Professional Documents

Culture Documents

Chrysler Standard

Chrysler Standard

Uploaded by

abraham_gin0 ratings0% found this document useful (0 votes)

107 views25 pagesstandard

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentstandard

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

107 views25 pagesChrysler Standard

Chrysler Standard

Uploaded by

abraham_ginstandard

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 25

CS-9003, Change E, Page 1

DAIMLERCHRYSLER CORPORATION CHARACTERISTICS STANDARD NO: CS-9003

Vehicle Engineering

Approved Source List Required: Yes Change: E

Volume: A Section: - Page: 311

ENVIRONMENTAL, HEALTH, AND OCCUPATIONAL SAFETY REQUIREMENTS FOR REGULATED

SUBSTANCES OR PROCESSES AND PRODUCT RECYCLING REPORTING REQUIREMENTS

1.0 GENERAL.

1.1 Purpose of the Standard

This standard provides vehicle environmental and occupational safety requirements as found in

Chryslers Material, Process and Performance Standards. It establishes, consistent and coordinated

product recyclability guidelines and targets to support:

- Employees' health

- Customers' health

- Suppliers' employee health

- The environment

for production materials and processes.

This standard was updated in August, 1997 to include policy direction or objectives relative to ISO 1402X

and 1404X draft requirements addressing Life Cycle Assessment, as well as EU directives dated April

1997 relative to vehicle recycability.

1.2 Scope of Application

This standard applies specifically Chrysler Corporation and its suppliers and sub suppliers for materials

and parts for vehicles designed or engineered for Chrysler or its subsidiaries for North American

production or export.

There may, in addition, be country or region specific requirements for dismantling and/or handling of end-

of-life vehicles. In these cases, specific accountability is as follows:

- Specific area or country standards will be addressed by Chrysler International Operations.

- Homologation issues relative to obtaining certificates for the sales of vehicles are addressed by the

Corporation Vehicle Homologation staff. This group will provide separate standards to meet whole

vehicle type and/or part approval.

- Chrysler Parts and Service Division will develop a separate system to track recyclability, recycled

content and regulated substances required by this standard, while utilizing this standard for all

replacement parts.

1.3 Vehicle Paints

Vehicle body paints applied by the car assembly plants, as well as those utilized on supplier painted

parts shall conform to the requirements established by Paint and Energy Management and Stationary

CS-9003, Change E, Page 2

Environmental Compliance. Other parts of the vehicle shall conform to the requirements of this

standard.

1.4 Coverage of this Standard

This standard covers those materials and processes used in manufacturing or contained in the vehicle

which:

- may be harmful to the occupational health or safety of Chrysler Corporation or supplier employees.

- could adversely affect the health of the customer.

- can have an impact on the recyclability of the vehicle.

- could cause deterioration of the environment.

This standard includes the following main topics:

Topic Par.

Strategic Recyclability and Recycled Material Content Guidelines 3.2

Strategic Recyclability of the Vehicle 3.2.1

Strategic Recycled Content 3.2.2

Strategic Variety of Plastics 3.2.3

Supplier Regulated Substance and Recyclability Certification (RSRC) Report 3.1.6

Restricted Regulated European Controlled Substances 4.1.3

Production Materials, Processes, Parts, Components, or Articles 2.2

Additional Reporting Requirements 4.5

Product Packaging and Labeling Appendix A

Statutes, Initiatives, and Regulations Appendix B

2.0 MATERIAL & PRODUCT STRATEGIES

2.1 Material Strategies

Where there is an approved material strategy, and that strategy has been approved by both Materials

Engineering and Pollution Prevention and Remediation, suppliers may choose to use the defined

material strategy while meeting the recycling guidelines set forth in this standard and/or completing a Life

Cycle Management Analysis.

2.2 Production Materials, Processes, Parts, Components, or "Articles"

2.2.1 New Items

None of the restricted substances listed in Table 5 (reference 4.1.2) shall be contained in any new

materials, processes, parts, components or articles. Those Regulated Substances listed in Table 6

(reference 4.1.2) may not be used without express authorization by Chrysler Corporation and a

supporting Life Cycle Management Analysis. (When their use is authorized, all proper safeguards must

be in place.)

Whenever a new material, process or part places a worker or the environment at risk for exposure to a

regulated substance, these items, shall not be used without approval from Chrysler Corporation. To

obtain this approval, the supplier must use the Supplier Regulated Substance and Recyclability

Certification (RSRC) Report to:

- Certify that the particular item, identified by part number and level of change, does not contain

substances listed in Tables 5 and 6, or residuals of these substances.

CS-9003, Change E, Page 3

- Requested approval for the use of any regulated substance listed in Table 6 through Chryslers

Production Restriction Screening Approval System prior to Production Part Approval Process Warrant

submission. Request for such approval must be directed to the lead Platform Engineering Group.

(Warrant submission requirements replace ISIR/ISLR sample submission reference Production Part

Approval Process Manual published by Automotive Industry Action Group AIAG.)

When substances found in Table 5 and 6 are used, a supplier must submit a Life Cycle Management

Analysis, conducted by one of the sources approved by Pollution Prevention and Remediation. Also

required is submittal of the Supplier Regulated Substances and Recyclability Certification in accordance

with the schedule indicated in Section 1.5.6 of this document. Additional supplier reporting requirements

are described in Section 2.5.

2.2.2 Carryover Materials, Processes, Parts and Components

Those items classified as carryover are grouped into three categories:

Those specifically identified for re-formulation

Those that are going to be in production beyond the 1996 model year

Those that are not planned to be in production beyond the 1996 model year

If exposure to any of these items alter risk to a worker or the environment, approval from Chrysler

Corporation is required for their use.

2.2.3 Carryover Items in Production beyond Model Year 1996

For items that are planned to be in production beyond 1996 model year, a list of carryover items which

contain regulated or restricted substances, or include such substances as residuals (either on the

surface or generated during processing) will be generated by Pollution Prevention and Remediation.

This list will based upon a review by Chryslers Product Development Teams, Pollution Prevention and

Remediation and the Industrial Hygiene and Toxicology Departments.

For these carryover items, the supplier must submit the Supplier Regulated Substance and Recyclability

Certification (SRSC) report to Chrysler within three (3) months of the date the item first appears on the

list. This report must:

- Indicate that the particular item, by part number, will not contain any of the substances or residuals

listed in Tables 5 and 6 by the date specified on the list, or

- Ask Chrysler to approve their continued use if the supplier intends such use of such beyond the date

specified on the list. (This continued use must be re-authorized through Chryslers Production

Restriction Screening Approval System.) The supplier must assure Chrysler that proper controls and/or

safeguards are or will be in place by the date specified on the list.

The supplier must also facilitate re-evaluation of the carryover item 18 months after it is initially listed,

and reconfirm the values of the initial submission.

At all times, the supplier must also ensure that the report on file with the Pollution and Remediation

Group represents current production.

2.2.4 Carryover Items in Production

For carryover items that will be in production after January 1997, the supplier must:

- Re-evaluate the item and modify it to reduce or eliminate substances listed in Tables 5 and 6

CS-9003, Change E, Page 4

- Certify the item does not contain substances listed in Tables 5 and 6 unless proper controls and

safeguards are in place, and the use of such substances have been re-authorized through Chryslers

Production Restriction Screening Approval System

- Submit to Chrysler a completed Supplier Regulated Substance and Recyclability Certification (RSRC)

report describing:

- Regulated substances used within the end item

- Recyclability information requested

No action is required for carryover items that will not be in production beyond the 1996 model year.

NOTE: Service parts under the control or issue of MOPAR will be handled outside this system. MOPAR

has established their own tracking system, and shall assume recovery, at MOPAR expense, of all

vehicles and/or parts they introduce through service parts.

2.2.5 Changes

Prior Chrysler Corporation approval is required for any proposed change to a material, process or part

that affects a workers exposure to a regulated substance, or where the environment may be affected.

This includes any part where a material or substance in material is altered by more that a + or 5 ppm,

or any part which includes a change in the process that affects health, safety, environment or other

relevant conditions. Such proposed changed shall be directed through the lead Vehicle Engineering

Platform and will require:

- submission of a Supplier Regulated Material Substance and Recyclability Certification report

- approval through Chryslers Pollution Prevention and Remediation Group, Manager-Life Cycle

Programs

- an approved change notice (CN, APCN or PCN)

- testing to met the requirements of PF-8500 and/or the Production Part Approval Process manual

- resubmission of sample, reference section 3.1

- full disclosure of Chryslers Industrial Hygiene Department, reference section 2.5

- submission of a Material Safety Data Sheet (MSDS) to Industrial Hygiene, reference section 2.5

NOTE: When any changes to production products and/or processes are made, it is the suppliers

responsibility to ensure that the Supplier Regulated Material Substance and Recyclability Certification

reports are on file with the Manager-Life Cycle Programs, Pollution Prevention and Remediation

Department.

FAILURE TO MEET THE ABOVE REQUIREMENTS, OR AN ATTEMPT BY THE SUPPLIER TO

SUBMIT RESTRICTED OR REGULATED SUBSTANCES WITHOUT BENEFIT OF REVIEW BY

CHRYSLER, SHALL BE SUFFICIENT CAUSE TO WARRANT REJECTION OF SHIPMENTS AND/OR

REMOVAL FROM THE CHRYSLER CORPORATION ENGINEERING APPROVED SOURCE LISTS

(EASL). IN SUCH CASE, POLLUTION PREVENTION AND REMEDIATION WILL REQUIRE

PROCUREMENT AND SUPPLY TO REMOVE THE SUPPLIER FROM THE EASL.

2.3 Pre-Production and Prototype Materials

All Material Standards (MS) relative to substances identified in Tables 5, 6 and 7, require approval by

Pollution Prevention and Remediation and Material Engineering prior to release. Pre-production and

pilot materials, as well as materials and parts used in development testing, require a non-production part

number before release (reference SMI-161). Test materials must have Material Safety Data Sheets and

RSRC reports.

CS-9003, Change E, Page 5

Individual policy statements may address the use of specific substances. These are contained in the

Policy paper in the Appendix.

3.0 RECYCLING

3.1 Key Regulations or Programs

3.1.1 Clean Air Act Amendments (CAAA)

The CAAA identifies 189 substances of which 28 are listed in Table 5 and 84 are listed in Table 6.

Foreign, state/provincial, or local regulations may classify additional substances as regulated and require

compliance.

3.1.2 Pollution Prevention Act

The Pollution Prevention Act drives measures for industry to incorporate into their environmental

programs. This law stresses the avoidance of substances such as those listed in Tables 5 and 6 which

contribute to pollution directly or indirectly through their processing.

3.1.3 Auto-Project

The Auto-Project is the forum that state regulatory agencies have chosen to work with the domestic auto

manufacturers to voluntarily remove substances such as those listed in Tables 5 and 6.

3.1.4 Cadmium Health Guidelines

New materials should not contain releasable cadmium. Existing materials should be reviewed for proper

controls or replaced whenever feasible. Chrysler's goal is to eventually eliminate the use of cadmium

from its processes and parts. The use or continued use of cadmium must be specifically approved or re-

approved by Chrysler Corporation for each application.

In addition, effective immediately, for approved applications, if occupational exposure to cadmium or its

compounds is 2.5 g/m

3

or greater or where significant exposure for example, ingestion can occur, the

plant is required to provide monitoring programs, medical exams, engineering controls, personal

protective equipment, emergency plans, and training. Refer to Code of Federal Regulations 29 CFR

1910.1027.

3.1.5 Re-processed Oils

Suppliers of products containing reprocessed oils must be certified through Chrysler's Pollution

Prevention and Remediation Department.

3.1.6 Vehicle Recycling

BACKGROUND: In markets which are of interest to Chrysler, agreements and regulations for handling

end-of-vehicle-life have been developed and are being enacted internationally. The Vehicle Recycling

Requirements which follow address product-based requirements only.

REQUIREMENTS: Recyclability is application dependent and is based on to a great extent, on the ease

of dismantling the vehicle and segregating materials efficiently. The analysis of product/part recyclability

is a requirement for all new products, as indicated in the 3rd edition of the Product Assurance Process

(PAP).

The supplier is required to provide recyclability information via the Supplier Regulated Substance and

Recyclability Certification (RSRC) Report detailed in Section 1.5.6. This report must be submitted within

CS-9003, Change E, Page 6

the time frame specified by the responsible platform program manager in order to meet both program

and regulatory reporting objectives. If specific timing requirements are not specified, the time

requirements found in Section 1.5.5 apply. Failure to submit the report will have an impact on the

suppliers rating, and the supplier is accountable for keeping the RSRC report current at all times.

The RSRC report does not negate PAP reporting requirements, which must also be complied with.

Helpful tools to assist in the compliance of this standard are found in the appendix of this standard.

Table 1, provided here, identifies the categories for recyclability and dismantling analysis.

Plastic parts marking guidelines, required as part of all Procurement Actions, are mandatory for material

identification. They are provided in PS-4480 based on SAE JI344.

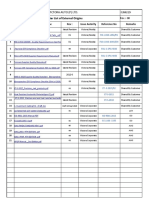

TABLE 1: RECYCLING AND DISMANTLING CATEGORIES

Category Definition

Recyclable

1 Part is remanufactured (ie. Starter transmission)

2 Part or material is recyclable if the infrastructure and technology is clearly

defined and functioning (ie. Body sheet metal).

3 Part or material is technically feasible if the technology exists but the

infrastructure does not exist (ie. TPO or RIM fascias)

4 Part or material can be technically recycled in the laboratory but no industrial

or commercial process exist (ie. PP and glycolysis)

5 Part or material has organic material that could be recovered for energy but

cannot be recycled (ie. Burning of synthetic tires)

6 Part or material containing inorganic material and no technology exists for

recycling or energy recovery.

Disassembly

1 Can easily remove part or material manually in one minute or less (i.e. Clip on

pillar trim).

2 Can with little effort remove part or material manually in one to three minutes

(i.e. Fan shroud)

3 Can mechanically or by shredding economically separate materials (i.e. Seat

assemblies or windshield glass)

4 Mechanical or shredding technology is under development (i.e. Instrument

panel)

5 No known process to separate part or material (i.e. Heated backlit glass or

electronic components).

3.2 Strategic Recyclability and Recycled Material Content Guidelines

This standard applies to new models and all new parts introduced with model year 1998, and addresses

the policy regarding vehicle recyclability, recycled material content and substance reporting. Excluded

are parts introduced by/for parts and service operations. These are the responsibility of the Chrysler

Parts and Service Division; and are covered by standards and guidelines developed by them in

conformance with this standard.

CS-9003, Change E, Page 7

3.2.1 Strategic Recyclability of the Vehicle

Recyclability is defined, for this standard, as the dismantling and separation of products or parts with the

goal of return - to use as a functional part or as a raw material for manufacture or utilization in another

product. The expressed objective is to divert these materials from the waste stream. The guidelines are

a reflection of the current direction under discussion in the European Economic Community and Japan

(reference other countries requirements through Materials Engineering).

The guidelines for strategic recycability of the vehicle, documented in Table 2 are based upon these

global discussions.

TABLE 2: STRATEGIC RECYCLABILITY OF VEHICLE INTRODUCED IN THE

FOLLOWING MODEL YEAR (1)

1998 1999 2000 2002 2005 2010

New Models 80% 82% 82% 85% 95% 95%

Carryover Models 75% 80% 82% 85% 85% 95%

(1) All values are by weight and include 5% for energy recovery. Values after

2002 for new models have a 10% energy recovery value included. For both new

and carryover models after 2010 a 10 % energy value applies.

NOTE: THIS TABLE SHOULD BE USED TO SET TARGETS FOR NEW VEHICLES AND WHEN

CURRENT VEHICLES ARE REFRESHED.

Individual Vehicle Platforms are responsible for evaluating these guidelines and determining whether

specific vehicles are intended for markets where recycling regulator requirements or

government/industry voluntary agreements apply. IF THE PLATFORM DETERMINES THAT A

VEHICLE IS DESTINED FOR SUCH A MARKET, STRATEGIC RECYCLABILITY OF THAT VEHICLE

BECOMES A PRODUCT REQUIREMENT. In all other cases, the recyclability of the vehicles is to be

reported against the 3rd edition of the PAP and section 2.1.6 of this standard.

3.2.2 Strategic Recycled Content

In an effort to simplify explanation of the Standard, the following definitions have been used for key

terms:

Recycled content: the portion of the product, part or materials weight that was DIVERTED FROM

WASTE STREAMS, either as post-consumer or post-industrial material content.

Post-consumer: products or parts which have reached the consumer prior to diversion from the waste

stream.

Post-industrial: products, parts or materials which have BEEN DIVERTED FROM THE PRODUCTION

STREAM AND ARE INDUSTRIAL WASTE OR BYPRODUCTS (sometimes referred to as factory

scrap). Post-industrial scrap can be used to produce materials or parts in the same or a different

process than the original.

NOTE: WHEN CALCULATING POST-INDUSTRIAL RECYCLED CONTENT, US GOVERNMENT

AGENCIES DO NOT ACCEPT THE INCLUSION OF FACTORY SCRAP AS POST-INDUSTRIAL

RECYCLED CONTENT. TO FACILITATE ACCURATE REPORTING, CHRYSLER CORPORATION

HAS ADOPTED THE SAME POLICY WITH REGARD TO FACTORY SCRAP.

Recognizing that a policy of consistent recycled content represents a competitive advantage for

Chrysler, targets have been established for the use of recycled material. In the interest of meeting this

CS-9003, Change E, Page 8

goal, Table 3 (below) has been provided to assist Platforms in setting targets for enhancing competitive

position.

TABLE 3: MINIMUM RECYCLE MATERIAL CONTENT TARGETS (weight %)

Material Class 1998 MY 1999 MY 2000 MY 2002 MY 2005 MY 2010 MY

Aluminum 5% 10% 15% 25% 25% 30%

Total Ferrous Metal 30% 30% 30% 35% 35% 40%

Total Plastic 10% 10% 20% 30% 30% 30%

Other 20% 20% 20% 25% 25% 30%

GOALS FOR RECYCLED CONTENT PRODUCTS, PARTS AND MATERIALS ARE TO BE

ACCOMPLISHED WITHOUT PENALTY TO CHRYSLER IN TERMS OF QUALITY, COST, WEIGHT,

TIMING AND PERFORMANCE. PARTS WHICH INCLUDE RECYCLED CONTENT ARE EXPECTED

TO BE EQUAL OR EXCEED THE PERFORMANCE OF PARTS PRODUCED FROM VIRGIN

MATERIAL. Life Cycle Management analysis may be used to justify differences in acquisition cost

factors ONLY when comparing different materials, formulations, process or recycled content.

3.2.3 Strategic Variety of Plastics

IT IS NECESSARY FOR THE SUPPLIER TO MEET ONE OF THE FOLLOWING PLASTIC DESIGN

CRITERIA, OR A LIFE CYCLE MANAGEMENT ANALYSIS MUST BE PERFORMED BY THE

SUPPLIER OF THE PART/PARTS:

- For mechanical separation, plastics must have a 0.03g/cm

-3

density distribution difference.

- If not mechanically separable, they must be compatible for recycling WITHOUT INCINERATION or

have a confirmed dismantling rating of 1 as defined in Table 1.

OTHERWISE, LIFE CYCLE MANAGEMENT ANALYSIS MUST BE PERFORMED BY THE SUPPLIER

OF THE PART/PARTS.

The format for performing this Life Cycle Management Analysis is described fully in the previous Section

1.5.3, Recycled Product, Part or Material Analysis for Single Parts and Components with Multiple Parts.

As in the previous section, results of analyses will be included as an appendix to this standard and, if

acceptable to the Platform, do not have to be performed again.

3.3 End of Life Vehicle Recovery

European regulations have begun to mandate some form of vehicle end-of-life recovery by the original

manufacturers of vehicles, and it has been widely suggested that end-of-life criteria could include factors

related to product recyclability, recycled content, dismantling factors and manuals as well as regulated

substances. The Swedish Producer Responsibility Ordinance, for example, places this a variation of this

requirement on manufacturers for vehicles produced after December 1997.

Questions regarding vehicle recycling may be addressed to the Vehicle Recycling Programs

Department.

4.0 REPORTING REQUIREMENTS RESTRICTED/REGULATED SUBSTANCES & ADDITIONAL

REPORTING

CS-9003, Change E, Page 9

4.1 Requirements

Approximately 1700 substances are regulated by international, federal, state/provincial or local

government units. These are also identified by Chrysler Corporation as having a significant impact on

the Corporation and its products. WHEREVER FEASIBLE MATERIALS AND PROCESSES SHALL BE

FORMULATED TO ELIMINATE CONSTITUENTS THAT:

- are listed in Tables 5, 6 and/or 7

- have been defined as hazardous by one or more government units

- could possibly harm the environment or the health of customers and employees if not managed

properly

- could have a potential negative occupational safety impact

This standard focuses on:

- Foremost, eliminating the use of substance listed in Table 5. Exceptions must be negotiated with

platforms and those offices identified in paragraph 1.5.

- Eliminating or drastically reducing the use of substances identified in Table 6. Where a process

involves or generates a regulated substance, altering the process to eliminate or diminish any risk.

- Substituting non-regulated substances for those listed in Tables 5 and 6.

- Promoting and facilitating recycling programs. Assuring that materials, products and processes

containing regulated substances meet the recycling and waste disposal requirements identified within

this document.

Suppliers, manufacturers and assembly plants should examine or re-examine each of their products and

processes to ascertain whether substances listed in Table 5 or 6 are contained in their products, or are

generated during processing; and to see if they affect the recyclability as identified in Chryslers Vehicle

Recycling Design Guidelines.

4.1.1 Restricted Substances

The restricted substances listed in Table 5 are those which, when used in substantial quantities, have

the potential to adversely impact the environment or human health. New materials, processes or

components using or containing these substances will be screened routinely by Chrysler Corporation,

and require suppliers to reformulate or redesign any materials or parts that use them. The presence of

these substances may require a Life Cycle Management analysis to compare possible alternatives.

When the materials cannot be reformulated, their use shall be minimized to the greatest extent possible.

The risk of exposure from these restricted substances shall be determined by the Platform and

representatives of those organizations identified in Section 1.6, Chryslers Production Restricted

Screening System. Appropriate permits based on projected manufacturing requirements must be

obtained if restricted substances are to be used, or if there is the potential for release to occur during

processing.

TABLE 5: RESTRICTED SUBSTANCES

SUBSTANCE C.A.S. NUMBER

1,1,1 Trichloroethane (Methyl Chloroform) 000071-55-6

1,1,2 Trichloroethane 000079-00-5

Asbestos 001332-21-4

Asbestos (Actinolite) 013768-00-8

CS-9003, Change E, Page 10

TABLE 5: RESTRICTED SUBSTANCES

SUBSTANCE C.A.S. NUMBER

Asbestos (Amosite) 012172-73-5

Asbestos (Anthophylite) 017068-78-9

Asbestos (Chrysotile) 012001-29-5

Asbestos (Crocidolite) 012001-28-4

Asbestos (Tremolite)

014567-73-8

Cadmium 007440-43-9

Cadmium Compounds Multiple

Carbon Tetrachloride 000056-23-5

CFC 11 (Freon 11) (1) 000075-69-4

CFC 113 (Freon 113) (1) 000076-13-1

CFC 114 (Freon 114) (1) 000076-14-2

CFC 12 (Freon 12) (1) 000075-71-8

Chromium 007447-40-3

Chromium Compounds Multiple

Ethylene Glycol (2) 000107-21-1

Ethylene Glycol Ethyl Ether Acetate 000111-15-9

Ethylene Glycol Methyl Ether Acetate 000110-49-6

Ethylene Glycol Methyl Ether 000109-86-4

Ethylene Glycol Ethyl Ether 000110-80-5

Lead Compounds (2) Multiple

Mercury (2) 007439-97-6

Mercury Compounds Multiple

Methane Dichloride (Methylene chloride)

000075-09-2

Methyl Ethyl Ketone

000078-93-3

N-Hexane 000110-54-3

Toluene

000108-88-3

______________________________

(1) Identified by the federal government for phaseout in 1997.

(2) Refer to the policy paper in the Appendix

4.1.2 Regulated Substances

Chrysler will also screen the regulated substances, listed in Table 6, before allowing them to be used in

new or carryover materials, processes or parts. These substances are targeted for reduction or

elimination, and if they are present Life Cycle Management analysis may be requested to evaluate

the selected material and possible alternatives.

TABLE 6: REGULATED SUBSTANCES

SUBSTANCE C.A.S. NUMBER

1,1 Dichloroethylene 000075-35-4

1,2 Dichloroethane

000107-06-2

1,4 Dioxane 000123-91-1

2-Acetylaminofluorene 000053-96-3

2-Nitropropane 000079-46-9

CS-9003, Change E, Page 11

TABLE 6: REGULATED SUBSTANCES

SUBSTANCE C.A.S. NUMBER

3,3 Dichlorobenzidine

000091-94-1

3,3 Dichlorobenzidine Salts Multiple

4-Aminobiphenyl 000092-67-1

4-Dimethylaminoazobenzene 000060-11-7

4,4' Methylene Dianiline (MDA) 000101-77-9

4,4' Methylene Bis-2-Chloroaniline 000101-14-4

Acetaldehyde 000075-07-0

Acetone 000067-64-1

Acrylic Acid 000079-10-7

Alpha-Naphthylamine 000134-32-7

Aluminum (Fume or Dust) (1) 007429-90-5

Antimony Compounds Multiple

Arsenic

007440-38-2

Arsenic Compounds Multiple

Barium 007440-39-3

Barium Compounds Multiple

Benzene

000071-43-2

Benzidine 000092-87-5

Beryllium (1)

007440-41-7

Beryllium Compounds (1) Multiple

Beta-Naphthylamine 000091-59-8

Beta-Propiolactone

000057-57-8

Bis (2-Chloroethyl) Ether 000111-44-4

Bis-Chloromethyl ether 000542-88-1

Butyl Acrylate 000141-32-2

Butyl Alcohol

000071-36-3

Butyl Benzyl Phthalate (3) 000085-68-7

Carbon Disulfide 000075-15-0

Chlorobenzene 000108-90-7

Chloroform (Trichloromethane) 000067-66-3

Chloromethane (Methyl Chloride) 000074-87-3

Cresylic Acid 001319-77-3

Cumene

000098-82-8

Cyanide Compounds Multiple

Di-N-Butyl Phthalate 000084-74-2

Di-N-Octyl Phthalate (DOP) 000117-84-0

Diethyl Hexyl Phthalate (DEHP) 000117-81-7

Dimethyl Phthalate 000131-11-3

Ethylbenzene

000100-41-4

Ethyleneimine

000151-56-4

Formaldehyde 000050-00-0

Hexachlorobenzene

000118-74-1

Hexachlorobutadiene 000087-68-3

Hydrogen Fluoride (2)

007664-39-3

M-Cresol 000108-39-4

Managanese (1) 007439-96-5

Managanese Compounds ( 1) Multiple

CS-9003, Change E, Page 12

TABLE 6: REGULATED SUBSTANCES

SUBSTANCE C.A.S. NUMBER

Methanol (3) 000067-56-1

Methyl Chloromethyl Ether 000107-30-2

Methyl-N-Butyl Keytone 000591-78-6

Methylene-bis-Phenyl Isocyanate (MDI) 000101-68-8

Molybdate Red

012656-85-8

N-nitrosodimethylamine 000062-75-9

Naphthalene 000091-20-3

Nickel (1) 007440-02-0

Nickel Compounds (1) Multiple

Nitrobenzene 000098-95-3

O-Cresol 000095-48-7

Orthodichlorobenzene 000095-50-1

P-Cresol 000106-44-5

Phenol 000108-95-2

Polyaromatic Hydrocarbons (PAHs) Multiple

Polycholorinated Biphenyls (PCBs) Multiple

Potassium Cresylate 012002-51-6

Propylene Oxide 000075-56-9

Selenium (1) 007782-49-2

Selenium Compounds (1) Multiple

Strontium Chromate

007789-06-2

Styrene 000100-42-5

Tetrachloroethylene (Perchloroethylene) 000127-18-4

Trichloroethylene 000079-01-6

Vinyl Chloride 000075-01-4

Zinc (Fume or Dust) (1) 007440-66-6

Zinc Compounds (1) Multiple

______________________________

(1) These substances are classified as regulated when processed. They are not regulated if they are used as an "article" and not

processed.

(2) Refer to the policy paper in the Appendix.

(3) These substances are regulated only when the concentration exceeds 5% by volume.

4.1.3 European Controlled Substances

Certain substances, controlled by usage, presence or application in Europe, will have the great impact

on Chrysler vehicles, if imported. These substances are indicated in Table 7. Export vehicles must not

use parts or components that contain these substances at a level of 1 ppm or more. If it is necessary to

use one of these substances at 1 ppm or more, a Life Cycle Management Analysis is required. Effective

June, 1997, exceptions can be granted only by the Manager, Life Cycle Programs in concurrence with

the Executrive for Recycling.

TABLE 7: EUROPEAN CONTROLLED SUBSTANCES

SUBSTANCE CAS NUMBER

Lead (elemental and compounds) Multiple

Cadimun (compounds) Multiple

Chromium (compounds) Multiple

CS-9003, Change E, Page 13

TABLE 7: EUROPEAN CONTROLLED SUBSTANCES

SUBSTANCE CAS NUMBER

Mercury 007439-97-6

PVC (Polyvinyl Chloride) 009002-86-2

These substance should be expressly avoided by Platforms as they are currently being targeted by the

European Union for elimination, except under specific use. In some cases, actual banning of the

substance is being considered. The impact of this is expected to affect vehicles produced in CY 2000.

4.2 Supplier Regulated Substance and Recyclability Certification Report

Chrysler Corporation has developed a Supplier Regulated Substance and Recyclability Certification

Report (RSRC) data collection and reporting system an Internet application through the Supplier Part

Information System (SPIN). RSRC was created to facilitate:

- reporting materials or substances used in products and processes

- reporting recycling information

- disclosing regulated substances

Suppliers are responsible for compliance with this requirement and should utilize this system to submit

data on parts supplied to Chrysler. Any questions on requirements should be referred to the Pollution

Prevention and Remediation staff, Manager, Life Cycle Programs.

The report is to completed in phases:

- At 104 weeks before launch (or earlier), the supplier must provide general information on the part/parts

they will provide for the specific model. This requires completion of the section on materials and

regulated substances.

- No later than 50 weeks before launch, the information on dismantling, recycling content and

recyclability is to be completed, as well as any changes to the previous entries.

- At launch, all information must be verified by the supplier.

(NOTE: Service and Parts will need to establish their own tracking system to identify differences

between materials and parts supplied by different suppliers and manufacturers, both for the regulated,

restricted substances in this stand for post-consumer and industrial-recycled content, overall part

recyclability and dismantling.)

EACH SUPPLIER IS RESPONSIBLE FOR ASSURING COMPLIANCE WITH THE RSRC

REQUIREMENTS. COMPLIANCE IS MEASURED AND REPORTED THROUGH CHRYSLERS

SUPPLIER RATING SYSTEM. If the supplier is unable to meet the recycled content targets identified in

Tables 2 and 3, or has not performed the Life Cycle Management Analysis required, the supplier cannot

complete the section referring to pre- or post-consumer content. As a result, the suppliers score will be

appropriately reduced.

4.3 Chrysler's Production Restriction Screening Approval System

To assist in monitoring, controlling and eliminating unhealthy or environmentally unsound materials, an

Information System (IS) screening and database has been created. This database contains information

derived from the completed Supplier Regulated Substance and Recyclability Certification (RSRC)

Reports. The screening will be on-line for review by:

- Vehicle Engineering Office, Materials Engineering

CS-9003, Change E, Page 14

- Vehicle Engineering Office, Vehicle Recycling Programs

- Product Strategy and Regulatory Affairs, Pollution Prevention & Remediation

- Employee Relations, Industrial Hygiene and Toxicology Department

4.4 Restricted and Regulated Substances Detection Limits for Reporting

- Restricted substances (Table 5) must be reported if they are intentionally added at 1 ppm or higher.

- Other trace substance must be reported if they are present at 100 ppm or higher.

This reporting requirements is mandatory whether the release occurs at a Chrysler facility during

manufacturing or at the end-of-life of the vehicle when the substance is disposed of or recycled. The

part or material supplier must make this determination.

IT IS SPECIFICALLY REQUIRED THAT CFCS (IDENTIFIED IN TABLE 5) BE REPORTED IF THEY

ARE PRESENT INTENTIONALLY OR AS A TRACE ABOVE 1 PPM, OR IF THEY ARE USED IN ANY

AMOUNT DURING THE MANUFACTURING OF THE PART OR SYSTEM FOR CHRYSLER.

For steel and metals with accepted formulations, as indicated by The American Iron & Steel Institute, the

formulations can be reported as the content for restricted substances. In the case of steel melts, when

material additions are added to the steel, only the part produced from the steel must be reported. As an

example of compliance with reporting requirements, non-leaded steel has up to 30 ppm lead content. It

does not have to be reported because it is not intentionally added above 1 ppm, and is not a trace above

100 ppm.

Excluded from this restricted and regulated substance reporting requirement are articles that do not

require any or all of the following in Chrysler facility during manufacturing or processing:

- machining

- drilling

- molding

- adhesive joining during manufacturing or processing in a Chrysler facility

Reporting an article is required if substances are released during dismantling or recycling.

Regulated substances (Table 6) must be reported only if intentionally added at 100 ppm or higher, or can

be found as a trace at 1000 ppm or higher. Under these conditions, reporting is required whether the

substance is released in a Chrysler facility during manufacturing or at the end of the useful life of the

vehicle during the disposal or recycling.

The information provided will serve as reporting levels for Chrysler and for the supplier to comply with

regulatory and legislative requirements on the local, state, national and international levels. As a result,

Chrysler and the supplier shall share joint liability for the disclosure. When levels requested for

regulatory purpose are below those identified by this standard, suppliers shall report such levels

immediately at no charge to Chrysler to a level as low as 1 ppm.

4.5 Additional Reporting Requirements

Prior to shipment of any production material or use of any process, the supplier (Corporate or outside

source) shall provide, at the request of Chryslers Industrial Hygiene and Toxicology Department:

-- a full disclosure sheet identifying the constituents in the materials or process and a Material Safety

Data Sheet (MSDS)

CS-9003, Change E, Page 15

-- sufficient information relative to the health (employee and customer), employee occupational safety,

and environmental effects of any product, material or process to allow review-for-compliance with

applicable North American rules and regulations and Chrysler Corporation policies

NOTE: Unless Chryslers Industrial Hygiene and Toxicology Department requests this information,

articles and ODD Box Items (PS-7000 Items) are specifically excluded from the preceding two

requirements.

5.0 CONTROLS

5.1 Production Part Approval Process

General requirements for production part approval for production and service commodities are contained

in the Production Part Approval Process manual published by the Automotive Industry Action Group

(AIAG).

5.2 Changes to this Standard

This standard shall not be changed without the concurrence of Chrysler's Industrial Hygiene and

Toxicology Department, Pollution Prevention and Remediation, Manager, Life Cycle Programs, Vehicle

Recycling Programs Department, and Materials Engineering. Proposed changes should be brought to

the attention of the Engineering Standards and Information Services Department.

5.3 Safety Precautions

This standard does not purport to address specific application dependent safety concerns associated

with the use of regulated substances by manufacturing, assembly operations, etc. It is the responsibility

of the supplier to establish appropriate health and safety practices for the particular manufacturing

process involved.

6.0 CONTACTS

Car and Truck Assembly Operations, Quality and Product Engineering, Paint and Energy Management

Vehicle Engineering Office, Materials Engineering

Vehicle Engineering Office, Vehicle Recycling Programs, Chrysler Technology Center, Auburn Hills MI

48326.

Product Strategy and Regulatory Affairs, Pollution Prevention and Remediation, Life Cycle Programs

(CIMS 482-0001-51), Chrysler Technology Center, Auburn Hills MI 48326.

Employee Relations, Industrial Hygiene and Toxicology Department

7.0 DEFINITIONS

Article - A part that is added to the product without any additional processing (machining, finishing, etc.)

by Chrysler Corporation and does not release regulated substances under normal use, for example a tail

light lens.

Auto Industry Pollution Prevention Project (Auto-Project) - The Auto-Project is a voluntary partnership

between government and the auto industry to promote voluntary pollution prevention. The project

CS-9003, Change E, Page 16

emphasizes source reduction of persistent toxic substances that adversely affect the Great Lakes.

Tables 4 and 5 list persistent toxic substances.

Chemical Abstract System (C.A.S.) - A numeric system established by the Chemical Abstract Services

and adopted by federal law to identify chemicals.

Clean Air Act Amendments (CAAA) - Legislation passed by the U.S. Congress and several states

which focuses on air emissions and technology to improve air quality. The Amendments to the Clean Air

Act re-authorize the CAA and expand areas of enforcement and further reduce levels of emissions. The

CAAA lists approximately 189 hazardous air pollutants (HAPs) which concern Chrysler.

Customer - Purchaser or user of a completed vehicle or service item, including dealers and

maintenance personnel.

Environment - The term environment as used within this standard refers to the external (air, water, and

land disposal pollution concerns) and to the interior of the completed vehicle.

Hazardous Air Pollutants (HAPs) - Any pollutant placed on a list so identified in the Clean Air Act

Amendments (CAA) of 1990 or amended by the EPA Administrator and presumed to have an adverse

impact on the environment and/or human health.

Hazardous Material - As defined in this document is any material specified by a North American

regulation or statute or otherwise categorized as such by Chrysler's Industrial Hygiene and Toxicology

Department as being potentially adverse to the health or safety of the worker, customer, or the

environment.

Hazardous Process - A process which may release regulated materials into the environment, or that

could potentially create health, occupational safety, or environmental problems during subsequent

employee or customer handling.

International Agency for Research on Cancer (IARC) - A United Nations' agency under the World

Health Organization that identifies and classifies chemical substances in relation to their potential for

causing cancer.

New item - Within this standard the term "new item" refers to any new design, any alteration of an

existing design which would result in a new production part number. This term does not encompass

"articles" as defined earlier.

Pollution Prevention Act - The Pollution Prevention Act stresses source reduction rather than waste

management and establishes a hierarchical policy for environmental protection. This act focuses on

prevention and reduction over control whenever possible.

Regulated Substance - A substance identified by Chrysler Corporation and found on:

- one or more Federal regulatory lists such as Clean Air Act and its amendments, Superfund

Amendments

Re-authorization Act, Auto-Project, EPA-Inventory of Toxic Pollutants -

- the state lists from Delaware, Illinois, Indiana, Michigan, Missouri, Ohio, and Wisconsin,

- as well as the carcinogen list for IARC, EPA, OSHA, American Conference of Government

Industrial Hygienists [ACGIH]).

- Refer to Table 6.

CS-9003, Change E, Page 17

8.0 GENERAL INFORMATION

Three asterisks *** after the paragraph header denotes multiple technical changes to the paragraph.

A triple asterisk before and after a string of text (***text***) identifies a single change.

Certain important information relative to this standard has been included in a separate standard. To

assure the parts submitted meet all of Chrysler requirements, it is mandatory that the requirements in

the following standard be met.

CS-9800 - Application of this standard, the subscription service, and approved sources

Within Engineering Standards, the designations <S> <E>, <N>, <T> , or <H> will be substituted for the

Safety, Emission, Noise, Theft Prevention, or Homologation Shields respectively. The designation

<D> will be substituted for the Diamond symbol.

9.0 REFERENCES

9.1 Chrysler Corporation Engineering Documents (1)

CS-9003

CS-9800

PF-8500

PS-7000

PS-4480

9.2 U.S.A. Statutes/Initiatives

Auto Industry Pollution Prevention Project

(Code of Federal Regulations) 29 CFR 1910.1027

(Code of Federal Regulations) 29 CFR 1910.1050

Clean Air Act

Clean Air Act Amendments of 1990

Comprehensive Environmental Response Compensation and Liability Act

Consumer Product Safety Act

Federal Hazardous Substance Act

Federal Water Pollution Control Act

Federal Insecticide Fungicide and Rodenticide Act

Occupational Safety and Health Act

Poison Prevention Packaging Act

Pollution Prevention Act of 1990

Hazardous Materials Transportation Act

IS0 14000

Resource Conservation and Recovery Act

Safe Drinking Water Act

Superfund Amendments and Re-Authorization Act of 1986

Toxic Substance Control Act

9.3 Canadian Statutes

Environmental Protection Act

Hazardous Products Act

Ontario Occupational Health and Safety Act

CS-9003, Change E, Page 18

Transportation of Dangerous Goods Act

National Pollution Release Inventory

9.4 Other References

Product Assurance Process manual

Chrysler, Ford, and General Motors, Production Part Approval Process manual, published by AIAG

Vehicle Recycling Design Guidelines, available from the Engineering Standards and Information

Services Department

_____________________________

(1) Chrysler Engineering Standards are available to suppliers from Integrated Systems Development,

Holland, Michigan, 49422 (Phone 616-396-0880).

10.0 ENGINEERING APPROVED SOURCE LIST

Life Cycle Management Analysis

The Traverse Group 734-747-9300 Wendy White

McLaren Hart 248-358-0400 Ed Hogan

Franklin Associates Ltd. 913-649-2225 William Franklin

11.0 BIBLIOGRAPHY

Date Standard Originally (Initially) Issued: February 16, 1987

Department Name and Number: Pollution Prevention and Remediation; Dept. 0165

Contact/Phone No: R.J. Kainz, (248) 576-5496

Date of Change: June 14, 1999

Model Year - Effectivity Code - Disposition Code:

Authority: Editorial.

Change Level: E

Description of Change: Removal of Cover Sheet, Presentation Invitation.

# # # # #

APPENDIX A, CS-9003, Change E, A-1

APPENDIX A: PRODUCT PACKAGING AND LABELING

The initial shipment to a facility of any product which contains regulated substances or may cause

harm to human health, occupational safety, or the environment, as defined in the laws and statues,

listed in paragraph 9.0, or in other appropriate legislation must be accompanied by a MSDS.

All products (materials, parts, or components) shall be shipped in suitable containers and labeled in

accordance with all applicable laws and regulations. In addition, labels should clearly state (in English

or the using facilities local language as appropriate) the information in the following Table.

LABELING REQUIREMENTS

Chrysler Corporation Production Part Number

Chrysler Corporation Material Standard Numbers

Name and C.A.S. of any Regulated Substance contained in the part or material which is not specifically

called out in a Chrysler Corporation Engineering Standard CS 9003 which require a label disclosure.

Date of Manufacture

Chrysler Corporation Supplier Code for the manufacturer of the product.

Appropriate warning labels required by OSHA or US EPA or any state shall be submitted to the plant and

Industrial Hygiene at least 14 working days prior to shipment to the plant.

APPENDIX B, CS-9003, Change E, B-1

APPENDIX B: STATUTES, INITIATIVES, AND REGULATIONS

B.1 Compliance

Materials specified through the Chrysler Corporation material, process, and performance standards on

Engineering drawings/CATIA models shall be formulated and used in such a manner as to comply with all

applicable laws and regulations including those listed under section 9.0.

B.2 Non-Compliance

Failure to conform to the applicable laws and regulations can result in fines, penalties, and/or imprisonment

imposed by civil authorities. In addition, Chrysler Corporation will remove the supplier from the Chrysler

Corporation approved source lists. Pollution Prevention and Remediation will request Procurement and

Supply to stop purchasing from the supplier.

APPENDIX C, CS-9003, Change E, C-1

APPENDIX C: ENVIRONMENTAL POLICY POSITIONS

LEAD: Lead should be eliminated when possible. Only recycled lead should be accepted in our parts or

materials. When a question exists whether to use lead or an alternative material a Life Cycle Management

Analysis should be performed to determine the best business decision. Lead has been demonstrated to

present both adverse environmental and health affects. Using of lead requires extended responsibility and

liability to the Corporation and must be controlled.

Position: When lead is required only RECYCLED (post industrial or consumer) lead should be used.

Lead free plastics must be considered as well as lead free solder.

MERCURY: Mercury has been banned in Sweden and proposed bans have been introduced in three

states. Alternative substances, parts or materials should be selected based on a Life Cycle Management

Analysis that addresses all the potential issues. Replacement parts will only be permitted for existing

vehicles in Sweden through 2002.

Position: Mercury MUST BE eliminated from new sources by Model Year 1998 and existing sources

by Model Year 2000.

CHROME (CHROMIUM): The usage of chrome on our cars and trucks is not prohibited provided no

releases occur in our plants. When a release occurs steps must be taken to control the emissions.

Recycling of Chrome materials and parts is an expensive operation and can add to the recovery cost of a

vehicle.

Position: Chrome parts should be provided to Chrysler as articles and be recyclable.

CADMIUM: Cadmium is a heavy metal that presents environmental and health problems if not properly

managed. During manufacturing, disposal and/or recycling the extent of exposure of individuals or the

environment must be monitored, controlled and /or labeled. When considering the usage of cadmium,

alternative materials or substances must be addressed. Substitutes may not be as durable or reliable but

can meet regulatory requirements for the vehicle, therefore, these alternatives should be considered to

avoid prohibitions or non-value added costs to Chrysler at End-of-life vehicle recovery.

Position: Cadmium fasteners shall be eliminated with the possible exception for safety applications,

alternative engineering approaches should be incorporated for new product introductions. Switches

should consider alternative contacts in areas where durability of the system does not warrant switch

life beyond the system life. NOTE EUROPE DOES NOT CONSIDER FASTENING A SEAT BELT

TO THE VEHICLE AS A SAFETY APPLICATION.

PVC: PVC plastic used in the vehicle should be reduced where possible. Restrictions in Europe are

expected and recovery is costly. European import models must find alternative materials for PVC. Under

current European energy recovery guideline plastic can be incinerated to obtain energy. In many European

and some North American incinerators temperatures are not high enough to destroy the dioxin produced be

incinerating PVC. Costs to convert these incinerators are prohibitive. If this material becomes a material of

choice in automobiles it is likely that bans on the usage will follow.

Position: PVC will only be used for European exports when supported by a Life Cycle Management

Analysis.

APPENDIX D, CS-9003, Change E, D-1

APPENDIX D: ANALYSIS OF RECYCLED PRODUCTS, PART OR MATERIAL FOR

INDIVIDUAL PARTS AND COMPONENTS WITH MULTIPLE PARTS

Targets in Table 3 (see section 3.2.2) are applied in the following cases:

- When the total combined weight of parts from a single supplier providing three or more parts on a vehicle

line is 1 pound or more.

- When a supplier with less than three parts on a vehicle line is providing parts weighing 1 pound or more.

TO CALCULATE COMPLIANCE WITH THE TARGETS, TABLE 2 PERCENTAGES ARE MEASURED

AGAINST THE TOTAL WEIGHT OF THE PART/PARTS SUPPLIED.

Example: 3 parts (relatively equal weight) = total weight over 10 pounds

-- first part 100% post-consumer content

-- second part 50 % post-consumer content

-- third part 0% post-consumer content

Overall recycle content from the supplier on that vehicle is 50%

IF A SUPPLIER REPLACES A PART CONTAINING RECYCLED CONTENT WITH A PART THAT DOES

NOT HAVE RECYCLED CONTENT, THE OVERALL LOSS OF RECYCLED CONTENT MUST BE

OFFSET IN THE VEHICLE.

Example: 3 parts (relatively equal weight) produced in TPO

-- one part with 100% recycled content is replaced with one of 100% virgin

material

-- the supplier must increase the recycled content in the remaining TPO parts to

reach an equivalent recycled content overall

IF THE SUPPLIER OF THREE OR MORE PARTS WEIGHING MORE THAN 1 POUND FAILS TO MEET

THE RECYCLED CONTENT REQUIREMENTS IDENTIFIED IN TABLE 2, A LIFE CYCLE MANAGEMENT

ANALYSIS MUST BE PERFORMED BY THAT SUPPLIER. To assist suppliers in accomplishing this, three

approved sources have been identified by Chrysler to conduct Life Cycle Management analyses, and the

supplier must select from this approved group. (NOTE: section 7.0)

A Life Cycle Management Analysis evaluates the impact on long and short term decisions. It integrates

quality, cost, timing, performance and weight with environment, occupational health and safety, as well as

recycling, to facilitate better decision making. The team which participates is comprised of members of the

Platform team (engineer and management), Corporate staff (industrial hygiene/environmental/vehicle

recycling/buyer-raw materials) and the supplier(s). Results are reviewed by the team and the Pollution

Prevention and Remediations Manager, Life Cycle Programs.

To simplify the process, where possible, the results of previous analyses are included in the appendix of this

standard. They do not have to be repeated if the platform engineer agrees with the results. As other Life

Cycle Management Analyses are conducted, they will be added to the appendix for future reference.

APPENDIX E, CS-9003, Change E, E-1

APPENDIX E: LIFE CYCLE MANAGEMENT ANALYSIS

The following Life Cycle Management Analyses are available for review at the Pollution Prevention and

Remediation Department.

Analysis

Date

Preferred

Selection

Advantage &

Savings/Finding

Long Life Remanufactured EG Antifreeze

Vs PG Antifreeze

Dec 1994 Long Life

Remanufactured

Antifreeze

Environmental

Impact reduced.

Design of car

Unimpaired.

Plastic vs Remanufactured Rubber

Splash Guards

Nov 1996 Remanufactured

Rubber

Increased

post consumer

content, equal cost.

Copper vs Non-Copper Brake Systems Mar 1997 Non-Copper Non-Copper

saves $14.23

per vehicle cost.

Steel vs Plastic Oil Filter Dec 1996 Steel Filter Steel saves

$74.23 cost/

vehicle

over life.

Cartridge TASO vs Plastic Oil Filter Dec 1996 Cartridge TASO Cartridge TASO saves

$92.24

cost /vehicle

over life.

Cartridge TASO vs Steel Oil Filter Dec 1996 Cartridge TASO Cartridge TASO saves

$18.03

Cost/vehicle

over life.

Lead vs Non-Lead Electro Coat

(at one plant)

Nov 1996 Non-Lead Electro Coat $147,000.00 total cost

savings per plant per

year.

Mercury vs Non-Mercury Switch Convince

Underhood Lighting

Jul 1995 Non-Mercury

Switch

$0.30 total per vehicle

savings.

Chrome vs Non-Chrome Wash Jan 1996 Non-Chrome Wash Pending

APPENDIX F, CS-9003, Change E, F-1

APPENDIX F: COMPATIBILITY OF PLASTIC

Separability is the critical function that all engineers must employ during engineering design. When separability is not possible compatibility is the

alternative solution. Found below is a compatibility chart based on information received from the major resin suppliers to Chrysler. Individual charts

are maintained by the Pollution Prevention and Remediation Department and can be reviewed. Please use these charts in the combining of plastic

parts.

A

B

S

A

S

A

E

P

D

M

E

V

A

C

P

A

P

BT

P

BT

//P

C

P

C

P

C

//A

B

S

P

C

//P

BT

P

C

//P

ET

P

E

P

ET

P

M

M

A

P

O

M

P

P

P

P

E

P

P

E+

P

S

P

P

O

P

P

O

+P

S

P

P

S

P

S

P

V

C

S

A

N

S

M

A

TE

O

TP

E

TP

O

TP

U

ABS 1 1 4 3 3 1 1 1 2 3 4 3 2 3 4 4 3 4 4 2 1 2 3 4 3 1

ASA 1 1 3 1 1 1 1 1 3 2 1 3 3 3 3 3 1 1 1

EMA 1 2

EVA 1 1

PA 3 2 1 1 3 3 4 3 3 3 3 3 4 4 4 3 3 4 4 4 4 3 3 1

PBT 3 2 4 3 1 1 1 2 1 2 4 2 4 4 4 3 3 4 4 4 3 3 4 4 3 2

PBT/PC 1 1 3 1 1 1 1 1 3 3 3 4 3 3 3 3 4 1 2

PC 1 1 4 4 1 1 1 1 1 2 4 2 2 4 4 2 3 4 4 4 1 3 4 4 3 3

PC/ABS 1 1 3 2 1 1 1 3 4 4 2 2 3 3 4 3 4 4 1 3 4 2

PC/PBT 2 1 3 1 1 1 3 1 1 3 2 2 3 3 4 3 3 4 1 3 4 1

PC/PET 3 3 2 2 4 1 1 3 2 3 3 3 4 3 4

PE 4 3 4 4 4 4 4 3 3 3 1 4 4 4 3 4 3 4 4 4 4 4 4 3 3

PET 3 2 3 3 3 3 1 2 1 2 4 1 4 4 3 3 3 4 4 4 3 4 4 4 3 3

PMMA 1 1 4 4 4 3 2 2 2 3 4 4 1 4 4 4 3 4 3 2 1 2 4 4 3 3

POM 4 3 3 4 4 4 4 3 4 4 4 1 4 3 3 4 4 4 4 4 4 2

PP 4 4 1 4 4 4 4 3 3 3 3 4 4 4 1 4 3 4 4 4 4 4 4 4 1 3

KEY

1 = Very Good Compatibility

2 = Good Compatibility

3 = Poor Compatibility

4 = Non-Compatibility

Blank Data Unknown

APPENDIX F, CS-9003, Change E, F-2

A

B

S

A

S

A

E

P

D

M

E

V

A

C

P

A

P

BT

P

BT

//P

C

P

C

P

C

//A

B

S

P

C

//P

BT

P

C

//P

ET

P

E

P

ET

P

M

M

A

P

O

M

P

P

P

P

E

P

P

E+

P

S

P

P

O

P

P

O

+P

S

P

P

S

P

S

P

V

C

S

A

N

S

M

A

TE

O

TP

E

TP

O

TP

U

PPE 3 2 4 4 4 4 4 4 4 4 1 1 4 1 4 4 1 4 4

PPE+PS 2 2 3 1 1 1

PPO 4 3 4 3 3 2 4 3 3 4 3 4 3 4 1 1 1 4 3 4

PPO+PS 3 3 3 1 2 3 3 3 3 3 3 3 3 1 1 1 4 3 3

PPS 4 4 4 4 4 4 4 4 4 1 4 4 4 4 4 4 4

PS 3 3 4 4 4 3 4 3 3 4 4 4 4 4 1 1 1 1 1 4 3 3 4 4 3

PVC 2 1 4 4 4 4 4 4 4 4 4 4 2 4 4 4 4 4 4 1 2 4 4 4 4 4

SAN 1 1 4 4 3 2 1 1 2 4 4 2 4 4 3 3 4 4 1 1 3 3 4 2

SMA 2 3 3 3 3 3 3 4 4 2 4 4 2 4 3 4 3 1 3 4

TEO 2 2 4 4 4 4 4 4 4 4 4 4 3 3 1 4

TPE 3 4 1 4 1 1 4 3 4 4 4 4 1 4 4 3 1 4

TPO 3 3 3 3 4 4 4 3 3 3 2 4 4 4 4 1

TPU 1 1 3 3 2 2 2 2 4 4 3 4 4 4 3 3 4 3 2 2 3 4 1

KEY

1 = Very Good Compatibility

2 = Good Compatibility

3 = Poor Compatibility

4 = Non-Compatibility

Blank Data Unknown

You might also like

- Rand Paul 2023 Festivus ReportDocument25 pagesRand Paul 2023 Festivus ReportJames Lynch100% (1)

- Ipc 620Document17 pagesIpc 620Oscar Manuel ApodacaNo ratings yet

- Cs 11000Document15 pagesCs 11000ibrahime mohammedNo ratings yet

- Baofeng Uv-5r Ce Certificate 18-211428Document3 pagesBaofeng Uv-5r Ce Certificate 18-211428anshadNo ratings yet

- Engineering Sample Evaluation ReportDocument1 pageEngineering Sample Evaluation ReportSudhaNo ratings yet

- COUNTER MEASURE of Customer ComplaintDocument2 pagesCOUNTER MEASURE of Customer Complaintpreetam kumarNo ratings yet

- New RoHS Labeling SJT 11364 2014 ENG FINAL UPDATE TEXT PDFDocument13 pagesNew RoHS Labeling SJT 11364 2014 ENG FINAL UPDATE TEXT PDFLeeNo ratings yet

- Humidity Indicator Card How To ReadDocument10 pagesHumidity Indicator Card How To ReadSneha PatelNo ratings yet

- J1171 Ignition Proof StandardDocument2 pagesJ1171 Ignition Proof StandardTan Akuma100% (1)

- GGG-R-791H: Class I - WoodDocument28 pagesGGG-R-791H: Class I - WoodAlex Boy Sandi ManaluNo ratings yet

- Terms of Reference - Livelihood AssessmentDocument5 pagesTerms of Reference - Livelihood AssessmentPlan International PhilippinesNo ratings yet

- Customer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012Document4 pagesCustomer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012befoaNo ratings yet

- UN Regulation No 79 For Steering EquipmentDocument37 pagesUN Regulation No 79 For Steering EquipmentAndrei ItemNo ratings yet

- Of ANSI/AGMA 9005-E02.: ISBN: 1-55589-973-8 Pages: 33Document1 pageOf ANSI/AGMA 9005-E02.: ISBN: 1-55589-973-8 Pages: 33gioNo ratings yet

- Mil PRF 32239Document36 pagesMil PRF 32239Guritno GustiantoNo ratings yet

- SAE AMS2772G-2016Document3 pagesSAE AMS2772G-2016Grain FixerNo ratings yet

- Sop 7.4.4 Counterfeit Parts PreventionDocument6 pagesSop 7.4.4 Counterfeit Parts PreventionEDGAR GONZALEZNo ratings yet

- GA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Document26 pagesGA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Manoj Pai D100% (1)

- Quality Specifications For Purchased PartsDocument29 pagesQuality Specifications For Purchased PartsDheeraj Kumar100% (1)

- Master List of External OriginDocument2 pagesMaster List of External OriginMohit AggarwalNo ratings yet

- OBS - 510 - Rev 01 - Eng MilliporeDocument4 pagesOBS - 510 - Rev 01 - Eng MilliporeSakthy ArunaNo ratings yet

- MIL-PRF-16173 Preamble Footnotes: QA FSC QPL Number Governing Spec Doc Date Doc Status Title QPL NotesDocument1 pageMIL-PRF-16173 Preamble Footnotes: QA FSC QPL Number Governing Spec Doc Date Doc Status Title QPL NotesSAMPATHUNo ratings yet

- Delphi Technologies Global Packaging and Shipping ManualDocument22 pagesDelphi Technologies Global Packaging and Shipping ManualTom ChanNo ratings yet

- Spill Report Form: SpillsDocument2 pagesSpill Report Form: SpillsNoor Muddassir Khan100% (1)

- PDI ReportDocument2 pagesPDI ReportPreetam GiteNo ratings yet

- Xfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument8 pagesXfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following Formssenzo scholar100% (1)

- TSZ0001G 11 P 1Document18 pagesTSZ0001G 11 P 1haryonoari68No ratings yet

- Mil PRF 38535 RevfDocument151 pagesMil PRF 38535 RevfdmsspbNo ratings yet

- Form 9b Power Press Machine Safety DeviceDocument1 pageForm 9b Power Press Machine Safety DeviceBharat ChakravartinNo ratings yet

- AIS-038 Rev 2Document110 pagesAIS-038 Rev 2tripathi prashant100% (1)

- Emissions and Odor in The Vehicle Interior: Mercedes-Benz DBL 5430Document24 pagesEmissions and Odor in The Vehicle Interior: Mercedes-Benz DBL 5430Mateo BanzanNo ratings yet

- Mil PRF 85285FDocument26 pagesMil PRF 85285Fchampyjm6532No ratings yet

- IS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible MotorsDocument10 pagesIS 8783 (Part-4-Sec.1) - 1995 - HR PVC Insulated - Winding Wires For Submersible Motorsshivam dwivediNo ratings yet

- HEMPADUR ZINC 15360 15360 en-GB PDFDocument2 pagesHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinNo ratings yet

- CF 601 1 Purchasing Quality Assurance RequirementsDocument3 pagesCF 601 1 Purchasing Quality Assurance RequirementsTrent CockerhamNo ratings yet

- Normazione 9.01102: Quality of SuppliesDocument67 pagesNormazione 9.01102: Quality of Suppliesvinicius_bacellarNo ratings yet

- Safety Data-Sheet According To Regulation (EC) No. 1907/2006 (REACH)Document6 pagesSafety Data-Sheet According To Regulation (EC) No. 1907/2006 (REACH)gro loka100% (1)

- Sop-Standard Operating Procedure: ObjectiveDocument4 pagesSop-Standard Operating Procedure: ObjectiveDivyashree PatilNo ratings yet

- En 14399 & en 15048 FPC Points To Be CoveredDocument8 pagesEn 14399 & en 15048 FPC Points To Be Coveredsks27974No ratings yet

- Supplier Declaration of Compliance - TSCADocument2 pagesSupplier Declaration of Compliance - TSCABlynic TanNo ratings yet

- MRMDocument50 pagesMRMRamesh KumarNo ratings yet

- S-1000 (S-SPEC-1) - Master - March2021Document107 pagesS-1000 (S-SPEC-1) - Master - March2021Rajesh KannanNo ratings yet

- PDI ChecklistDocument2 pagesPDI ChecklistOverhauled ArtsNo ratings yet

- Pre-Mob Inspection Checklists 2 January 2016Document378 pagesPre-Mob Inspection Checklists 2 January 2016slamet4riadiNo ratings yet

- Un-qd-ff-860 Fai ביצוע - engDocument6 pagesUn-qd-ff-860 Fai ביצוע - engmsy021yahoo.comNo ratings yet

- Astm F1089-02 - Standard Test Method For Corrosion of Surgical InstrumentsDocument3 pagesAstm F1089-02 - Standard Test Method For Corrosion of Surgical InstrumentsmurleyjNo ratings yet

- STEICObitumenboards en IDocument4 pagesSTEICObitumenboards en Imanit fernandesNo ratings yet

- The Company'S Factory Production Control System (FPC) FPC 0: BackgroundDocument7 pagesThe Company'S Factory Production Control System (FPC) FPC 0: BackgroundSandy D. RockNo ratings yet

- Quality Assurance, Inspection, Auditing, RecordsDocument2 pagesQuality Assurance, Inspection, Auditing, Recordsapi-121413724No ratings yet

- MTD - QF.17.01CalibrationDocument2 pagesMTD - QF.17.01CalibrationvinothNo ratings yet

- Part Sample WarrantDocument1 pagePart Sample WarrantmageroteNo ratings yet

- Anexo - 19 - ING - FPW - IFN053 - Junx14 KDCS - FCADocument20 pagesAnexo - 19 - ING - FPW - IFN053 - Junx14 KDCS - FCAValdinei OliveiraNo ratings yet

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocument4 pagesIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesVenkateswaran venkateswaranNo ratings yet

- Manualul Calitatii Aviatie PDFDocument15 pagesManualul Calitatii Aviatie PDFStefan GrozaNo ratings yet

- Anexa 3 BI261Document69 pagesAnexa 3 BI261ahmadove1No ratings yet

- Spira FOD Prevention Program 2 11 2021Document14 pagesSpira FOD Prevention Program 2 11 2021Tin NguyenNo ratings yet

- Comparison For 3668 2019 and ISO 21898Document2 pagesComparison For 3668 2019 and ISO 21898PRIYAH CoomarasamyNo ratings yet

- Rsms - Package - 2007 Wss M99p999-A1Document63 pagesRsms - Package - 2007 Wss M99p999-A1Yan WendelNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Cs 9003Document22 pagesCs 9003ibrahime mohammed100% (1)

- AS9100C WhitePaperDocument10 pagesAS9100C WhitePaperlugarxNo ratings yet

- Conversion Formulas ADocument14 pagesConversion Formulas Aabraham_ginNo ratings yet

- Delphi Manual RequirementsDocument20 pagesDelphi Manual Requirementsabraham_ginNo ratings yet

- Chrysler StandardDocument25 pagesChrysler Standardabraham_ginNo ratings yet

- Control of Porosity of AlumnumDocument9 pagesControl of Porosity of Alumnumabraham_ginNo ratings yet

- Control of Porosity of AlumnumDocument9 pagesControl of Porosity of Alumnumabraham_ginNo ratings yet

- Main Causes For HysteresisDocument2 pagesMain Causes For Hysteresisabraham_ginNo ratings yet

- Units, Dimensions & Conversion Factors: Fundamental DerivedDocument5 pagesUnits, Dimensions & Conversion Factors: Fundamental Derivedabraham_ginNo ratings yet

- 67 A B C D E F G H: Hospital General AltoDocument2 pages67 A B C D E F G H: Hospital General AltoAlejandra Ramos BaezNo ratings yet

- Report-Pharmaceutical Sector StudyDocument92 pagesReport-Pharmaceutical Sector Studymidhun babuNo ratings yet

- Hse Management System FrameworkDocument38 pagesHse Management System FrameworkTomNo ratings yet

- 2006 PNLE IssueDocument2 pages2006 PNLE IssueBernz KyNo ratings yet

- Project Report On Field Study in Insurance SectorDocument86 pagesProject Report On Field Study in Insurance Sectorsunny_choudhary@hotmail.com100% (1)

- Letter of Inquiry PHW Hazard PayDocument2 pagesLetter of Inquiry PHW Hazard PayBonapi Katerine SogrubNo ratings yet

- Environment Management System ManualDocument5 pagesEnvironment Management System ManualtoanvmpetrologxNo ratings yet

- The End of The Nation StateDocument13 pagesThe End of The Nation Stateganeshswamy4No ratings yet

- Homeopathy in HealthcareDocument2 pagesHomeopathy in HealthcareKayPeaBNo ratings yet

- Kellerman - 1986 - Protection or Peril - An Analysis of Firearm-Related Deaths in The HomeDocument4 pagesKellerman - 1986 - Protection or Peril - An Analysis of Firearm-Related Deaths in The Homesavvy_as_98-1No ratings yet

- Garcia Rueda Vs Pascasio - DigestDocument1 pageGarcia Rueda Vs Pascasio - DigestSharon G. Balingit0% (1)

- National Training Policy 2012Document12 pagesNational Training Policy 2012anon_119311609No ratings yet

- Concept Note Eng PDFDocument2 pagesConcept Note Eng PDFJamalNo ratings yet

- 45 Declared Communist Takover Goals 1963Document3 pages45 Declared Communist Takover Goals 1963TheAntiMarxNo ratings yet

- Case Study 1Document2 pagesCase Study 1Sel MNo ratings yet

- Federal Insurance Contributions ActDocument3 pagesFederal Insurance Contributions ActMaryNo ratings yet

- Notice: Grants and Cooperative Agreement Awards: Human Immunodeficiency Virus (HIV) — Tuberculosis Elimination Advisory CouncilDocument1 pageNotice: Grants and Cooperative Agreement Awards: Human Immunodeficiency Virus (HIV) — Tuberculosis Elimination Advisory CouncilJustia.comNo ratings yet

- Basic Safety Procedures in High Risk Activities and IndustriesDocument20 pagesBasic Safety Procedures in High Risk Activities and IndustriesMark Goldwyn BlandoNo ratings yet

- Pe PMG 02004 01Document351 pagesPe PMG 02004 01Arabel Vilas SerínNo ratings yet

- Thomsom - A Defence of AbortionDocument9 pagesThomsom - A Defence of AbortionMary KimNo ratings yet

- Research AgendaDocument42 pagesResearch Agendajocelyn sosa agustinNo ratings yet

- TourismDocument13 pagesTourismcatagbacan handig barangayNo ratings yet

- Star Cardiac Care Brochure PlatinumDocument8 pagesStar Cardiac Care Brochure PlatinumAbhishek GuptaNo ratings yet

- Information Broucher Nursing ExcellenceDocument16 pagesInformation Broucher Nursing ExcellenceShantu Shirurmath100% (1)

- E-Brochure UGNEET-2023 14-07-2023 EnglishDocument83 pagesE-Brochure UGNEET-2023 14-07-2023 EnglishdhnaushNo ratings yet

- ARP Bill As Passed by Senate - BILLS-117hr1319easDocument628 pagesARP Bill As Passed by Senate - BILLS-117hr1319easClever PloyNo ratings yet

- LEGISLATION Reducing Criminalization To Improve Community Health and Safety Amendment Act of 2017Document5 pagesLEGISLATION Reducing Criminalization To Improve Community Health and Safety Amendment Act of 2017Team_Grosso100% (1)

- Centro Escolar University Manila Makati Malolos Activity Proposal FormDocument4 pagesCentro Escolar University Manila Makati Malolos Activity Proposal FormAlvinDumanggasNo ratings yet