Professional Documents

Culture Documents

High Efficiency Silicon Solar Cells by plasma-CVD Method

High Efficiency Silicon Solar Cells by plasma-CVD Method

Uploaded by

Diani Ainun NisaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Efficiency Silicon Solar Cells by plasma-CVD Method

High Efficiency Silicon Solar Cells by plasma-CVD Method

Uploaded by

Diani Ainun NisaCopyright:

Available Formats

Sa~r ~

ana Salllt C.M~

ELSEVIER Solar Energy Materials and Solar Cells 34 (1994) 193-199

High efficiency silicon solar cells by plasma-CVD method

K. F u j i m o t o *, Y. Sogawa, K. Shima, Y. O k a y a s u , K. K u m a g a i

Corporate Research and Development Laboratory, Tonen Corporation 1-3-1, Nishi-Tsurugaoka Ohi-machi, lruma-gun, Saitama 356, Japan

Abstract

We have succeeded in obtaining excellent Back Surface Field (BSF) structures by depositing a highly doped silicon layer on the back side of the substrate even though the textured wafer is used. The substantial increase of the spectral response in longer wavelength has been observed and an increase of Voc has also been found. The BSF formation technology, together with the low temperature grown thin a-Si emitter layer with appropriate bandgap, has enabled us to obtain a very high Js of 40.5 m A / c m 2, thus a high active area conversion efficiency of 18.9% (Vo= 0.592 V, FF = 0.789).

1. Introduction To reduce the manufacturing cost of a photovoltaic system, it is very effective to increase the conversion efficiency of solar ceils, given that the cell fabrication cost is kept inexpensive. The state-of-the-art semiconductor process technologies, such as point contact [1], buried contact [2], surface passivation [3], etc., have enabled the realization of more than 20% in conversion efficiency of silicon solar cells, although the fabrication process is very complicated and thus expensive. The aim of the present paper is to demonstrate that the low temperature deposition process, such as plasma-CVD method, is very effective for obtaining high efficiency silicon solar cells in a simple procedure. Low temperature deposition method has several advantages: (1) the method does not depend on the complicated, expensive, processes as described, (2) it is expected to eliminate the degradation of bulk silicon properties, e.g., the diffusion of impurities and the defect formation, that are inherent to high temperature process, and (3) the depth

* Corresponding author. 0927-0248/94/$07.00 1994 Elsevier Science B.V. All rights reserved SSDI 0 9 2 7 - 0 2 4 8 ( 9 4 ) 0 0 0 3 2 - N

194

K. Fujimoto et al. / Solar Energy Materials and Solar Cells 34 (1994) 193-199

Table 1 BSF layer preparation condition Back pressure (Torr) Source gas Flow rate (sccm) Substrate temp. (C) RF power ( W / c m 2) Deposition pressure (Torr) Deposition rate ( n m / s ) 10-6 P H 3 / S i H 4 / H 2 = I).01/1/30 10 - 20 150 -200 001 - {).04 0.1 - 0.5 {}.01- 0.02

of the junction can be accurately controlled. In the deposition process it is possible to fabricate a very thin emitter layer (10 nm), which enhances the spectral response in shorter wavelengths. However, previous research has shown that the spectral response in longer wavelengths is inferior to the conventional solar cells [4]. At the 38th spring meeting of the Japan Society of Applied Physics in 1991, we proposed that the BSF structure by depositing a highly doped thin silicon layer was very effective for the increase of spectral response in longer wavelength and a high conversion efficiency of 16% was obtained using flat single-crystalline silicon wafers. Recently, we have studied the properties of the BSF layer and BSF effect in detail and the BSF structure was applied to well textured single silicon wafers. Consequently, the solar cells with very high Jsc of 40.5 m A / c m 2 have been obtained using all low temperature processes below 200C.

2. Experimental

2.1. BSF layers properties

BSF layers were mainly prepared with P H 3 / S i l l 4 mixed gases highly diluted by hydrogen as shown in Table 1. The epitaxially aligned films were obtained on the Si (100) surface and poly- or micro-crystalline films were obtained on the Si (111) surface, which were verified by reflection high-energy electron diffraction (RHEED) observation (Fig. 1). The mobility and carrier concentration of the very thin BSF layer were measured by the Hall effect with the structure of BSF layer(n +)/Cz-Si(p-) and the results are tabulated in Table 2. Both films have very high carrier concentration of around 1021//cm 3 which is more than that of the BSF layers prepared by other methods such as the thermal diffusion method, ion implantation, the Al paste method, and so on. The degree of the BSF effect was estimated from the effective diffusion length by the electrodeless surface photo-voltage (SPV) method using CMS-III (Semiconductor Diagnostics Incorporated) and solar cell performance. The diffusion length could be measured after only SC1 cleaning for N-type wafers. The surface of well-textured wafers consists of a pyramid with (111) planes and the BSF effect dependence of the wafer orientation was examined. Almost the

~!~ ~iiii~ i !~ ~~,~, ~

~ii~~!~! ~

,~ ?~

~i~

~ ~i ~i~i

~ ,~

196

K. Fujimoto et al. / Solar Energy Materials and Solar Cells 34 (1994) 193-199

Table 2 The electrical properties of BSF layer Crystal structure Carrier density (cm -3) Mobility (cm 2 / V s ) Resistivity (~2 cm) On Si (100) epitaxial ~ 102I 20 ~ 40 ~ 1 x 10 3 On Si (111) multi-crystalline ~ 102I 10 ~ 20 ~ 2 x 10 -3

same BSF effect was confirmed on Si (100) and Si (111). A-Si (n ) layers also showed the BSF effect but the degree of the photo response enhancement in the longer wavelength was smaller than that of crystalline BSF layer at our conditions. The BSF effect by film deposition is very sensitive to the back side surface condition such as contamination before deposition and careful pre-treatment is necessary. The BSF layer had better be prepared at first for good reproducibility.

2.2. Solar cells f a b r i c a t i o n

The solar cell structure and the fabrication sequence are shown in Fig. 2. N-type Cz-Si with resistivity of 1-5 [l cm was used for the substrate. The wafer was etched with potassium hydroxide (KOH) solutions in order to obtain textured surface. The thickness of the wafer after etching was about 350 Ixm. BSF layers and emitter layers were deposited by the PCVD-method. The deposited emitter layer properties affect the solar cell performance just like a-Si solar cells. The emitter layers with wide band gap and low resistivity are desired for high performance. A-SiC films and /zc-Si films were also examined but the solar cells with a-Si emitter layer showed higher performance. Takayama et al. [4] reported the usefulness of the buffer layer between a-Si(p ) and c-Si wafer. In this work, we have studied the way to get high performance without a buffer layer for the simplification of the process. After deposition of the emitter layers, indium-tin-oxide(ITO) films were fabricated by DC-magnetron sputtering as transparent conductive oxides and 1st

finger [A[g paste] I 2nd-AR coat[ MgF2] front electrode [ITO, 80nm] emitter layer [ a-Si(p+),- 10nm] Cz-Si wafer [n-,0.35mm] BSF layer [PCVD-Si(n+),20nm] back electrode [ AI]

BSF formation junction formation [ front electrode back electrode

I

fin[ger electrode I 2nd AR coat

a. b. Fig. 2. The solar cell structure (a) and the fabrication sequence (b).

K Fujimoto et aL/Solar Energy Materials and Solar Cells 34 (1994) 193-199

197

800 600 400

'

I on Si(lO0)[ C) on Si(111)

,_1

.o_ = 200

--3

20 40 60 80 100 n+ Film Thickness (nm)

Fig. 3. The effective diffusion length dependence on the thickness of BSF layer. The diffusion length was measured by SPV method.

anti-reflection flms. MgF 2 films were deposited by electron-beam evaporation as 2nd anti-reflection films. Silver paste with resin was used for the finger electrode by the screen printing technique. The resistivity of the silver paste after annealing at 200~C is as low as 1 10 -5 fl cm. The designed active cell area is 1.21 cm 2 but the real active cell area was 1.17 cm 2 which was measured by a laser microscope. The decrease of active area is due to the blot of the surface electrode. Al-films were evaporated for the back electrode and ohmic contact was obtained after annealing at about 200C. All these processes are performed below 200C.

3. Results and discussion Generally speaking, the degree of BSF effect depends on the wafer diffusion length and wafer thickness [5]. Wafers used in this work have diffusion length of about 300 ixm which was measured by the SPV method. This value of diffusion length is comparable with the wafer thickness and a considerable BSF effect is expected. In Fig. 3, the effective diffusion length by the SPV method dependence on the BSF layer thickness is shown and the increase of diffusion length has been observed for the wafers with BSF layer. The diffusion length more than wafer thickness is not accurate but the enhancement of BSF effect was obvious. High carrier concentration of BSF layers enables us to obtain good BSF effect with the thickness of as thin as 20 nm.. Recently, we have started computer simulation of the BSF effect dependence on the carrier concentration using the program of "VENUS" and it is indicated from the rough calculation that the BSF layers with higher carrier concentration shows higher solar cell performances. The details of the simulation such as BSF layer characteristics, the boundary conditions and emitter layer properties, etc,. must still be improved and the qualitative discussion will be carried out in the near future.

198

K. Fujimoto et al. / Solar Energy Materials and Solar Cells 34 (1994) 193-199

do LU

0.8 0.6

g 0.4

0

--~ 0.2 -5 (.3 0 200

400 600 800 1000 1200 wave length (nm)

Fig. 4. The spectral response of the solar cells with BSF structure and without BSF structure. The increase of the spectral response in the longer wavelength has been observed.

The difference of the spectral response between the solar cells with and without BSF structure is shown in Fig. 4. It has been verified, as shown in Fig. 4, that the spectral response in the longer wavelength strongly depends on the back side structure. The effective diffusion length of the solar cells showing good BSF effect was estimated more than 1 mm from the spectral response for the longer wavelength (800 n m < A < 1000 nm), though the correct estimation is difficult in case of longer diffusion length more than the wafer thickness. The collection efficiency of about 50% at 1100 nm is comparable with surface passivated high efficiency solar cells [6]. The collection efficiency of more than 85% at 400 nm is also very high and this is due to the very thin emitter layer and very high J ..... of 40.5 m A / c m 2 was estimated from the collection efficiency and AM1.5 spectrum (100 m W / c m 2 ) .

50

I V0c: 0592 V I ~ Jsc= 40.50 mA;cm 2 / / FF= 0789 ~/ / elf.= 18.9 % I

E

0

30

"E 2 0 Voc = 0.575 V Jsc =37.96 mA/cm 2 I FF= 0.782 I

.1\\

I

t~ t'~

|11

0.2

0.4 0.6 Voltage (V)

0.8

Fig, 5. The characteristics of the solar cells with good BSF layer. Solid line: with BSF layer. Broken line: without BSF layer.

K. Fujimoto et al. / Solar Energy Materials and Solar Cells 34 (1994) 193-199

199

The photo current-voltage characteristics of the solar cells with good BSF effect is shown in Fig. 5. Voc and FF were measured at about 25C after Jsc was set at calculated value and the very high efficiency of 18.9% was obtained. The Voc of the solar cell with BSF structure is higher than that without BSF structure. However, the Vo:value of the well-textured solar cells was 20-30 mV smaller than that of the flat surface solar ceils at the same condition and the solar cells with an emitter layer thicker than 40 nm had Vo-values near the values of flat solar cells, but the thicker emitter solar cells showed an decrease of J,c and conversion efficiency. It is considered that this problem is due to the structure of the interface between the emitter layer and the well textured wafers. This problem will be overcome due to the optimization of the emitter layer preparation condition including buffer layer insertion.

4. Conclusion

Crystalline silicon solar cells fabricated by the low temperature PCVD-method have been studied and an excellent BSF structure has been obtained by depositing a highly doped silicon thin layer on the back of the substrate. The substantial enhancement of the spectral response in longer wavelength was observed and a very high Jsc of 40.5 m A / c m 2 has been achieved. The BSF formation technology and thin a-Si emitter layer with appropriate bandgap has enabled us to obtain very high active area efficiency of 18.9%.

Acknowledgement

This work is supported by NEDO (New Energy and Industrial Technology development Organization), as part of the New-Sunshine Program under Ministry of International Trade and Industry.

References

[1] R.R. King, R.A. Sinton and R.M. Swanson, Appl. Phys. Lett. 54 (1989) 1460-1462. [2] M.A. Green, Proc. 10th EC Photovoltaic Solar Energy Conf., 1991, pp. 250-253. [3] M.A. Green, A.W. Blakers, J. Shi, E.M, Keller and S.R. Wenham, IEEE Trans. Electr. Dev. 31 (1984) 679-683. [4] T. Takayama, M. Taguchi, S. Kuroda, T. Matsuyama, M. Tanaka, S. Tsuda, S. Nakano and Y. Kuwano, Proc. l l t h EC Photovoltaic Solar Energy Conf., 1992, pp. 1057-1060. [5] J. Knobloch, A. Aberle, W. Warta and B. Voss, Technical Digest 5th Int. Phtovoltaic Specialists Conf., 1990, pp. 955-958. [6] C.M. Chong, S.R. W e n h a m and M.A. Green, Appl. Phys. Lett. 52 (1988) 407-409.

You might also like

- Research Article: Investigation of Antireflective Porous Silicon Coating For Solar CellsDocument4 pagesResearch Article: Investigation of Antireflective Porous Silicon Coating For Solar CellsandrewtomsonNo ratings yet

- Yang2010 PDFDocument5 pagesYang2010 PDFMainur RahmanNo ratings yet

- Silicon Nanowire-Based Solar Cells On Glass: Synthesis, Optical Properties, and Cell ParametersDocument6 pagesSilicon Nanowire-Based Solar Cells On Glass: Synthesis, Optical Properties, and Cell Parameterssumona1111No ratings yet

- 7 - 2008 - Cas - The Laboratory Technology of Crystalline Silicon Solar CellsDocument4 pages7 - 2008 - Cas - The Laboratory Technology of Crystalline Silicon Solar CellsserhanNo ratings yet

- Three-Dimensional Nanostructure Fabrication by Focused-Ion-Beam Chemical-Vapor-DepositionDocument33 pagesThree-Dimensional Nanostructure Fabrication by Focused-Ion-Beam Chemical-Vapor-DepositionGeoffrey MooreNo ratings yet

- Brunets Et Al. - 2009 - Low-Temperature Fabricated TFTs On Polysilicon StripesDocument8 pagesBrunets Et Al. - 2009 - Low-Temperature Fabricated TFTs On Polysilicon StripesBourne UltimaNo ratings yet

- Akgul 2017Document5 pagesAkgul 2017Eman NasirNo ratings yet

- Al2O3 Trong PinDocument10 pagesAl2O3 Trong PinHà An Đỗ NgọcNo ratings yet

- SdarticleDocument6 pagesSdarticleBoodeppa NatarajuNo ratings yet

- MPM144 13 SakharovDocument6 pagesMPM144 13 SakharovВадим АрыковNo ratings yet

- Heliyon: SciencedirectDocument17 pagesHeliyon: Sciencedirectfatima benfrihaNo ratings yet

- Nio Used As Window Layer FOR Si Solar Cells: V.Bhargavi 315207238011 1/2 M.TECH Nano TechnologyDocument26 pagesNio Used As Window Layer FOR Si Solar Cells: V.Bhargavi 315207238011 1/2 M.TECH Nano Technologyanand sureshNo ratings yet

- CTS7Document17 pagesCTS7Halima MoudnibNo ratings yet

- 2006 InvestigationDocument4 pages2006 Investigationsoma_durga6606No ratings yet

- Fabrication and Characterization of Highly Efficient Thin-Film Polycrystalline-Silicon Solar Cells Based On Aluminium-Induced CrystallizationDocument5 pagesFabrication and Characterization of Highly Efficient Thin-Film Polycrystalline-Silicon Solar Cells Based On Aluminium-Induced CrystallizationSarah GloverNo ratings yet

- Thin Solid FilmsDocument9 pagesThin Solid FilmsBhabani Sankar SwainNo ratings yet

- Transparent Conducting Zno:Al Films Via CCVD For Amorphous Silicon Solar CellsDocument4 pagesTransparent Conducting Zno:Al Films Via CCVD For Amorphous Silicon Solar CellsEidelsayedNo ratings yet

- PV Labnotes-Lab1Document6 pagesPV Labnotes-Lab1Vendy KristiNo ratings yet

- Light Trapping in Silicon Nanowire Solar Cells: Erik Garnett and Peidong YangDocument13 pagesLight Trapping in Silicon Nanowire Solar Cells: Erik Garnett and Peidong Yangdamaya1701No ratings yet

- Opt Quant Electron Vo. 41, No.3,2009Document14 pagesOpt Quant Electron Vo. 41, No.3,2009rsdubeNo ratings yet

- Ultra-Low Threshold InAs:GaAs Quantum DotDocument6 pagesUltra-Low Threshold InAs:GaAs Quantum Dotwong MichaelNo ratings yet

- Non Linear Optics Solac Filter Folded TypeDocument3 pagesNon Linear Optics Solac Filter Folded TypebhaktameltNo ratings yet

- Fabrication of Nanostructure Cds Thin Film On Nanocrystalline Porous SiliconDocument8 pagesFabrication of Nanostructure Cds Thin Film On Nanocrystalline Porous SiliconRup JoshiNo ratings yet

- Equation Relating Voc and JSC - 2Document7 pagesEquation Relating Voc and JSC - 2NILOFARNo ratings yet

- Capoen Et Al. - 2005 - Study of Structural and Optical Properties of InSb-doped SiO2 Thin FilmsDocument6 pagesCapoen Et Al. - 2005 - Study of Structural and Optical Properties of InSb-doped SiO2 Thin FilmsBourne UltimaNo ratings yet

- Incorporation of Copper Indium Back End Layers in The Solution Based Cu (In, Ga) Se2 Films Enhancement of Photovoltaic Performance of Fabricated Solar Cells ThesisDocument40 pagesIncorporation of Copper Indium Back End Layers in The Solution Based Cu (In, Ga) Se2 Films Enhancement of Photovoltaic Performance of Fabricated Solar Cells ThesisHanry SkywalkerNo ratings yet

- 073-076 Reilly, E.KDocument4 pages073-076 Reilly, E.KDebnath MajiNo ratings yet

- Solar Energy Materials & Solar Cells: Guangtao Yang, René A.C.M.M. Van Swaaij, Hairen Tan, Olindo Isabella, Miro ZemanDocument7 pagesSolar Energy Materials & Solar Cells: Guangtao Yang, René A.C.M.M. Van Swaaij, Hairen Tan, Olindo Isabella, Miro ZemanMaiman LatoNo ratings yet

- JApplPhys 93 3837 PDFDocument7 pagesJApplPhys 93 3837 PDFEidelsayedNo ratings yet

- Copper As Conducting Layer in Advanced Front Side Metallization Processes For Crystalline Silicon Solar Cells, Exceeding 20% On Printed Seed LayersDocument5 pagesCopper As Conducting Layer in Advanced Front Side Metallization Processes For Crystalline Silicon Solar Cells, Exceeding 20% On Printed Seed LayerssofyanmouvitchNo ratings yet

- Yan 2014Document8 pagesYan 2014munira sultanaNo ratings yet

- Salman2017Document4 pagesSalman2017u1802119No ratings yet

- Orientation of Mgo Thin Films On Si (001) Prepared by Pulsed Laser DepositionDocument5 pagesOrientation of Mgo Thin Films On Si (001) Prepared by Pulsed Laser Depositioneid elsayedNo ratings yet

- Steeves SPIE 9151-4Document13 pagesSteeves SPIE 9151-4felipe_fismed4429No ratings yet

- An Optical Cloak Made of DielectricsDocument4 pagesAn Optical Cloak Made of DielectricsuiliandreyerNo ratings yet

- Splar SystemDocument10 pagesSplar SystemMd Fazlul HaqueNo ratings yet

- CuO Based Solar Cell With V2O5 BSF Layer - Theoretical Validation of Experimental DataDocument12 pagesCuO Based Solar Cell With V2O5 BSF Layer - Theoretical Validation of Experimental DataNur Aisyah ShariNo ratings yet

- Thin Solid Films, 31: (1976) 235-241 © Elsevier Sequoia S.A., Lausanne - Printed in SwitzerlandDocument7 pagesThin Solid Films, 31: (1976) 235-241 © Elsevier Sequoia S.A., Lausanne - Printed in SwitzerlandMuizzudin AzaliNo ratings yet

- Id 2470Document5 pagesId 2470EsiTech ConferenceNo ratings yet

- Nanostructured Cobalt Zinc Ferrite Thin Films For Gas Sensor ApplicationDocument10 pagesNanostructured Cobalt Zinc Ferrite Thin Films For Gas Sensor ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Artigo Sobre RevestimentosDocument11 pagesArtigo Sobre RevestimentosGustavo PamplonaNo ratings yet

- Structural Fluctuation of Sio, Network at The Interface With SiDocument4 pagesStructural Fluctuation of Sio, Network at The Interface With SiAnonymous BW2VsFifi9No ratings yet

- 17.3% Efficient Black Silicon Solar Cell Without Dielectric Antireflection CoatingDocument6 pages17.3% Efficient Black Silicon Solar Cell Without Dielectric Antireflection CoatingMohsen GoodarziNo ratings yet

- Synthesis and Properties of Crystalline Thin Film of Antimony Trioxide On SiDocument1 pageSynthesis and Properties of Crystalline Thin Film of Antimony Trioxide On SiYasirNo ratings yet

- 2010 Investigation of Thickness Dependence of Structure and Electric Properties of SolGel Derived BiScO3PbTiO3 Thin FilmsDocument7 pages2010 Investigation of Thickness Dependence of Structure and Electric Properties of SolGel Derived BiScO3PbTiO3 Thin FilmsAnaghaNo ratings yet

- Polycrystalline Silicon Thin Films For MEMS ApplicationsDocument5 pagesPolycrystalline Silicon Thin Films For MEMS Applicationsrajesh langojuNo ratings yet

- Development of Rear Surface Passivated Cu (In, Ga) Se2 Thin Film Solar Cells With Nano-Sized Local Rear Point ContactsDocument7 pagesDevelopment of Rear Surface Passivated Cu (In, Ga) Se2 Thin Film Solar Cells With Nano-Sized Local Rear Point ContactsmendaburkiwiNo ratings yet

- Preparation of Plasma-Polymerized SiOx-like Thin Films From A MixtureDocument6 pagesPreparation of Plasma-Polymerized SiOx-like Thin Films From A MixturekgvtgNo ratings yet

- Strejn U BFO Filmu - Ujimoto2011Document5 pagesStrejn U BFO Filmu - Ujimoto2011Bojan StojadinovićNo ratings yet

- Epitaxial (Ba, SR) Tio Ferroelectric Thin Films For Integrated OpticsDocument25 pagesEpitaxial (Ba, SR) Tio Ferroelectric Thin Films For Integrated Opticsmsh-666No ratings yet

- Large Area 2D and 3D Colloidal Photonic Crystals Fabricated by A Roll-to-Roll Langmuir Blodgett MethodDocument8 pagesLarge Area 2D and 3D Colloidal Photonic Crystals Fabricated by A Roll-to-Roll Langmuir Blodgett MethodJayNo ratings yet

- Detailed Study On The Role of Nature and Distribution of Pinholes and Oxide Layer On The Performance of Tunnel Oxide Passivated Contact TOPCon Solar CellDocument6 pagesDetailed Study On The Role of Nature and Distribution of Pinholes and Oxide Layer On The Performance of Tunnel Oxide Passivated Contact TOPCon Solar Cellgxf980518No ratings yet

- Anneling Using LaserDocument9 pagesAnneling Using LaserVivek BelaNo ratings yet

- Investigation On Light-Trapping Schemes in Crystalline Silicon Thin-Film Solar Cell On Glass Superstrate by Ray TracerDocument9 pagesInvestigation On Light-Trapping Schemes in Crystalline Silicon Thin-Film Solar Cell On Glass Superstrate by Ray TracerMADHIYAH YAHAYA BERMAKAINo ratings yet

- Integrated Ferroelectrics: An International JournalDocument8 pagesIntegrated Ferroelectrics: An International JournalBhabani Sankar SwainNo ratings yet

- Thickness Effects of Thermally Evaporated C60 Thin Films On Regular-Type CH3NH3PbI3 Based Solar Cells - 2 PDFDocument6 pagesThickness Effects of Thermally Evaporated C60 Thin Films On Regular-Type CH3NH3PbI3 Based Solar Cells - 2 PDFDimas Dwi Surya ANo ratings yet

- 002 2015 Solar Cells With Grating SurfaceDocument6 pages002 2015 Solar Cells With Grating SurfaceAshwag MalkiNo ratings yet

- Fabrication and Properties of High-Efficiency Perovskite/PCBM Organic Solar CellsDocument5 pagesFabrication and Properties of High-Efficiency Perovskite/PCBM Organic Solar CellsJhon BurbanoNo ratings yet

- A Enm 201401229Document6 pagesA Enm 201401229Bhabani Sankar SwainNo ratings yet

- Digital IC FamilyDocument33 pagesDigital IC FamilyVenkat ArunNo ratings yet

- Unisonic Technologies Co., LTD: 20A, 600V N-CHANNEL Power MosfetDocument3 pagesUnisonic Technologies Co., LTD: 20A, 600V N-CHANNEL Power MosfetJuan Carlos RuizNo ratings yet

- MOSIS TSMC 0.18um Lambda-By-2 RulesDocument21 pagesMOSIS TSMC 0.18um Lambda-By-2 RulessubashNo ratings yet

- Nota Unit 7Document36 pagesNota Unit 7F1036No ratings yet

- High-NA EUV OpticsDocument43 pagesHigh-NA EUV OpticsGary Ryan DonovanNo ratings yet

- Publication 12 4795 82Document12 pagesPublication 12 4795 82Saud AloufiNo ratings yet

- 5305SDocument10 pages5305SHugo Camacho RamirezNo ratings yet

- Transistor (BJT)Document13 pagesTransistor (BJT)sanjeevani rawatNo ratings yet

- P2503NPG Niko SemDocument7 pagesP2503NPG Niko Semrodrigo2016.cdNo ratings yet

- EEE-BEE026 - Micro Eelectro Mechanical Systems - Mr. K. Dwarakesh.KDocument21 pagesEEE-BEE026 - Micro Eelectro Mechanical Systems - Mr. K. Dwarakesh.KAleme AddisieNo ratings yet

- 25773-Test Continuity With An LED PDFDocument5 pages25773-Test Continuity With An LED PDFWill MamaniNo ratings yet

- Bandgap of PN DiodeDocument2 pagesBandgap of PN DiodeVikash Singh100% (6)

- Thyristors CH 7Document23 pagesThyristors CH 7Harris AnchesNo ratings yet

- Process OwnerDocument3 pagesProcess OwnerHarold ConsigoNo ratings yet

- EE2027 - Consolidated List of Equations (Mid-Term Quiz)Document5 pagesEE2027 - Consolidated List of Equations (Mid-Term Quiz)NixNo ratings yet

- ST2009DHI: High Voltage Fast-Switching NPN Power TransistorDocument7 pagesST2009DHI: High Voltage Fast-Switching NPN Power TransistorMiloud ChouguiNo ratings yet

- Ch. 3 - BJT SummaryDocument2 pagesCh. 3 - BJT SummaryJesryniel PlazaNo ratings yet

- Etch BibleDocument438 pagesEtch BibleMattVukNo ratings yet

- RCA-40406 Al 40411-TRANSISTORESDocument6 pagesRCA-40406 Al 40411-TRANSISTORESJosué GuzmánNo ratings yet

- SPC 6601Document11 pagesSPC 6601ciro_svNo ratings yet

- L21 ECEN5827 NotesDocument21 pagesL21 ECEN5827 Notes3nadhsNo ratings yet

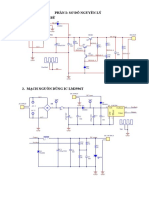

- Phần I: Sơ Đồ Nguyên Lý 1. Mạch Ổn Áp BùDocument13 pagesPhần I: Sơ Đồ Nguyên Lý 1. Mạch Ổn Áp BùTrung VũNo ratings yet

- VVIMP QUESTIONS Basic Physics (22102)Document5 pagesVVIMP QUESTIONS Basic Physics (22102)Prathamesh Nawale100% (2)

- Ec2254 NolDocument376 pagesEc2254 NolkumararguruNo ratings yet

- Discontinued Products and Service Parts (NND)Document7 pagesDiscontinued Products and Service Parts (NND)RudyXPNo ratings yet

- EC302Document23 pagesEC302api-3853441No ratings yet

- Immersion Lithography Photomask and Wafer-Level MaDocument34 pagesImmersion Lithography Photomask and Wafer-Level MaTao HouNo ratings yet

- Answers To Selected Problems: 2 36V 1 2 DS 3 XDocument26 pagesAnswers To Selected Problems: 2 36V 1 2 DS 3 XLeonardo Ramos100% (1)

- CJ3401-HF RevB289632Document5 pagesCJ3401-HF RevB289632alteromr mrNo ratings yet

- The MOS Capacitor: N Polysilicon Gate Gate Oxide 3.9 0Document10 pagesThe MOS Capacitor: N Polysilicon Gate Gate Oxide 3.9 0VLSI_IITRNo ratings yet