Professional Documents

Culture Documents

Intelligent Compaction For Soils and Subbase Materials

Intelligent Compaction For Soils and Subbase Materials

Uploaded by

Hussain ElarabiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intelligent Compaction For Soils and Subbase Materials

Intelligent Compaction For Soils and Subbase Materials

Uploaded by

Hussain ElarabiCopyright:

Available Formats

Intelligent Compaction for Soils and Subbase Materials

Introduction

TechBrief

The Transportation Pooled Fund (TPF) study, Accelerated Implementation of Intelligent Compaction Technology for Embankment Subgrade Soils, Aggregate Base and Asphalt Pavement Material is being conducted under TPF-5 (128). It is a three year study beginning September 2007 and ending September 2010. Visit the IC project website for further details on IC technologies: IntelligentCompaction.com

Intelligent compaction (IC) is a construction method relatively new to the USA that uses modern vibratory rollers equipped IC components and technologies. The IC technology and IC-related quality assurance (QA) specifications on earth work has existed in Europe for more than 20 years. Under the on-going FHWA/TPF IC studies, various single drum IC rollers from manufacturers around the world have been demonstrated at full scale projects targeting cohesive/incohesive soils, granular subbase, and stabilized base . Components of soils and subbase IC include: singledrum IC rollers, roller measurement system, global position system (GPS) radio/receiver/base station, infrared temperature sensors, and integrated reporting system. Therefore, a soils/subbase IC roller can adapt its behavior in response to varying situations and requirements - being intelligent! There are many benefits using soils/subbase IC rollers. To name a few: improved quality control (QC) of compaction, better correlate to compaction of deeper layer, monitor levels of compaction for 100% coverage area, and many more...

IC System

(courtesy of Bomag)

Top Three Factors for Soils/Subbase Compaction: Moisture! Moisture! and Moisture!

Soils/Subbase IC Rollers in the US

There are at least 5 vendors around the world have been developing single-drum IC rollers. Currently, there are two various types of soils/subbase IC rollers available in the US that meet the above IC roller requirements: Bomag USA, Case/Ammann, Caterpillar, Dynapac, Sakai America, and Volvo. Most of the above single-drum IC roller manufacturers offer smooth drum and padfoot models.

Bomag

Case/ Ammann

Caterpillar

Dynapac

Sakai

Page 2

INTELLIGENT COMPACTION FOR SOILS AND SUBBASE MATERIALS

Sakai IC system

Sakai Soil IC System

The basis of the Sakai IC system is the IC roller (equipped with CCV measurement system, temperature sensors, and GPS radio/receiver) and a GPS with radio base station. All measurements are consolidated to the CIS display. IC data can then be transferred to PCs via USB ports for further reporting/documentation and integration with CAD systems. The Sakai Compaction control value (CCV) is a unitless vibratory-based technology which makes use of an accelerometer mounted to the roller drum to create a record of machine-ground interaction. Its value represents the stiffness of the compacted pavement layers underneath. The concept behind the CCV is that as the ground stiffness increases, the roller drum starts to enter into a jumping motion which results in vibration accelerations at various frequency components. The current Sakai IC system does not yet consist of auto-feedback.

Bomag Soil IC System

Bomag BCM05 System

The Bomag IC system is called VarioControl IC system. The Bomag IC roller is equipped with two acceleration transducers, processor/control unit, distance measurement, GPS radio/antenna, Bomag Operation Panel (BOP), and onboard BCM 05 documentation system (BCM 05-Tablet-PC, BCM 05 mobile software). This system is capable of measuring compaction values that can be transferred to another computer using USB memory sticks for further analysis and reporting using the BCM05 office software. The Bomag IC measurement value is called Evib [MN/m2] or vibration modulus (more strictly, stiffness). The Evib values are computed based on the compression paths of contact forces vs. drum displacement curves. The Evib values increase with increasing pass number. Evib also responds to changes of material density and asphalt mixture temperature (with dropping compaction temperature, Evib of asphalt mixtures becomes greater). The Bomag Evib values correlate well with load bearing capacities (Ev1/Ev2) from the plate loading tests. The feedback control in the Bomag IC system is called VarioControl that enables the automatic adaption of the amplitude during the compaction process.

US DEPARTMENT OF TRANSPORTATION

Page 3

Case/Ammann Soil IC System

The Case/Ammann IC system is called the ACE and feedback drum system. The ACEplus system was formed by combining the former Ammann Compaction Expert (ACE) measurement and control system with continuous compaction control (CCC). The roller-integrated stiffness (ks) measurement system on the Case/Ammann IC rollers was introduced by Ammann during late 1990s considering a lumped parameter two-degree-of-freedom spring-mass-dashpot system. The spring-mass-dashpot model has been found effective in representing the drum-ground interaction behavior. The drum inertia force and eccentric force time histories are determined from drum acceleration and eccentric position (neglecting frame inertia). The IC soil stiffness, ks, can be determined when there is no loss of contact between drum and soil. It is closely related to the plate loading test results. ACE is an electronic measuring and controlling system for vibrating rollers. It is an automatic close-loop control automatically adjusts roller vibratory amplitudes and frequencies to suit the characteristic of the compacted ground condition. The Case/Ammann ACE auto feedback system can adjust the roller vibratory frequency and amplitude at each roller pass depending on the condition of the compacted ground condition thus, optimize the compaction with least desirable number of passes.

Number of Passes/Time

Compaction/Soil Stiffness

Caterpillar Soil IC System

Radio Display GPS Receiver

Compaction Depth

The Caterpillar IC system include an accelerometer, slope sensor, controllers, communication data radio, Real-time Kinematic (RTK) GPS receiver, an off-board GPS base station, and onboard report system. The slope (angle) sensor measures the left/right tilt of the drum to a range of 45. Collectively, the above components are integrated into so-called Caterpillar AccuGrade system to provide accurate IC measurements during compaction. The Caterpillar IC measurement values for indication of levels of compaction include compaction meter values (CMV), resonance meter values (RMV), and machine drive power (MDP).

Controllers

Slope Sensor

Accelerometer

The CMV was developed by Geodynamic in 1970s. CMV is defined as a scaled ratio of the second harmonic vs. the first harmonic of the drum vertical acceleration amplitudes based on a spectral analysis. The scaling is made so that CMV values could Slightly harder Soft material Hard material material cover a range of 150. The CMV is reported as average values within two cycles of vibration or typically 0.5 seconds. The resulting CMV is a dimensionless, relative value requiring constant roller parameters SA SA SA such as drum diameter, linear load, frequency, amplitude, speed, and etc. Since the CMV is an integral with contribution from large depths (3 to 6 ft for Caterpillar IC rollers) with the highest weighting of the layers closest to the surface, caution should be taken when comparing CMV to the top layer compaction level (often measured by other 0,5F F 2F fq 0,5F F 2F fq 0,5F F 2F fq in-situ devices such as nuclear gauges or LWD) only.

CMV 8 50 150

Page 4

INTELLIGENT COMPACTION FOR SOILS AND SUBBASE MATERIALS

LWD

Dynapac Soil IC System

The DCA system measures CMV as an indicator of compaction quality. The CMV technology uses accelerometers to measure drum accelerations in response to soil behavior during compaction operations (Figure 17). The ratio between the amplitude of the first harmonic and the amplitude of the fundamental frequency provides an indication of the soil compaction level. An increase in CMV value indicates increasing compaction.

DCP

CMV is a dimensionless parameter that depends on roller dimensions (i.e., drum diameter, weight) and roller operation parameters (i.e., frequency, amplitude, and speed). The machine used on this project reported a measurement value approximately every 0.5 m at the drum center along the direction of travel. The machine also reported a bouncing value (BV) which provides an indication of the drum behavior (e.g., continuous contact, partial uplift, double jump, rocking motion, and chaotic motion) and is calculated using Equation 3. When the machine is operated in AFC mode, reportedly the amplitude is reduced when BV approaches 14 to prevent drum jumping.

NG

In-situ Point Tests

FWD

For IC correlation analysis, in-situ tests are used to directly obtain the response of the compacted materials under various loading situations and drainage/moisture conditions. Recommended in-situ test devices for soils/subbase/stabilized IC are as followings (Dynamic Seismic Pavement Analyzer - DSPA - and Briaud Compaction Device - BCD - are still being evaluated):

PLT PLT

Light Weight Deflectometer (LWD) Dynamic Cone Penetrometer (DCP) Calibrated Nuclear Moisture-Density Gauge for soils and subbase (NG) Falling Weight Deflectometer (FWD) Static Plate Loading Test (PLT)

In-situ moisture testing is also recommended if available. Soil samples are often taken from the test sites to perform moisture measurement, Proctor tests, and etc. When a padfoot roller is used for compaction, the compacted materials should be carefully excavated down to the bottom of the pad to create a level surface for in-situ testing.

ISU geotechnical mobile lab

DSPA

BCD

US DEPARTMENT OF TRANSPORTATION

Page 5

Global Positioning System (GPS)

The Global Positioning System (GPS) is a location system based on satellite signals and their ground stations. Depending on the quality of the receiver, the environment, the type of measurements made, and how the measurements are processed, the positioning accuracy of GPS can vary from a few meters to below 1 centimeter, permitting a wide range of positioning applications from vehicle navigation to studies of the motion of the Earth's tectonic plates. GPS is used in the IC system to record the coordinates of rollers at each pass. However, there are several external sources that may introduce errors into a GPS position including: atmospheric conditions, ephemeris errors/clock drift/measurement noise, selective availability, multipath, and etc. The IC systems normally use differential correction GPS (or DGPS) to improve accuracies. Differential correction requires a second GPS receiver, a base station, collecting data at a stationary position on a precisely known point (e.g., a surveyed benchmark). With the known physical location of the base station, a correction factor can be computed by comparing the known location with the GPS location determined by using the satellites. Then, the correction factor can be applied to the GPS data collected by a GPS receiver in the field. Recommended GPS requirements for IC are as follows:

RTK-GPS (Real Time Kinematic-GPS) system (radio and receiver) on IC rollers. System reports and records values in Northing and Easting and vertical position in meters in UTM coordinates for the project site. If an offset is necessary between GPS antenna and center of drum, the IC system settings and GPS measurements have to be validated onsite.

Current RTK-GPS system for IC may require a GPS base station, though standalone systems are evolving to obtain desirable accuracy. The Universal Transverse Mercator Coordinate (UTM) system provides coordinates, northings and eastings, on a world wide flat grid for easy computation. Therefore, UTM is normally used in the IC data processing. The Universal Transverse Mercator Coordinate system divides the Earth into 60 zones, each being 6 degrees longitude wide, and extending from 80 degrees south latitude to 84 degrees north latitude. The polar regions are excluded. The first zone starts at the International Date Line (longitude 180 degrees) proceeding eastward. Cautions should be taken when the area of interest extends from one zone to another. Under this IC study, the UTM zones are restricted in the US from zone No. 10 to zone No. 19. It is recommended that all in-situ test locations are measured using portable DGPS systems and reported with the same UTM zone as IC data.

GPS Records & Maps The Compaction Results Displays measurements and Guides the Operator Accelerometer on drum Measures soil stiffness as an indication of Soil Compaction

GPS Base Station = Centimeter accuracy

Page 6

INTELLIGENT COMPACTION FOR SOILS AND SUBBASE MATERIALS

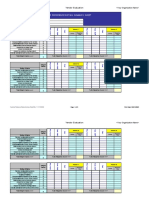

FM 156, Fort Worth, TX Cohesive SG, Stabilized SG, and Aggregate SB

TX IC Demonstration

Case/Ammann IC padfoot roller measures soil stiffness ks values for multiple passes. It identifies localized wet area with moisture content of about 27% that could be not compacted. Compaction curve (i.e. compaction values vs. roller passes) can be effectively established using the Case/ Ammann IC padfoot roller. The curve is consistent with back-calculated mechanistic soil properties from in-situ tests such as LWD and DCP.

20

Average kSIPD (MN/m)

Soft spots (i.e. hard-tocompacted) and underground structures can easily located by the Case/Ammann IC roller.

0 200 Depth (mm) Depth (mm) Point 13 400 600 800 0 Point 12 200

ELWD Z2 = 47.5 MPa EV1 = 42.1 MPa EV2 = 121.1 MPa EFWD D3 = 57 MPa EDSPA = 44 MPa

400 600 800

DCP refusal (Box Culvert)

Point13

ELWD Z2 = 58.4 MPa EV1 = 96.9 MPa EV2 = 381.1 MPa EFWD D3 = 145 MPa EDSPA = 88 MPa

0 10 20 30 40 50 60 CBR (%)

Pass1

0 10 20 30 40 50 60

35 Average w (%) 30 25 20 15 10 5 0 2 4 6 8 10 0 18 Average CBR (%) 2 4 6 8 10

Std. Proctor wopt = 17.8%

Point12

0

CBR (%)

20

Localized Wet Area

Lane 1 2 3 4 5

18 16 14 12 10 8

Point 5

Point5

Depth (mm)

200 400 600 800 0 10 20 30 40 50 60

40

60

w = 29.5% d = 13.8 kN/m3 ELWD Z2 = 11.6 MPa

Distance (m)

80

Box Culvert

0 Point 1 200 Depth (mm) 400 600 800

Average ELWD-Z2 (MPa)

100

Cohesive Subgrade

18 15 12 9 6 0 2 4 6 8 10

CBR (%)

15 12 9 6 3 0 2 4 6 8 10

120

140

w = 20.8% d = 16.0 kN/m3 ELWD Z2 = 61.1 MPa

Point1

0 10 20 30 40 50 60 CBR (%)

160

180

Pass

Pass

US 69, Pleasanton, KS Cohesive SG, and Aggregate SB

KS IC Demonstration

Compaction curve for cohesive soils using the Sakai padfoot IC roller was established the first time according to the past published literature.

7 6 5 CCV 4 3 2 1 0 20 18 d (kN/m3) 16 14 12 10 0 2 4 6 8 10 12 14 Pass

Values corrected using w% values after Pass 1 TB 4 Lane 3:

Comparison between the Sakai padfoot and smooth drum IC measurements indicates that they results are consistentwhich is very encouraging.

Production compaction using the Caterpillar padfoot IC roller successfully track compaction levels of various materials such as fat clay and lean clay subgrade.

MDP80

>140 135 130 125 120 115 0

60 50 ELWD-Z2 (MPa) 40 30 20 10 0 2 4 6 8 10 12 14 20 15 CBR (%) 10 5 0 0 2 4 6 8 10 12 14 Pass 0 2 4 6 8 10 12 14 Pass Pass

MDP for Pass Number 1 2 3

Elevation (Pass #3)

Pass Number 2

Elev. (m)

>245.67 245.67 245.06 244.45 243.84 243.23 242.62 <242.62

a = 2.19 mm, v = 6 km/h, f = 26 Hz (High amp setting)

Passes

>9 8 7 6 5 4 3 2 1

US 219, Springville, NY Non-cohesive SG, and Aggregate SB

NY IC Demonstration

The Caterpillar smooth drum IC measurements of CMV and MDP on granular subgrade are found to be comparable.

CMV Pass 2 a = 0.90 mm CMV Pass 3 a = 0.90 mm MDP40 Pass 1 Static MDP40 Pass 2 a = 0.90 mm MDP40 Pass 3 a = 0.90 mm

Contribution of truck traffic to compaction on aggregate base is identified by the Caterpillar smooth drum IC roller.

Truck traffic contributing to compaction

Compaction with the Bomag smooth drum IC roller were evaluated using manual/auto modes and track/GPS modes.

Map 1 Manual a = 0.70 mm Map 2 Auto amax = 1.90 mm Map 3 Lane 3 Map 4 Lane 3 Manual Manual a = 0.70 mm a = 0.70 mm Map 5 Lane 3 Manual a = 0.70 mm Map 6 Lane 3 Manual a = 1.10 mm

Pass Count

(10)

CMV Final Pass

MDP40 Final Pass

Lane 1 2 3

(9) (8) 200 m

4 5

(7)

In-Situ Test Locations

(6)

76

Passes

(4) (3) CMV

>100 80 60 40 20 0

(5) MDP40 (2)

>145 140 135 130 125 120

>9 8 7 6 5 4 3 2 1

CMV

>100 80 60 40 20 0

MDP40

>140 130 120 110 100 90 0

(1)

GPS Mode

Track Mode

GPS Mode

280 m

US DEPARTMENT OF TRANSPORTATION

Page 7

MS IC Demonstration

The effects of curing vs. time for stabilized granular subgrade can be monitored with the Case/Ammann smooth drum IC roller.

Manual Mode - TB4 Shortly after stabilization ks Amp. Freq. ks Manual Mode - TB9 After 2-day cure Amp. Freq. ks AFC Mode - TB9 After 2-day cure Amp. Freq. k s (MN/m)

Effects of time delay for compacting stabilized base materials are being investigated with the prelim results indicates that the delay of compaction may reduce the dry density.

In-situ Sample Proctor (Approx. 1.5 hr after placement and 30 to 40 min after mixing): Stabilized Subgrade: 122.8 pcf @ w = 10% Stabilized Base: 120.5 pcf @ 11.4%

US 84, Wayne County, MS Non-cohesive SG, Aggregate SB, STB

The unstabilized granular subgrade compactability were evaluated with both the Caterpillar and Case/ Ammann smooth drum IC rollers with consistent results.

Amp. (mm)

MDP40

CMV MDP40

>140 140 130 120 110 100 <100

Manual Mode ks Amp. Freq.

AFC Mode ks Amp. Freq.

128

Amp. (mm)

Freq. (Hz)

126 Dry Density (pcf) 124 122 120 118 116 114 0 50 100 150

CMV

>20 20 15 10 5 2 <2

Stabilized Base Stabilized Subgrade

109.5 m

304 m

Freq. (Hz)

200

250

300

Static pass after vibratory compaction pass

Static pass after vibratory compaction pass

Time (minutes)

Factors Affecting IC RMVs

There are many factors affecting IC roller-integrated measurements (RMV). It is crucial to future harmonization of IC RMVs and IC-based acceptance specification to understand these effects thoroughly.

Moisture Effects were modeled via multiple regression techniques.

Model

Range of measurement values Machine operations (amplitude, frequency, speed) and roller jumping Non-uniform drum/soil contact Limited number of in-situ measurements for correlation

Uncertainty in spatial pairing of point measurements and RMVs Not enough information to interpret the results Measurement errors associated with the RMVs and in-situ point test measurements

CCVPD = b0 + b1 ELWD-Z2 + b2 a + b3 w

CCVPD = b0 + b1 EFWD-D4.5 + b2 a

CCVPD = b0 + b1 d + b2 a + b3 w

Heterogeneity in underlying layer support conditions Moisture content variation

CCVPD = b0 + b1 CBR + b2 a + b3 w

TPF States get plenty of handson the IC technologies at the IC Demo Open Houses.

Influence Depth of IC RMVs and In-situ Tests

Investigation of the influence depths of IC roller compaction and measurements vs. other in-situ point tests (e.g. LWD, DCP, NG, and BCD) are being investigated.

Embankment Granular Subgrade

#3 #2 Lane # 1

Trench widths = 1 m and 2m #1 1m wide 10 m #2 trench #3 ~60 m Loose trenches

The relationship among influence or measurement depths of various devices would affect how correlation tests should be conducted and analyzed/interpreted.

ImpactForce FromRollers

300mm LWD/FWD

200mm LWD Nuclear DensityGauge

Dynamic ConePenetrometer

2.1m

0.3m

0.2m

0.3m 1.0m

2.1m Influencedepths areassumed ~ 1xB(width)

Stay tuned for more results from the IC research team.

2m wide trench

Recommendations

Validation of the IC Global Positioning System (GPS) setup prior to the compaction operation using a survey grade GPS handheld unit is crucial to providing precise and correct measurements.

Benefits of Intelligent Compaction

Improve

To correlate in-situ tests with IC data properly, in-situ test locations must be established using a hand-held GPS rover unit that is tied into the project base station and offers survey grade accuracy.

Density better performance Improve Efficiency cost savings Increase Information better QC/QA

Use of IC RMVs can be as part of intelligent QC/QA. Further study on linking IC RMVs to mechanistic QA parameters in top 1~3 m are strongly recommended.

Standardization is strongly recommended to accelerate the implementation IC for State agencies: a standard IC data storage format, an independent viewing/analysis software tool, and detailed data collection plan

Contact Victor (Lee) Gallivan, P.E. victor.gallivan@dot.gov FHWA Office of Pavement Technology, 575 N. Pennsylvania St., Indianapolis, Indiana 46204. (317) 226-7493 George Chang, Ph.D., P.E. gkchang@thetranstecgroup.com The Transtec Group, 6111 Balcones Drive, Austin TX 78731. (512) 451-6233 Research This TechBrief was developed by Dr. George Chang, and Qinwu Xu from the Transtec Group. The project team also includes: Dr. Robert Otto Rasmussen and David Merritt of the Transtec Group, Larry Michael of LLM Asphalt Consulting, Dr. David White of Iowa State University, and Bob Horan of the Asphalt Institute. Distribution This TechBrief is being distributed according to a standard distribution. Direct distribution is being made to FHWAs field offices. Availability This technical brief is freely available from the FHWA DTFH61-07-C-R0032 research project team Accelerated Implementation of Intelligent Compaction technology for Embankment Soils, Aggregate Base, and Asphalt Pavement Materials. The goal of this technical brief is to better inform the public about this study. Key Words compaction, intelligent compaction, roller, soils, subgrade, aggregate, embankment, stabilized base, asphalt, HMA, pavement performance, quality control, quality assurance. Notice This TechBrief is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of information exchange. The TechBrief does not establish policies or regulations, nor does it imply Federal Highway Administration (FHWA) endorsement of any products or the conclusions or recommendations presented here. The U.S. Government assumes no liability for the contents or their use. Quality Assurance Statement FHWA provides high-quality information to serve Government, industry, and the public in a manner that promotes public understanding. Standards and policies are used to ensure and maximize the quality, objectivity, utility, and integrity of its information. FHWA periodically reviews quality issues and adjusts its programs and processes to ensure continuous quality improvement.

You might also like

- FWD Analysis Jaipur-Reengus Report RevisedDocument69 pagesFWD Analysis Jaipur-Reengus Report RevisedPremNo ratings yet

- Resource Plan TemplateDocument4 pagesResource Plan TemplateHussain ElarabiNo ratings yet

- Procurement Plan TemplateDocument3 pagesProcurement Plan TemplateHussain Elarabi100% (1)

- Quality Plan TemplateDocument3 pagesQuality Plan TemplateHussain ElarabiNo ratings yet

- Maccaferri Flexible Pavement Design SpreadsheetDocument10 pagesMaccaferri Flexible Pavement Design SpreadsheetAlbaro Andres TorricoNo ratings yet

- 012 Piling WorkDocument17 pages012 Piling WorkFara Atika Bha Ney100% (3)

- Intelligent Compaction For Asphalt MaterialsDocument6 pagesIntelligent Compaction For Asphalt MaterialsHussain ElarabiNo ratings yet

- Intelligent CompactionDocument16 pagesIntelligent CompactionrppoudyalNo ratings yet

- S55 - Intelligent Compaction in Louisiana - LTC2013Document52 pagesS55 - Intelligent Compaction in Louisiana - LTC2013walaywan100% (1)

- FHWA TechBrief IC Hif13053Document9 pagesFHWA TechBrief IC Hif13053ALBERTO ROCHERNo ratings yet

- Intelligent Compaction - Case StudyDocument7 pagesIntelligent Compaction - Case StudyGorazdNo ratings yet

- Quality Controle PlanDocument17 pagesQuality Controle PlanMohamed Amine ZemouriNo ratings yet

- Obstacle Detection For Unmanned Ground Vehicles:: A Progress ReportDocument14 pagesObstacle Detection For Unmanned Ground Vehicles:: A Progress ReportPrasenjit SahaNo ratings yet

- Evaluation of Intelligent Compaction For Asphalt MaterialsDocument9 pagesEvaluation of Intelligent Compaction For Asphalt Materialszhizhang5591No ratings yet

- Intelligent Compaction of SoilsDocument4 pagesIntelligent Compaction of SoilsAgatha NjeriNo ratings yet

- Test Method OthersDocument15 pagesTest Method OthersEnd End100% (1)

- ZFG 3000-1Document24 pagesZFG 3000-1Ali GursesNo ratings yet

- Folleto T-5Document5 pagesFolleto T-5giulianogjNo ratings yet

- Method Statement Dynamic Load TestDocument14 pagesMethod Statement Dynamic Load TestmarcvenzNo ratings yet

- Design of Flexible Pavement Using ExperiDocument7 pagesDesign of Flexible Pavement Using ExperiSokheng HourNo ratings yet

- CSIR2Document2 pagesCSIR2Sony ZebuaNo ratings yet

- CDR Presentation ContentDocument20 pagesCDR Presentation Contentbhavya rachhoyaNo ratings yet

- Sims Tank Inspection SoftwareDocument4 pagesSims Tank Inspection SoftwareWilmer CarrascoNo ratings yet

- Data AquisationDocument11 pagesData Aquisationengineair007No ratings yet

- Site Suitability Report C10XB: Cremorne Wharf DepotDocument84 pagesSite Suitability Report C10XB: Cremorne Wharf Depotinfo1639No ratings yet

- Application of Industrial Can Bus Technology For Leo-SatellitesDocument0 pagesApplication of Industrial Can Bus Technology For Leo-SatellitesrganagarajNo ratings yet

- Dynamic Pile Load TestDocument8 pagesDynamic Pile Load Testarno assassinNo ratings yet

- Low Cost Data Adquisition System To Register Fuel Consumption in Diesel Engine VehiclesDocument4 pagesLow Cost Data Adquisition System To Register Fuel Consumption in Diesel Engine Vehiclessmatuszak97No ratings yet

- POSMV - 2005 - 09 - Motion Sensor ComparisonDocument18 pagesPOSMV - 2005 - 09 - Motion Sensor Comparisonchakib tabNo ratings yet

- Viga Electronica PDFDocument8 pagesViga Electronica PDFOrlando RojasNo ratings yet

- RCS Brochure Tcm533-1172411Document8 pagesRCS Brochure Tcm533-1172411Ronald OsorioNo ratings yet

- Multibeam Calibration ModuleDocument41 pagesMultibeam Calibration ModuleYano MaximataNo ratings yet

- Falling Weight DeflectometerDocument5 pagesFalling Weight DeflectometerWilfredo TejerinaNo ratings yet

- A Low Cost, Open-Architecture-Based System Satellite Telemetry & ControlDocument8 pagesA Low Cost, Open-Architecture-Based System Satellite Telemetry & ControlNile PheronNo ratings yet

- GRF WKSHP PPT02Document19 pagesGRF WKSHP PPT02Elsad Sadiqov100% (1)

- Global Reporting Format: AIS Aspects (SNOWTAM)Document19 pagesGlobal Reporting Format: AIS Aspects (SNOWTAM)Elsad SadiqovNo ratings yet

- IMS ManualDocument66 pagesIMS Manualghafoorian_khoshgovar1488No ratings yet

- Dynapac 1Document16 pagesDynapac 1Ashwin KulkarniNo ratings yet

- ECDIS Standing Orders by Master - DHTPeony - MARIS9000Document14 pagesECDIS Standing Orders by Master - DHTPeony - MARIS9000Harbinder SinghNo ratings yet

- C2SAT Catalogue V1.71 PDFDocument35 pagesC2SAT Catalogue V1.71 PDFOrionTroconisNo ratings yet

- Optimoor CapabilitiesDocument2 pagesOptimoor CapabilitiesIgnatius SamrajNo ratings yet

- An Investigation of The Distribution of Mobile Crane Loads For Construction ProjectsDocument9 pagesAn Investigation of The Distribution of Mobile Crane Loads For Construction ProjectsrodrigoNo ratings yet

- Test Bench Algorithms For Catamaran Roll Simulation (Lipko)Document11 pagesTest Bench Algorithms For Catamaran Roll Simulation (Lipko)naufragatoNo ratings yet

- Site Suitability Report C05XQ: Barn ElmsDocument85 pagesSite Suitability Report C05XQ: Barn Elmsinfo1639No ratings yet

- Method Statement of Plate Load Test: Dhaka Mass Rapid Transit Development ProjectDocument7 pagesMethod Statement of Plate Load Test: Dhaka Mass Rapid Transit Development ProjectAminulIslamNo ratings yet

- AGC Theory & DescriptionDocument11 pagesAGC Theory & DescriptionAnil SharmaNo ratings yet

- F. Goto: Niigata Engineering Co.: Development of A Robot Asphalt PaverDocument8 pagesF. Goto: Niigata Engineering Co.: Development of A Robot Asphalt PaverKadirNo ratings yet

- Osprey - Fpso Tanker Berthing and Position TrackingDocument6 pagesOsprey - Fpso Tanker Berthing and Position TrackingArun Kumar PancharajNo ratings yet

- Geotech. Eng. SoftwareDocument10 pagesGeotech. Eng. SoftwareJAY PATELNo ratings yet

- Core Gamma Logger System PDFDocument3 pagesCore Gamma Logger System PDFamirakhavansafarNo ratings yet

- Vertical Vessel Foundation Design-Sample PointsDocument3 pagesVertical Vessel Foundation Design-Sample PointsHUSSAIN PATTANNo ratings yet

- IAC2014 - IC-CAT - SteveRyan Caterpiller 2Document17 pagesIAC2014 - IC-CAT - SteveRyan Caterpiller 2AndresNo ratings yet

- Gagan+ Irnss: Dr.K.Krishna NaikDocument31 pagesGagan+ Irnss: Dr.K.Krishna Naikamrutha lahariNo ratings yet

- Robotics and Automation Astrandal VigneshDocument2 pagesRobotics and Automation Astrandal VigneshVIGNESH L RNo ratings yet

- Eee Zg512 Ec-3r First Sem 2013-2014Document5 pagesEee Zg512 Ec-3r First Sem 2013-2014Shivam ShuklaNo ratings yet

- S100 RTK Receiver User Guide: September 3, 2020Document59 pagesS100 RTK Receiver User Guide: September 3, 2020Edmundo Oña Puga ッNo ratings yet

- Advisory Circular: Global Reporting Format (GRF) For Runway Surface ConditionsDocument8 pagesAdvisory Circular: Global Reporting Format (GRF) For Runway Surface ConditionsElsad SadiqovNo ratings yet

- 4 Flexible Pavement Design 2018 PDFDocument73 pages4 Flexible Pavement Design 2018 PDFMohd Nasharuddin100% (1)

- Site Suitability Report C07AR/CL008: Dormay StreetDocument80 pagesSite Suitability Report C07AR/CL008: Dormay Streetinfo1639No ratings yet

- ICRollersDocument54 pagesICRollersoustadhNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Good Meetings Practice DocumentDocument4 pagesGood Meetings Practice DocumentHussain ElarabiNo ratings yet

- Lessons Learned Checklist TemplateDocument4 pagesLessons Learned Checklist TemplateHussain ElarabiNo ratings yet

- Issue Log TemplateDocument4 pagesIssue Log TemplateHussain ElarabiNo ratings yet

- WordDocument76 pagesWordHussain ElarabiNo ratings yet

- Customer Reference Rating SummaryDocument3 pagesCustomer Reference Rating SummaryHussain ElarabiNo ratings yet

- Risk Management Plan TemplateDocument4 pagesRisk Management Plan TemplateHussain ElarabiNo ratings yet

- Consultant Evaluation SummaryDocument2 pagesConsultant Evaluation SummaryHussain ElarabiNo ratings yet

- Project Plan TemplateDocument4 pagesProject Plan TemplateHussain ElarabiNo ratings yet

- Project Budget PlannerDocument25 pagesProject Budget PlannerHussain ElarabiNo ratings yet

- Change Request Form TemplateDocument3 pagesChange Request Form TemplateHussain ElarabiNo ratings yet

- Meeting Minutes TemplateDocument2 pagesMeeting Minutes TemplateHussain ElarabiNo ratings yet

- Communication Plan TemplateDocument6 pagesCommunication Plan TemplateHussain ElarabiNo ratings yet

- Weighing Your OptionsDocument53 pagesWeighing Your OptionsHussain ElarabiNo ratings yet

- Checklist For Equipment - SafetyDocument43 pagesChecklist For Equipment - SafetyHussain ElarabiNo ratings yet

- General Contractor Qa QC Plan Complete SampleDocument28 pagesGeneral Contractor Qa QC Plan Complete SampleHussain ElarabiNo ratings yet

- Change Management Plan TemplateDocument6 pagesChange Management Plan TemplateHussain ElarabiNo ratings yet

- Scope Statement TemplateDocument4 pagesScope Statement TemplateHussain ElarabiNo ratings yet

- Project Planning Risk Evaluation Checklist: 1. InstructionsDocument6 pagesProject Planning Risk Evaluation Checklist: 1. InstructionsnsadnanNo ratings yet

- WBS DictionaryDocument10 pagesWBS DictionaryHussain ElarabiNo ratings yet