Professional Documents

Culture Documents

12 Impeller

12 Impeller

Uploaded by

Prasekky Hanung PermadiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 Impeller

12 Impeller

Uploaded by

Prasekky Hanung PermadiCopyright:

Available Formats

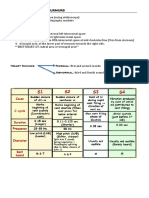

StepstoDrawPumpImpeller:Thestepsbelowshowonewaytodrawtheimpeller.

Youshouldmake

surethatyourimpellerisnotlargerthantheoneshownoritmaynotfitinthepumphousing.

1. Changeunitstoinches:

Tools>Options>Document

Properties>Unitsandthenselect:

IPS(inch,pound,second)

2. SelectExtrudedBoss/Basefrom

theFeaturestoolbar

3. SelecttheTopPlanefordrawing.

4. SelectCirclefromtheSketch

toolbar.Nowpositionthepointer

overtheorigin,anddrawacircle

withadiameterofapproximately

0.9inches.

5. SelectSmartDimensionfromthe

Sketchtoolbar,andsetthediameter

ofthecircleto0.9inches.

6. Returnandextrudethecircletoa

heightof0.12inches.Thenclickthe

greencheckmarktoacceptthis

extrusiondimension.

7. ClickonExtrudeBoss/Base,and

selectthebottomofthedisk.

8. Drawa0.2inchdiametercircleon

thebottomofthedisk,and

protrudeitoutwardfromthediskto

adistanceof0.03inches.

9. ClickonExtrudeBoss/Base,and

begintodrawthe2Dfeaturesthat

willdefinetheimpellerblades.

Selectthetopfaceofthediskfor

drawing.

10. Drawa0.2inchdiametercircle

centeredontheorigin.

11. SelecttheSplinetoolontheSketch

toolbarandproceedtodrawthe

profilesofanimpellerblade.

12. Drawarcstodefineanimpeller

blade.Notethatthedimensionsare

notcritical.But,dontmakethe

bladestoonarrowastheywilleasily

breakoffduringpumpassembly

(theoneshownisalmosttoothin).

13. Drawanadditionalcirclethat

coincideswiththeouterboundary

ofthedisk(0.9inchesindiameter).

Thiscirclewillbeusedtodefinethe

outeredgeoftheimpellerblade.

14. SelecttheTrimEntitiestoolfrom

theSketchtoolbartoeliminatethe

portionsoftheinnerandouter

circlesthatarenotpartofthe

impellerblade.SelecttheTrimto

closestoptionfortrimming.

15. Eliminatetheredportionofthe

innercircle(itwillturnredwhen

youyourpointerisintheright

place).Repeatthisfortheouter

circle.Clickthegreencheckmarkto

endthetrimmingprocess.

16. Youshouldnowhavethe2Dprofile

ofasingleimpellerblade.Besureto

saveyourworkasyougoalong.

17. Holdthe<Ctrl>buttonwhileyou

clickaroundtheboundaryofthe

bladeprofile.Thelineswillturn

greenastheyareselected.

18. SelectCircularPatternfrom...

Tools>SketchTools

19. Select3forthenumberofinstances

oftheimpellerblade(youcanhave

morethan3bladesifyoulike).Since

youdefinedtheinitialdiskcentered

abouttheorigin,SolidWorks

automaticallyselectsthecenter

pointastheaxisaboutwhichcoping

occurs.Clickthegreencheckmark

whenyouaredone.

20. Returnandextrudetheblades

outward0.32inches.Thisshould

leave0.03inchofgapbetweenthe

impellerandthefaceplateofthe

pump.

21. SelecttheFillettoolfromthe

featurestoolbar.

22. Roundtheedgesshowntothe

largestradiuspossible.Ifyougetan

error,itislikelythatyouareusinga

radiusthatistoolarge.Addingthis

radiuswillmaketheblades

stronger.

23. SelectExtrudedCutfromthe

featurestoolbar.

24. Cutouta0.086inchholethrough

thecenterofthepart.

25. Saveyourfileasapartfile(SLDPRT)andasaSTLfile(.stl)usingthefollowingnaming

convention:

a. firstinitial,underscore,lastname.SLDPRTexample:j_doe.SLDPRT

b. firstinitial,underscore,lastname.STLexample:j_doe.STL

Tosavethe.STLfile,youwillneedtogotoFile>SaveAs>Saveastype:andchooseSTL

(*.stl).ThenclickonOptions,andenter0.001infortheDeviationtoleranceand2.000degfor

theAngletolerance.ThiswillensurethatyourSTLfileproducesasmoothpartwhenit

prints.Printoutapictureofyourimpellerandturnitinwithyourhomework.

Gettogetherwithyourpartner,andselectoneofyourimpellerstohaveprintedofABSplastic

onarapidprototypingmachine.EmailyourSLDPRTandSTLfilestoyourinstructorforprinting.

Note:BesuretoexitSolidWorksbeforesendingyourfile.Theinstructorshavehadtroublein

thepastreadingSolidWorksfiles;webelievethatsendingafilethathasnotbeenproperly

closedmayrenderitunreadable.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Índice Guild of American Lutherie BooksDocument283 pagesÍndice Guild of American Lutherie BooksDaniel AndradeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Exhaust Temperature SpreadDocument5 pagesExhaust Temperature Spreadchdeepak96100% (8)

- Standard Welded Wire Mesh For Concrete ReinforcementDocument3 pagesStandard Welded Wire Mesh For Concrete Reinforcementmarksantana100% (2)

- Analysis Wind Load Uniform Building Clode UbcDocument1 pageAnalysis Wind Load Uniform Building Clode UbcPapatsarsa SrijangNo ratings yet

- Accusine SWP 20 - 480 A Active Harmonic Filter: ReceivingDocument2 pagesAccusine SWP 20 - 480 A Active Harmonic Filter: ReceivingCata CatalinNo ratings yet

- E Exe Ef Fluorescent: Standard S Specification FeaturesDocument4 pagesE Exe Ef Fluorescent: Standard S Specification FeaturesrelaxjackNo ratings yet

- 2019 Asset Management PlanDocument162 pages2019 Asset Management PlanticoNo ratings yet

- Lenis Scale ManualDocument43 pagesLenis Scale ManualbjpNo ratings yet

- San Andres Cop Pel 981Document21 pagesSan Andres Cop Pel 981RubenNo ratings yet

- Medibuddy-EnrolPolicyConditions 22Document23 pagesMedibuddy-EnrolPolicyConditions 22Vadivelan BaskarNo ratings yet

- Starbucks Business Report ManagementDocument21 pagesStarbucks Business Report ManagementParidhi LapalikarNo ratings yet

- 3 Quarter Examination: Technology and Livelihood Education 9 IDocument4 pages3 Quarter Examination: Technology and Livelihood Education 9 IAgp GalvadoresNo ratings yet

- Stokes Second Problem by Laplace TransformDocument19 pagesStokes Second Problem by Laplace TransformSidra AfzalNo ratings yet

- Index: High-Grade KeyboardDocument15 pagesIndex: High-Grade KeyboardDavid Emanuel Dauo0% (1)

- P1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsDocument63 pagesP1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsHgoglezNo ratings yet

- An Epistle of JeremiahDocument3 pagesAn Epistle of JeremiahBenson MuimiNo ratings yet

- Bridas WN Clase 150Document1 pageBridas WN Clase 150juan ormacheaNo ratings yet

- Science Form 4 - Chapter 5Document74 pagesScience Form 4 - Chapter 5Eric ChewNo ratings yet

- FB-1 - Beam Detector Specification PDFDocument1 pageFB-1 - Beam Detector Specification PDFRafiq MagdyNo ratings yet

- Fixed Asset RegisterDocument3 pagesFixed Asset Registerzuldvsb0% (1)

- Task 1 - Pre Knowledge Quiz - CARRODocument15 pagesTask 1 - Pre Knowledge Quiz - CARROClaudia FilipoNo ratings yet

- Thunder Cake StoryDocument5 pagesThunder Cake Storyapi-21226401No ratings yet

- T50e Replace DriveDocument24 pagesT50e Replace DrivevcalderonvNo ratings yet

- 7th Heart Sounds and MurmursDocument6 pages7th Heart Sounds and MurmursbabibubeboNo ratings yet

- MCQ's of Industrial Hydraulics & Pneumatics Laboratory: B. One DirectionDocument3 pagesMCQ's of Industrial Hydraulics & Pneumatics Laboratory: B. One Directionyuvarajballal100% (4)

- Seminar Report On Smart Note TakerDocument22 pagesSeminar Report On Smart Note TakerSritejNo ratings yet

- Envasadora 1Document191 pagesEnvasadora 1Alicia Del Rocío SaniNo ratings yet

- Learning Plan CLE-9Document5 pagesLearning Plan CLE-9Caren PondoyoNo ratings yet

- Cross Reference Odpowiedniki - DanfossDocument29 pagesCross Reference Odpowiedniki - DanfossDanielEscobarMontecinosNo ratings yet