Professional Documents

Culture Documents

Special Campaign: The New Generation of HAM-solid Carbide High Performance Drills Superdrill and Niro-Drill

Special Campaign: The New Generation of HAM-solid Carbide High Performance Drills Superdrill and Niro-Drill

Uploaded by

2dex1adwief2m1a6Copyright:

Available Formats

You might also like

- DIN 8555 Welding StandardDocument4 pagesDIN 8555 Welding StandardAntonius Dwi Putranto N100% (3)

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranNo ratings yet

- Comparing Steel Plate Grades Ebook PDFDocument5 pagesComparing Steel Plate Grades Ebook PDFJayaseelan GNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- TurningDocument64 pagesTurningSerhat DoğandemirNo ratings yet

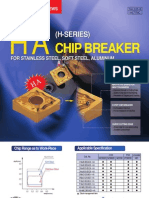

- Chip Breaker: (H-Series)Document2 pagesChip Breaker: (H-Series)Swaraj VishwakarmaNo ratings yet

- G-Pak18 1Document89 pagesG-Pak18 1Elmedin FazlicNo ratings yet

- UTP Tool Welding BrochureDocument12 pagesUTP Tool Welding Brochurekamals55No ratings yet

- Tank Power PDFDocument22 pagesTank Power PDFstctoolNo ratings yet

- Somta Tools User GuideDocument150 pagesSomta Tools User GuideBarrie Van Wyk100% (1)

- CatalogDocument18 pagesCataloglangtu2011No ratings yet

- Alfra Catalogue 21 CuttingDocument41 pagesAlfra Catalogue 21 CuttingMartín LópezNo ratings yet

- Koco Koco Kocovvv Koco Koco Kocovv Koco KocoDocument0 pagesKoco Koco Kocovvv Koco Koco Kocovv Koco KocoSun SunNo ratings yet

- 15 Rotating Toolholders WNT2013Document177 pages15 Rotating Toolholders WNT2013Natrajj SivakumarNo ratings yet

- Campaign: Solid Carbide End MillsDocument8 pagesCampaign: Solid Carbide End Mills2dex1adwief2m1a6No ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Secco Catalogo 1Document16 pagesSecco Catalogo 1emilio_707No ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- Drill Bit - WikipediaDocument55 pagesDrill Bit - Wikipediaaddisugebre2125No ratings yet

- Dme CatalogDocument28 pagesDme Cataloggalici2002No ratings yet

- CoroKey 2008engDocument208 pagesCoroKey 2008engStela LjevarNo ratings yet

- Plates PDFDocument10 pagesPlates PDFkarthiksaadhanaNo ratings yet

- VARGUS - Gear Milling New - InchDocument6 pagesVARGUS - Gear Milling New - InchGilberto ManhattanNo ratings yet

- 2 ATI Steellram U INCIMA DimenzijeDocument4 pages2 ATI Steellram U INCIMA DimenzijeBosko LukavicNo ratings yet

- Unit 6 - Die CastingDocument86 pagesUnit 6 - Die CastingNeo TarunNo ratings yet

- Handbook ESAB - MecTIGDocument15 pagesHandbook ESAB - MecTIGRobertoNo ratings yet

- OhnsDocument9 pagesOhnsspsurya2013No ratings yet

- American StandardDocument24 pagesAmerican StandardmitulfavsNo ratings yet

- Preheat Ions For A 514 Grade B MaterialDocument2 pagesPreheat Ions For A 514 Grade B Materialjrod64No ratings yet

- Pas CTG Tur Cer-Cermet enDocument36 pagesPas CTG Tur Cer-Cermet enshumi27No ratings yet

- XAR 400 (WB 703) EnglischDocument3 pagesXAR 400 (WB 703) Englischgheoda8926No ratings yet

- Introducing Chipbreaker Types: Chipbreaker System For Positive Turning InsertsDocument1 pageIntroducing Chipbreaker Types: Chipbreaker System For Positive Turning Inserts8075catNo ratings yet

- En 10028 2 P265GH - Boiler Plate Steel - ProductsDocument2 pagesEn 10028 2 P265GH - Boiler Plate Steel - ProductsShankey JAlanNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Procut Catalogue 2010 Procut is an internationally renowned brand of high quality carbide burrs, and forms a key part of ATA Group, a privately owned organisation with over 50 years experience in the supply of metal working solutions to all major industrial sectors. We are committed to providing our customers with high performance products that maximise productivity and reduce costs. Our headquarters and global production centre based in Cavan, Ireland, is accredited to ISO9001:2008 and equipped with the latest CNC technology delivering product of unrivalled quality and consistency.Document19 pagesProcut Catalogue 2010 Procut is an internationally renowned brand of high quality carbide burrs, and forms a key part of ATA Group, a privately owned organisation with over 50 years experience in the supply of metal working solutions to all major industrial sectors. We are committed to providing our customers with high performance products that maximise productivity and reduce costs. Our headquarters and global production centre based in Cavan, Ireland, is accredited to ISO9001:2008 and equipped with the latest CNC technology delivering product of unrivalled quality and consistency.Sun SunNo ratings yet

- ST Lawrence Ultra-MetDocument6 pagesST Lawrence Ultra-Metmpcd07No ratings yet

- Sumiten 780SDocument2 pagesSumiten 780Sdiah131No ratings yet

- Alu ENDocument44 pagesAlu ENlelixNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- Kinkelder StandardDocument24 pagesKinkelder StandardJason StephensNo ratings yet

- Nimonic 80A (TM) Super Alloy Material Property Data Sheet - Product Availability and Request A QuoteDocument5 pagesNimonic 80A (TM) Super Alloy Material Property Data Sheet - Product Availability and Request A QuotedharmatejakademNo ratings yet

- Tube Alloy 240 oDocument2 pagesTube Alloy 240 oelias667No ratings yet

- Steels For Oil - Gas - ExplorationDocument16 pagesSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNo ratings yet

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- 13 Solid Carbide Milling CuttersDocument309 pages13 Solid Carbide Milling CuttersManu GimenezNo ratings yet

- Broca Canhão CatalogoDocument48 pagesBroca Canhão CatalogodkfaNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- S690QLDocument4 pagesS690QLReginaldo Matias NunesNo ratings yet

- Pferd - Limas Rotativas Cat. 202Document64 pagesPferd - Limas Rotativas Cat. 202MinatelNo ratings yet

- Application - Cast Iron RepairDocument16 pagesApplication - Cast Iron RepairAnonymous L0ChmPGNo ratings yet

- Automotive Aluminium Product OverviewDocument36 pagesAutomotive Aluminium Product OverviewSophia GarciaNo ratings yet

- Cemented Tunsten Carbide Metalforming Grades ChartDocument2 pagesCemented Tunsten Carbide Metalforming Grades Chartflytorahul100% (3)

- Fisa Tehnica ROBODURDocument1 pageFisa Tehnica ROBODURdneprmt1No ratings yet

- Iscar Grade ChartDocument1 pageIscar Grade ChartsmarjanNo ratings yet

- Alumec PDFDocument7 pagesAlumec PDFetamil87No ratings yet

- High Speed Steel PDFDocument1 pageHigh Speed Steel PDFYogesh PatelNo ratings yet

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsFrom EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsRating: 5 out of 5 stars5/5 (1)

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Powerfix 100: Haff & Schneider Haff & SchneiderDocument2 pagesPowerfix 100: Haff & Schneider Haff & Schneider2dex1adwief2m1a6No ratings yet

- Digigraph: Haff & Schneider Haff & SchneiderDocument2 pagesDigigraph: Haff & Schneider Haff & Schneider2dex1adwief2m1a6No ratings yet

- A Classic - Revamped!: NC High Pressure Vice, Version TC 200Document2 pagesA Classic - Revamped!: NC High Pressure Vice, Version TC 2002dex1adwief2m1a6No ratings yet

- NC-High Pressure Vice T-REX For 5 - Sided Machining: New Products at AllmaticDocument6 pagesNC-High Pressure Vice T-REX For 5 - Sided Machining: New Products at Allmatic2dex1adwief2m1a6No ratings yet

- Campaign: Solid Carbide End MillsDocument8 pagesCampaign: Solid Carbide End Mills2dex1adwief2m1a6No ratings yet

Special Campaign: The New Generation of HAM-solid Carbide High Performance Drills Superdrill and Niro-Drill

Special Campaign: The New Generation of HAM-solid Carbide High Performance Drills Superdrill and Niro-Drill

Uploaded by

2dex1adwief2m1a6Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Campaign: The New Generation of HAM-solid Carbide High Performance Drills Superdrill and Niro-Drill

Special Campaign: The New Generation of HAM-solid Carbide High Performance Drills Superdrill and Niro-Drill

Uploaded by

2dex1adwief2m1a6Copyright:

Available Formats

SPECIAL

C A M PA I G N

Valid until

December 31,

2005

The new generation of

HAM-solid carbide high performance drills

Superdrill and Niro-Drill

HAM Precision take the safe side!

HAM -

the better idea for

innovative cutting technique

We design and manufacture individual special tools according your drawing and

your specic request.

Solid carbide twist drill Superdrill

with optimised cutting geometry until 3xD

short

Catalogue no: 280TA-C

Design:

Norm:

Carbide grade:

Shank:

Point angle:

Point grinding:

Side Rake angle:

Prole:

DIN 6537, short

micro grain

DIN 6535 HA

140

special point grinding, CNC-ground

30

special chip ute geometry

Application:

High performance spiral twist drill for highest bore hole quality and

economical out-put. For drilling of cast iron, malleable cast iron,

steel, steel castings, Cr-Ni-steel, heatresisting steel and

short-chipping material. Specially suited for NC-drilling with high

feed rate per revolution.

TA-C solid lubricant coating on TiAlN-basis with excellent facilitation of evacuation of chips, reduction of initial wear,

prevention of material built-up on cutting edges.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors in shrink t chucks and expansion chuck

holders.

order-no.

280-0280

280-0300

280-0320

280-0325

280-0330

280-0340

280-0350

280-0370

280-0380

280-0400

280-0420

280-0430

280-0450

280-0465

280-0480

280-0490

280-0500

280-0510

280-0550

280-0555

280-0580

280-0600

280-0610

280-0620

280-0640

280-0650

280-0660

280-0670

280-0680

280-0690

280-0700

280-0720

280-0740

d1

m7

mm

2,80

3,00

3,20

3,25

3,30

3,40

3,50

3,70

3,80

4,00

4,20

4,30

4,50

4,65

4,80

4,90

5,00

5,10

5,50

5,55

5,80

6,00

6,10

6,20

6,40

6,50

6,60

6,70

6,80

6,90

7,00

7,20

7,40

d2

h6

mm

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

8

8

8

8

8

8

8

8

8

8

8

l1

l2

l3

mm

62

62

62

62

62

62

62

62

66

66

66

66

66

66

66

66

66

66

66

66

66

66

79

79

79

79

79

79

79

79

79

79

79

mm

20

20

20

20

20

20

20

20

24

24

24

24

24

24

28

28

28

28

28

28

28

28

34

34

34

34

34

34

34

34

34

41

41

mm

14

14

14

14

14

14

14

14

17

17

17

17

17

17

20

20

20

20

20

20

20

20

24

24

24

24

24

24

24

24

24

29

29

TA-C coated

price

/pc.

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

18,30

22,20

22,20

22,20

22,20

22,20

22,20

22,20

22,20

22,20

22,20

22,20

order-no.

280-0750

280-0780

280-0790

280-0800

280-0850

280-0860

280-0880

280-0900

280-0930

280-0950

280-0980

280-1000

280-1020

280-1030

280-1040

280-1050

280-1100

280-1120

280-1150

280-1180

280-1200

280-1250

280-1280

280-1300

280-1350

280-1380

280-1400

280-1450

280-1480

280-1500

280-1550

280-1580

280-1600

d1

m7

mm

7,50

7,80

7,90

8,00

8,50

8,60

8,80

9,00

9,30

9,50

9,80

10,00

10,20

10,30

10,40

10,50

11,00

11,20

11,50

11,80

12,00

12,50

12,80

13,00

13,50

13,80

14,00

14,50

14,80

15,00

15,50

15,80

16,00

d2

h6

mm

8

8

8

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

12

12

12

14

14

14

14

14

14

16

16

16

16

16

16

l1

l2

l3

mm

79

79

79

79

89

89

89

89

89

89

89

89

102

102

102

102

102

102

102

102

102

107

107

107

107

107

107

115

115

115

115

115

115

mm

41

41

41

41

47

47

47

47

47

47

47

47

55

55

55

55

55

55

55

55

55

60

60

60

60

60

60

65

65

65

65

65

65

mm

29

29

29

29

35

35

35

35

35

35

35

35

40

40

40

40

40

40

40

40

40

43

43

43

43

43

43

45

45

45

45

45

45

TA-C coated

price

/pc.

22,20

22,20

22,20

22,20

25,30

25,30

25,30

25,30

25,30

25,30

25,30

25,30

32,70

38,40

38,40

38,40

38,40

38,40

38,40

38,40

38,40

50,70

50,70

50,70

50,70

50,70

50,70

67,70

67,70

67,70

67,70

67,70

67,70

On request shank form DIN 6535 HB or HE available without extra charge..

Please specify on your order the requested shank form..

Solid carbide twist drill Superdrill

with optimised cutting geometry until 3xD

Catalogue no:

short

285TA-C

with interior coolant

Design:

Norm:

Carbide grade:

Shank:

Point angle:

Point grinding:

Side Rake angle:

Prole:

DIN 6537, short

micro grain

DIN 6535 HAK

140

special point grinding, CNC-ground

30

special chip ute geometry

Application:

High performance spiral twist drill for highest bore hole quality and

economical out-put. For drilling of cast iron, malleable cast iron, steel,

steel castings, Cr-Ni-steel, heatresisting steel and short-chipping material.

Specially suited for NC-drilling with high feed rate per revolution.

TA-C solid lubricant - coating on TiAlN-basis with excellent facilitation of evacuation of chips, reduction of initial wear,

prevention of material built-up on cutting edges.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors in shrink t chucks and expansion

chuck holders.

order-no.

285-0300

285-0320

285-0330

285-0340

285-0350

285-0380

285-0400

285-0420

285-0430

285-0450

285-0480

285-0490

285-0500

285-0510

285-0550

285-0580

285-0600

285-0610

285-0620

285-0640

285-0650

285-0660

285-0670

285-0680

285-0690

285-0700

285-0720

285-0740

285-0750

285-0780

285-0790

d1

m7

mm

3,00

3,20

3,30

3,40

3,50

3,80

4,00

4,20

4,30

4,50

4,80

4,90

5,00

5,10

5,50

5,80

6,00

6,10

6,20

6,40

6,50

6,60

6,70

6,80

6,90

7,00

7,20

7,40

7,50

7,80

7,90

d2

h6

mm

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

8

l1

l2

l3

mm

62

62

62

62

62

66

66

66

66

66

66

66

66

66

66

66

66

79

79

79

79

79

79

79

79

79

79

79

79

79

79

mm

20

20

20

20

20

24

24

24

24

24

28

28

28

28

28

28

28

34

34

34

34

34

34

34

34

34

41

41

41

41

41

mm

14

14

14

14

14

17

17

17

17

17

20

20

20

20

20

20

20

24

24

24

24

24

24

24

24

24

29

29

29

29

29

TA-C coated

price

/pc.

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

33,50

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

38,30

order-no.

285-0800

285-0850

285-0860

285-0880

285-0900

285-0930

285-0950

285-0980

285-1000

285-1020

285-1030

285-1040

285-1050

285-1100

285-1120

285-1150

285-1180

285-1200

285-1250

285-1280

285-1300

285-1350

285-1380

285-1400

285-1450

285-1480

285-1500

285-1550

285-1580

285-1600

d1

m7

mm

8,00

8,50

8,60

8,80

9,00

9,30

9,50

9,80

10,00

10,20

10,30

10,40

10,50

11,00

11,20

11,50

11,80

12,00

12,50

12,80

13,00

13,50

13,80

14,00

14,50

14,80

15,00

15,50

15,80

16,00

On request shank form DIN 6535 HBK or HEK available without extra charge.

Please specify on your order the requested shank form..

d2

h6

mm

8

10

10

10

10

10

10

10

10

12

12

12

12

12

12

12

12

12

14

14

14

14

14

14

16

16

16

16

16

16

l1

l2

l3

mm

79

89

89

89

89

89

89

89

89

102

102

102

102

102

102

102

102

102

107

107

107

107

107

107

115

115

115

115

115

115

mm

41

47

47

47

47

47

47

47

47

55

55

55

55

55

55

55

55

55

60

60

60

60

60

60

65

65

65

65

65

65

mm

29

35

35

35

35

35

35

35

35

40

40

40

40

40

40

40

40

40

43

43

43

43

43

43

45

45

45

45

45

45

TA-C coated

price

/pc.

38,30

45,00

45,00

45,00

45,00

45,00

45,00

45,00

45,00

63,60

63,60

63,60

63,60

63,60

63,60

63,60

63,60

63,60

86,10

86,10

86,10

86,10

86,10

86,10

131,10

131,10

131,10

131,10

131,10

131,10

Solid carbide twist drill Superdrill

with optimised cutting geometry until 5xD

Catalogue no:

283TA-C

Design:

Norm:

Carbide grade:

Shank:

Point angle:

Point grinding:

Side Rake angle:

Prole:

DIN 6537, long

micro grain

DIN 6535 HA

140

special point grinding, CNC-ground

30

special chip ute geometry

long

Application:

High performance spiral twist drill for highest bore hole quality and

economical out-put. For drilling of cast iron, malleable cast iron, steel,

steel castings, Cr-Ni-steel, heatresisting steel and short-chipping material.

Specially suited for NC-drilling with high feed rate per revolution.

TA-C solid lubricant coating on TiAlN-basis with excellent facilitation of evacuation of chips, reduction of initial wear,

prevention of material built-up on cutting edges.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors in shrink t chucks and expansion

chuck holders.

order-no.

283-0300

283-0320

283-0330

283-0340

283-0350

283-0380

283-0390

283-0400

283-0410

283-0420

283-0430

283-0440

283-0450

283-0460

283-0470

283-0480

283-0490

283-0500

283-0510

283-0520

283-0530

283-0540

283-0550

283-0560

283-0570

283-0580

283-0590

283-0600

283-0610

283-0620

283-0630

283-0640

283-0650

283-0660

283-0670

283-0680

283-0690

283-0700

283-0710

283-0720

283-0730

283-0740

283-0750

283-0760

283-0770

283-0780

283-0790

d1

m7

mm

3,00

3,20

3,30

3,40

3,50

3,80

3,90

4,00

4,10

4,20

4,30

4,40

4,50

4,60

4,70

4,80

4,90

5,00

5,10

5,20

5,30

5,40

5,50

5,60

5,70

5,80

5,90

6,00

6,10

6,20

6,30

6,40

6,50

6,60

6,70

6,80

6,90

7,00

7,10

7,20

7,30

7,40

7,50

7,60

7,70

7,80

7,90

d2

h6

mm

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

l1

l2

l3

mm

66

66

66

66

66

74

74

74

74

74

74

74

74

74

74

82

82

82

82

82

82

82

82

82

82

82

82

82

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

mm

28

28

28

28

28

36

36

36

36

36

36

36

36

36

36

44

44

44

44

44

44

44

44

44

44

44

44

44

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

mm

23

23

23

23

23

29

29

29

29

29

29

29

29

29

29

35

35

35

35

35

35

35

35

35

35

35

35

35

43

43

43

43

43

43

43

43

43

43

43

43

43

43

43

43

43

43

43

TA-C coated

price

/pc.

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

23,50

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

26,00

order-no.

283-0800

283-0810

283-0820

283-0830

283-0840

283-0850

283-0860

283-0870

283-0880

283-0890

283-0900

283-0910

283-0920

283-0930

283-0940

283-0950

283-0960

283-0970

283-0980

283-0990

283-1000

283-1010

283-1020

283-1030

283-1040

283-1050

283-1080

283-1100

283-1120

283-1150

283-1180

283-1200

283-1210

283-1220

283-1250

283-1280

283-1300

283-1350

283-1380

283-1400

283-1450

283-1480

283-1500

283-1550

283-1580

283-1600

d1

m7

mm

8,00

8,10

8,20

8,30

8,40

8,50

8,60

8,70

8,80

8,90

9,00

9,10

9,20

9,30

9,40

9,50

9,60

9,70

9,80

9,90

10,00

10,10

10,20

10,30

10,40

10,50

10,80

11,00

11,20

11,50

11,80

12,00

12,10

12,20

12,50

12,80

13,00

13,50

13,80

14,00

14,50

14,80

15,00

15,50

15,80

16,00

d2

h6

mm

8

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

12

12

12

12

12

12

12

12

12

12

12

14

14

14

14

14

14

14

14

16

16

16

16

16

16

l1

l2

l3

mm

91

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

118

118

118

118

118

118

118

118

118

118

118

124

124

124

124

124

124

124

124

133

133

133

133

133

133

mm

53

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

71

71

71

71

71

71

71

71

71

71

71

77

77

77

77

77

77

77

77

83

83

83

83

83

83

mm

43

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

56

56

56

56

56

56

56

56

56

56

56

60

60

60

60

60

60

60

60

63

63

63

63

63

63

TA-C coated

price

/pc.

26,00

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

29,90

43,80

43,80

43,80

43,80

43,80

43,80

43,80

43,80

43,80

43,80

43,80

59,30

59,30

59,30

59,30

59,30

59,30

59,30

59,30

79,90

79,90

79,90

79,90

79,90

79,90

On request shank form DIN 6535 HB or HE available without extra charge.

Please specify on your order the requested shank form..

Solid carbide twist drill Superdrill

with optimised cutting geometry until 5xD

Catalogue no:

long

286TA-C

with interior coolant

Design:

Norm:

Carbide grade:

Shank:

Point angle:

Point grinding:

Side Rake angle:

Prole:

DIN 6537, long

micro grain

DIN 6535 HAK

140

special point grinding, CNC-ground

30

special chip ute geometry

Application:

High performance spiral twist drill for highest bore hole quality and

economical out-put. For drilling of cast iron, malleable cast iron, steel,

steel castings, Cr-Ni-steel, heatresisting steel and short-chipping material.

Specially suited for NC-drilling with high feed rate per revolution.

TA-C solid lubricant coating on TiAlN-basis with excellent facilitation of evacuation of chips, reduction of initial wear, prevention

of material built-up on cutting edges.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors in shrink t chucks and expansion

chuck holders.

order-no.

286-0300

286-0320

286-0325

286-0330

286-0340

286-0350

286-0370

286-0380

286-0390

286-0400

286-0410

286-0420

286-0430

286-0440

286-0450

286-0460

286-0465

286-0470

286-0480

286-0490

286-0500

286-0510

286-0520

286-0530

286-0540

286-0550

286-0555

286-0560

286-0570

286-0580

286-0590

286-0600

286-0610

286-0620

286-0630

286-0640

286-0650

286-0660

286-0670

286-0680

286-0690

286-0700

286-0710

286-0720

286-0730

286-0740

286-0750

286-0760

286-0770

d1

m7

mm

3,00

3,20

3,25

3,30

3,40

3,50

3,70

3,80

3,90

4,00

4,10

4,20

4,30

4,40

4,50

4,60

4,65

4,70

4,80

4,90

5,00

5,10

5,20

5,30

5,40

5,50

5,55

5,60

5,70

5,80

5,90

6,00

6,10

6,20

6,30

6,40

6,50

6,60

6,70

6,80

6,90

7,00

7,10

7,20

7,30

7,40

7,50

7,60

7,70

d2

h6

mm

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

l1

l2

mm

66

66

66

66

66

66

66

74

74

74

74

74

74

74

74

74

74

74

82

82

82

82

82

82

82

82

82

82

82

82

82

82

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

mm

28

28

28

28

28

28

28

36

36

36

36

36

36

36

36

36

36

36

44

44

44

44

44

44

44

44

44

44

44

44

44

44

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

l3

TA-C coated

price

mm

/pc.

23

36,60

23

36,60

23

36,60

23

36,60

23

36,60

23

36,60

23

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

29

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

35

36,60

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

43

42,10

order-no.

286-0780

286-0790

286-0800

286-0810

286-0820

286-0830

286-0840

286-0850

286-0860

286-0870

286-0880

286-0890

286-0900

286-0910

286-0920

286-0930

286-0940

286-0950

286-0960

286-0970

286-0980

286-0990

286-1000

286-1010

286-1020

286-1030

286-1040

286-1050

286-1080

286-1100

286-1120

286-1150

286-1180

286-1200

286-1210

286-1220

286-1250

286-1280

286-1300

286-1350

286-1380

286-1400

286-1450

286-1480

286-1500

286-1550

286-1580

286-1600

d1

m7

mm

7,80

7,90

8,00

8,10

8,20

8,30

8,40

8,50

8,60

8,70

8,80

8,90

9,00

9,10

9,20

9,30

9,40

9,50

9,60

9,70

9,80

9,90

10,00

10,10

10,20

10,30

10,40

10,50

10,80

11,00

11,20

11,50

11,80

12,00

12,10

12,20

12,50

12,80

13,00

13,50

13,80

14,00

14,50

14,80

15,00

15,50

15,80

16,00

On request shank form DIN 6535 HBK or HEK available without extra charge.

Please specify on your order the requested shank form..

d2

h6

mm

8

8

8

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

12

12

12

12

12

12

12

12

12

12

12

14

14

14

14

14

14

14

14

16

16

16

16

16

16

l1

l2

l3

mm

91

91

91

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

118

118

118

118

118

118

118

118

118

118

118

124

124

124

124

124

124

124

124

133

133

133

133

133

133

mm

53

53

53

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

71

71

71

71

71

71

71

71

71

71

71

77

77

77

77

77

77

77

77

83

83

83

83

83

83

mm

43

43

43

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

49

56

56

56

56

56

56

56

56

56

56

56

60

60

60

60

60

60

60

60

63

63

63

63

63

63

TA-C coated

price

/pc.

42,10

42,10

42,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

49,10

70,00

70,00

70,00

70,00

70,00

70,00

70,00

70,00

70,00

70,00

70,00

93,40

93,40

94,00

94,00

94,00

94,00

94,00

94,00

143,20

143,20

143,20

143,20

143,20

143,20

Solid carbide twist drill Superdrill

with optimised cutting geometry until 8xD

Catalogue no:

extra long

292TA-C

with interior coolant

Design:

Norm:

Carbide grade:

Shank:

Point angle:

Point grinding:

Side Rake angle:

Prole:

according HAM Standard, extra long

micro grain

DIN 6535 HAK

140

special point grinding, CNC-ground

30

special chip ute geometry

Application:

High performance spiral twist drill for highest bore hole quality and

economical out-put. For drilling of cast iron, malleable cast iron, steel,

steel castings, Cr-Ni-steel, heatresisting steel and short-chipping material.

Specially suited for NC-drilling with high feed rate per revolution.

TA-C solid lubricant coating on TiAlN-basis with excellent facilitation of evacuation of chips, reduction of initial wear,

prevention of material built-up on cutting edges.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors in shrink t chucks and expansion

chuck holders.

order-no.

292-0500

292-0550

292-0600

292-0650

292-0680

292-0700

292-0750

292-0800

292-0850

292-0900

292-0950

292-1000

292-1020

292-1050

292-1100

292-1150

292-1200

292-1250

292-1300

292-1350

292-1400

292-1450

292-1500

292-1550

292-1600

292-1650

292-1700

292-1750

292-1800

292-1850

292-1900

292-1950

292-2000

d1

m7

mm

5,0

5,5

6,0

6,5

6,8

7,0

7,5

8,0

8,5

9,0

9,5

10,0

10,2

10,5

11,0

11,5

12,0

12,5

13,0

13,5

14,0

14,5

15,0

15,5

16,0

16,5

17,0

17,5

18,0

18,5

19,0

19,5

20,0

d2

h6

mm

6

6

6

8

8

8

8

8

10

10

10

10

12

12

12

12

12

14

14

14

14

16

16

16

16

18

18

18

18

20

20

20

20

l1

mm

95 (90)

95 (97)

95 (97)

114 (106)

114 (106)

116

116

116

142 (131)

142 (131)

142 (140)

142 (140)

162 (145)

162 (145)

162 (145)

162 (145)

162 (145)

178 (161)

178 (161)

178 (161)

178 (161)

203 (181)

203 (181)

203 (181)

203 (181)

222 (197)

222 (197)

222 (197)

222 (197)

243 (216)

243 (216)

243 (216)

243 (216)

l2

mm

57 (50)

57

57

76 (66)

76 (66)

76

76

76

95 (87)

95 (87)

95 (98)

95 (98)

114 (98)

114 (98)

114 (98)

114 (98)

114 (98)

133 (114)

133 (114)

133 (114)

133 (114)

152 (131)

152 (131)

152 (131)

152 (131)

171 (147)

171 (147)

171 (147)

171 (147)

190 (164)

190 (164)

190 (164)

190 (164)

l3

mm

48 (41)

48

48

64 (56)

64 (56)

66

66

66

80 (75)

80 (75)

80 (84)

80 (84)

96 (84)

96 (84)

96 (84)

96 (84)

96 (84)

112 (98)

112 (98)

112 (98)

112 (98)

128 (112)

128 (112)

128 (112)

128 (112)

144 (126)

144 (126)

144 (126)

144 (126)

160 (140)

160 (140)

160 (140)

160 (140)

TA-C coated

price

/pc.

71,10

71,10

71,10

81,40

81,40

81,40

81,40

81,40

95,80

95,80

95,80

95,80

122,60

122,60

122,60

122,60

122,60

174,10

174,10

174,10

174,10

225,60

225,60

225,60

225,60

277,10

277,10

277,10

277,10

327,60

327,60

327,60

327,60

Please note change of design measurements: old measurements in brackets, subject to availability

On request shank form DIN 6535 HBK or HEK available without extra charge.

Please specify on your order the requested shank form..

Solid carbide twist drill Niro-Drill

until 5xD

Catalogue no:

long

270TA-CN

with interior coolant

Design:

Norm:

Carbide grade:

Shank:

Point grinding:

Point angle:

Side Rake angle:

Prole:

DIN 6537, long

micro grain

DIN 6535 HAK

special point grinding, CNC-ground

140

30

special chip ute geometry

W

NE

Application:

High performance drilling on high-capacity CNC machines and machining centres, for

trouble-free serial production of long-chipping material such as INOX-TITAN.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors

in shrink t chucks and expansion chuck holders.

order-no.

270-0300

270-0310

270-0320

270-0330

270-0340

270-0350

270-0360

270-0370

270-0380

270-0390

270-0400

270-0410

270-0420

270-0430

270-0440

270-0450

270-0460

270-0470

270-0480

270-0490

270-0500

270-0510

270-0520

270-0530

270-0540

270-0550

270-0560

270-0570

270-0580

270-0590

270-0600

270-0610

270-0620

270-0630

270-0640

270-0650

270-0660

270-0670

270-0680

270-0690

270-0700

270-0710

270-0720

270-0730

270-0740

270-0750

270-0760

270-0770

270-0780

d1

m7

mm

3,0

3,1

3,2

3,3

3,4

3,5

3,6

3,7

3,8

3,9

4,0

4,1

4,2

4,3

4,4

4,5

4,6

4,7

4,8

4,9

5,0

5,1

5,2

5,3

5,4

5,5

5,6

5,7

5,8

5,9

6,0

6,1

6,2

6,3

6,4

6,5

6,6

6,7

6,8

6,9

7,0

7,1

7,2

7,3

7,4

7,5

7,6

7,7

7,8

d2

h6

mm

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

l1

l2

mm

66

66

66

66

66

66

66

66

74

74

74

74

74

74

74

74

74

74

82

82

82

82

82

82

82

82

82

82

82

82

82

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

91

mm

28

28

28

28

28

28

28

28

36

36

36

36

36

36

36

36

36

36

44

44

44

44

44

44

44

44

44

44

44

44

44

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

53

l3

Z TA-CN coated

price

mm

/pc.

23 2

40,60

23 2

40,60

23 2

40,60

23 2

40,60

23 2

40,60

23 2

40,60

23 2

40,60

23 2

40,60

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

29 2

41,70

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

35 2

44,20

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

43 2

46,00

order-no.

270-0790

270-0800

270-0810

270-0820

270-0830

270-0840

270-0850

270-0860

270-0870

270-0880

270-0890

270-0900

270-0910

270-0950

270-0970

270-0980

270-1000

270-1010

270-1020

270-1030

270-1040

270-1050

270-1060

270-1070

270-1080

270-1090

270-1100

270-1110

270-1120

270-1130

270-1140

270-1150

270-1160

270-1170

270-1180

270-1190

270-1200

270-1250

270-1280

270-1300

270-1350

270-1380

270-1400

270-1450

270-1480

270-1500

270-1550

270-1580

270-1600

d1

m7

mm

7,9

8,0

8,1

8,2

8,3

8,4

8,5

8,6

8,7

8,8

8,9

9,0

9,1

9,5

9,7

9,8

10,0

10,1

10,2

10,3

10,4

10,5

10,6

10,7

10,8

10,9

11,0

11,1

11,2

11,3

11,4

11,5

11,6

11,7

11,8

11,9

12,0

12,5

12,8

13,0

13,5

13,8

14,0

14,5

14,8

15,0

15,5

15,8

16,0

On request shank form DIN 6535 HBK or HEK available without extra charge.

Please specify on your order the requested shank form.

d2

h6

mm

8,0

8,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

14,0

14,0

14,0

14,0

14,0

14,0

16,0

16,0

16,0

16,0

16,0

16,0

l1

l2

mm

91

91

103

103

103

103

103

103

103

103

103

103

103

103

103

103

103

118

118

118

118

118

118

118

118

118

118

118

118

118

118

118

118

118

118

118

118

124

124

124

124

124

124

133

133

133

133

133

133

mm

53

53

61

61

61

61

61

61

61

61

61

61

61

61

61

61

61

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

71

77

77

77

77

77

77

83

83

83

83

83

83

l3

Z TA-CN coated

price

mm

/pc.

43 2

46,00

43 2

46,00

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

49 2

55,60

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

56 2

76,30

60 2

102,00

60 2

102,00

60 2

102,00

60 2

102,00

60 2

102,00

60 2

102,00

63 2

153,50

63 2

153,50

63 2

153,50

63 2

153,50

63 2

153,50

63 2

153,50

Solid carbide twist drill Niro-Drill

until 8xD

Catalogue no:

extra long

271TA-CN

with interior coolant

Design:

Norm:

Carbide grade:

Shank:

Point grinding:

Point angle:

Side Rake angle:

Prole:

according HAM Standard, extra long

micro grain

DIN 6535 HAK

special point grinding, CNC-ground

140

30

special chip ute geometry

W

NE

Application:

High performance drilling on high-capacity CNC machines and machining centres, for

trouble-free serial production of long-chipping material such as INOX-TITAN.

Shank tolerance compared to h6 (-0,002 up to 0,005) is restricted, for adaptors

in shrink t chucks and expansion chuck holders.

order-no.

271-0300

271-0310

271-0320

271-0330

271-0340

271-0350

271-0360

271-0370

271-0380

271-0390

271-0400

271-0410

271-0420

271-0430

271-0440

271-0450

271-0460

271-0470

271-0480

271-0490

271-0500

271-0510

271-0520

271-0530

271-0540

271-0550

271-0560

271-0570

271-0580

271-0590

271-0600

271-0610

271-0620

271-0630

271-0640

271-0650

271-0660

271-0670

271-0680

271-0690

271-0700

271-0710

271-0720

271-0730

271-0740

271-0750

271-0760

d1

m7

mm

3,0

3,1

3,2

3,3

3,4

3,5

3,6

3,7

3,8

3,9

4,0

4,1

4,2

4,3

4,4

4,5

4,6

4,7

4,8

4,9

5,0

5,1

5,2

5,3

5,4

5,5

5,6

5,7

5,8

5,9

6,0

6,1

6,2

6,3

6,4

6,5

6,6

6,7

6,8

6,9

7,0

7,1

7,2

7,3

7,4

7,5

7,6

d2

h6

mm

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

6,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

8,0

l1

l2

mm

72

72

72

72

72

72

72

72

81

81

81

81

81

81

81

81

81

81

95

95

95

95

95

95

95

95

95

95

95

95

95

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

mm

34

34

34

34

34

34

34

34

43

43

43

43

43

43

43

43

43

43

57

57

57

57

57

57

57

57

57

57

57

57

57

76

76

76

76

76

76

76

76

76

76

76

76

76

76

76

76

l3

Z TA-CN coated

price

mm

/pc.

29 2

55,60

29 2

55,60

29 2

55,60

29 2

55,60

29 2

55,60

29 2

55,60

29 2

55,60

29 2

55,60

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

36 2

58,70

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

48 2

63,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

order-no.

271-0770

271-0780

271-0790

271-0800

271-0810

271-0820

271-0830

271-0840

271-0850

271-0860

271-0870

271-0880

271-0890

271-0900

271-1000

271-1010

271-1020

271-1030

271-1040

271-1050

271-1060

271-1070

271-1080

271-1090

271-1100

271-1110

271-1120

271-1130

271-1140

271-1150

271-1160

271-1170

271-1180

271-1190

271-1200

271-1250

271-1280

271-1300

271-1350

271-1380

271-1400

271-1450

271-1480

271-1500

271-1550

271-1580

271-1600

d1

m7

mm

7,7

7,8

7,9

8,0

8,1

8,2

8,3

8,4

8,5

8,6

8,7

8,8

8,9

9,0

10,0

10,1

10,2

10,3

10,4

10,5

10,6

10,7

10,8

10,9

11,0

11,1

11,2

11,3

11,4

11,5

11,6

11,7

11,8

11,9

12,0

12,5

12,8

13,0

13,5

13,8

14,0

14,5

14,8

15,0

15,5

15,8

16,0

d2

h6

mm

8,0

8,0

8,0

8,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

10,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

12,0

14,0

14,0

14,0

14,0

14,0

14,0

16,0

16,0

16,0

16,0

16,0

16,0

l1

l2

mm

114

114

114

114

142

142

142

142

142

142

142

142

142

142

142

162

162

162

162

162

162

162

162

162

162

162

162

162

162

162

162

162

162

162

162

178

178

178

178

178

178

203

203

203

203

203

203

mm

76

76

76

76

95

95

95

95

95

95

95

95

95

95

95

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

114

133

133

133

133

133

133

152

152

152

152

152

152

l3

Z TA-CN coated

price

mm

/pc.

64 2

83,50

64 2

83,50

64 2

83,50

64 2

83,50

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

80 2

112,30

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

96 2

153,50

112 2

219,40

112 2

219,40

112 2

219,40

112 2

219,40

112 2

219,40

112 2

219,40

128 2

287,40

128 2

287,40

128 2

287,40

128 2

287,40

128 2

287,40

128 2

287,40

On request shank form DIN 6535 HBK or HEK available without extra charge.

Please specify on your order the requested shank form.

Regrinding and Recoating of

Solid carbide high-performance Superdrill and Niro-Drill

Superdrill

Typ 280TA-C, 283TA-C, 285TA-C, 286TA-C, 292TA-C

Niro-Drill

Typ 270TA-CN, 271TA-CN

d1

mm

regrinding and

recoating

/pc.

2,8

6,0

12,20

6,1

8,0

13,20

8,1

10,0

14,10

10,1

12,0

20,10

12,1

14,0

20,70

14,1

16,0

22,70

16,1

18,0

23,60

18,1

20,0

24,50

The most important HAM drill point geometries

4-facet point

4-facet point

10

gradually tapered

drill point with

point thinning

gradually tapered twist drill Superdrill

drill point

HAM 280, HAM 283,

with point thinning HAM 285, HAM 286,

HAM 292

margin approximately 20

negative at point and side

rake angle

twist drill Niro-Drill

HAM 270, HAM 271

3-uted drill

HAM 385

HAM 322, HAM 323,

HAM 326

Kevlar point

HAM 342

Cutting data for solid carbide high performance drills Superdrill

Material

Cutting speed

Vc [m/min]

Unalloyed steel

without IC

with IC

80 - 100 - 120

100 - 120 - 160

0,06

0,10

0,14

feed

f [mm/U]

[mm]

8

10

12

16

20

0,18

0,25

0,25

0,30

0,20

coolant

We recommend basically the bold printed cutting speed and the average feed of the cutting diameter.

These data may be adjusted according to your individual requirements..

E/S

800 N/mm

2

-0,10 -0,18 -0,20 -0,25 -0,30 -0,35 -0,40 -0,50

Unalloyed steel

70 - 90 - 110

90 - 110 - 150

0,06

0,10

0,14

0,18

0,20

0,25

0,25

0,30

E/S

> 800 N/mm

3

-0,10 -0,18 -0,20 -0,28 -0,30 -0,35 -0,40 -0,50

Alloyed steel

60 - 80 - 100

80 - 100 - 130

0,05

0,08

0,10

0,15

0,18

0,20

0,30

0,30

E/S

1200 N/mm

4

-0,08 -0,15 -0,15 -0,20 -0,25 -0,30 -0,40 -0,45

Alloyed steel

50 - 70 - 90

60 - 80 - 100

0,05

0,08

0,10

0,15

0,18

0,20

0,30

0,30

E/S

> 1200 N/mm

5 *

-0,08 -0,10 -0,15 -0,20 -0,25 -0,30 -0,40 -0,45

Stainless steel (VA)

40 - 50 - 70

50 - 60 - 90

0,05

0,08

0,10

0,15

0,18

0,20

0,25

0,30

E/S

-0,08 -0,12 -0,15 -0,20 -0,25 -0,30 -0,35 -0,40

6

Cast iron

80 - 100 - 140

100 - 140 - 180

0,10

0,12

0,20

0,30

0,35

0,45

0,60

0,70

T/E

and malleable cast iron

7 *

Aluminium,

-0,15 -0,20 -0,30 -0,40 -0,50 -0,60 -0,80 -1,00

100 - 140 - 200

150 - 200 - 300

0,10

0,12

0,20

0,30

0,35

0,45

0,60

0,70

E/S

long chipping

8 *

-0,15 -0,20 -0,30 -0,40 -0,50 -0,60 -0,80 -1,00

Aluminium,

100 - 150 - 220

180 - 220 - 320

0,10

0,12

0,20

0,30

0,35

0,45

0,60

0,70

E/S

short chipping

9 *

-0,15 -0,20 -0,30 -0,40 -0,50 -0,60 -0,80 -1,00

Aluminium,

60 - 120 - 180

80 - 150 - 230

0,08

0,10

0,15

0,20

0,30

0,35

0,40

0,50

E/S

alloyed to 12% Si

10 *

Brass, bronze,

-0,12 -0,15 -0,20 -0,30 -0,40 -0,50 -0,60 -0,80

80 - 120 - 180

100 -150 -230

0,08

0,10

0,15

0,20

0,30

0,35

0,40

0,50

E/S

copper, zinc, red bronze

-0,12 -0,15 -0,20 -0,30 -0,40 -0,50 -0,60 -0,80

The above mentioned data for Vc (cutting speed) are valid for drilling depth 3xD.

For other drilling depths please multiply with specic correction factor.

without

interior

coolant

drilling depth

1xD

3xD

5xD

Correction factor for cutting speed

Vc x 1,2

Vc x 1,0

Vc x 0,7

with

interior

coolant

drilling depth

1xD

3xD

5xD

8xD

Correction factor for cutting speed

Vc x 1,2

Vc x 1,0

Vc x 0,8

Vc x 0,7

* We recommend to use our solid carbide high performance drill

Niro-Drill for material nos 5, 7, 8, 9 and 10.

IC = interior coolant

S = cutting oil

f = feed per revolution [mm/U]

E/S = emulsion / cutting oil

P = compressed air

Vc = cutting speed (m/min)

E = emulsion

N = air waterfog (P = 6 - 8 bar)

U

T/E

STA

= revolution

= dry / emulsion

= sawdust collector

11

Cutting data for solid carbide high performance drills Niro-Drill

Material

Cutting speed

Vc [m/min]

with IC

1 V2A, V4A

50 - 60 - 70

feed

f [mm/U]

[mm]

8

10

0,04

0,06

0,08

0,10

0,12

0,15

0,20

0,30

-0,06

-0,08

-0,10

-0,12

-0,15

-0,18

-0,30

-0,40

0,10

0,12

0,20

0,30

0,35

0,45

0,60

0,70

-0,15

-0,20

-0,30

-0,40

-0,50

-0,60

-0,80

-1,00

0,10

0,12

0,20

0,30

0,35

0,45

0,60

0,70

-0,15

-0,20

-0,30

-0,40

-0,50

-0,60

-0,80

-1,00

0,08

0,10

0,15

0,20

0,30

0,35

0,40

0,50

-0,12

-0,15

-0,20

-0,30

-0,40

-0,50

-0,60

-0,80

0,02

0,03

0,04

0,06

0,08

0,10

0,12

0,14

-0,03

-0,04

-0,05

-0,07

-0,10

-0,12

-0,14

-0,15

0,08

0,10

0,15

0,20

0,30

0,35

0,40

0,50

-0,12

-0,15

-0,20

-0,30

-0,40

-0,50

-0,60

-0,80

0,10

0,12

0,15

0,20

0,22

0,25

0,28

0,30

-0,12

-0,15

-0,18

-0,22

-0,25

-0,28

-0,30

-0,40

0,10

0,12

0,15

0,20

0,22

0,25

0,28

0,30

-0,12

-0,15

-0,18

-0,22

-0,25

-0,28

-0,30

-0,40

0,10

0,12

0,15

0,20

0,22

0,25

0,28

0,30

-0,12

-0,15

-0,18

-0,22

-0,25

-0,28

-0,30

-0,40

12

16

20

coolant

We recommend basically the bold printed cutting speed and the average feed of the cutting diameter.

These data may be adjusted according to your individual requirements..

E/S

2 Aluminium,

150 - 200 - 300

E/S

long shipping

3 Aluminium,

180 - 200 - 320

E/S

short shipping

4 Aluminium

80 - 150 -230

E/S

alloyed to12% Si

5 Titanium, titanium alloy

20 - 30 - 40

6 brass, bronze,

100 - 150 - 230

E/S

copper, zinc, red bronze

7 Thermoplastic

70 - 75 - 80

E/S

8 Duroplastic

100 - 110 - 120

E/S

Epoxy resin

110 - 150 - 180

E/S

The above mentioned data for Vc (cutting speed) are valid for drilling depth 3xD.

For other drilling depths please multiply with specic correction factor.

with

interior

coolant

drilling depth

1xD

3xD

5xD

8xD

Correction factor for cutting speed

Vc x 1,2

Vc x 1,0

Vc x 0,8

Vc x 0,7

IC = interior coolant

S = cutting oil

f = feed per revolution [mm/U]

12

E/S = emulsion / cutting oil

P = compressed air

Vc = cutting speed (m/min)

E = emulsion

N = air waterfog (P = 6 - 8 bar)

U

T/E

STA

= revolution

= dry / emulsion

= sawdust collector

You might also like

- DIN 8555 Welding StandardDocument4 pagesDIN 8555 Welding StandardAntonius Dwi Putranto N100% (3)

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranNo ratings yet

- Comparing Steel Plate Grades Ebook PDFDocument5 pagesComparing Steel Plate Grades Ebook PDFJayaseelan GNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- TurningDocument64 pagesTurningSerhat DoğandemirNo ratings yet

- Chip Breaker: (H-Series)Document2 pagesChip Breaker: (H-Series)Swaraj VishwakarmaNo ratings yet

- G-Pak18 1Document89 pagesG-Pak18 1Elmedin FazlicNo ratings yet

- UTP Tool Welding BrochureDocument12 pagesUTP Tool Welding Brochurekamals55No ratings yet

- Tank Power PDFDocument22 pagesTank Power PDFstctoolNo ratings yet

- Somta Tools User GuideDocument150 pagesSomta Tools User GuideBarrie Van Wyk100% (1)

- CatalogDocument18 pagesCataloglangtu2011No ratings yet

- Alfra Catalogue 21 CuttingDocument41 pagesAlfra Catalogue 21 CuttingMartín LópezNo ratings yet

- Koco Koco Kocovvv Koco Koco Kocovv Koco KocoDocument0 pagesKoco Koco Kocovvv Koco Koco Kocovv Koco KocoSun SunNo ratings yet

- 15 Rotating Toolholders WNT2013Document177 pages15 Rotating Toolholders WNT2013Natrajj SivakumarNo ratings yet

- Campaign: Solid Carbide End MillsDocument8 pagesCampaign: Solid Carbide End Mills2dex1adwief2m1a6No ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Secco Catalogo 1Document16 pagesSecco Catalogo 1emilio_707No ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- Drill Bit - WikipediaDocument55 pagesDrill Bit - Wikipediaaddisugebre2125No ratings yet

- Dme CatalogDocument28 pagesDme Cataloggalici2002No ratings yet

- CoroKey 2008engDocument208 pagesCoroKey 2008engStela LjevarNo ratings yet

- Plates PDFDocument10 pagesPlates PDFkarthiksaadhanaNo ratings yet

- VARGUS - Gear Milling New - InchDocument6 pagesVARGUS - Gear Milling New - InchGilberto ManhattanNo ratings yet

- 2 ATI Steellram U INCIMA DimenzijeDocument4 pages2 ATI Steellram U INCIMA DimenzijeBosko LukavicNo ratings yet

- Unit 6 - Die CastingDocument86 pagesUnit 6 - Die CastingNeo TarunNo ratings yet

- Handbook ESAB - MecTIGDocument15 pagesHandbook ESAB - MecTIGRobertoNo ratings yet

- OhnsDocument9 pagesOhnsspsurya2013No ratings yet

- American StandardDocument24 pagesAmerican StandardmitulfavsNo ratings yet

- Preheat Ions For A 514 Grade B MaterialDocument2 pagesPreheat Ions For A 514 Grade B Materialjrod64No ratings yet

- Pas CTG Tur Cer-Cermet enDocument36 pagesPas CTG Tur Cer-Cermet enshumi27No ratings yet

- XAR 400 (WB 703) EnglischDocument3 pagesXAR 400 (WB 703) Englischgheoda8926No ratings yet

- Introducing Chipbreaker Types: Chipbreaker System For Positive Turning InsertsDocument1 pageIntroducing Chipbreaker Types: Chipbreaker System For Positive Turning Inserts8075catNo ratings yet

- En 10028 2 P265GH - Boiler Plate Steel - ProductsDocument2 pagesEn 10028 2 P265GH - Boiler Plate Steel - ProductsShankey JAlanNo ratings yet

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Procut Catalogue 2010 Procut is an internationally renowned brand of high quality carbide burrs, and forms a key part of ATA Group, a privately owned organisation with over 50 years experience in the supply of metal working solutions to all major industrial sectors. We are committed to providing our customers with high performance products that maximise productivity and reduce costs. Our headquarters and global production centre based in Cavan, Ireland, is accredited to ISO9001:2008 and equipped with the latest CNC technology delivering product of unrivalled quality and consistency.Document19 pagesProcut Catalogue 2010 Procut is an internationally renowned brand of high quality carbide burrs, and forms a key part of ATA Group, a privately owned organisation with over 50 years experience in the supply of metal working solutions to all major industrial sectors. We are committed to providing our customers with high performance products that maximise productivity and reduce costs. Our headquarters and global production centre based in Cavan, Ireland, is accredited to ISO9001:2008 and equipped with the latest CNC technology delivering product of unrivalled quality and consistency.Sun SunNo ratings yet

- ST Lawrence Ultra-MetDocument6 pagesST Lawrence Ultra-Metmpcd07No ratings yet

- Sumiten 780SDocument2 pagesSumiten 780Sdiah131No ratings yet

- Alu ENDocument44 pagesAlu ENlelixNo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- Kinkelder StandardDocument24 pagesKinkelder StandardJason StephensNo ratings yet

- Nimonic 80A (TM) Super Alloy Material Property Data Sheet - Product Availability and Request A QuoteDocument5 pagesNimonic 80A (TM) Super Alloy Material Property Data Sheet - Product Availability and Request A QuotedharmatejakademNo ratings yet

- Tube Alloy 240 oDocument2 pagesTube Alloy 240 oelias667No ratings yet

- Steels For Oil - Gas - ExplorationDocument16 pagesSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNo ratings yet

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- 13 Solid Carbide Milling CuttersDocument309 pages13 Solid Carbide Milling CuttersManu GimenezNo ratings yet

- Broca Canhão CatalogoDocument48 pagesBroca Canhão CatalogodkfaNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- S690QLDocument4 pagesS690QLReginaldo Matias NunesNo ratings yet

- Pferd - Limas Rotativas Cat. 202Document64 pagesPferd - Limas Rotativas Cat. 202MinatelNo ratings yet