700

11

22

28

2004-12-17, G Grimfjrd, Progrim AB

Status Code: D = Direct agreement with EN and/or AS/ASTM standard.

P = Partly in agreement with EN and/or AS/ASTM standard. See remarks for further information!

Pr = Preliminary standard existing, for instance prEN-..

M = Equivalent material is missing in EN and/or AS/ASTM standard. See remarks for further information!

W = SS designation withdrawn. See remarks for further information!

H = Historical status (no equivalent or replacement standard or designation found).

O = Other standards (national or corporative) are existing and given.

Remarks: *) Swedish designation in ( ) has been converted to European standard in exact agreement. New Swedish designation is the same as the EN preceded by "SS-".

**) EN- and/or US-designation in square [ ] brackets has no exact equivalent. Designation indicated is near to earlier SS- specification. See remarks for each case.

**) Designation in round ( ) brackets complies with the former German Standard (DN) "Werkstoff" No.

1) n some thickness ranges, Weldox plate does not fully conform with this standard. For exact information, consult directly with SSAB expert!

2) Warning!! No equivalent US designation exists. Please note that US and EN standards are differently structured. Direct translation is often difficult.

3) Ovako 280 and SKF 280 are the same

4) Requirements of E-10149-2 are met, in many cases with better properties.

5) SS 1144 does not conform with any steel designation. Commonly used DC grades are 1142 and 1147.

6) Warning! Check composition of ASTM, often different to SS and EN. Can e g give other welding properties. f required, specify different composition in drawing/order.

7) SO A2

8) SO C3

9) Warning!! Special standard. No direct equivalents. Considerable deviations SAE vs. SS standard, must be cleared before any substitution!!!

10) Warning!! f other delivery condition than "normalized" is specified, the ASTM spec becomes no longer valid. Specify additional requirements in drawing/order.

11) Warning!! Charpy impact values must be checked vs ASTM and if required specified in drawing/contract. Alternatively, chose different ASTM toughness class!

12) Withdrawn. No equivalent existing. See SS-EN 10 025 for substitution.

13) Less good EN equivalent.

14) Withdrawn. No equivalent existing. See SS-EN 10 113 for substitution.

15) Warning!! S control range 0.020-0.035 % has to be specified for US market.

16) No EN equivalent exists yet. Please refer to DN standard and designation.

17) Warning!! A large number of AS varieties, related to area of application. Must be specified for each case!

18) C max 0.07% for EN- and max 0.08 for ASTM standards.

19) Available also as tubes/rings (for instance Ovako, grade 21NiCrMo2).

20) Note: 21NiCrMo2 (earlier, withdrawn DN standard), and 20NiCrMo2 (SO-683-11) are directly comparable to AS/SAE 8620.

21) Warning!! Not in ASTM standard. Some differences in AS/SAE composition, that must be checked with producer and clarified in drawing/contract!

22) For certain thickness ranges, the Weldox plate does not fully conform with this standard. Refer to SSAB datasheet or to sales support!

23) Warning!! ASTM agreement only for -01 (normalized condition).

24) Check also A 284 Grade D and A 573 Grade 65 (possibly also A 283 C, D, 284 C, A 573-58) for correct toughness class!

25) Check also A 573-70 and A 633 A for correct toughness class!

26) Check also A 572-50 for correct toughness class!

27) Check also A 573-70 for correct toughness class!

28) Warning!! A 514 comprises 5 different grades, most of them with too high Ec-values. This might be critical to welding properties!

Shape Code: C = Casting

F = Flat product (plate, strip). Fp = Plate, Fs = strip

B = Bar. Bf, -s, -r, -p, -w = Flat, square, round/rod, profile bar, wide bar

W = Wire, Wr = Wire Rod

T = Tube, pipe

S = Forging

H = Semi products (blooms, billets,.)

You might also like

- Dimensionerings PM: Packrummet-Etapp 6, Årstaberg, StockholmDocument82 pagesDimensionerings PM: Packrummet-Etapp 6, Årstaberg, StockholmMohammad Minhajur AhmedNo ratings yet

- Standard: Presskruvar Press ScrewsDocument6 pagesStandard: Presskruvar Press ScrewsGustavo FelipeNo ratings yet

- RanabalkDocument12 pagesRanabalkscribd_namn100% (3)

- Swe TB d10 0015653 Varmforzinkning StalDocument8 pagesSwe TB d10 0015653 Varmforzinkning StalbedogyulaNo ratings yet

- DIN Tolearnace and MachiningDocument88 pagesDIN Tolearnace and MachiningAnonymous METdvGewNo ratings yet

- Flange Po Standardima - en NormaDocument124 pagesFlange Po Standardima - en Normajerkoo1509No ratings yet

- Retenc. Bola FlygtDocument2 pagesRetenc. Bola FlygtAlejandro AguanteNo ratings yet

- Hydropower SWEDocument16 pagesHydropower SWEGrigoregaNo ratings yet

- EN 1 4404 - 1408 Valbruna Nordic SvenskaDocument2 pagesEN 1 4404 - 1408 Valbruna Nordic Svenskachouli8No ratings yet

- Tekniska Data AluminiumDocument22 pagesTekniska Data Aluminiumradule021No ratings yet

- Nordic FlangesDocument96 pagesNordic FlangesJevgenij ZaneborecNo ratings yet

- Plug STD 1119, 22 PDFDocument3 pagesPlug STD 1119, 22 PDFAndras StegerNo ratings yet

- Plug STD 1119, 22Document3 pagesPlug STD 1119, 22Andras StegerNo ratings yet

- NF - Katalog - Prod - 2018 - v37 Mått FlänsarDocument119 pagesNF - Katalog - Prod - 2018 - v37 Mått FlänsarSebastianNo ratings yet

- Datablad Motsvarande Normer Specialstalssorter Tibnors LagerprogramDocument1 pageDatablad Motsvarande Normer Specialstalssorter Tibnors Lagerprogramdneprmt1No ratings yet

- Broschyr 20180110Document4 pagesBroschyr 20180110Anna MalmqvistNo ratings yet

- Prel. Sammanfattning Av Ändringar P182 Fjärde UpplaganDocument58 pagesPrel. Sammanfattning Av Ändringar P182 Fjärde UpplaganPatrik AlfredssonNo ratings yet

- StålDocument18 pagesStålLars NilssonNo ratings yet

- Beto SFGDocument42 pagesBeto SFGZaiga PūķeNo ratings yet

- Standard STD 1125: Orientation OrienteringDocument11 pagesStandard STD 1125: Orientation OrienteringAndres ElezcanoNo ratings yet

- JordspettDocument4 pagesJordspettThomas SniderNo ratings yet

- Produktdatablad Kamstalsbult O25 M24Document2 pagesProduktdatablad Kamstalsbult O25 M24KristofferNo ratings yet

- AGA Aluminum Welding Guide SE586 173598Document16 pagesAGA Aluminum Welding Guide SE586 173598Thomas SjölingNo ratings yet

- Acero Ss 1330Document9 pagesAcero Ss 1330RodrigoNo ratings yet

- Handbok2011 ByggbeslagDocument248 pagesHandbok2011 ByggbeslagPatrik AlfredssonNo ratings yet

- Mitsubishi-Katalog v4Document36 pagesMitsubishi-Katalog v4Jorik NursultanovNo ratings yet

- FK 2270Document2 pagesFK 2270Nguyen KhaNo ratings yet

- Monteringsanvisning Kota SkorstenDocument12 pagesMonteringsanvisning Kota SkorstenKen KrutNo ratings yet

- STD 1125,241Document6 pagesSTD 1125,241marcelo rezendeNo ratings yet

- FM C & D Brosjyre M24 - SVDocument4 pagesFM C & D Brosjyre M24 - SVBereket Tekle-HaileNo ratings yet

- FK 4610Document2 pagesFK 4610Nguyen KhaNo ratings yet

- BH22 Utg2Document56 pagesBH22 Utg2niklas7484No ratings yet

- FK 2863Document4 pagesFK 2863Nguyen KhaNo ratings yet

- Fusion Welding Steel 07 A 3 MM - STD 181-0002Document12 pagesFusion Welding Steel 07 A 3 MM - STD 181-0002Rudiney TrombettaNo ratings yet

- Fuel Nipple STD 311-0004 PDFDocument10 pagesFuel Nipple STD 311-0004 PDFAndras StegerNo ratings yet

- Svets-Handbok Reparationer UnderhallDocument129 pagesSvets-Handbok Reparationer UnderhallTorsten Sjögren100% (1)

- Jordning Guide 2023Document8 pagesJordning Guide 2023mattias.k1973No ratings yet

- Broschyr Gitterstolpe 20141009Document16 pagesBroschyr Gitterstolpe 20141009milosgmilanovicNo ratings yet

- Cast Iron Manifold Biblio Research Master SwedishDocument146 pagesCast Iron Manifold Biblio Research Master SwedishFredNo ratings yet

- Handbok-Version Beräkning Joma BeslagDocument344 pagesHandbok-Version Beräkning Joma BeslagNikola KuridzaNo ratings yet

- Kulorprogram 2011Document4 pagesKulorprogram 2011grimsausage7364No ratings yet

- 13 91 Rapport ScreenDocument60 pages13 91 Rapport ScreenDariush AlipourNo ratings yet

- BE ArmeringshandbokenDocument21 pagesBE ArmeringshandbokenStephanie OrmazabalNo ratings yet

- Hajom VinduerDocument32 pagesHajom VinduerFiskarhedenvillan DanmarkNo ratings yet

- Byggståls HandbokenDocument56 pagesByggståls HandbokenbedogyulaNo ratings yet

- Kapitel 3Document8 pagesKapitel 3Mahyar MashayekhiNo ratings yet

- Plannja Tekniskinfo 2015 1 PDFDocument60 pagesPlannja Tekniskinfo 2015 1 PDFBashar AlshathirNo ratings yet

- Termiska BeräkningarDocument7 pagesTermiska BeräkningarAli NadirNo ratings yet

- FK 4620Document4 pagesFK 4620Nguyen KhaNo ratings yet

- STD 1112,32 Rev. 04Document4 pagesSTD 1112,32 Rev. 04Reginaldo SantosNo ratings yet

- Use One Plate,: Antal Kassetter 18Document1 pageUse One Plate,: Antal Kassetter 18Osvaldo Rodrigo Muñoz ClaroNo ratings yet

- FK 60832Document6 pagesFK 60832Nguyen KhaNo ratings yet

- PK-R97 Tilltryck Mindre FilDocument64 pagesPK-R97 Tilltryck Mindre Filn_costiqueNo ratings yet

- NA Skruvkat 2012O 19 Jul 2012 LowResDocument102 pagesNA Skruvkat 2012O 19 Jul 2012 LowResTorbjörn SundelinNo ratings yet

- Corporate Standard STD 1107: Orientering OrientationDocument4 pagesCorporate Standard STD 1107: Orientering OrientationVinayak V SNo ratings yet

- 11.range Mma, Mig, TigDocument4 pages11.range Mma, Mig, TigvaseaNo ratings yet

- Product - Brochure - Elbjorn - Distribution Assemblies - SeDocument3 pagesProduct - Brochure - Elbjorn - Distribution Assemblies - SeDami IonelaNo ratings yet

- Guide Sleeve STD 1119,12Document3 pagesGuide Sleeve STD 1119,12Andras StegerNo ratings yet