Professional Documents

Culture Documents

Is.4162.1.1985 Graduated Pipettess

Is.4162.1.1985 Graduated Pipettess

Uploaded by

Bala MuruCopyright:

Available Formats

You might also like

- Instrumentation and Measurement in Electrical EngineeringFrom EverandInstrumentation and Measurement in Electrical EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- Iso 835Document20 pagesIso 835Oswaldo Avalos QuispeNo ratings yet

- 6280Document13 pages6280sanbarunNo ratings yet

- Disclosure To Promote The Right To InformationDocument27 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- IS 460 Part 1Document19 pagesIS 460 Part 1Muhammed NoufalNo ratings yet

- Is 4251 1967Document18 pagesIs 4251 1967Nataraj NagarajanNo ratings yet

- Is 7326-3 (1976)Document11 pagesIs 7326-3 (1976)slamienkaNo ratings yet

- 2720 (Part-XXI) PDFDocument10 pages2720 (Part-XXI) PDFSoundar PachiappanNo ratings yet

- Is.2470.1.1985 Septic Tank Part 2Document29 pagesIs.2470.1.1985 Septic Tank Part 2V Jay KrNo ratings yet

- Is 2720.8.1983Document14 pagesIs 2720.8.1983Elumalai Srinivasan100% (2)

- IS CODE Fire ResistantDocument25 pagesIS CODE Fire ResistantSunil KalwaniyaNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationsharathknNo ratings yet

- Is 774 1984 R 1995Document24 pagesIs 774 1984 R 1995nagaraju3135No ratings yet

- Is 3068 - 1986 Specification For Broken Brick (Burnt Clay) Coarse Aggregate For Use in Lime ConcreteDocument9 pagesIs 3068 - 1986 Specification For Broken Brick (Burnt Clay) Coarse Aggregate For Use in Lime ConcretePrapa KaranNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Is.4968.2.1976 Dynamic Cone Penetration Method Using Bentonite SlurryDocument14 pagesIs.4968.2.1976 Dynamic Cone Penetration Method Using Bentonite SlurryMilind GuptaNo ratings yet

- Is 1200 (Part 21) 1973 Method of Measurement of Building and Civil Engineering Works, Part 21 - Wood-Work and JoineryDocument13 pagesIs 1200 (Part 21) 1973 Method of Measurement of Building and Civil Engineering Works, Part 21 - Wood-Work and JoineryRoseNo ratings yet

- Reaffirmed 1995Document10 pagesReaffirmed 1995mondianeerajNo ratings yet

- Disclosure To Promote The Right To Information: IS 3913 (2005) : Suspended Sediment Load Samplers (WRD 1: Hydrometry)Document19 pagesDisclosure To Promote The Right To Information: IS 3913 (2005) : Suspended Sediment Load Samplers (WRD 1: Hydrometry)octatheweelNo ratings yet

- Is 2373 Water MetersDocument25 pagesIs 2373 Water Metersnp27031990No ratings yet

- Disclosure To Promote The Right To InformationDocument28 pagesDisclosure To Promote The Right To InformationAMIAMINo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Is 15058 2002Document12 pagesIs 15058 2002Santosh KumarNo ratings yet

- Is 2720 2 1973 PDFDocument24 pagesIs 2720 2 1973 PDFbiswanirman100% (1)

- Ieee C.57.104-1991Document39 pagesIeee C.57.104-1991Dimas F Febryanto100% (1)

- IS2026Document142 pagesIS2026Imran HussainNo ratings yet

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationJaisree Balu PydiNo ratings yet

- IS 2720 Part-41.1977Document20 pagesIS 2720 Part-41.1977कृत्या नंद झाNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationhumayun mdNo ratings yet

- Is 6913 1973Document11 pagesIs 6913 1973diwakar1978No ratings yet

- Is 14845 2000 PDFDocument21 pagesIs 14845 2000 PDFmethusalakannanNo ratings yet

- IS 4880-3 (1976) - Code of Practice For Design of Tunnels Conveying Water, Part 3 - Hydraulic Design PDFDocument20 pagesIS 4880-3 (1976) - Code of Practice For Design of Tunnels Conveying Water, Part 3 - Hydraulic Design PDFrahuldevpatel5No ratings yet

- " RTR:+-#L': CarryingDocument41 pages" RTR:+-#L': CarryingAaron WilsonNo ratings yet

- Is 10500 1991Document16 pagesIs 10500 1991Ramu NagulaganiNo ratings yet

- Is 9178 1 1979 PDFDocument29 pagesIs 9178 1 1979 PDFHarshil AminNo ratings yet

- Conduit SpecificationDocument22 pagesConduit Specificationamijetomar08No ratings yet

- Is 1200 2 1974 PDFDocument20 pagesIs 1200 2 1974 PDFAr Hussain MojahidNo ratings yet

- BP107 (A4) 1Document4 pagesBP107 (A4) 1Huda TajuddinNo ratings yet

- Is 2470 - 2Document24 pagesIs 2470 - 2lunar_vipNo ratings yet

- Pitot Tube StandartDocument45 pagesPitot Tube Standartdesrytandi0% (1)

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationduonzaNo ratings yet

- Is 10096-2 (1983)Document17 pagesIs 10096-2 (1983)slamienkaNo ratings yet

- Is 1344 1981Document15 pagesIs 1344 1981VijayKatariaNo ratings yet

- CO2 ScrubberDocument73 pagesCO2 ScrubberDarshan ShahNo ratings yet

- 9178 3Document72 pages9178 3govimanoNo ratings yet

- IS 9178-Part-1 PDFDocument32 pagesIS 9178-Part-1 PDFvijay84mech100% (2)

- BIS Multi Purpose Dry BatteriesDocument15 pagesBIS Multi Purpose Dry BatteriessreeramaNo ratings yet

- Indian Standard: Specification FOR Single Faced Sluice Gates (200 To 1200 MM Size.)Document25 pagesIndian Standard: Specification FOR Single Faced Sluice Gates (200 To 1200 MM Size.)gpskumar22No ratings yet

- Hydrodynamically Stable Towed Transmitter BodyDocument9 pagesHydrodynamically Stable Towed Transmitter BodyManoj T IssacNo ratings yet

- 4516 PDFDocument10 pages4516 PDFRajesh BabuNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Photonics, Volume 2: Nanophotonic Structures and MaterialsFrom EverandPhotonics, Volume 2: Nanophotonic Structures and MaterialsNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Is.6886.1973 Axial Load Fatigue TestDocument17 pagesIs.6886.1973 Axial Load Fatigue TestBala MuruNo ratings yet

- ISO 14253 1 1998 DAmd 1 E Character PDF DocumentDocument6 pagesISO 14253 1 1998 DAmd 1 E Character PDF DocumentBala MuruNo ratings yet

- Specific Criteria Site Calibration Laboratories: For Site Testing andDocument11 pagesSpecific Criteria Site Calibration Laboratories: For Site Testing andBala MuruNo ratings yet

- Bench Centre Is.5980.1978Document3 pagesBench Centre Is.5980.1978Bala MuruNo ratings yet

- EURAMET CG 18 02 Non Automatic Weighing InstrumentsDocument83 pagesEURAMET CG 18 02 Non Automatic Weighing InstrumentsPurwanto NugrohoNo ratings yet

- Is.1672.1967 Dairy ThermometerDocument14 pagesIs.1672.1967 Dairy ThermometerBala MuruNo ratings yet

- Nabl News Letter 40Document40 pagesNabl News Letter 40Bala MuruNo ratings yet

- Pipe Thread STDDocument1 pagePipe Thread STDBala MuruNo ratings yet

- Try It For Yourself: Platform OverviewDocument32 pagesTry It For Yourself: Platform OverviewМаниш НахтвандерерNo ratings yet

- 101-0020 USB-RS485 Converter Manual R2Document8 pages101-0020 USB-RS485 Converter Manual R2Juan Pablo Villazon RichterNo ratings yet

- Mgiter-Navsari Electrical Engineering Department Lesson PlanningDocument3 pagesMgiter-Navsari Electrical Engineering Department Lesson PlanningJAY S TANDELNo ratings yet

- Quality in Practice - Building Trust Through Quality at GerbDocument6 pagesQuality in Practice - Building Trust Through Quality at Gerbsakshi1404No ratings yet

- Research Article: Linkage Between Economic Value Added and Market Value: An AnalysisDocument14 pagesResearch Article: Linkage Between Economic Value Added and Market Value: An Analysiseshu agNo ratings yet

- Chocolate Chip Banana BreadDocument8 pagesChocolate Chip Banana BreadouruleNo ratings yet

- Clap SwitchDocument2 pagesClap SwitchAakash GhoderaoNo ratings yet

- Focus2 2E Workbook Answers PDFDocument1 pageFocus2 2E Workbook Answers PDFРоксоляна Бубон0% (1)

- Prerequisites From Differential Geometry: 1 Isotopies and Vector FieldsDocument8 pagesPrerequisites From Differential Geometry: 1 Isotopies and Vector FieldsnotafacefuckerNo ratings yet

- Marketing Moguls Gartons IIM Kashipur FinalsDocument22 pagesMarketing Moguls Gartons IIM Kashipur FinalsTarun SinghNo ratings yet

- Answer Key For The 11th Grade English Final TestDocument1 pageAnswer Key For The 11th Grade English Final TestMyagmarsuren NyamtaivanNo ratings yet

- English 8 Q2M3Document5 pagesEnglish 8 Q2M3Mark Jhoriz VillafuerteNo ratings yet

- Apply 5S ProceduresDocument8 pagesApply 5S Proceduresdagmabay136No ratings yet

- René Prieto-Body of Writing - Figuring Desire in Spanish American Literature - Duke University Press Books (2000)Document309 pagesRené Prieto-Body of Writing - Figuring Desire in Spanish American Literature - Duke University Press Books (2000)Mariana AveituaNo ratings yet

- Spec Merlin Gerin MCCBDocument85 pagesSpec Merlin Gerin MCCBTen ApolinarioNo ratings yet

- Historia The FelidsDocument5 pagesHistoria The Felidsbalim01100% (1)

- Maklumat Vaksinasi: Vaccination DetailsDocument2 pagesMaklumat Vaksinasi: Vaccination DetailsNORFADHLI ARIFNo ratings yet

- Eve To Her Daughters: (Judith Wright, 1915 - 2000)Document3 pagesEve To Her Daughters: (Judith Wright, 1915 - 2000)Angelica PagaduanNo ratings yet

- GTB Jeremiah DownloadDocument87 pagesGTB Jeremiah DownloadEdwin PitangaNo ratings yet

- Lab 7b - Bilateral Transfer and Observational LearningDocument3 pagesLab 7b - Bilateral Transfer and Observational Learningapi-448989844No ratings yet

- 3.5 T Bolier ManualDocument206 pages3.5 T Bolier Manualchandravadiyaketan150467% (3)

- Analyzer SiteHawkDocument2 pagesAnalyzer SiteHawknickNo ratings yet

- 30+ Types of Project RiskDocument1 page30+ Types of Project RiskSulemanNo ratings yet

- Crevis Blower Control Feeding System: Scale AQ ASDocument2 pagesCrevis Blower Control Feeding System: Scale AQ ASpablo esteban jara reyesNo ratings yet

- Academic TranscriptDocument1 pageAcademic Transcriptdangthanhhd79No ratings yet

- A New Mutuel Kerberos Authentication Protocol For Distributed SystemsDocument10 pagesA New Mutuel Kerberos Authentication Protocol For Distributed SystemsRahul prabhaNo ratings yet

- Project 2 Wikipedia Project ReflectionDocument2 pagesProject 2 Wikipedia Project Reflectionapi-659259835No ratings yet

- WEEK 17 LAB EXERCISE Reproductive System Male Female 1Document6 pagesWEEK 17 LAB EXERCISE Reproductive System Male Female 1DELA CRUZ, JENISSE LOUISSENo ratings yet

- AI Aur Sunni Naujawan (Roman Urdu)Document26 pagesAI Aur Sunni Naujawan (Roman Urdu)Mustafawi PublishingNo ratings yet

- Business Day - Insights - Credit Management - February 2021Document2 pagesBusiness Day - Insights - Credit Management - February 2021SundayTimesZANo ratings yet

Is.4162.1.1985 Graduated Pipettess

Is.4162.1.1985 Graduated Pipettess

Uploaded by

Bala MuruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is.4162.1.1985 Graduated Pipettess

Is.4162.1.1985 Graduated Pipettess

Uploaded by

Bala MuruCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 4162-1 (1985): Specification for Graduated Pipettes,

Part 1: General Requirements [CHD 10: Glassware]

IS : 4162 ('art 1) -1985

Indian Standard

SPECIFICATION FOR

GRADUATED PIPETTES

PART I GENERAL REQUIREMENTS

( First Revision)

Laboratoryware and Related Apparatus Sectional Committee,

. CDC 33 .

1l.fIrum/i,.,

Bhabha Atomic Raearch Centre, Trombay,

Bombay

Mnnlns

SIdI S. V. Gvt.AVA!C& (.oUuru" to .

Dr M. SaDkar DaII )

Da G. S.BAJWA Defeace Sciencc Laboratory, MiDiatry of Dcl'euce

( R&D), Ncw Delhi .

Da N. K. B...aJU Indian Agricultural ReRarCh Inatitute (ICAR),

NewDc1hi

Da K. S. RAM (.um.,,)

SBaI N. G. BAIAK Directorate General of Technieal Devdopmeat,

New Delhi .

Sam I. It. KAPooa (A.lImwJU)

SDJ M. L. BJr.uoAJq National Test House, Calcutta

DaB. B. PAL (.."..,.)

SBaJ S. K. CRAItLUAaTI Devdopment ComJniIaiOI1er, Small Scalc Indwtna,

NewDclhi

SBaJ I . R. MUJlDAaGl ( Alu",.,,)

LT-Ccn. M. CRAjlwoaTY Dira:tor-GeDeral Armed Forcea Medical Serriccs,

Miniatry of DcfeDcc (DGAFMS ), New Delhi

Da A. V. DlvuAa Bio-Sc:icace Corporation, Bombay

!sal R. K. GADODIA Swutik'I"hermometer Co. Delhi

SIIaI D. S. GAIlOIlIA (.4llirMt.)

SIDI V_A l'ItAumGUPTA Hicb'I'bamclmeten ( IDdia) Ltd, Aliprh

S8aI S. C. ItAPILA(A.ltmtta14)

Da R. C. KBDA Puahpak Entcrprisel, BoIabay

SIIaI D. C. KRuA ( .f1InuU )

S_MOIIINDPNAT. National Pbyaica1 Laboratory (CSIR), New Delhi

S_B. G.MATBoa ( .4l,.,..)

(CMIiaM.. ,.,2)

Copyrlgltt 1986

INDIAN STANDARDS INSTlT'UnON

TIIia pub1icat!0D iI protoc;ted under 1M 1ttdUI1t Co""'" An (XIV.of 1"') aad

rq:cuClucdoa to wholll or to part b1UlJ""tlICIIPl withwritt.- JlII'lII1IIioD orlM

IbaU lie deemed to be iDIrin..... of CClP1rIIb& __...... Act.

IS: 4161(Part 1 )-1985

(c"'"jrI_I-I' 1)

MI1fII1J"s JU;UI/tIiIII

S... P. R.. llAo BoroIil Glua Worb Ltd. Bombay

SHaI U. T. 'fi1lll1l {AltmulU)

SPI H. N RAVI Modern lnatrllmeD... Banplorc

Da F. L. SA1DllAJfA . Haft'tiDe lnatitute. Bombay

SRIlI A. B. C.URODLUL (.fIt__)

SRIlIBa.uro K. SAMPAT The Scieuliic Indiu Gu Co Ltd, Calcutta

SHU D. R. S (AlIIrM")

SHU S. K. SUGAJ. Tano.na ProclueuLtd. Calcutta

SHa' J. C. SRAJIDILYA Top SyriDge M.r.Dufa.c:turiq Co, Bombay

SBUJ. K. WAD(.&II'UU)

S.a. G. S. SJIVIU.A MirWtry oCDcfcnco( 001). NaIFDeJhj

SIIU K. K. AGNIBOTU ( .4l11tMU)

Da B. C. SJIfRA Ceutnl Glau &: Ceramic a-arch laiatitute

( CSrR ). Calcutta

SIIU R. S.. .

SBU G. P. SarVAaTAYA India MeteolCllical Department, New Delhi

8IIU S. GoPI NA'I'B (.41"""') .

SIIIlI SAm. CirAJID... Dim:cor GeIleral, lSI C&-4I.im M-w}

Director ( Chem )

SUrIItIry

....M. M. M.u.aoraA

Deptdf Direct (Chcm.). lSI

Volumetric Glauware Subcommittee. CDC 33 : J

c.-

Sau P. 8oroIil Glau Wor" Ltd, Bcmtbay

MlItI1Hrs

S... U. T. T__

Sbri P. R. Rao)

Sau S. V. GULAVAQ BhabhaAtomie 1leIearc:h Centie, Bombay

Sau K . M. MArnlAL MiDiatry or Defence (001)

S... R.. K. GtJIOYA( .4lJnuu) .

SIIIlI MoBDlllaa NA'I'B NadosWPh}'lica1 Laboratory ( CSIR). NewDeIhl

SIIIlI BaAJIU K. SAIII'AT The Seicntilie Illdiaa Glaa CO Ltd. Calcutta

SBu D. R. Sa (.4l1m1ort,)

SIIIlIJ. C. SIWfDJLYA Top SyriDge MaIlufactt&riq Co, Bombay

SsuJ. It. WAD( .411mM11 )

n..B. C. Snou. Qcntral Glul a: Ceramic Raearclt Inltitute

{CSIR}. Ca1catta

SBu S. VAIDYAlfATBU Vendl Glall Worb Pvt Ltd.lIaDplore

2

IS: 4161 (Put 1)-1985

Indian Standard

SPECIFICATION FOR

GRADUATED PIPETtES

PART 1 GENERAL REQUIREMENTS

( First Revision)

o. FOREWORD

0.1 This Indian Standard (Firat Revision) was adopted by the Indian

Standards Institution on 30 October 1985, after the draft finalized by the

Laboratoryware and Related Apparatus Sectional Committee had been

approved by the Chemical Division Council.

0.% This standard was originally published as IS: 4162-1967. Subsequently,

International Organization for Standardization brought out the following

standardsz

ISO 835/1-1981 LaboratoIY g1assware-Graduated pipettes-Part 1 z

General requirements

ISO 835/2-1981 Laboratory glasswaro-Graduated pipettes-Part 2 ~

Pipettes for which no waiting time is specified.

ISO 835/3-1981 Laboratory glassware-Graduated pipctte.-Part 3 I

Pipettes for which a waiting time of 15 s is specified.

ISO 835/4-1981 Laboratory glassware-Graduated pipettes-Part 4 :

Blow-out pipettes.

The committee responsible for the preparation of this standard decided

to revise IS : 4162-1967 to align with these ISO standards. Accordinglythis

standard is now being revised in four parts : -Part I-General requirements,

Part 2-Pipettes for which no waiting time is specified; Part 3-Pipcttes for

~ i waiting time of IS seconds is specified; and Part 4-Blow-out

pipettes.

8.3 In this revisionthe following have been included:

a) Method of setting of meniscus,

b) Procedure for measurement of capacity,

.Specificatioo Cor lfIlduated pipettcl.

3

IS : 4162 (Part 1 ) -198!

c) Pipettes having OS-ml capacity with Class A accuracy for Type 4

only.

d) Pipettes for which a waiting time of 15s has been .specified.

e) Pipettes known as pipettes. and

f) Table for dimensions haw been modified to bring in line with ISO

Standards.

0.4 This standard contains 13.2 which calls for agreement between the

purchaser and-the supplier.

o5 For the purpose of decldin' whether a particu1arrequirement of this

standard is complied with. the fl;nal value. observed or c:alcuIated, express-

ing the result of a test or analysIS. shan be rounded off in accordance with

IS : The number of signifiC811t places retained in the rounded

off value should be the same as that of the specified values in this

standard.

1. SCOPE

1.1 This standard ( Part 1 ) specifies the general requirements for graduated

pipeUel. suitable for general laboratory purposes.

1.1.1 The requirements specified are in conformity with IS: 8729-I'77t.

1.1.t.l Limits of .error for class A l'ipettes are shown in relation to

capacity in Appendil: A and in relatton to diameter at meniscus in

AppendixB.

2. TERMINOLOGY

2.1 Por the purpose of this standard. the definitions given in IS:

in addition to the foUowinS shall apply.

2.1.1 Reference Tempnature - The __perature at which the pipette is

intended to deliver its nominal volume (nominal capacity ). is27C.

2.1.2 Unit of Volume - The unit of volume is the cubic centimetre

(em' ). for which the Dame JDillilitre (D1l) is used.

2.1.3 Capacity

2.1.3.1 Capacity for Type 1 pipette - The capacity corresponding to

any graduation line of a pipette is the volume of water at 27*Cexpressed in

*R.ules for roUDdin, off Dumuica1 values ( rlVi*).

tPriDciples of CODJtrw:OOIl and aqjUltmeut of volumetric glUIWaN.

tGloeary of terms related to 11&11 and glUlWare (jirlt mIirioII).

4

IS : 416% (Part 1 ) 1985

millilitres, delivered by the pipette at 27C when emptied the line

to that graduation line. the outftow being unrestricted until makmg the

final setting of the meniscus on the graduation line, and no allowed

for drainage of the liquid adhering to the wall before makmg final

setting.

1.1.3.% Capacity lor Type 2 pipette - The capacity corresponding to

any graduation line of a pipette is the volume of water at 27C. expressed

in millilitres delivered by the pipette at 27C. when emptied from that gra-

duation line to the jet. the outflow being restricted until it is sure that the

meniscus has come to rest in the jet before removing the pipette from the

receiving vessel.

1.1.:U Capacity for Ty,. 3 pipette - The capacity corresponding to

any graduation line of pipette is the volume of water at 27OC. expressed in

millilitrcs. delivered by the pipette at noc. when emptied from the zero

line to that graduation line or in the case of total capacity delivering, to

the jet. the outftow being unrestricted until making the final setting of the

meniscus on the graduation line. and the -period aUowed for draining of

liquid adhering to the wall before making the final setting.

2.1.3.4 Capacity for 4 ( /S s waittn8 time) pipette - The capacity

corresponding to any graduation line is the volume of water at 27C.

expressed in millilitres, delivered by the pipette at 27C when emptied frOlJl

the zero line to that-graduation line. the outilowbeing interrupted whc:nthe

meniscus has come to a few mil1imetres above the graduation line. final

setting is made to the graduation line after waiting time of 15s,

In the caseof delivery of total capacity to the jet. the outflow shall be

unrestricted and a time of IS s shall be observed before removing

the pipette from the receiving veSsel.

2.1.3.5 for Type S ( blow-out) pipette - The capacity

correspondiDg to any araduation line for a graduated blow-out pipette is

the volume of water at 27C. expressed in millilitres, delivered by the

pipette at 27C. when emptied from the graduation line to the jet outflow

being unrestricted until it is sure that the meniscus has come-to reU in the

jet. with delivery being completed by expelling the last drop by

bloWJng.

2.104 Delirery Time - delivery time is.the time occupied by the free

descent of the water menISCUS from the hIghest graduation line to the

10000est line, in the case of I pipettes or to the point at

whichthe mernaeus appean to come to rest JD the Jet for Type 2 T)'PCl 3

lJP!'4 and:X:ype s In case, the pipette shall remam in

vertical poaition and WIth the reeemns vessel slightly inclined so that the

tip of tile jet is !It contact with the inside of the vessel. but without move-

ment of one aJ81Dst the other.

,

IS : 4162 ( Part 1 ) 1915

2.1.5 Deli"ery Jel- The lower end of the pipette which has been

Jradually tapered without any sudden constriction at the orifice and could

live rise to turbulent outfiow is called delivery jet.

2.1.6 Wailing Time- The waiting time is defined as the period of time

to be observed after the meniscus appeared to have come to reat in the jet,

and before the tip of the jet shall be removed from the receivin. vessel.

3. TYPES OF PIPEITES

3.1 The following types of graduated pipettes are specified.

a) Type 1- Graduated pipettes adjusted for delivery of a liquid

from zero lino ar the top to any graduation line, nominal .

capacity represented by the lowest graduation line, no waitin,

aimeis specified for accuracy. Class A and Class B (lee Part 2

of this standard ).

b) Type 2 - Graduated pipette adjusted for delivery of a liquid

from any graduation line down to the jet, nominal capacity

.represented by the highest graduation line. no waiting time is

specified for accuracy Class A and Class B (see Part 2 of this

standard ).

c:) Type 3 - Graduated pipette adjusted for delivery of a liquid

from zero line at the top to any araduation line, nominal

capacity obtained by delivery down to the jet, no waiting time is

specified for accuracy Class B only ( see Part 2 oftbia standard ).

d) Type 4- Graduated pipettes adjusted for deIiveryof a liquid

from zero line at the top to any graduated line, nominal c:apaclty

obtained by delivery down to the Jet. 15 s waiting time is specified

for ac:c:uracy ClaasA only (see Part 3 of this standard ).

e) Type S - Graduated pipettes adjusted for delivery of a liquid

from any graduation line down to the nominal capacity represen-

ted by the highest gTaduation line, the last drop in the jet

to be blown out lor accuracy Class B only (see Part 4 of this

standard).

4. ACCURACY

4.1 The graduated pipettes shall have the foDowing two c:lassea of ac:curacy

(lee Table 1): .

a) Class A - For the higher grade suitable for precision work.

b) Class 11- For the lower grade suitable for JCDeral purposes.

6

"

IS ; 4161 ( Part I ) - 1985

.s, NOMINAL CAPACITY

5.1 The graduated pipettes shall be of 0" ml, I mI, 2 mI, Sml, 10mI and

2.5 m1 nominal capacities respectively.

5.1 Procenre for MelSaremeat of Capadty

5.2.1 The dry and clean pipette shall be held in a ver?cal position and

filled with water to few millimetres above the graduation line or above tho

zero line, depending upon .the type of pipette the menis.cusshall then

be set to the line. Any drop adhering to the jet of the pipette shall be

removed by bringins the surface of a glaslvessel into contact with tho tip

oltho pipette.

5.1.2 Delivery shall then be made into another glass vessel slightly

inclined, so that the tip of tho jet is in contact with the inside of the

vessel, but without movement or one against tho other throughout the

delivery time and waiting period in for the Typo 4 pipette only ( see Part 2

of this standard). In case of S pipettes. the liquid remaining in the

tip of the jet shall be blown out m tho glass vessel.

5.1.3 To ensure that delivery is complete in the case of Type I. Type 2

and . Type 3 pipettes, a waiting time of approximately 3 s shall be observed

before removing the pipettes from the receiving vessel.

Nors - The waitiDI period or! s it apeciSedoaly rOl' the purpole or definitiOll. 1JI

use, it is UDDecaaarr to adhere; dOle to Ih1Iperiod, it it .umcient to be certain that

the mcIliacul hal come to rat ill tile jet before retDOriJls thc pipette Crom COQtac:C with

the receiviDt .esIC:l.

5.1.4 Thewater delivered as described in 5.2.1 to 5.%.3 above is cOllected

in a previous weight glass container -and is weighed again to determine

the mass. of the water delivered. The temperature of water, air and

boremetric pressure are noted and that the volume of water delivered by the

pipette at 27C is calculated by applyinl appropriate corrections as liven

in IS: 1729-1977-.

,. UMITS 0' VOLUMETRIC ERROR

&rors in the volume shall not exceed tile limits as shown

m:r

ablc

I . These limits represent the maximum permissible error at any

PO!Dt and the maximum permitted diff'crence bctW'CCll the errors at any two

poJDtl.

.PriDcipIa of CUiiftlldioa aDdMljlutmem of vohamctric

7

IS : 416'1. ( Part 1 ). 1985

TABLE I CAPACITIES, SUB-DIVISION AND UMrn O' ERROR

(Cla.s. 6.1 )

0'01

0'02

0'05

0'1

Class B

ml

(5)

SILUI.Ur

SCALa DIvmON

NOIlUfAL

CAPACITY

SL

No.

'Class A

ml ml m1

(1) (2) (') (4)

i) 0'5 0'01 0-005

ii) 1 0'01 0'006

iii) 2 0'02 0'01

iv) 5 0'05 0'03

v) 10 0'1 0'05

vi) 25 0-1 0'1

vii) 25 0'2 0'1 0'2

NoD 1- Ifpipettca are required of capacitica and/or lub-divilioDI other than thOle

listed in this table, "it is recommended that they coDform to the essential requirement of

this part of specificatiOD.

NOTa 2 - The limitl ofvolumetric error shall Dot exceed the lDlallat lCale diYiliOll.

7. CONSTRUCTION

7.1 Materi..

1.1.1 Graduated pipettes shall be constructed from glass of suitable

chemical and thermal properties, shall be as free as Car as possible from

visible defects and shall be reasonably free from internal stress. When

graded according to the metbod prescribed in IS : 2303-1963* the pipettes

shall confirm to Type 1 of the glass.

Non- Amber or other coloured g1asI IDay beased tor spec:iaI purposes.

7.1. DiaaeasiODS

7.2.1 Graduated pipettes shall comply with dimensional requirements

given in Table 2.

7.3 FiDisII- The graduated pipettes shall be ofrcauIar shape and smoothly

finished. They shall be symmetrical about the axis.

7.3.1 Top of i p ~ t t - The top of pipette shall be finished square with

the axis of the pipette and shall be frco from any blemishes which might

interfere with the required accurate control by the finsa' in settin. tho

meniscus. The end may be lightlyfire-polilhed or smoothly Jfound with a

slight bevel on tho outside.

-Method of gradiur "lISfor alblinity.

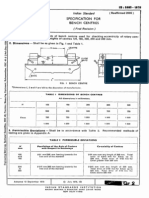

8

TABLE 2 DDDNlIONS

( C1QU# 702.1 )

DnOllfl101l1 NOMINAL CAPACITY, m1

(mm> r ~ ______~

0'5 1 2 5 10 25 25-

D!ttance (rom zero line to lawen

MQJt

- 220 220 220 220 220

gr.duation line (or Type 1 pipettea Min

- 160 160 180 180 180

Eaential Distance from highest to 10wClt MQJt 220 220 220 220 220 220 290

dimentiOIlI li3:ed pu.tion lines for each Milt 140 140 140 160 160 160 250

Cmm) o apipette

Diataace from JUPat ....du.tion Min 100 100 100 100 100 100 100

line to top of pipette

'0

Exteraal cnalDeteJ' of auction tube MQJt

- - - 8'3 8'S SoS OoS

Mill - - - 6'8 68 6'8 6'8

Leqth altube oIuaiform bore bdow Min 10 10 10 10 10 10 10

lowest ....duation line

OYenllleqth S60 360 360 360 360 360 450

fi.l

..

..

llec"'I'''C''o:led Leqth aI tapered portion Conning jet 20 20 20 25 25 30 SO

e

namlaal

climenJiOIll F.stemal diameta of jet .t top of 25 25 25 3 S 3 3

-

<mm) bcvd

~

Wall tbicbell

::l

2 2 15 I 1 I I ...

'-'

Valid only for til, 25/01 ml pipette <SII Part' oflhil atandaJd ).

,

...

\0

00

Ut

IS : 4161(Part 1 ) - 1985

7.3.1 let - The lower end of the graduated pipette shall

terminate in d.elivery jet a smooth and gradual taper without any

sudden constncnon at the orifice which could give rise to turbulent outflow.

. The end of the jet shall be Jinished by one of the methods listed below

(In the order of preference) :

a) Smoothly ground square with the axis sliptly bevelled on the

outside and fire-polished; ,

b) Smoothly ground square with the axis, slightly bevelled on the

outside; and

c) Cut square with the axis and fire-polishect.

8. GRADUATION AND FIGURING

&1 Gradllltioa Uae.

8.1.1 Graduation lines shall be clean permanent and uniform lines of

thickness not exceeding 03 mm.

8.1.1 All graduation lines shall lie in planes at right angles to the

longitudinal fUil of the pipette.

8.2 S,acia, of Grad....oD LIDes

8.2.1 There shall be no evident irregularity in the spacing of the

pduation Jines.

8.2.2 The limits on the spacing of graduation lines shall besuch thit the

scale lengths are within the limits allowed in Table 2.

&3 L.ltJa 01Gn...tioD LiHI

8.3.1 Graduation Pattern 1

a) The length of the short linea shan beapproximately, but not

less than SO percent of the circumference of the pipcUel;

b) The length of the medium lines shall be approximately 65 percent

of the circumference of the pipettes and shall extend symmetri-

calIyat each end beyond the end of the short linea; and

c) The Jong lines shall extend compIetcJy round the c:in:umference of

the pipettes, but a saP. not exceeding 10 pcm:Dt 01tho c:ircam.

ference, may be permitted.

8.3.2 Graduation Pattern 2 .

a) The length of the short JiDea shaI! bcnot leas than 10 percent and

not more than 20 perceotof tho c:ircumfCll'CDce oftho pipettes;

10

IS : 416% ( Put 1 ) 198!

b}The -JIh of lhe medium wa ,han be approximately ' :5 times

dw _,til or the short liJIII aDd ahaJ1 ellald Symmctllcally at

~ end bc,ond the CDda or the Ihort liDa; and

c) The 10D' lines ,haJJ extend completely round the circumference

of the pipetta but PP. DOt elalCldinl 10 percent of the

cucumlerenc:e. may be pmnitteel.

U-J GroJ-'iDII PGII",. J

.) n. Imltb 0( the sbort liDa IhaJI be Dot ICII than 10 percent

aDd DOt more tban 20 percentof the circumference or the pipettes;

b) ne !eDith 0( tbe mcdilUD lina ,baD be .ppfosimately I'S times

the IenJtb or the sIkm linea and ahan extend lymJDetric:aUy at

each CIId bcyODd dw ends of tho ,bon tiDeS; and

e) The Ienatb of the lon, liDa ahaJJ benot leu than twice tho lenath

01 the.nort liDa and sball uteud ,ymmetrically at each end

beyond tbe end oftbe short and medium 1iDcs.

IA ~ 1M Se'.I.tA "G....... U.. (1ft 111.1)

Ul OIl pipettes ia which the YOlume equiftlent of the smallest seale

dirision is 0-0I ml or 0-1 mJ:

.} Emy tCDtb ",.dllation liDe shaD be a long line;

b) t'berc ahaU be medium line midway between two CODsecutive

lOll' lines; aDd

c) t'bere shall be four short lines between coDJecutive medium and

kJq rmea.

.....2 OIl pipettes in which the YOIume equivalent of the smallest ecale

4iwisioe II 01U .. or 0'2ml:

a) 1!wrJ 6f\b lfaduatiOD line abaIl be a Jon, line; ad

b) n.eahaJl be(our abort liDes bttwecotwoCOIlIClc:Utivc malinca.

c ~ ~ o ~ r : ~ ill -bich tbe YOla&me equinJaat of the smallest ae

a) 2wry lath padaatioa liDe shall be.lon,liDe;

b) 1'1IIen ~ be rour medham lines equaUJ spICed betweentwo

COIaaeC\a1Ye 1oa,1iDa; aad

c) ~ e ,baD one short tiDe belwem two CODIeCUtive medium

.... Clf bet CODIClCUItfe mcdiua aJld loa, linea.

U ......... GIII u..(.. J1I.%)

U1 OIl pipettes pachaated aceontin\: ttan J

*'" "..boa 1_ lUll lie 011 an pa ~ :1 ~ cadi or the

_,nlllty Yc:mc:aJ liDe downthe

11

IS :4162( Part 1 ).1985

o

0'01 0-02

0,'

O-Qt

0'2

1 2 3

A GRADUATION PATTERN

0

0 0

-

-

-

-

-

-

-

1 2

3'

B GRADUATION PATTERN II

0 0 0

-

--

- -

1 2 3

C GRADUATION PATTERN lIJ

FIG. I LEN<mI AND or Ol,ADUA11O'N lJ.-

GRADUATION

PAHUN J

fJo. 2 ,...... or OUDUA1'ICII'f l.DGI

12

IS : 4162 ( PII1 1) -1915

centre of the front of the pipette, the lines themselves extending

to the left when the pipette is viewed from the front In the posmon of

norma) use.

8.5.1 On pipettes graduated according to pattern 2 or 3, the mid-points

of the short and medium graduation lines shall lie on an vertical

line down the centre of the front of the pipette, when the pipette IS viewed

from the front in the position of normal use.

8.6 FJpriag of Grad.doD LiaeI- Details are given in Table 3.

TDLB 3 fiGURING OF GJUDUATJON UNBS

SL

No.

(I)

i)

ii)

jji)

iv)

v)

vi)

vii)

NOIlllUL

CAPAClI'rY

(mt )

(2)

0'5

1

2

5

10

25

25

SIIALLUT SCAU

DlVDtOlll

(ml )

(3)

0'01

0'01

0'02

0'05

0'1

0'1

0'2

FIOUaaDAT

EVERY

(mt)

(4)

0'1

0'1

0'2

0'5

1'0

1'0

2'0

,. PERMANANCY AND VISIBILITY os GRADUATION LINES,

FIGURES INSCRJPrIONS AND MAIlIINGS

'.1 AIl figures inscriptions and markings shall be of such size and form as

to be clearly legible under normal condition of use. .

'.1 AU araduation Jines. figures inscriptions and markings shall be clearly

visible and permanent.

,.3 If enamel colours are used for above purpose. the requirements of

IS : shan becomplied with.

':4If any other method is for above purposes, the araduated

pIpettes shall be completely l1Dmcraed In 0'1 N hYdrochloric solution and

autoclave at 98'1 tN/rn

l

at 120"C for 30 minutes. The marleing shall not

show appreciable reduction in intensity.

*Method. for .-iDs the chelQical resistuu:e or enamel. used Cor colour coding and

colour markmg.

13

IS ; 4162 ( Part 1 ) - 1985

10. SETTING OF THE MENISCUS

10.1 The meniscus is set so that the plane of the upper edge of the

graduation line is horizontally tangential of the lowest point of the menis-

cus, the line to sight being in the same plane.

11. DEUVERY TIME

11.1 The delivery time shall be within the limits specified for the particular

pipettes.

11.1 The delivery time is determined with the pipetto in a vertical

position and with the receivin g vessel slightly inclined ao that the tip of the

jet is in contact with the inside of the vessel, but without movement of one

against the other.

NOTIl - It is important that glall receiving vessel iI used. Capillary dl'ectl

inftuenemg the delivny time depend eowiderably oa the material oa which the liquid

runs down.

u. COLOUR CODING

11.1 If colour coding is used on these graduated pipettes, it shall comply

with the requirements of IS : and IS: 11469-198St.

13. MARKING AND PACKING

13.1 Each pipette shall be market permanently and legibly on its surface

with the following information:

a) Nominal capacity followed by 'ml';

b) Letter 21C to indicate the reference temperature;

c) Letter 'N or 'B' to indicate the class of accuracy for which the

pepette has been adjusted;

d) The waiting time, if specified;

e) The delivery time;

f) Type of pipette;

g) Asmall white ring (etched, sand-blasted 0 r enamelled) close to

the top of the pipette, in the case of blow-out pipettes. Addi-

tionally, these pipettes may have an inscription that the instru-

ment is a blow-out pipette, for example, 'blow-out';

h) Maker's name or 'reeognized trade-mark, if any; and

J) ''The letter 'Ex' to indicate that the pipette has been adjusted for

delivery".

SpecifiClLtion -colour ccx1ing of pipettes.

t Method of --.j1Jl chemU:a1 residaoc:e ore:aameIs used for coIoar codinr.

14

IS : "16% (Part 1). 1985

13.1.1 The pipette mayalso be marked with the lSI Certification Mark.

NOTJI - The we of the lSI Certification Mark ialO"emed by-the proviaionJ of the

Indian Standanb Institution (Certificatioa Mub) Ad, and the Rules and Regulation

made theftuDder. The lSI Mu& OD producta covered by an Indian Standard conveye

the.-.nee that they have been produced to comply with the requirementl of that

ltandard under a well-defined IYItemof inlpection. tc:Itinl and quality control which

iI deviled and I U ~ by lSI and operated by the producer. lSI marked pro-

ductl are aIIo COIltlnUOUlly checked by lSI for conformity to that ltandard u a further

I&fesuard. Detaill of conditiom under which a licence for the lIIe of the lSI CertifiCA-

tion Mark may begranted to manufacturen or proc:eaors, m"y be obtained from the

Indian Standard. In.titution.

13.% Tho pipettes shall be packed as agreed to between the purchaser and

the supplier.

1'" SAMPLING

14.1 Representative samples of the pipette shaD be draq as prescribed in

AppendixC .

P P E N I ~ A

(C/Quse 1.1.1.1)

ULATIONSIDP BETWEEN VOLUMETRIC CAPACITY AND

LIMITS OF EUO. FOR CLASS A PIPETTES AS

REQUIRED BY 3.4 OF IS: 7829-1977"

2S 10

/

-:

I'

V

V

-:

./

/'

/'

6

5

0.5

10

30

2 5

CAPACITY OF PIPETTE

1

ml

Principla of CDIIItnIctioll and adjustment of YOlumetricsi-ware.

"3. 100

-It

o

ffi SO

15

(S : 4161 (Part 1 ) 1985

10

5

u,

o

!:e

!e

... -

u.1II:

t-III: 0.9

Zw

0.7

>t-

-w

52

w3

111:0

w

z

::i

1.8 206 3.8 5.9 8010 to"' 0.3

MENISCUS DIAMETER, mm

APPENDIX C

( C/llUU 14.1)

SAMPLING OF GRADUATED PIPEIIES

c-i, SCALE OF SAMPLING

C-l.l Lot -Ina single consignment of the pipettes ofthe same type, class

and capacity shall constitute a lot .

C-t.1 Sampleshan be tested from lot the cOnformity of

the pipettes to the requirements of this specificatJOD and shall be m accord-

ance with Table 4.

PrillCiples ofconstruetion and adjustment oIYGl.-etric pl.laW&tt.

16

IS : 4161 ( Part 1 ) - 1985

TABLE 4 NUMBER -OF PI "I"I'ES TO BB SELECTED

( ClauR 01.2 )

Lor Sua SAllPUI Srza POa -SAMPUI Srza POIt

DEITIlucmva TBST . NOIfDaITllUarlva

Tan

(I) (2) (3)

Up to 25 1 3

26 to 50 2 3

C-l.3Pipettes shall be selected from the lot at random and in order to

ensure the randomness of selection. the method given in IS : 4905-1968*

may befollowed.

C-Z. CRITERIA FOR CONFORMITY

C-Z.l The lot shall bedeclared as conforming to the specificationif all the

pipettes selected. pass destructive and non-destructive tests.

-Methods for random lampling.

17

AMENDMENT NO. I JULY 2007

TO

IS 4162 (PART 1): 1985 SPECIFICATION FOR

GRADUATED PIPETTES

PART 1 GENERAL REQUIREMENTS

( First Revision)

(Page 8, clause 7.1.1) - Substitute the following for the existing clause:

'7.1.1 Graduated pipettes shall. be constructed from glass of suitable chemical

and thermal properties, shall be as free as far as possible from visible defects

and shall be reasonably free from internal stress. When graded according to the

method prescribed in IS 2303 (Part l/Sec 1) : 1994*, the pipettes shall conform

to Class HGB 1 of the glass.'

NOTE - Amber or other coloured glass may be used for special purposes,'

(Page 8,/ootnote marked *) - Substitute the following for the existing:

'*Grading glass for alkalinity: Part I Hydrolytic resistance, Section 1 Hydrolytic resistance

of glass grains at 9S'C - Method of test and c1assification (first revision). '

(Page 15, clause 13.1.1) - Substitute the following for the existing

clause:

'13.1.1 BIS Certification Mark

The pipette may also be marked with the Standard Mark.

13.1.1.1 The use of the Standard Mark is governed by the provisions of Bureau

of l 'dian Standards Act, 1986 and the Rules and Regulations made thereunder.

The details of conditions under which the licence for the use of Standard Mark

may be granted to manufacturers or producers may be obtained from the Bureau

of Indian Standards. '

(CRD 10)

Reprography Unit, BIS, New Delhi, India

INTERNATIONAL SYSTEM Of UNITS (81 UNITS)

8 ... Unit.

QuVttlty

Unl' Symbol

lenatJI

metre m

M..,

kilogram kg

nme .eeond I

"Electric current ampere A

Thermodynamic IIelvln K

temperature

luminoul Intenally candela cd

Amount of lub,tance mole mol

Supplem.ntary Unlb

Quantity

Unl'

Symbol

Plane angle radian rad

Solid angle steradian sr

Derived UnIts

Quantity Unl'

SymbOl DeflnlUoll

Force newton N N-1 kjl. m/a"

Energ, Joule J J - 1 N.m

Power

watt W W - 1 J/I

Flux

weber Wb 1 Wb -1 V.I

Flux denally

tella T 1 T -1 Wb/m"

Frequency

hertz Hz t Hz- 1 ell (a_I)

aeetrle conductanc.

lIemena

S S-1A/V

Electromotive force

volt

V 1

V - t W/A

Pr.alure, atre.s

pa,cal Pe Pa - 1 N/m"

You might also like

- Instrumentation and Measurement in Electrical EngineeringFrom EverandInstrumentation and Measurement in Electrical EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- Iso 835Document20 pagesIso 835Oswaldo Avalos QuispeNo ratings yet

- 6280Document13 pages6280sanbarunNo ratings yet

- Disclosure To Promote The Right To InformationDocument27 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- IS 460 Part 1Document19 pagesIS 460 Part 1Muhammed NoufalNo ratings yet

- Is 4251 1967Document18 pagesIs 4251 1967Nataraj NagarajanNo ratings yet

- Is 7326-3 (1976)Document11 pagesIs 7326-3 (1976)slamienkaNo ratings yet

- 2720 (Part-XXI) PDFDocument10 pages2720 (Part-XXI) PDFSoundar PachiappanNo ratings yet

- Is.2470.1.1985 Septic Tank Part 2Document29 pagesIs.2470.1.1985 Septic Tank Part 2V Jay KrNo ratings yet

- Is 2720.8.1983Document14 pagesIs 2720.8.1983Elumalai Srinivasan100% (2)

- IS CODE Fire ResistantDocument25 pagesIS CODE Fire ResistantSunil KalwaniyaNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationsharathknNo ratings yet

- Is 774 1984 R 1995Document24 pagesIs 774 1984 R 1995nagaraju3135No ratings yet

- Is 3068 - 1986 Specification For Broken Brick (Burnt Clay) Coarse Aggregate For Use in Lime ConcreteDocument9 pagesIs 3068 - 1986 Specification For Broken Brick (Burnt Clay) Coarse Aggregate For Use in Lime ConcretePrapa KaranNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Is.4968.2.1976 Dynamic Cone Penetration Method Using Bentonite SlurryDocument14 pagesIs.4968.2.1976 Dynamic Cone Penetration Method Using Bentonite SlurryMilind GuptaNo ratings yet

- Is 1200 (Part 21) 1973 Method of Measurement of Building and Civil Engineering Works, Part 21 - Wood-Work and JoineryDocument13 pagesIs 1200 (Part 21) 1973 Method of Measurement of Building and Civil Engineering Works, Part 21 - Wood-Work and JoineryRoseNo ratings yet

- Reaffirmed 1995Document10 pagesReaffirmed 1995mondianeerajNo ratings yet

- Disclosure To Promote The Right To Information: IS 3913 (2005) : Suspended Sediment Load Samplers (WRD 1: Hydrometry)Document19 pagesDisclosure To Promote The Right To Information: IS 3913 (2005) : Suspended Sediment Load Samplers (WRD 1: Hydrometry)octatheweelNo ratings yet

- Is 2373 Water MetersDocument25 pagesIs 2373 Water Metersnp27031990No ratings yet

- Disclosure To Promote The Right To InformationDocument28 pagesDisclosure To Promote The Right To InformationAMIAMINo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Is 15058 2002Document12 pagesIs 15058 2002Santosh KumarNo ratings yet

- Is 2720 2 1973 PDFDocument24 pagesIs 2720 2 1973 PDFbiswanirman100% (1)

- Ieee C.57.104-1991Document39 pagesIeee C.57.104-1991Dimas F Febryanto100% (1)

- IS2026Document142 pagesIS2026Imran HussainNo ratings yet

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationJaisree Balu PydiNo ratings yet

- IS 2720 Part-41.1977Document20 pagesIS 2720 Part-41.1977कृत्या नंद झाNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationhumayun mdNo ratings yet

- Is 6913 1973Document11 pagesIs 6913 1973diwakar1978No ratings yet

- Is 14845 2000 PDFDocument21 pagesIs 14845 2000 PDFmethusalakannanNo ratings yet

- IS 4880-3 (1976) - Code of Practice For Design of Tunnels Conveying Water, Part 3 - Hydraulic Design PDFDocument20 pagesIS 4880-3 (1976) - Code of Practice For Design of Tunnels Conveying Water, Part 3 - Hydraulic Design PDFrahuldevpatel5No ratings yet

- " RTR:+-#L': CarryingDocument41 pages" RTR:+-#L': CarryingAaron WilsonNo ratings yet

- Is 10500 1991Document16 pagesIs 10500 1991Ramu NagulaganiNo ratings yet

- Is 9178 1 1979 PDFDocument29 pagesIs 9178 1 1979 PDFHarshil AminNo ratings yet

- Conduit SpecificationDocument22 pagesConduit Specificationamijetomar08No ratings yet

- Is 1200 2 1974 PDFDocument20 pagesIs 1200 2 1974 PDFAr Hussain MojahidNo ratings yet

- BP107 (A4) 1Document4 pagesBP107 (A4) 1Huda TajuddinNo ratings yet

- Is 2470 - 2Document24 pagesIs 2470 - 2lunar_vipNo ratings yet

- Pitot Tube StandartDocument45 pagesPitot Tube Standartdesrytandi0% (1)

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationduonzaNo ratings yet

- Is 10096-2 (1983)Document17 pagesIs 10096-2 (1983)slamienkaNo ratings yet

- Is 1344 1981Document15 pagesIs 1344 1981VijayKatariaNo ratings yet

- CO2 ScrubberDocument73 pagesCO2 ScrubberDarshan ShahNo ratings yet

- 9178 3Document72 pages9178 3govimanoNo ratings yet

- IS 9178-Part-1 PDFDocument32 pagesIS 9178-Part-1 PDFvijay84mech100% (2)

- BIS Multi Purpose Dry BatteriesDocument15 pagesBIS Multi Purpose Dry BatteriessreeramaNo ratings yet

- Indian Standard: Specification FOR Single Faced Sluice Gates (200 To 1200 MM Size.)Document25 pagesIndian Standard: Specification FOR Single Faced Sluice Gates (200 To 1200 MM Size.)gpskumar22No ratings yet

- Hydrodynamically Stable Towed Transmitter BodyDocument9 pagesHydrodynamically Stable Towed Transmitter BodyManoj T IssacNo ratings yet

- 4516 PDFDocument10 pages4516 PDFRajesh BabuNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Photonics, Volume 2: Nanophotonic Structures and MaterialsFrom EverandPhotonics, Volume 2: Nanophotonic Structures and MaterialsNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Is.6886.1973 Axial Load Fatigue TestDocument17 pagesIs.6886.1973 Axial Load Fatigue TestBala MuruNo ratings yet

- ISO 14253 1 1998 DAmd 1 E Character PDF DocumentDocument6 pagesISO 14253 1 1998 DAmd 1 E Character PDF DocumentBala MuruNo ratings yet

- Specific Criteria Site Calibration Laboratories: For Site Testing andDocument11 pagesSpecific Criteria Site Calibration Laboratories: For Site Testing andBala MuruNo ratings yet

- Bench Centre Is.5980.1978Document3 pagesBench Centre Is.5980.1978Bala MuruNo ratings yet

- EURAMET CG 18 02 Non Automatic Weighing InstrumentsDocument83 pagesEURAMET CG 18 02 Non Automatic Weighing InstrumentsPurwanto NugrohoNo ratings yet

- Is.1672.1967 Dairy ThermometerDocument14 pagesIs.1672.1967 Dairy ThermometerBala MuruNo ratings yet

- Nabl News Letter 40Document40 pagesNabl News Letter 40Bala MuruNo ratings yet

- Pipe Thread STDDocument1 pagePipe Thread STDBala MuruNo ratings yet

- Try It For Yourself: Platform OverviewDocument32 pagesTry It For Yourself: Platform OverviewМаниш НахтвандерерNo ratings yet

- 101-0020 USB-RS485 Converter Manual R2Document8 pages101-0020 USB-RS485 Converter Manual R2Juan Pablo Villazon RichterNo ratings yet

- Mgiter-Navsari Electrical Engineering Department Lesson PlanningDocument3 pagesMgiter-Navsari Electrical Engineering Department Lesson PlanningJAY S TANDELNo ratings yet

- Quality in Practice - Building Trust Through Quality at GerbDocument6 pagesQuality in Practice - Building Trust Through Quality at Gerbsakshi1404No ratings yet

- Research Article: Linkage Between Economic Value Added and Market Value: An AnalysisDocument14 pagesResearch Article: Linkage Between Economic Value Added and Market Value: An Analysiseshu agNo ratings yet

- Chocolate Chip Banana BreadDocument8 pagesChocolate Chip Banana BreadouruleNo ratings yet

- Clap SwitchDocument2 pagesClap SwitchAakash GhoderaoNo ratings yet

- Focus2 2E Workbook Answers PDFDocument1 pageFocus2 2E Workbook Answers PDFРоксоляна Бубон0% (1)

- Prerequisites From Differential Geometry: 1 Isotopies and Vector FieldsDocument8 pagesPrerequisites From Differential Geometry: 1 Isotopies and Vector FieldsnotafacefuckerNo ratings yet

- Marketing Moguls Gartons IIM Kashipur FinalsDocument22 pagesMarketing Moguls Gartons IIM Kashipur FinalsTarun SinghNo ratings yet

- Answer Key For The 11th Grade English Final TestDocument1 pageAnswer Key For The 11th Grade English Final TestMyagmarsuren NyamtaivanNo ratings yet

- English 8 Q2M3Document5 pagesEnglish 8 Q2M3Mark Jhoriz VillafuerteNo ratings yet

- Apply 5S ProceduresDocument8 pagesApply 5S Proceduresdagmabay136No ratings yet

- René Prieto-Body of Writing - Figuring Desire in Spanish American Literature - Duke University Press Books (2000)Document309 pagesRené Prieto-Body of Writing - Figuring Desire in Spanish American Literature - Duke University Press Books (2000)Mariana AveituaNo ratings yet

- Spec Merlin Gerin MCCBDocument85 pagesSpec Merlin Gerin MCCBTen ApolinarioNo ratings yet

- Historia The FelidsDocument5 pagesHistoria The Felidsbalim01100% (1)

- Maklumat Vaksinasi: Vaccination DetailsDocument2 pagesMaklumat Vaksinasi: Vaccination DetailsNORFADHLI ARIFNo ratings yet

- Eve To Her Daughters: (Judith Wright, 1915 - 2000)Document3 pagesEve To Her Daughters: (Judith Wright, 1915 - 2000)Angelica PagaduanNo ratings yet

- GTB Jeremiah DownloadDocument87 pagesGTB Jeremiah DownloadEdwin PitangaNo ratings yet

- Lab 7b - Bilateral Transfer and Observational LearningDocument3 pagesLab 7b - Bilateral Transfer and Observational Learningapi-448989844No ratings yet

- 3.5 T Bolier ManualDocument206 pages3.5 T Bolier Manualchandravadiyaketan150467% (3)

- Analyzer SiteHawkDocument2 pagesAnalyzer SiteHawknickNo ratings yet

- 30+ Types of Project RiskDocument1 page30+ Types of Project RiskSulemanNo ratings yet

- Crevis Blower Control Feeding System: Scale AQ ASDocument2 pagesCrevis Blower Control Feeding System: Scale AQ ASpablo esteban jara reyesNo ratings yet

- Academic TranscriptDocument1 pageAcademic Transcriptdangthanhhd79No ratings yet

- A New Mutuel Kerberos Authentication Protocol For Distributed SystemsDocument10 pagesA New Mutuel Kerberos Authentication Protocol For Distributed SystemsRahul prabhaNo ratings yet

- Project 2 Wikipedia Project ReflectionDocument2 pagesProject 2 Wikipedia Project Reflectionapi-659259835No ratings yet

- WEEK 17 LAB EXERCISE Reproductive System Male Female 1Document6 pagesWEEK 17 LAB EXERCISE Reproductive System Male Female 1DELA CRUZ, JENISSE LOUISSENo ratings yet

- AI Aur Sunni Naujawan (Roman Urdu)Document26 pagesAI Aur Sunni Naujawan (Roman Urdu)Mustafawi PublishingNo ratings yet

- Business Day - Insights - Credit Management - February 2021Document2 pagesBusiness Day - Insights - Credit Management - February 2021SundayTimesZANo ratings yet