Professional Documents

Culture Documents

Internal Inspection Checklist - Fire Tube Boiler

Internal Inspection Checklist - Fire Tube Boiler

Uploaded by

naidooriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Internal Inspection Checklist - Fire Tube Boiler

Internal Inspection Checklist - Fire Tube Boiler

Uploaded by

naidooriCopyright:

Available Formats

U.S.

Postal Service

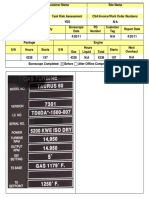

INTERNAL INSPECTION CHECKLIST FIRE TUBE BOILER

(Continue on reverse) Postmaster Boiler Type Hot Water Boiler No. Size BTU/HR (or) BHP Building Safety Relief Valve Setting (psig) Burner Serial No. Date Last Hydrostatic Test Model No.

Certificate Issued Yes No Temporary City and State

Expiration Date

Steam Boiler

Manufacturer Model

Boiler Operating Pressure (psig) Capacity

Date Installed

Fuel Primary Secondary

No. Months Per Year Boiler Normally Operated

Reference Criteria: National Board Inspection Code, ASME and Pressure Vessel Code. ITEM 1. Boiler General: Review Form 4772, Equipment Inventory History Record (I-204.6) a. b. c. 2. Evidence of leakage or corrosion (I-203) Evidence of cracking, burning or bagging Boiler parts free to expand under operating conditions.

( )

REMARKS

Setting a. Satisfactory b. Condition of c. Foundation Buckstays Brickwork

3.

Main Piping (I-203.5) a. b. c. d. Proper stop and non-return valves Adequacy of drains in steam leads Proper supports and anchors Piping free to expand

4.

Blow-Off (I-203.6) a. b. c. d. e. Proper valves and piping Evidence of leakage of valves Freedom for expansion of piping Adequacy of blow-off tanks vent Observe test of blow-off valves

5.

Feed Water System (I-203.4) a. b. c. d. e. f. Proper arrangement of stop and check valves Evidence of external corrosion particularly where pipe passes through smoke box Adequate means of feeding boiler Source of feed water and make up Maximum amount of condensate returned to boiler Condition of expansion tank

6.

Water Column and Gauge Glass (I-203.2) a. b. c. Proper arrangement of piping valves, gauge cocks, blow-off drain piping Clear visibility of water level. Observe test of column and glass

PS Form

4085, September, 1984

You might also like

- QAP For Civil WorkDocument9 pagesQAP For Civil WorkAnonymous TjdHCu50% (4)

- Water-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaDocument21 pagesWater-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- GB 150.4 Fabrication, Inspection and Testing, and Acceptance PDFDocument43 pagesGB 150.4 Fabrication, Inspection and Testing, and Acceptance PDFhuangjlNo ratings yet

- 030-Itp For Ug GRP Piping PDFDocument22 pages030-Itp For Ug GRP Piping PDFKöksal Patan90% (10)

- Boroscopeo Turbina PDFDocument9 pagesBoroscopeo Turbina PDFegr00No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Internal Inspection Checklist - Fire Tube Boiler PDFDocument2 pagesInternal Inspection Checklist - Fire Tube Boiler PDFWaqar Dar100% (1)

- (Review Operating Log) Form 4846Document1 page(Review Operating Log) Form 4846naidooriNo ratings yet

- Indicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalDocument3 pagesIndicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalmsuidNo ratings yet

- Asme Boiler StandardsDocument2 pagesAsme Boiler StandardsHasan RiazNo ratings yet

- Form P-7 Manufacturers Data Report For Safety Valves As Required by The Provisions of The ASME Code Rules, Section IDocument2 pagesForm P-7 Manufacturers Data Report For Safety Valves As Required by The Provisions of The ASME Code Rules, Section IMohamed Ahmed MaherNo ratings yet

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoNo ratings yet

- FormP 2Document2 pagesFormP 2Mohamed Ahmed MaherNo ratings yet

- Important Indian Boiler RegulationsDocument87 pagesImportant Indian Boiler RegulationsPrakash Kakani100% (2)

- Hi-Tech Engineering Corporation India Pvt. LTD., BaramatiDocument2 pagesHi-Tech Engineering Corporation India Pvt. LTD., Baramatig_sanchetiNo ratings yet

- Specifications, Scope of Work, Bid Rejection/Evaluation CriteriaDocument59 pagesSpecifications, Scope of Work, Bid Rejection/Evaluation CriteriaSOPANNo ratings yet

- At/Ut/Uss: T F, A T !Document1 pageAt/Ut/Uss: T F, A T !Jerico LlovidoNo ratings yet

- MDR Form A-1Document2 pagesMDR Form A-1Yuvraj ThoratNo ratings yet

- Form P-4 Manufacturer'S Partial Data Report As Required by The Provisions of The ASME Code Rules, Section IDocument2 pagesForm P-4 Manufacturer'S Partial Data Report As Required by The Provisions of The ASME Code Rules, Section Iganesh82No ratings yet

- Indian Boiler Regulation: Reulation. 4 Standard RequirementsDocument7 pagesIndian Boiler Regulation: Reulation. 4 Standard Requirementssandi1111No ratings yet

- ASME U-1 Blank FormDocument2 pagesASME U-1 Blank Formjeff501No ratings yet

- Standard Requirements: Regulation 386Document5 pagesStandard Requirements: Regulation 386Arunachalam NagarajanNo ratings yet

- Technical - Spec - For - Safety - Relief - Valve 8Document1 pageTechnical - Spec - For - Safety - Relief - Valve 8Anonymous vwbLPTpjNo ratings yet

- HSB HPBoilerLogDocument2 pagesHSB HPBoilerLogeborresonNo ratings yet

- Air Reciever 538017Document20 pagesAir Reciever 538017ismailinesNo ratings yet

- ScopeDocument7 pagesScopeSiva ShankarNo ratings yet

- Pre-Concrete Inspection Checklist IDDocument1 pagePre-Concrete Inspection Checklist IDAndrew AndersonNo ratings yet

- Indirect Fired HeaterDocument3 pagesIndirect Fired Heatermatteo2009No ratings yet

- 15483Document6 pages15483uddinnadeemNo ratings yet

- Qap Upvc PipesDocument3 pagesQap Upvc PipesAnonymous ciKyr0t33% (3)

- FormU 1Document2 pagesFormU 1Mohamed Ahmed MaherNo ratings yet

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning ChecklistsMuhammad Akram100% (2)

- Checklist Typical Format PMSDocument4 pagesChecklist Typical Format PMShappale2002No ratings yet

- Scope: PurposeDocument6 pagesScope: Purposezahid_497No ratings yet

- 4.IBR Rules PDFDocument87 pages4.IBR Rules PDFKiran Sahu67% (3)

- Duty Specification FOR Hot Oil System Package Unit: GeneraDocument5 pagesDuty Specification FOR Hot Oil System Package Unit: GeneraSuchart TarasapNo ratings yet

- BS 5352Document30 pagesBS 5352vb_pol@yahooNo ratings yet

- FormP 4Document2 pagesFormP 4Mohamed Ahmed MaherNo ratings yet

- Form U-1Document2 pagesForm U-14508366279No ratings yet

- 88 Series 2 Boiler: Suggested SpecificationsDocument4 pages88 Series 2 Boiler: Suggested SpecificationsAdam Bin Abu BakarNo ratings yet

- Form XIX: (See Regulation 376 (FF) and 376 (FFF) )Document2 pagesForm XIX: (See Regulation 376 (FF) and 376 (FFF) )amol shindeNo ratings yet

- Indian Boilers Regulations - 1950Document21 pagesIndian Boilers Regulations - 1950dchz_62No ratings yet

- Technical Comparison Format - Process Gas Reciprocating CompressorDocument11 pagesTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 pagesAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutNo ratings yet

- Proof Test Method and Report Documentation Guideline BackgroudDocument4 pagesProof Test Method and Report Documentation Guideline BackgroudBenyoub LyesNo ratings yet

- Essar Steel PlantDocument62 pagesEssar Steel PlantKrishnadev C.SNo ratings yet

- Boiler InspectionDocument6 pagesBoiler Inspectiondaimahesh100% (1)

- AB-040 Boil PV Repair-Alter ReportDocument2 pagesAB-040 Boil PV Repair-Alter ReportjohnjuantamadNo ratings yet

- Main Valves Data SheetDocument18 pagesMain Valves Data SheetMahmoud GaberNo ratings yet

- Datasheet For Ball ValveDocument16 pagesDatasheet For Ball ValveDamu JankerboyNo ratings yet

- Boiler SpecificationDocument18 pagesBoiler SpecificationAtul Jain100% (3)

- QAP1Document33 pagesQAP1sanjiv66669No ratings yet

- BPVC Viii-1 U-1Document3 pagesBPVC Viii-1 U-1wisnu_bayusaktiNo ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- QAP GeneralDocument1 pageQAP GeneralVenkatRaghavendar100% (3)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardFrom EverandBioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- HJHJ PP PDFDocument1 pageHJHJ PP PDFnaidooriNo ratings yet

- History of BoltsDocument1 pageHistory of BoltsnaidooriNo ratings yet

- ResistorsDocument1 pageResistorsnaidooriNo ratings yet

- Ppon BasDocument1 pagePpon BasnaidooriNo ratings yet

- HFGFVCNVCCCCGDocument1 pageHFGFVCNVCCCCGnaidooriNo ratings yet

- HJGHGH DsDocument1 pageHJGHGH DsnaidooriNo ratings yet

- SsdertDocument1 pageSsdertnaidooriNo ratings yet

- XxcvbssaaDocument1 pageXxcvbssaanaidooriNo ratings yet

- XFGGFCDocument1 pageXFGGFCnaidooriNo ratings yet

- DDFGPMDocument1 pageDDFGPMnaidooriNo ratings yet

- SSDFGFGNHHFNDocument1 pageSSDFGFGNHHFNnaidooriNo ratings yet

- JjjreaaaDocument1 pageJjjreaaanaidooriNo ratings yet

- BuuupiwDocument1 pageBuuupiwnaidooriNo ratings yet

- AaaswpDocument1 pageAaaswpnaidooriNo ratings yet

- MMBSGWDocument1 pageMMBSGWnaidooriNo ratings yet

- KkaseDocument1 pageKkasenaidooriNo ratings yet

- New Text Document - TXT Fiihvvb UjDocument1 pageNew Text Document - TXT Fiihvvb UjnaidooriNo ratings yet

- VVDDWXDocument1 pageVVDDWXnaidooriNo ratings yet

- MmkcaDocument1 pageMmkcanaidooriNo ratings yet

- MMMNBGDocument1 pageMMMNBGnaidooriNo ratings yet

- DffeaaabDocument1 pageDffeaaabnaidooriNo ratings yet

- AaqcxzDocument1 pageAaqcxznaidooriNo ratings yet

- MmpouDocument1 pageMmpounaidooriNo ratings yet

- DdfgqwaDocument1 pageDdfgqwanaidooriNo ratings yet

- MMH DDFFDVVDocument1 pageMMH DDFFDVVnaidooriNo ratings yet

- CVGGKDocument1 pageCVGGKnaidooriNo ratings yet

- Aawrtza PDFDocument1 pageAawrtza PDFnaidooriNo ratings yet

- AawrtzaDocument1 pageAawrtzanaidooriNo ratings yet

- JHJJGGPDocument1 pageJHJJGGPnaidooriNo ratings yet

- PooiiuDocument1 pagePooiiunaidooriNo ratings yet