Professional Documents

Culture Documents

Boiler Change Over BL1802

Boiler Change Over BL1802

Uploaded by

ebin_thankachan1988Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Change Over BL1802

Boiler Change Over BL1802

Uploaded by

ebin_thankachan1988Copyright:

Available Formats

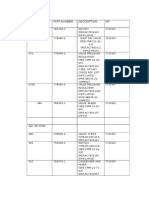

Boiler Change Over (BL1801--------BL1802)

Open vent valve Open water valve for draining for drum level 50% Ask operator to close the water drain valve when level reaches below 70mm (LC1808)

Put PM1838---MAN Mode Set MV----3% When Drum level LC 1808 come Put SV------35 mm Put LC1808 -----AUTO Mode

(35-37)

Ask operator to ensure water isolation valve in open condition Ask operator to start boiler On reaching boiler to Main Burner Ignition Position ,automatically (MAN-CAS)

FC1818------------CAS Mode Make FQ1805(fuel gas)---200-250NM3/hr Adjust PM1838 MV----2-3% Monitor PR1819 carefully.steam drum pressure(It starts Increasing) When PR1819 -----------3.0 kg/cm2 Ask operator to open the stean drum valve When PR 1819----------9.0 kg/cm2 Ask operator to open receiver valve Monitor PC1840 Fluctuation Put PM1838--------AUTO Mode Load sharing (XR0001)

Give the sharing SV for XR0001 ,when PC1840 PVgoes less than SV Parameters decreases on stopping boiler & increases on starting boiler

XR0001 1-----0.9 0.8 0.7 0.6 0.5 0.4 BL1801-1 BL1802-0 0.3 0.2 0.1 0 Bl1802 full loaded

On reaching XR001-----Zero, Ask operator to stop Boiler

Close receiver valve Off Boiler Close steam drum valve (UP)

On stopping Boiler monitor PC1840 & PR1819 Put LC1808 -----CAS Mode & watch

Start Hydrazine Pump (15 stroke) Po4 kept stopstart after lab result Open CBD Flow (350LPH)

On stopping boiler PC1840 WILL Reduce Then increase the PC1840 .SV & When PV starts rising Make PC1840 .SV normal Keep running both Po4 & Hydrazine pump for stopping boiler until waterl filling

After 5 min Put LC1806 (BL1801)-----CAS----AUTO PM 1836(BL1801)----AUTO----MAN,,,,(MV0)

You might also like

- Framo Ballast Operation ManualDocument13 pagesFramo Ballast Operation Manualspamalstublieft183275% (4)

- Pierburg 2e3 Maintenance and RepairDocument11 pagesPierburg 2e3 Maintenance and Repairq1q1q1q1100% (2)

- Boiler LogicsDocument42 pagesBoiler LogicsSupratim Pal100% (2)

- Blow Off Valves DescriptionDocument12 pagesBlow Off Valves DescriptionParmeshwar Nath TripathiNo ratings yet

- Predstavitev Prednosti Novih AQUAREA F-Generacije Toplotnih ČrpalkDocument51 pagesPredstavitev Prednosti Novih AQUAREA F-Generacije Toplotnih ČrpalkBurek TurekNo ratings yet

- A320 Questionnaire1Document142 pagesA320 Questionnaire1alegiustizieri77% (22)

- LPBP HPSU Document PDFDocument131 pagesLPBP HPSU Document PDFGanga PrasadNo ratings yet

- 60 Ton Per HR Advance Empire Boiler Operation ManualDocument15 pages60 Ton Per HR Advance Empire Boiler Operation Manualrozg788152100% (1)

- MS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Document12 pagesMS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Prakash WarrierNo ratings yet

- Updated Standard Operation Manual For Tank Vent Gas Recovery System Feb. 2013Document3 pagesUpdated Standard Operation Manual For Tank Vent Gas Recovery System Feb. 2013Steve WanNo ratings yet

- Unit Cold Start Up RizalDocument11 pagesUnit Cold Start Up RizalDillah JRNo ratings yet

- All About HidrolicDocument7 pagesAll About Hidrolicpiteng1945100% (3)

- Npti Training ManualDocument34 pagesNpti Training Manualsanju0156No ratings yet

- Чеклист - Подготовка паровой системыDocument5 pagesЧеклист - Подготовка паровой системыСлава ТрофимовNo ratings yet

- Reciprocating CompressorDocument37 pagesReciprocating CompressorJithin DasNo ratings yet

- RTR RHSG Start-Up Time Chart (Cold Start-Up)Document8 pagesRTR RHSG Start-Up Time Chart (Cold Start-Up)Sarah Frazier100% (1)

- List of Equipment Handling 060309Document1 pageList of Equipment Handling 060309ZoebairNo ratings yet

- MFTDocument5 pagesMFTguddu yadav100% (1)

- Frick CompressorDocument37 pagesFrick CompressorAnuj Gupta100% (1)

- Fuel Gas System DescriptionDocument19 pagesFuel Gas System DescriptionParmeshwar Nath TripathiNo ratings yet

- 2.3.2 GT DetailsDocument40 pages2.3.2 GT DetailsSarah Cohen100% (3)

- Table DickyDocument7 pagesTable DickyRestianingNo ratings yet

- Group PresentationDocument46 pagesGroup PresentationkrishnamanikandanNo ratings yet

- Gas Plant - 3Document67 pagesGas Plant - 3viettanctNo ratings yet

- Unit Normal Shutdown To ColdDocument100 pagesUnit Normal Shutdown To Coldishak100% (2)

- Basic Chiller System Design Part1Document55 pagesBasic Chiller System Design Part1Sivakumar Nadaraja100% (2)

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- HP LP BypassDocument37 pagesHP LP BypassSCE RIHANDNo ratings yet

- Control ProtectionDocument81 pagesControl ProtectionFebry Aryanto100% (1)

- EmergencyDocument24 pagesEmergencySanjeevImprove100% (1)

- Fsss Comon LogicDocument5 pagesFsss Comon LogicKUNALJAYNo ratings yet

- Brochure Console Units - MIHP09-18 1Document2 pagesBrochure Console Units - MIHP09-18 1alogentleNo ratings yet

- AP GBDocument2 pagesAP GBTitu NicuNo ratings yet

- LP Bypass SystemDocument7 pagesLP Bypass SystemJackSparrow86No ratings yet

- Starting Up and Stopping of The GasplantDocument5 pagesStarting Up and Stopping of The GasplantHendra TambunanNo ratings yet

- E-I-04-Instrument List PDFDocument4 pagesE-I-04-Instrument List PDFManu BadilloNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul_choubey_9100% (1)

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- SC 1200 PneumaticMarineDocument56 pagesSC 1200 PneumaticMarinemavericksilver100% (1)

- Control Philosophy - UpdatedDocument13 pagesControl Philosophy - UpdatedAlvin SmithNo ratings yet

- UVN SeriesDocument3 pagesUVN SeriesgreatharunNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul ranaNo ratings yet

- List of BHEL TOP File Handed Over To DocumentationDocument578 pagesList of BHEL TOP File Handed Over To DocumentationNaresh PattanaikNo ratings yet

- Lecture On ATRS & Speed-Load ControlDocument44 pagesLecture On ATRS & Speed-Load Control06nikhil100% (3)

- TR Tram ENDocument33 pagesTR Tram ENKique Angeles88% (8)

- MF6400 WSM 09 en PDFDocument632 pagesMF6400 WSM 09 en PDFosteanuNo ratings yet

- Preparation and RequirementDocument2 pagesPreparation and RequirementAdy FardyNo ratings yet

- Check List GT Ready To Start Condition: No. Item Keterangan Status CatatanDocument9 pagesCheck List GT Ready To Start Condition: No. Item Keterangan Status Catatanmail_mulyadi5151No ratings yet

- Operation Boiler Bed 130 T For Steam BlowingDocument17 pagesOperation Boiler Bed 130 T For Steam BlowingerickwasaNo ratings yet

- Startup TurbinDocument15 pagesStartup TurbinHans AntartikaNo ratings yet

- Ata 21 Air ConditioningDocument9 pagesAta 21 Air Conditioninggreatest everNo ratings yet

- WO. Type WO. No. Description Tag Status: S/D Activity"Document1 pageWO. Type WO. No. Description Tag Status: S/D Activity"HashemAliHashemNo ratings yet

- Specs of Indoor UnitsDocument17 pagesSpecs of Indoor UnitsShanmugasundaram RaghuramanNo ratings yet

- Prodialog Alarm CodesDocument4 pagesProdialog Alarm CodesbozionelosNo ratings yet

- 210 MW O & M AnualDocument207 pages210 MW O & M Anualsenthil031277100% (2)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Fecl3 CoagulationDocument8 pagesFecl3 Coagulationebin_thankachan1988No ratings yet

- Jordan DetailsDocument60 pagesJordan Detailsebin_thankachan1988No ratings yet

- Oxidation Is Loss of Electrons. Reduction Is Gain of ElectronsDocument1 pageOxidation Is Loss of Electrons. Reduction Is Gain of Electronsebin_thankachan1988No ratings yet

- Pumps&control SystemDocument103 pagesPumps&control Systemebin_thankachan1988No ratings yet

- Ejectors: Principles and BenefitsDocument2 pagesEjectors: Principles and Benefitsebin_thankachan1988No ratings yet

- Fluid Bed DryerDocument5 pagesFluid Bed Dryerebin_thankachan1988No ratings yet