Professional Documents

Culture Documents

Initial Design Considerations

Initial Design Considerations

Uploaded by

ioanchiCopyright:

Available Formats

You might also like

- Textbook Promoting Successful Transition To Adulthood For Students With Disabilities 1St Edition Robert L Morgan Ebook All Chapter PDFDocument53 pagesTextbook Promoting Successful Transition To Adulthood For Students With Disabilities 1St Edition Robert L Morgan Ebook All Chapter PDFvicki.vaught30780% (5)

- Construction Kickoff Meeting AgendaDocument3 pagesConstruction Kickoff Meeting AgendaTrajce StojanovNo ratings yet

- Control Panel LayoutDocument15 pagesControl Panel Layoutreddylogin100% (2)

- Verification of Lifting EquipmentDocument14 pagesVerification of Lifting EquipmentsurnaikNo ratings yet

- SAP BO Developer Interview Questions and AnswersDocument7 pagesSAP BO Developer Interview Questions and AnswersPruthve RaajNo ratings yet

- LeanBooklet in OrderDocument32 pagesLeanBooklet in OrderioanchiNo ratings yet

- Intrusion Detection Guide Fnvbdo PDFDocument139 pagesIntrusion Detection Guide Fnvbdo PDFHarish JainNo ratings yet

- Investment AgreementDocument2 pagesInvestment AgreementNaif Omar100% (1)

- Automation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionDocument24 pagesAutomation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionMuhammad Adeel Ahsen100% (1)

- Sms 32 V 50Document107 pagesSms 32 V 50Mihret SaracNo ratings yet

- Temperature Sensor Using Microcontroller Using 8051: B Tech (Telecommunication), Project Stage - IDocument20 pagesTemperature Sensor Using Microcontroller Using 8051: B Tech (Telecommunication), Project Stage - Iprateek2022No ratings yet

- MySAP TipsDocument28 pagesMySAP TipsSyed Nadir Haseeb Bukhari100% (1)

- IES200 5 Digital Circuits and Design 2 Laboratory Program M eDocument8 pagesIES200 5 Digital Circuits and Design 2 Laboratory Program M eMathew ClewlowNo ratings yet

- Unit I Overview & Instructions: Cs6303-Computer ArchitectureDocument16 pagesUnit I Overview & Instructions: Cs6303-Computer Architecturetamizhanps100% (1)

- Design Patterns LabDocument29 pagesDesign Patterns Labssambangi555No ratings yet

- Autostructure - The Easy Way To Create The Internal Structure of Your ShipDocument17 pagesAutostructure - The Easy Way To Create The Internal Structure of Your ShipSetyo ThreebNo ratings yet

- OPNET IT Guru Analysis of MPLS Implementation Benefits in WSN Over IP For 6LoWPAN Network Nodes.Document33 pagesOPNET IT Guru Analysis of MPLS Implementation Benefits in WSN Over IP For 6LoWPAN Network Nodes.Wao Eric WamolaNo ratings yet

- Getting Acquainted With The SAP R/3 Interface (Release 4.6 C), and The Sales and Distribution ProcessDocument8 pagesGetting Acquainted With The SAP R/3 Interface (Release 4.6 C), and The Sales and Distribution ProcessanandhuslmNo ratings yet

- Introduction To Simulink For Simulating Amplitude Modulation and DemodulationDocument7 pagesIntroduction To Simulink For Simulating Amplitude Modulation and DemodulationImam S KrisnaNo ratings yet

- C-Guide To CDMA Network Interference Test-20070526-A-2.0Document43 pagesC-Guide To CDMA Network Interference Test-20070526-A-2.0Jackson A. PlusNo ratings yet

- Real Time Systems 7th Sem ECE VTU Unit 1 Introduction To Real Time Systems RamisuniverseDocument10 pagesReal Time Systems 7th Sem ECE VTU Unit 1 Introduction To Real Time Systems RamisuniverseMatthew BattleNo ratings yet

- Chatlog 2-22-14 To 4 - 27 - 14 - Weekend Performance Tuning - Analyzing With DBA Skillsets - Every Sat - Sun 10 - 00 Am To 5 - 00 PM 2014-04-19 13 - 58Document2 pagesChatlog 2-22-14 To 4 - 27 - 14 - Weekend Performance Tuning - Analyzing With DBA Skillsets - Every Sat - Sun 10 - 00 Am To 5 - 00 PM 2014-04-19 13 - 58KamilarustamNo ratings yet

- Notes On Solid State InterlockingDocument58 pagesNotes On Solid State InterlockingElton RibeiroNo ratings yet

- UNIT-1 Introduction To Embedded Systems Two Mark Questions and AnswersDocument30 pagesUNIT-1 Introduction To Embedded Systems Two Mark Questions and AnswersBharath RamanNo ratings yet

- Oracle E Business Suite R12 BOM and WIPDocument27 pagesOracle E Business Suite R12 BOM and WIPSenthil KumarNo ratings yet

- Fieldbus Calculator User Manual V1 5 0Document18 pagesFieldbus Calculator User Manual V1 5 0giusssyNo ratings yet

- Notes On Parts ListDocument18 pagesNotes On Parts Listplan2222100% (1)

- Experiment No. 3 Tanner Ic Work Flow Waveform Using W-Edit 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)Document4 pagesExperiment No. 3 Tanner Ic Work Flow Waveform Using W-Edit 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)robertz_tolentino014No ratings yet

- Section Low Voltage Motor Control Centers Part 1 - GeneralDocument8 pagesSection Low Voltage Motor Control Centers Part 1 - GeneralNardi VallejoNo ratings yet

- ECC PT1 (12) 040 Orange SeamcatDocument3 pagesECC PT1 (12) 040 Orange SeamcatRina PuspitasariNo ratings yet

- Knitting CalculationsDocument11 pagesKnitting CalculationsK.s. RameshNo ratings yet

- Tutorial For Urbano Canalis 7 Version 3Document74 pagesTutorial For Urbano Canalis 7 Version 3Carlos Macedo CarvalhoNo ratings yet

- Shailesh Singh Visen: ObjectiveDocument4 pagesShailesh Singh Visen: ObjectiveSurya NandaNo ratings yet

- Lanmark Class F SFTP en 2006Document17 pagesLanmark Class F SFTP en 2006alecs126No ratings yet

- HAN ReportDocument19 pagesHAN ReportVarun SharmaNo ratings yet

- Preparation of Transformer SpecDocument57 pagesPreparation of Transformer SpecboopelectraNo ratings yet

- Lant Control Design Handbook 27LH2V v3 0 3Document112 pagesLant Control Design Handbook 27LH2V v3 0 3danena88No ratings yet

- Avr+lcd ReportDocument95 pagesAvr+lcd ReportyrikkiNo ratings yet

- Introduction To The Atmel Atmega16 Microcontroller: Learning ObjectivesDocument13 pagesIntroduction To The Atmel Atmega16 Microcontroller: Learning Objectivesraj4110640No ratings yet

- Factory Layout Principles: UK-RF Closed Nuclear Cities PartnershipDocument14 pagesFactory Layout Principles: UK-RF Closed Nuclear Cities PartnershipSikander GirgoukarNo ratings yet

- Informatica Map/Session Tuning Covers Basic, Intermediate, and Advanced Tuning Practices. (By: Dan Linstedt)Document14 pagesInformatica Map/Session Tuning Covers Basic, Intermediate, and Advanced Tuning Practices. (By: Dan Linstedt)narendrareddybanthiNo ratings yet

- EAM Upgrade To 12.1.xDocument16 pagesEAM Upgrade To 12.1.xPritesh MoganeNo ratings yet

- Tuning GuideDocument11 pagesTuning GuidePham LongNo ratings yet

- dSPACE Tutorial PDFDocument22 pagesdSPACE Tutorial PDFHichem HamdiNo ratings yet

- DWLR, Bubbler Type (SW)Document7 pagesDWLR, Bubbler Type (SW)hydrologyproject0No ratings yet

- Lesson Mechanalysis - The Key To Machinery ConditionDocument13 pagesLesson Mechanalysis - The Key To Machinery Conditionmister pogiNo ratings yet

- AbInitio FAQsDocument14 pagesAbInitio FAQssarvesh_mishraNo ratings yet

- UMTS Network Post Luanch Optimization and Evolution TrainingDocument170 pagesUMTS Network Post Luanch Optimization and Evolution TrainingFouzan SaeedNo ratings yet

- Section - 7 Water Treatment PlantDocument24 pagesSection - 7 Water Treatment PlantRavi ShankarNo ratings yet

- CBC-RAC Servicing (Domestic) NC IIDocument99 pagesCBC-RAC Servicing (Domestic) NC IIBinalonan Pangasinan100% (2)

- WJ59FF (Wuxi Wenjiao Free Fall Lifeboat)Document33 pagesWJ59FF (Wuxi Wenjiao Free Fall Lifeboat)abu_shofiaNo ratings yet

- Hammer Quick Lessons PDFDocument19 pagesHammer Quick Lessons PDFsebasfarsaNo ratings yet

- Ewsd-Electronic Switching System DigitalDocument44 pagesEwsd-Electronic Switching System Digitalvandong87dnNo ratings yet

- Optimisation Guideline PA2Document36 pagesOptimisation Guideline PA2engineermajiddNo ratings yet

- LecoDocument45 pagesLecoSameera Chaminga100% (1)

- 1 What Are The Major Differences Between ESX 3.5 and Vsphere?Document8 pages1 What Are The Major Differences Between ESX 3.5 and Vsphere?ramesh2440No ratings yet

- Quanser Qbot - ManualDocument23 pagesQuanser Qbot - ManualCarlos Solon Soares Guimarães Jr.No ratings yet

- Schematics Tutorial Creating SchematicDocument8 pagesSchematics Tutorial Creating SchematicJenish MacwanNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- Debugging Systems-on-Chip: Communication-centric and Abstraction-based TechniquesFrom EverandDebugging Systems-on-Chip: Communication-centric and Abstraction-based TechniquesNo ratings yet

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Automotive Equipment Usage and Repair StrategiesFrom EverandAutomotive Equipment Usage and Repair StrategiesRating: 5 out of 5 stars5/5 (1)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- Ussr Germany NDocument110 pagesUssr Germany NioanchiNo ratings yet

- Twelve Systems Engineering RolesDocument12 pagesTwelve Systems Engineering RolesioanchiNo ratings yet

- Materials SelectionDocument3 pagesMaterials SelectionioanchiNo ratings yet

- The Prehistoric Background of Illyrian A PDFDocument11 pagesThe Prehistoric Background of Illyrian A PDFioanchiNo ratings yet

- Afghanistan 1979, The War That Changed The World: Director(s) : Gulya MIRZOEVA Writer(s) : Gulya MIRZOEVADocument2 pagesAfghanistan 1979, The War That Changed The World: Director(s) : Gulya MIRZOEVA Writer(s) : Gulya MIRZOEVAioanchiNo ratings yet

- BosDocument29 pagesBosioanchiNo ratings yet

- COG VT Operating ManualDocument7 pagesCOG VT Operating ManualioanchiNo ratings yet

- Bucket ElevatorsDocument36 pagesBucket Elevatorsioanchi100% (1)

- Laser and Waterjet CapabilitiesDocument5 pagesLaser and Waterjet CapabilitiesioanchiNo ratings yet

- Materials & FinishesDocument7 pagesMaterials & FinishesioanchiNo ratings yet

- Automotive Study RO-SBDocument69 pagesAutomotive Study RO-SBioanchiNo ratings yet

- GT&C Canadian ConstructionDocument34 pagesGT&C Canadian ConstructionioanchiNo ratings yet

- OSHA Risk Assessment Toolchecklist For Hazard and Sectors Part 3 and 4Document69 pagesOSHA Risk Assessment Toolchecklist For Hazard and Sectors Part 3 and 4ioanchiNo ratings yet

- Sample-Risk Assessment & Safe Work Method StatementDocument4 pagesSample-Risk Assessment & Safe Work Method StatementioanchiNo ratings yet

- Machinery Cost Estimates-IIIDocument52 pagesMachinery Cost Estimates-IIIioanchiNo ratings yet

- Mechanical Design Standards: Bending Guidelines 1Document9 pagesMechanical Design Standards: Bending Guidelines 1ioanchiNo ratings yet

- Tool Steel SeminarDocument23 pagesTool Steel SeminarioanchiNo ratings yet

- Bin and Hopper Design LectureDocument73 pagesBin and Hopper Design LectureGanesh.MahendraNo ratings yet

- Sop MMD 08 11 Purchase Order Terms and Conditions PDFDocument7 pagesSop MMD 08 11 Purchase Order Terms and Conditions PDFIip EriyaniNo ratings yet

- D H Reid - Organic Compounds of Sulphur, Selenium, and Tellurium Vol 1-Royal Society of Chemistry (1970)Document518 pagesD H Reid - Organic Compounds of Sulphur, Selenium, and Tellurium Vol 1-Royal Society of Chemistry (1970)julianpellegrini860No ratings yet

- Myanmar Companies Law 2017Document188 pagesMyanmar Companies Law 2017Let's Save Myanmar100% (1)

- BCG GE McKinsey MatrixDocument22 pagesBCG GE McKinsey MatrixAthmanath SR KrishnanNo ratings yet

- Regional Trial Court: Motion To Quash Search WarrantDocument3 pagesRegional Trial Court: Motion To Quash Search WarrantPaulo VillarinNo ratings yet

- AWS Well Architected FrameworkDocument30 pagesAWS Well Architected FrameworkkichnaNo ratings yet

- Inquiries and Immersion, Krg846Document33 pagesInquiries and Immersion, Krg846Hannah Louise Gutang PortilloNo ratings yet

- MDSW TamilNadu06Document14 pagesMDSW TamilNadu06miningnova1No ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

- Data Communication and Networking Prelims ExamDocument7 pagesData Communication and Networking Prelims ExamSagarAnchalkarNo ratings yet

- Customer Satisfaction Employee InvolvementDocument35 pagesCustomer Satisfaction Employee InvolvementSARA JANE CAMBRONERONo ratings yet

- Doe School PlanDocument16 pagesDoe School PlanHNNNo ratings yet

- How A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Document87 pagesHow A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Michaele ErmiasNo ratings yet

- Yoseph ShiferawDocument72 pagesYoseph Shiferawmaheder wegayehuNo ratings yet

- Investment and Portfolio Management: ACFN 3201Document16 pagesInvestment and Portfolio Management: ACFN 3201Bantamkak FikaduNo ratings yet

- Manulife Smart Call Call MenuDocument1 pageManulife Smart Call Call MenuNazreen AmirdeenNo ratings yet

- Saudi Indian Embassy ContactDocument4 pagesSaudi Indian Embassy ContactjagateesanNo ratings yet

- The 60 MM Diameter Solid Shaft Is Subjected To The... PDFDocument3 pagesThe 60 MM Diameter Solid Shaft Is Subjected To The... PDFxy2h5bjs27No ratings yet

- Südmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesDocument2 pagesSüdmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesBob DylanNo ratings yet

- Dwnload Full Organization Development The Process of Leading Organizational Change 4th Edition Anderson Test Bank PDFDocument35 pagesDwnload Full Organization Development The Process of Leading Organizational Change 4th Edition Anderson Test Bank PDFliamhe2qr8100% (15)

- Institute of Cost and Management Accountants of Pakistan: Employment Application FormDocument2 pagesInstitute of Cost and Management Accountants of Pakistan: Employment Application FormRashidAliNo ratings yet

- CV (2) - 2Document3 pagesCV (2) - 2abhishek.berkmanNo ratings yet

- History of Insurance-WWW - SELUR.TKDocument9 pagesHistory of Insurance-WWW - SELUR.TKselurtimaNo ratings yet

- XrayDocument9 pagesXraySohail AhmedNo ratings yet

- Pumba Cap 3 2022Document15 pagesPumba Cap 3 2022adityakamble070103No ratings yet

- 3 Odometer DisclosureDocument1 page3 Odometer DisclosureJuan Carlos MartinezNo ratings yet

Initial Design Considerations

Initial Design Considerations

Uploaded by

ioanchiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Initial Design Considerations

Initial Design Considerations

Uploaded by

ioanchiCopyright:

Available Formats

Mechanical Design Department Design Standards & Practices

Initial Design Considerations

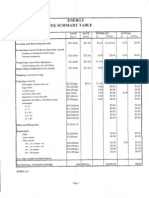

Initial Design Considerations.............................................................................................1 Drawing Layout (General Assemblies)....................................................................... Drawing Layout (System!"ell Layouts)......................................................................# $asic Design Practices..................................................................................................% $earing Applications....................................................................................................&

215466380.doc Rev date Nov. 21, 2002

Mechanical Design Department Design Standards & Practices

Drawing Layout (General Assemblies)

1. The general assembly should have a m n mum o! t"o v e"s but #re!erably three. Th s " ll #rov de the sho# " th a clear # cture o! the des gn. $! necessary nclude add t onal sheets or other v e"s. 2. The general assembly dra" ng must be dra"n to scale, th s " ll be the master !or chec% ng the des gn and creat ng the deta ls. 3. &rov de all the necessary re!erence d mens ons on the general assembly, re!er to stat on assembly gu del nes. 'e.g. he ght o! #art, he ght o! tool, stro%e o! tool, etc.( These d mens ons must be ver ! ed dur ng the val dat on #rocedure. 4. $! necessary nclude notes on the e)#lanat ons o! !unct ons or !or other #ert nent n!ormat on. 5. *l"ays sho" the #arts that are be ng assembled n the assembly dra" ng. 6. *l"ays sho" the #os t ons o! mov ng #arts n the general assembly to ensure there are no nter!erences. +. Re!erence other assembl es n #hantom to #rov de a clearer # cture on the !unct on o! the assembly. ', th the names and dra" ng numbers o! the assembl es ncluded( 8. *ssembly dra" ngs should be !ull scale "hen ever #ract cal. -. .se sect on v e"s "hen necessary !or clar ty. 10. /on0t clutter the general assembly " th unnecessary l nes. Ty# cally you should not sho" any more than t"o com#onents dee#. The #ur#ose o! the general assembly s to commun cate a clear understand ng o! the assembly. 11. 1ho" scre"s, do"els, ! tt ngs, sensors etc. "henever t s !elt there may be nter!erence. 12. $t s also m#ortant that the geometry be created us ng three 'better !our( dec mal #laces even ! the d mens on " ll only a##ear " th t"o dec mal #laces. ' .e. .3+5 not .38(. 13. /eta ls should only sho" enough v e"s to #rov de a clear # cture o! the deta l. 14. 2nsure the deta ls are not cluttered. 15. $n *uto3*/ !ollo" the *T1 layer ng standards at all t mes.

215466380.doc Rev date Nov. 21, 2002

Mechanical Design Department Design Standards & Practices

Drawing Layout (System/Cell Layouts)

1. $t s the res#ons b l ty o! the 4echan cal /es gn 5rou# to nclude the n!ormat on outl ned n the 6 ne 6ayout.doc, !ound n 6ayout 5u del nes 7 e)am#les, on the 1ystem layout dra" ng. 8urther note on /uct ng, 9unct on bo)es and ma n electr cal #anel. a. The n!ormat on, n *utocad, res de on a layer labeled :/uct; n the overall system layout '000( or ! necessary on sheet <2 o! th s layout. 1heet <2 may be a s m#l ! ed vers on o! the ma n layout that only sho"s a #hantom outl ne, or a converted 1, em#ty cell, o! each cell. b. The duct layout " ll be develo#ed " th the ass stance o! the 2lectr cal /es gner and " ll be ma nta ned by the 4echan cal /es gner. The 2lectr cal /es gner " ll be res#ons ble !or order ng all duct ng. c. *s changes or rev s ons occur t s the res#ons b l ty o! the 4echan cal /es gner to u#date the layout and n!orm the 2lectr cal /es gner o! any changes. The duct symbols can be !ound n the #ull do"n menu n *utocad.

2. 3ell layouts " ll nclude the n!ormat on outl ned n the 3ell 6ayout.doc, !ound n 6ayout 5u del nes 7 e)am#les. 3ell 6ayouts done n *uto3*/, " ll e)clude any unnecessary l ne "or% that " ll clutter the dra" ng 'e.g. most h dden l nes, all !asteners and most centerl nes(. 3. The cell layout must nclude guard ng, e ther *T1 standard guard ng or #urchased guard ng. The cell guard ng " ll come !rom ts o"n assembly dra" ng, re!er to the 4echan cal *ssembly 1tructure. 8or *T1 guard ng " ll sho" #anel=door s >es and locat ons. /eta l dra" ngs are not re?u red !or *T1 guard ng. $! the cell s be ng guarded " th #urchase guard ng the des gner must re?u s t on the mater al. 4. @unct on bo)es must be sho"n n the cell layout. The mechan cal des gner s to obta n the actual s >e !rom the electr cal des gner a dra" ng o! the actual enclosure to be used. Th s s to ensure the cell has stayed " th n the ma) mum l m ts !or sh ## ng. 1h ## ng 3ons derat ons.doc 5. The locat on and s >e o! the duct ng must be sho"n n the cell layout. 6. 1ho" the locat on o! the valve ban%s and a rl ne #re#arat on e?u #ment. 1ymbols !or these com#onents are acce#table. +. Aalloon any th rd #arty e?u #ment "h ch s not ballooned n other assembl es 'e.g. bo"l !eeders, "elders, etc.(. 8. 1ho" o#erators ! a##l cable. -. B#erators control #anels " ll be sho"n n the cell layout. 215466380.doc Rev date Nov. 21, 2002 3

Mechanical Design Department Design Standards & Practices

10. Aalloon all assembl es and #rov de the assembly number and descr #t on n the AB4 on the dra" ng. 11. *ll stat on=cell descr #t ons must nclude a >one, cell and a stat on number. Th s number " ll a##ear on the dra" ng and the dra" ng reg ster. Re!er to 4echan cal Number ng Area%do"n.doc !or com#lete gu del ne. The add t on o! th s number " ll ta%e u# valuable s#ace " th n our dra" ng descr #t on so be br e! " th your descr #t on. 8or systems that do not have >ones the >one number s one. $t s m#ortant the number ng be cons stent " th the electr cal dra" ngs. 3hec% th s dur ng your rev e" o! the $=B. Th s number " ll be lam nated to the tool ng !or dent ! cat on.

Basic Design Practices

1. Cee# the des gn s m#le. 2. .se standard *T1 hard"are, 1tandard &roducts and 1tandard /es gns "herever #oss ble '"here a##l cable(. $! a mod ! cat on s re?u red to a standard #roduct deta ls o! the change must de documented n the 9ob documentat on. 3. 3hec% the des gn l brar es !or reusable des gns. 4. 3ommerc al #roducts should be used "henever #oss ble. $n most cases th s " ll reduce the cost o! the tool ng and m#rove rel ab l ty. 5. Bn h gh s#eed a##l cat ons des gn the tool ng " th shoc% absorbers or cush on ng dev ces. 6. &er shable tool ng should be des gned as nserts that can be eas ly re#laced. +. /es gn n lubr cat on ! tt ngs and grease grooves "here necessary. 3hec% assembly !or lubr cat on access. 8. /o"els are #re!erred over Ceys '#oc%ets( !or #os t on ng change over tool ng. /o"els are chea#er !or locat ng #arts, but do"els do not ta%e load ng as "ell as #oc%ets. 4ater al select on must be cons dered "hen us ng do"els and #oc%et ng s #re!erred "hen load ng ncreases. -. /es gn serv ceab l ty nto assembl es. 3ons der both ease o! setDu# !or *T1 and ease o! re#a r !or the customer. 3om#onents that may "ear should be eas ly access ble !or change. 10. /es gn rel ab l ty nto assembl es. &oc%et ng or do"el ng such tems as sto# bloc%s, #unches, cyl nder mounts, etc. " ll ensure accurate assembly s?uareness and #os t on ng o! the tool ng "h ch could a!!ect the !unct on. Cee# n m nd the 215466380.doc Rev date Nov. 21, 2002 4

Mechanical Design Department Design Standards & Practices

tool " ll be d sassembled !rom t me to t me and reassemble must be easy and accurate. 11. /es gn access b l ty nto the assembly. 8lo" controls, sensors, sto#s, etc. must be access ble !or ad9ustments. 12. $nclude sensors and mount ng brac%ets n the des gn. 13. 3alculate the cycle t me o! the tool to ensure t s "ell " th n the re?u red mach ne cycle. .se the *T1 t m ng chart !or determ n ng mach ne cycle t me. 14. 2nsure that the actuators are s >ed to handle the loads at the re?u red cycle t me. $t may be necessary to nvolve other des gn #ersonnel to calculate th s. ' .e. motor s >es, etc.( 15. 1#r ngs should not be com#ressed more than 1=2 o! the r length 'chec% manu!acturers recommendat ons(. .se stoc% s#r ngs and nclude s#r ng data n your A.B.4. / e s#r ngs do not com#ress the same amount as com#ress on s#r ngs. 1ee the catalogue !or d e s#r ng data. 16. * note should be #laced on the assembly dra" ng that ncludes s#r ng !orces, stro%es, loads etc. 1+. /o not reta n # vot # ns by #ress ! t. .se 3Dcl #s, set scre"s or reta n ng #lates. 18. /o not bury scre"s under other tool ng. Th s " ll only add to !rustrat on "hen try ng to d sassemble the tool ng. 1-. 3learance holes that mount "eldments to the tables should be 1 standard clearance hole s >e larger than the actual !astener re?u red to mount the assembly ' .e. 410 clearance hole !or an 48 !astener(. 20. 3yl nders should al"ays have !loat ng cou#l ngs '8esto !le) ble connectors, TD nuts(. 21. $nclude an a##ro#r ate amount o! e)tra stro%e n sl des !or ad9ustment 'ad9ustment n e ther d rect on(. 22. Rev e" your des gn !or !le) ng and load ng. $t may be necessary to nvolve other des gn #ersonnel to analy>e th s. 23. 2nsure the des gn !ollo"s correct ergonom c standards. 4a%e the des gn com!ortable to use, ma nta n and re#a r. 1ee E/es gn !or 2rgonom csE. 24. 2nsure the des gn !ollo"s the Fealth and 1a!ety standards. 1ee :/es gn !or 1a!ety;. 25. Rev e" the accuracy o! the a##l cat on to ensure the tool can accommodate the accuracy re?u rements. The tolerance o! tool must match the a##l cat on n accuracy. 26. ,hen handl ng or # c% ng a customer #art, use the h gh accuracy !eatures on the #art. 215466380.doc Rev date Nov. 21, 2002 5

Mechanical Design Department Design Standards & Practices

2+. *ll &allets and d al nests must be numbered. The standard des gn s a tag made !rom 1=16; 5ravo#ly, '"h te( !astened " th a <2 ) 1=4 dr ve r vet or a <4D40 ) 1=4 &h l #s head mach ne scre". Th s des gn should cover most a##l cat ons ho"ever there may be cases "here an alternat ve s re?u red. The dra" ng ! le can be located through the 1ol d,or%s !eature #allet under 8GH*T1 /es gnsH1, 8eature &alletH&allet &artsH4 sc. &arts. 28. $! an assembly re?u res a sh ll or tool !or setu# #ur#oses nclude the des gn and deta l o! th s tool " th the assembly. 8ollo" $1B #rocedure. 2-. &rov de ta##ed holes !or l !t ng heavy tool ng by crane or !or%l !t. 30. *ll angular and #rec s on ad9ustable sto# scre"s should have s#her cal ends and be hardened. 31. /o"el holes n bases to be trans!erred to tableto# at assembly should be ! rst dr lled 1=2mm or 1=32; unders >e o! do"el. 32. *ll &allets and d al nests re?u re 344 ns#ect ons '1ee $1B #rocedure 200.2-( 33. ,hen us ng 6 near Aear ng ra ls, ensure the ra l s #oc%eted dee# enough to clear !or the cham!er. The ra l should never be #oc%eted to a tolerance length" se. Ra ls are never to e)act measurements n the length. The #oc%et should have clearance on both ends. 34. , th h gh tor?ue a##l cat ons '#ulley dr ves, gear dr ves etc.( use :transtor?ue; ta#er loc% bush ngs. 35. $nclude n the des gns, "hen re?u red, cable trac%s, cable trac% mounts and order the mater als. The select on o! cable trac% " ll re?u re n#ut !rom the 2lectr cal /es gner. Iou " ll need to %no" the cable s >es, ?uant ty o! cable n the trac%, ?uant ty o! a r l nes n the trac%, bend rad us o! the cable etc. 36. ,hen attach ng a hose bet"een a grease e9ector and a needle, m n m >e the chance o! grease dr ## ng a!ter e9ect ng by the !ollo" ng methodsG a( use nylon re n!orced hydraul c hose. b( use small d ameter hose '1=8; or J; $/(. c( %ee# hose length to a m n mum. 3+. ,hen us ng a 3amco $nde)er the des gner must clearly label numer cally the nests on the d al #late that s to be mounted on the 3amco. 38. $nstruct ons !or mount ng=mach n ng d al #lates to camco nde)er " th overload clutch are as !ollo"sG 4ount d al #late to nde)er d rectly us ng all mount ng holes. Trans!er one do"el through #late and nto nde)er. ,hen su##ort ng the under s de o! the d al the d al #late should have "ear #lates. The d al #late must be mach ned n these locat ons to #rov de an accurate he ght !or the "ear #lates.

215466380.doc Rev date Nov. 21, 2002

Mechanical Design Department Design Standards & Practices

4ach ne d al #late "h le attached to nde)er. 3ycle nde)er nto #os t on !or mach n ng. The d al #late must be mach ned n the locat on o! all d al nests to #rov de an accurate he ght. $nstall clutch assembly to nde)er " th the d al #late '"ear #late on bottom, clutch on to#( Trans!er the t"o '2( e) st ng do"el holes !rom the "ear #late nto the d al #late. NoteG The do"els that are ncluded " th the "ar #late " ll be re?u red !or assembly. / sassemble nde)er, d al #late and clutch. Fave d al #late #lated.

3-. $nstruct ons !or assembly 4ount "ear #late to d al #late us ng e) st ng do"els only. The threaded holes n the "ear #late are used to remove the "ear #late. &lace d al #late " th "ear #late on the nde)er. $nstall the clutch to the nde)er. NoteG The d al #late cannot be scre"ed to the nde)er Bverload clutches are seldom used 'other than customer re?uest(, the reason be ng, that by the t me the overload clutch engages, the damage s usually done(. 3ams and #ro) m ty s" tches are used to sense the d"ell and the nde) o! the camco. These are a standard #roduct. '#lease see standard #roduct manual(

40. ,hen des gn ng gr ##er ! ngers !or the *T1 gr ##ers, the #oc%et !or locat ng the ! nger to the gr ##er should be cleared belo" the mount ng hole. The ! nger should datum o!! the shoulder above the mount ng hole.

Bearing Applications

1. * bush ng length should be at least 1 1=2 t mes the d stance the load s o!!set. The length o! a bush ng should also be 1 1=2 t mes the d ameter 'or " dth( o! the sl d ng member. 2. & vot # ns that carry an o!!set load should be avo ded. 3. Rad al bear ngs should be a #ress ! t to the sha!t or the $./. o! the bear ng. Aear ng tolerances are automat cally created us ng the bear ng tolerance macro ns de our 3*/ so!t"are #rograms. 4. 8or h gh s#eed or h gh load rotary mot ons use some style o! rad al ball bear ng. 5. There are several ty#es o! l near bear ngs ava lable. Ae sure the bear ng ty#e matches the a##l cat on. 6. ,hen us ng l near ball bear ngs and sha!t ng 'Thomson, Aarden, and standard ty#e( al"ays use t"o bear ngs. Th s style o! bear ng has a great amount o! a) al=rotat onal movement "hen us ng only one. 215466380.doc Rev date Nov. 21, 2002 +

Mechanical Design Department Design Standards & Practices

+. $n the case "here bush ngs and locat ng # ns have been used !or locat on #ur#oses ' .e.G change over #late on a #allet( the amount o! # n engagement to the bush ng " ll a!!ect the d !! culty n "h ch the #late s removed !rom the # ns. Bne # n should be round and the other should be d amond sha#ed. The # n engagement should also be m n mal. 8. Ae sure to chec% the ty#es o! load ng "hen us ng rad al ball bear ngs. ' .e.G a) al, rad al( $t may be necessary to use an angular or a style o! bear ng. -. $! a h gh load, h gh #rec s on l near bear ng s re?u red use 1T*R style ra l bear ngs. 10. *l"ays order bear ngs " th seals or sh elds ! the bear ng s e)#osed or not lubr cated

215466380.doc Rev date Nov. 21, 2002

You might also like

- Textbook Promoting Successful Transition To Adulthood For Students With Disabilities 1St Edition Robert L Morgan Ebook All Chapter PDFDocument53 pagesTextbook Promoting Successful Transition To Adulthood For Students With Disabilities 1St Edition Robert L Morgan Ebook All Chapter PDFvicki.vaught30780% (5)

- Construction Kickoff Meeting AgendaDocument3 pagesConstruction Kickoff Meeting AgendaTrajce StojanovNo ratings yet

- Control Panel LayoutDocument15 pagesControl Panel Layoutreddylogin100% (2)

- Verification of Lifting EquipmentDocument14 pagesVerification of Lifting EquipmentsurnaikNo ratings yet

- SAP BO Developer Interview Questions and AnswersDocument7 pagesSAP BO Developer Interview Questions and AnswersPruthve RaajNo ratings yet

- LeanBooklet in OrderDocument32 pagesLeanBooklet in OrderioanchiNo ratings yet

- Intrusion Detection Guide Fnvbdo PDFDocument139 pagesIntrusion Detection Guide Fnvbdo PDFHarish JainNo ratings yet

- Investment AgreementDocument2 pagesInvestment AgreementNaif Omar100% (1)

- Automation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionDocument24 pagesAutomation, Prouction Systems and CIM MP GROOVER CHAPTER 7 SolutionMuhammad Adeel Ahsen100% (1)

- Sms 32 V 50Document107 pagesSms 32 V 50Mihret SaracNo ratings yet

- Temperature Sensor Using Microcontroller Using 8051: B Tech (Telecommunication), Project Stage - IDocument20 pagesTemperature Sensor Using Microcontroller Using 8051: B Tech (Telecommunication), Project Stage - Iprateek2022No ratings yet

- MySAP TipsDocument28 pagesMySAP TipsSyed Nadir Haseeb Bukhari100% (1)

- IES200 5 Digital Circuits and Design 2 Laboratory Program M eDocument8 pagesIES200 5 Digital Circuits and Design 2 Laboratory Program M eMathew ClewlowNo ratings yet

- Unit I Overview & Instructions: Cs6303-Computer ArchitectureDocument16 pagesUnit I Overview & Instructions: Cs6303-Computer Architecturetamizhanps100% (1)

- Design Patterns LabDocument29 pagesDesign Patterns Labssambangi555No ratings yet

- Autostructure - The Easy Way To Create The Internal Structure of Your ShipDocument17 pagesAutostructure - The Easy Way To Create The Internal Structure of Your ShipSetyo ThreebNo ratings yet

- OPNET IT Guru Analysis of MPLS Implementation Benefits in WSN Over IP For 6LoWPAN Network Nodes.Document33 pagesOPNET IT Guru Analysis of MPLS Implementation Benefits in WSN Over IP For 6LoWPAN Network Nodes.Wao Eric WamolaNo ratings yet

- Getting Acquainted With The SAP R/3 Interface (Release 4.6 C), and The Sales and Distribution ProcessDocument8 pagesGetting Acquainted With The SAP R/3 Interface (Release 4.6 C), and The Sales and Distribution ProcessanandhuslmNo ratings yet

- Introduction To Simulink For Simulating Amplitude Modulation and DemodulationDocument7 pagesIntroduction To Simulink For Simulating Amplitude Modulation and DemodulationImam S KrisnaNo ratings yet

- C-Guide To CDMA Network Interference Test-20070526-A-2.0Document43 pagesC-Guide To CDMA Network Interference Test-20070526-A-2.0Jackson A. PlusNo ratings yet

- Real Time Systems 7th Sem ECE VTU Unit 1 Introduction To Real Time Systems RamisuniverseDocument10 pagesReal Time Systems 7th Sem ECE VTU Unit 1 Introduction To Real Time Systems RamisuniverseMatthew BattleNo ratings yet

- Chatlog 2-22-14 To 4 - 27 - 14 - Weekend Performance Tuning - Analyzing With DBA Skillsets - Every Sat - Sun 10 - 00 Am To 5 - 00 PM 2014-04-19 13 - 58Document2 pagesChatlog 2-22-14 To 4 - 27 - 14 - Weekend Performance Tuning - Analyzing With DBA Skillsets - Every Sat - Sun 10 - 00 Am To 5 - 00 PM 2014-04-19 13 - 58KamilarustamNo ratings yet

- Notes On Solid State InterlockingDocument58 pagesNotes On Solid State InterlockingElton RibeiroNo ratings yet

- UNIT-1 Introduction To Embedded Systems Two Mark Questions and AnswersDocument30 pagesUNIT-1 Introduction To Embedded Systems Two Mark Questions and AnswersBharath RamanNo ratings yet

- Oracle E Business Suite R12 BOM and WIPDocument27 pagesOracle E Business Suite R12 BOM and WIPSenthil KumarNo ratings yet

- Fieldbus Calculator User Manual V1 5 0Document18 pagesFieldbus Calculator User Manual V1 5 0giusssyNo ratings yet

- Notes On Parts ListDocument18 pagesNotes On Parts Listplan2222100% (1)

- Experiment No. 3 Tanner Ic Work Flow Waveform Using W-Edit 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)Document4 pagesExperiment No. 3 Tanner Ic Work Flow Waveform Using W-Edit 1. Objective (S) : 2. Intended Learning Outcomes (Ilos)robertz_tolentino014No ratings yet

- Section Low Voltage Motor Control Centers Part 1 - GeneralDocument8 pagesSection Low Voltage Motor Control Centers Part 1 - GeneralNardi VallejoNo ratings yet

- ECC PT1 (12) 040 Orange SeamcatDocument3 pagesECC PT1 (12) 040 Orange SeamcatRina PuspitasariNo ratings yet

- Knitting CalculationsDocument11 pagesKnitting CalculationsK.s. RameshNo ratings yet

- Tutorial For Urbano Canalis 7 Version 3Document74 pagesTutorial For Urbano Canalis 7 Version 3Carlos Macedo CarvalhoNo ratings yet

- Shailesh Singh Visen: ObjectiveDocument4 pagesShailesh Singh Visen: ObjectiveSurya NandaNo ratings yet

- Lanmark Class F SFTP en 2006Document17 pagesLanmark Class F SFTP en 2006alecs126No ratings yet

- HAN ReportDocument19 pagesHAN ReportVarun SharmaNo ratings yet

- Preparation of Transformer SpecDocument57 pagesPreparation of Transformer SpecboopelectraNo ratings yet

- Lant Control Design Handbook 27LH2V v3 0 3Document112 pagesLant Control Design Handbook 27LH2V v3 0 3danena88No ratings yet

- Avr+lcd ReportDocument95 pagesAvr+lcd ReportyrikkiNo ratings yet

- Introduction To The Atmel Atmega16 Microcontroller: Learning ObjectivesDocument13 pagesIntroduction To The Atmel Atmega16 Microcontroller: Learning Objectivesraj4110640No ratings yet

- Factory Layout Principles: UK-RF Closed Nuclear Cities PartnershipDocument14 pagesFactory Layout Principles: UK-RF Closed Nuclear Cities PartnershipSikander GirgoukarNo ratings yet

- Informatica Map/Session Tuning Covers Basic, Intermediate, and Advanced Tuning Practices. (By: Dan Linstedt)Document14 pagesInformatica Map/Session Tuning Covers Basic, Intermediate, and Advanced Tuning Practices. (By: Dan Linstedt)narendrareddybanthiNo ratings yet

- EAM Upgrade To 12.1.xDocument16 pagesEAM Upgrade To 12.1.xPritesh MoganeNo ratings yet

- Tuning GuideDocument11 pagesTuning GuidePham LongNo ratings yet

- dSPACE Tutorial PDFDocument22 pagesdSPACE Tutorial PDFHichem HamdiNo ratings yet

- DWLR, Bubbler Type (SW)Document7 pagesDWLR, Bubbler Type (SW)hydrologyproject0No ratings yet

- Lesson Mechanalysis - The Key To Machinery ConditionDocument13 pagesLesson Mechanalysis - The Key To Machinery Conditionmister pogiNo ratings yet

- AbInitio FAQsDocument14 pagesAbInitio FAQssarvesh_mishraNo ratings yet

- UMTS Network Post Luanch Optimization and Evolution TrainingDocument170 pagesUMTS Network Post Luanch Optimization and Evolution TrainingFouzan SaeedNo ratings yet

- Section - 7 Water Treatment PlantDocument24 pagesSection - 7 Water Treatment PlantRavi ShankarNo ratings yet

- CBC-RAC Servicing (Domestic) NC IIDocument99 pagesCBC-RAC Servicing (Domestic) NC IIBinalonan Pangasinan100% (2)

- WJ59FF (Wuxi Wenjiao Free Fall Lifeboat)Document33 pagesWJ59FF (Wuxi Wenjiao Free Fall Lifeboat)abu_shofiaNo ratings yet

- Hammer Quick Lessons PDFDocument19 pagesHammer Quick Lessons PDFsebasfarsaNo ratings yet

- Ewsd-Electronic Switching System DigitalDocument44 pagesEwsd-Electronic Switching System Digitalvandong87dnNo ratings yet

- Optimisation Guideline PA2Document36 pagesOptimisation Guideline PA2engineermajiddNo ratings yet

- LecoDocument45 pagesLecoSameera Chaminga100% (1)

- 1 What Are The Major Differences Between ESX 3.5 and Vsphere?Document8 pages1 What Are The Major Differences Between ESX 3.5 and Vsphere?ramesh2440No ratings yet

- Quanser Qbot - ManualDocument23 pagesQuanser Qbot - ManualCarlos Solon Soares Guimarães Jr.No ratings yet

- Schematics Tutorial Creating SchematicDocument8 pagesSchematics Tutorial Creating SchematicJenish MacwanNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- Debugging Systems-on-Chip: Communication-centric and Abstraction-based TechniquesFrom EverandDebugging Systems-on-Chip: Communication-centric and Abstraction-based TechniquesNo ratings yet

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Automotive Equipment Usage and Repair StrategiesFrom EverandAutomotive Equipment Usage and Repair StrategiesRating: 5 out of 5 stars5/5 (1)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- Ussr Germany NDocument110 pagesUssr Germany NioanchiNo ratings yet

- Twelve Systems Engineering RolesDocument12 pagesTwelve Systems Engineering RolesioanchiNo ratings yet

- Materials SelectionDocument3 pagesMaterials SelectionioanchiNo ratings yet

- The Prehistoric Background of Illyrian A PDFDocument11 pagesThe Prehistoric Background of Illyrian A PDFioanchiNo ratings yet

- Afghanistan 1979, The War That Changed The World: Director(s) : Gulya MIRZOEVA Writer(s) : Gulya MIRZOEVADocument2 pagesAfghanistan 1979, The War That Changed The World: Director(s) : Gulya MIRZOEVA Writer(s) : Gulya MIRZOEVAioanchiNo ratings yet

- BosDocument29 pagesBosioanchiNo ratings yet

- COG VT Operating ManualDocument7 pagesCOG VT Operating ManualioanchiNo ratings yet

- Bucket ElevatorsDocument36 pagesBucket Elevatorsioanchi100% (1)

- Laser and Waterjet CapabilitiesDocument5 pagesLaser and Waterjet CapabilitiesioanchiNo ratings yet

- Materials & FinishesDocument7 pagesMaterials & FinishesioanchiNo ratings yet

- Automotive Study RO-SBDocument69 pagesAutomotive Study RO-SBioanchiNo ratings yet

- GT&C Canadian ConstructionDocument34 pagesGT&C Canadian ConstructionioanchiNo ratings yet

- OSHA Risk Assessment Toolchecklist For Hazard and Sectors Part 3 and 4Document69 pagesOSHA Risk Assessment Toolchecklist For Hazard and Sectors Part 3 and 4ioanchiNo ratings yet

- Sample-Risk Assessment & Safe Work Method StatementDocument4 pagesSample-Risk Assessment & Safe Work Method StatementioanchiNo ratings yet

- Machinery Cost Estimates-IIIDocument52 pagesMachinery Cost Estimates-IIIioanchiNo ratings yet

- Mechanical Design Standards: Bending Guidelines 1Document9 pagesMechanical Design Standards: Bending Guidelines 1ioanchiNo ratings yet

- Tool Steel SeminarDocument23 pagesTool Steel SeminarioanchiNo ratings yet

- Bin and Hopper Design LectureDocument73 pagesBin and Hopper Design LectureGanesh.MahendraNo ratings yet

- Sop MMD 08 11 Purchase Order Terms and Conditions PDFDocument7 pagesSop MMD 08 11 Purchase Order Terms and Conditions PDFIip EriyaniNo ratings yet

- D H Reid - Organic Compounds of Sulphur, Selenium, and Tellurium Vol 1-Royal Society of Chemistry (1970)Document518 pagesD H Reid - Organic Compounds of Sulphur, Selenium, and Tellurium Vol 1-Royal Society of Chemistry (1970)julianpellegrini860No ratings yet

- Myanmar Companies Law 2017Document188 pagesMyanmar Companies Law 2017Let's Save Myanmar100% (1)

- BCG GE McKinsey MatrixDocument22 pagesBCG GE McKinsey MatrixAthmanath SR KrishnanNo ratings yet

- Regional Trial Court: Motion To Quash Search WarrantDocument3 pagesRegional Trial Court: Motion To Quash Search WarrantPaulo VillarinNo ratings yet

- AWS Well Architected FrameworkDocument30 pagesAWS Well Architected FrameworkkichnaNo ratings yet

- Inquiries and Immersion, Krg846Document33 pagesInquiries and Immersion, Krg846Hannah Louise Gutang PortilloNo ratings yet

- MDSW TamilNadu06Document14 pagesMDSW TamilNadu06miningnova1No ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

- Data Communication and Networking Prelims ExamDocument7 pagesData Communication and Networking Prelims ExamSagarAnchalkarNo ratings yet

- Customer Satisfaction Employee InvolvementDocument35 pagesCustomer Satisfaction Employee InvolvementSARA JANE CAMBRONERONo ratings yet

- Doe School PlanDocument16 pagesDoe School PlanHNNNo ratings yet

- How A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Document87 pagesHow A GPU Works: Kayvon Fatahalian 15-462 (Fall 2011)Michaele ErmiasNo ratings yet

- Yoseph ShiferawDocument72 pagesYoseph Shiferawmaheder wegayehuNo ratings yet

- Investment and Portfolio Management: ACFN 3201Document16 pagesInvestment and Portfolio Management: ACFN 3201Bantamkak FikaduNo ratings yet

- Manulife Smart Call Call MenuDocument1 pageManulife Smart Call Call MenuNazreen AmirdeenNo ratings yet

- Saudi Indian Embassy ContactDocument4 pagesSaudi Indian Embassy ContactjagateesanNo ratings yet

- The 60 MM Diameter Solid Shaft Is Subjected To The... PDFDocument3 pagesThe 60 MM Diameter Solid Shaft Is Subjected To The... PDFxy2h5bjs27No ratings yet

- Südmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesDocument2 pagesSüdmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesBob DylanNo ratings yet

- Dwnload Full Organization Development The Process of Leading Organizational Change 4th Edition Anderson Test Bank PDFDocument35 pagesDwnload Full Organization Development The Process of Leading Organizational Change 4th Edition Anderson Test Bank PDFliamhe2qr8100% (15)

- Institute of Cost and Management Accountants of Pakistan: Employment Application FormDocument2 pagesInstitute of Cost and Management Accountants of Pakistan: Employment Application FormRashidAliNo ratings yet

- CV (2) - 2Document3 pagesCV (2) - 2abhishek.berkmanNo ratings yet

- History of Insurance-WWW - SELUR.TKDocument9 pagesHistory of Insurance-WWW - SELUR.TKselurtimaNo ratings yet

- XrayDocument9 pagesXraySohail AhmedNo ratings yet

- Pumba Cap 3 2022Document15 pagesPumba Cap 3 2022adityakamble070103No ratings yet

- 3 Odometer DisclosureDocument1 page3 Odometer DisclosureJuan Carlos MartinezNo ratings yet