Professional Documents

Culture Documents

Failure of ID Fan Shaft and Bearing Assembly

Failure of ID Fan Shaft and Bearing Assembly

Uploaded by

Snehasish MukherjeeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Failure of ID Fan Shaft and Bearing Assembly

Failure of ID Fan Shaft and Bearing Assembly

Uploaded by

Snehasish MukherjeeCopyright:

Available Formats

PROJECT : PROBLEM :

TALCHER STPP FAILURE OF ID FAN 5-B SHAFT AND BEARING ASSEMBLY

ID Fan 5-B was trial run on 25/04/04 with both inlet and outlet gates in open condition. Fan bearing temperature was observed to be raising and hence, the fan was stopped. The bearing was opened for inspection. It was observed that the liners of drive end and non-drive end bearings were damaged and the babbit has come out. The shaft journal was having pitting and which was observed to be the cause for damage of bearing liners. The following items were also damaged:1. 2. 3. 4. Shaft assembly Liner dodge pillow block assembly (expansion NDE ) Liner dodge pillow block assembly (non-expansion - DE) Thrust plate kit

On verification of records, it was observed that the shaft was inspected and cleared for erection by BHEL/Ranipet on 02/12/03, when it was taken up by Site about rusting and pitting of shaft. Further, the shaft supplied for Unit-6 was also found pitted at the journal portion. Site has inspected the bearings and polished the shaft further with oil stone and run with Servo system 68 oil with new liners on 03/05/04. The bearing temperature was found raising and it was stopped. On inspection of bearing, the babbit was observed to be slightly peeled off. Ranipet expert was deputed to site and journal was further polished. More viscous servo system 100 oil, which was recommended by bearing supplier, M/s Dodge/USA was used and the fan was run. Fan performance was observed to be in order. However, NTPC was

insisting to replace the shaft, since they do not want shaft with repaired journal in newly supplied Fan. It was decided to replace the shaft by a new one for final acceptance of the equipment by NTPC. The shaft supplied in mandatory spare to NTPC is also pitted and rusted. Further, the bearing liners were damaged due to pitting on the shaft journal. Similar pitting in ID Fan shaft journal portion is reported from NTPC/Ramagundam site also. Conclusion: The damage to shaft journal is attributable to lack of protection against corrosion probably due to poor preservation, packing and transport or storage. This could avoid high cost to BHEL/customer by way of replacement/delay in erection & commissioning, which is a deemed profit.

You might also like

- Learn MarathiDocument3 pagesLearn Marathiapi-371067764% (11)

- Dec ManualDocument50 pagesDec Manualjesus paul cuellar zegarraNo ratings yet

- Forced Draft BlowerDocument108 pagesForced Draft BlowerTrevor ChandlerNo ratings yet

- ID Fan BoilerDocument23 pagesID Fan BoilerAli BariNo ratings yet

- Flue Gas Duct Opening Details at Chimney V1 R1Document2 pagesFlue Gas Duct Opening Details at Chimney V1 R1oundhakarNo ratings yet

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementmohammadNo ratings yet

- 0497 4 Flow Straightener Catalog Sheet 05 14Document2 pages0497 4 Flow Straightener Catalog Sheet 05 14mkfe2006No ratings yet

- LAC - Air Oil Cooler With AC Motor For Industrial Use - HY10-6001 UKDocument12 pagesLAC - Air Oil Cooler With AC Motor For Industrial Use - HY10-6001 UKMorgan PalmaNo ratings yet

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- ID Fan Motor Data Sheet, Rev. 1Document8 pagesID Fan Motor Data Sheet, Rev. 1Suman GhoshNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Fan Inlet System EffectsDocument4 pagesFan Inlet System EffectsEzrizal Yusuf100% (1)

- An Engineers CasebookDocument87 pagesAn Engineers CasebookParesh AdhwaryuNo ratings yet

- Sulphur Remelters PDFDocument4 pagesSulphur Remelters PDFNenadNo ratings yet

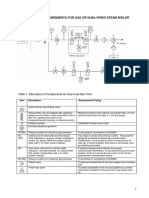

- Gas Train Requirements For Gas or Dual Fired Steam Boiler PDFDocument2 pagesGas Train Requirements For Gas or Dual Fired Steam Boiler PDFringo limNo ratings yet

- Resistance Equivalent Length FittingsDocument3 pagesResistance Equivalent Length FittingsRicardo DaclanNo ratings yet

- ESP Is The Static PressureDocument7 pagesESP Is The Static PressureArlene DeiparineNo ratings yet

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisNo ratings yet

- KAT B 5512 HYsec Edition2 en 12 10Document16 pagesKAT B 5512 HYsec Edition2 en 12 10Sathishkumar DhamodaranNo ratings yet

- 5a - Boiler Construction Continued - Internals - Superheaters LockedDocument0 pages5a - Boiler Construction Continued - Internals - Superheaters Lockedganeshan100% (1)

- Gearmotor Sizing Guide PDFDocument5 pagesGearmotor Sizing Guide PDFAnonymous Hy5Ir9QXNo ratings yet

- Vra Types Sealing For AgitatorDocument4 pagesVra Types Sealing For Agitatorxiaohe2019No ratings yet

- Shaft Clamp ElsDocument20 pagesShaft Clamp ElsAlejandro Fabián MoreyraNo ratings yet

- Kiln Stop Due To ID Fan VibrationDocument1 pageKiln Stop Due To ID Fan VibrationSafrin SangiaNo ratings yet

- The Basic Oxygen Steelmaking (BOS) ProcessDocument7 pagesThe Basic Oxygen Steelmaking (BOS) Processaecsuresh35No ratings yet

- Movex 2016USALDocument332 pagesMovex 2016USALserenetaNo ratings yet

- Catalytic Activated Ceramic Dust Filter For Removal of Dust NOx Dioxin and VOCs 2006Document5 pagesCatalytic Activated Ceramic Dust Filter For Removal of Dust NOx Dioxin and VOCs 2006Joseph RileyNo ratings yet

- FMEA TemplateDocument28 pagesFMEA TemplatehiryanizamNo ratings yet

- D Fog PDFDocument8 pagesD Fog PDFTanmay MajhiNo ratings yet

- Modulating Control (Operating Procedure)Document32 pagesModulating Control (Operating Procedure)goodgranitNo ratings yet

- Air CannonDocument2 pagesAir CannonJohn FulksNo ratings yet

- Flow ConditionerDocument6 pagesFlow ConditionerIdehen KelvinNo ratings yet

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal Arrangementmasoud67aNo ratings yet

- Heavy Duty Industrial FanDocument16 pagesHeavy Duty Industrial FanAli MarsousiNo ratings yet

- Pump System Hinsom Bore PumpDocument78 pagesPump System Hinsom Bore Pumpsaroat moongwattanaNo ratings yet

- Specification of Rotameters: S.NO. Description SpecificationsDocument2 pagesSpecification of Rotameters: S.NO. Description Specificationssushant_jhawerNo ratings yet

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 pagesControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımNo ratings yet

- Galvalume Sheet R ValueDocument2 pagesGalvalume Sheet R ValueEr Praveen Raj RNo ratings yet

- 2 How To Make A Pump Selection - Intro To PumpsDocument7 pages2 How To Make A Pump Selection - Intro To PumpsMohammed MustafaNo ratings yet

- Manual Do Soprador AfsDocument1,597 pagesManual Do Soprador AfsJoão Paulo Sacramento100% (6)

- Astm A 209 PDFDocument3 pagesAstm A 209 PDFBez SofNo ratings yet

- Pleated Filter Pressure Drop PDFDocument12 pagesPleated Filter Pressure Drop PDFAmbrish SinghNo ratings yet

- Inspection Checklist Fin Fan CoolerDocument2 pagesInspection Checklist Fin Fan CoolerAnoopNo ratings yet

- Valve Sizing and Selection: FREE ResourcesDocument6 pagesValve Sizing and Selection: FREE ResourcesSARATH KRISHNAKUMARNo ratings yet

- Common Steel StandardsDocument3 pagesCommon Steel Standardsva3ttnNo ratings yet

- Cahpter 5 Special SteelDocument50 pagesCahpter 5 Special SteelhealgoseNo ratings yet

- K Tron K2 ML D5 S60 失重秤数据Document2 pagesK Tron K2 ML D5 S60 失重秤数据ARK MurpheyNo ratings yet

- PGI2003 FastStartup&DesignForCyclingDocument20 pagesPGI2003 FastStartup&DesignForCyclingscarrion80100% (1)

- Kramer H.J.M. - 2000 - Modeling of Industrial Crystallizers For Control and Design Purposes PDFDocument7 pagesKramer H.J.M. - 2000 - Modeling of Industrial Crystallizers For Control and Design Purposes PDFhusseinNo ratings yet

- W6D800GD0101 DatasheetDocument5 pagesW6D800GD0101 DatasheetMurat KavasNo ratings yet

- Packed Fluid BedDocument26 pagesPacked Fluid BedgeogeogeoNo ratings yet

- Clampco CatalogueDocument39 pagesClampco CatalogueMisaghNo ratings yet

- MS 06 16 PDFDocument4 pagesMS 06 16 PDFPrateek RajNo ratings yet

- What Is A Fired Heater in A RefineryDocument53 pagesWhat Is A Fired Heater in A RefineryCelestine OzokechiNo ratings yet

- Bin DesignDocument14 pagesBin DesignHogar Belo HorizonteNo ratings yet

- P&ID Process Cooling Symbols and Their Usage PDFDocument4 pagesP&ID Process Cooling Symbols and Their Usage PDFHV UioNo ratings yet

- Chapter4analysis of Clamping ForceDocument10 pagesChapter4analysis of Clamping ForceMohammad umarNo ratings yet

- Summary of Anchor / Nozzle Movements For Vertical VesselDocument17 pagesSummary of Anchor / Nozzle Movements For Vertical VesselArindomNo ratings yet

- Shell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)Document2 pagesShell Minimum Thickness Calculations: D (FT) G E Fill Height (FT)trijaya landscapeNo ratings yet

- Liquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignFrom EverandLiquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignNo ratings yet

- HP Universal Print Driver 4.5.0.2 Release Notes: April 2008Document7 pagesHP Universal Print Driver 4.5.0.2 Release Notes: April 2008Snehasish MukherjeeNo ratings yet

- Annex 3 General Instructions Regarding Essential QualificationsDocument2 pagesAnnex 3 General Instructions Regarding Essential QualificationsSnehasish MukherjeeNo ratings yet

- Comparison of Is 2062 and InsulationDocument4 pagesComparison of Is 2062 and InsulationSnehasish MukherjeeNo ratings yet

- BendingDocument7 pagesBendingAsif RajaNo ratings yet

- Caepipe-To-Caesar-Ii: User's ManualDocument95 pagesCaepipe-To-Caesar-Ii: User's ManualSnehasish Mukherjee100% (1)

- Nozzle LoadDocument3 pagesNozzle LoadSnehasish MukherjeeNo ratings yet

- Waterhammer Part 2Document4 pagesWaterhammer Part 2Snehasish MukherjeeNo ratings yet

- TestDocument1 pageTestSnehasish MukherjeeNo ratings yet

- ReadmeDocument1 pageReadmeSnehasish MukherjeeNo ratings yet

- For Information About Installing, Running and Configuring Firefox Including A List of Known Issues and Troubleshooting InformationDocument1 pageFor Information About Installing, Running and Configuring Firefox Including A List of Known Issues and Troubleshooting InformationSnehasish MukherjeeNo ratings yet

- For Information About Installing, Running and Configuring Firefox Including A List of Known Issues and Troubleshooting InformationDocument1 pageFor Information About Installing, Running and Configuring Firefox Including A List of Known Issues and Troubleshooting InformationSnehasish MukherjeeNo ratings yet