Professional Documents

Culture Documents

Atmel 2596 Sensor Based Control of Three Phase Brushless DC Motors Application Note Avr443

Atmel 2596 Sensor Based Control of Three Phase Brushless DC Motors Application Note Avr443

Uploaded by

Bogdan CosteaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atmel 2596 Sensor Based Control of Three Phase Brushless DC Motors Application Note Avr443

Atmel 2596 Sensor Based Control of Three Phase Brushless DC Motors Application Note Avr443

Uploaded by

Bogdan CosteaCopyright:

Available Formats

APPLICATION NOTE

Atmel AVR443: Sensor-based Control of Three Phase

Brushless DC Motor

Atmel AVR 8-bit Microcontrollers

Features

Less than 5s response time on Hall sensor output change

Theoretical maximum of 1600k RPM

Over-current sensing and stall detection

Support for closed loop regulation

UART, TWI and SPI available for communication

Introduction

The use of Brushless DC (BLDC) motors is continuously increasing. The reason is

obvious: BLDC motors have a good weight/size to power ratio and excellent

acceleration performance, require little or no maintenance and generate less acoustic

and electrical noise than universal (brushed) DC motors.

In a Universal DC motor, brushes control the commutation by physically connecting

the coils at the correct moment. In BLDC motors the commutation is controlled by

electronics. The electronics can either have position sensor inputs that provide

information about when to commutate or use the Back Electromotive Force

generated in the coils. Position sensors are most often used in applications where the

starting torque varies greatly or where a high initial torque is required. Position

sensors are also often used in applications where the motor is used for positioning.

Sensor-less BLDC control is often used when the initial torque does not vary much

and where position control is not in focus, e.g. in fans.

This application note describes the control of a BLDC motor with Hall Effect position

sensors (referred to simply as Hall sensors). The implementation includes both

direction and open loop speed control.

Figure 1. Atmel ATmega48 controlling a BLDC motor with Hall sensors.

2596CAVR07/2013

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

2

Table of Contents

1. Theory of Operation ............................................................................. 3

1.1 Operation of Fundamental BLDC Motor ............................................................ 3

1.2 Implementation Hall Sensor Based Control of BLDC Motor ........................... 4

1.3 Software Description ......................................................................................... 6

1.4 Performance of Current Implementation ........................................................... 7

2. Revision History ................................................................................... 8

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

3

1. Theory of Operation

Control of a BLDC motor with position sensors can be implemented on sufficiently powerful microcontroller featuring

basic hardware peripherals such as Analog to Digital Converter (ADC) and a timer with PWM output. The Atmel

ATmega48 covers the requirements for BLDC motor control well with resources left for other tasks still. Other relevant

tasks could e.g. be communication using SPI, UART or TWI protocols.

A three-phase BLDC consists of a Stator with a number of coils. The fundamental three-phase BLDC motor has three

coils (see Figure 1). Usually the three coils are referred to as U, V and W. In many motors the fundamental number of

coils is replicated to have smaller rotation steps and smaller torque ripple.

The rotor in a BLDC motor consists of an even number of permanent magnets. The number of magnetic poles in the

rotor also affects the step size and torque ripple of the motor. More poles give smaller steps and less torque

ripple. Figure 1-1 shows different configurations of motors with more than one fundamental set of coils and multiple

poles.

Figure 1-1. BLDC motors of different types. Motor (a) has two fundamental sets of coils and four poles, (b) has three

sets of coils and eight poles and (c) has four sets of coils and eight poles.

The fact that the coils are stationary while the magnet is rotating makes the rotor of the BLDC rotor lighter than the rotor

of a conventional universal DC motor where the coils are placed on the rotor.

1.1 Operation of Fundamental BLDC Motor

To simplify the explanation of how to operate a three-phase BLDC motor a fundamental BLDC with only three coils is

considered.

To make the motor rotate the coils are energized (or activated) in a predefined sequence, making the motor turn in

one direction, say clockwise. Running the sequence in reverse order makes the motor run in the opposite direction. One

should understand that the sequence defines the direction of the current flow in the coils and thereby the magnetic field

generated by the individual coils. The direction of the current determines the orientation of the magnetic field generated

by the coil. The magnetic field attracts and rejects the permanent magnets of the rotor. By changing the current flow in

the coils and thereby the polarity of the magnetic fields at the right moment and in the right sequence the motor

rotates. Alternation of the current flow through the coils to make the rotor turn is referred to as commutation.

A three-phase BLDC motor has six states of commutation. When all six states in the commutation sequence have been

performed the sequence is repeated to continue the rotation. The sequence represents a full electrical rotation. For

motors with multiple poles the electrical rotation does not correspond to a mechanical rotation. A four-pole BLDC motor

uses two electrical rotation cycles per mechanical rotation. When specifying the number of Rotations per Minute

subsequently, the number of electrical rotations is referred to unless otherwise mentioned.

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

4

The most elementary commutation driving method used for BLDC motors is an on-off scheme: A coil is either

conducting (in one or the other direction) or not conducting. Connecting the coils to the power and neutral bus induces

the current flow (accomplished using a driver stage). This is referred to as square wave commutation or block

commutation. An alternative method is to use a sinusoidal type waveform. This application note covers the block

commutation method.

The strength of the magnetic field determines the torque and speed of the motor. By varying the current flow through

the coils the speed and torque of the motor can be varied. The most common way to control the current flow is to

control the (average) current flow through the coil. This can be accomplished by switching the supply voltage to the coils

on and off so that the relation between on and off time defines the average voltage over the coil and thereby the

average current.

Figure 1-2. Current flow through the coils/magnetic field generated by the coils U, V and W in the six commutation

states for a BLDC motor. Hall sensor outputs are also shown.

U

V

W

1 2 3 4 5 6 1

H1

H2

H3

For BLDC motors the commutation control is handled by electronics. The simplest way to control the commutation is to

commutate according the outputs from a set of position sensors inside the motor. Usually Hall sensors are used. The

Hall sensors change their outputs when the commutation should be changed (see Figure 1-2). Quite simple!

Secondary functions for the electronics in a BLDC motor control application is to ensure that the speed is as desired

either by open or closed loop control. In either case it is however also recommended to have stall detection (blocked

motor) and overload detection.

1.2 Implementation Hall Sensor Based Control of BLDC Motor

The implementation is controlling a BLDC motor in open loop. The motor current is measured and speed is monitored,

to be able to respond to stall and overload situations. Three PWM channels are connected to the low side of the driving

Half-bridges to control the speed of the motor. A BLDC motor driver stage, consisting of three half-bridges, can be seen

in Figure 1-3.

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

5

Figure 1-3. Typical driver-bridge for a three-phase BLDC motor.

The driver stage is implemented slightly different in practice to accommodate for the lacking possibility to control the

high side FETs directly from logic output levels from the AVR

. An implementation using dedicated FET drivers is used

for the Atmel ATAVRMC100 development board, an alternative implementation could be the one described in Figure 1-

4.

Figure 1-4. Driver circuit for the U, V and W motor coils (only U driver shown).

Three PWM channels, OC0A, OC0B and OC2B, control the low side of the driver bridge (e.g. UL on Figure 1-4). This

gives the possibility to control the current flow using hardware based PWMs with a minimum of timer resources in use.

This controls the speed of the motor: by varying the duty cycle of the PWM output the current flow and thereby the

speed (and torque) of the motor is controlled.

It is also possible to have PWM based control of the high side of the bridge, but that would require all the Atmel

ATmega48 timers. Further, it would require either that shoot through protection is integrated in the driver circuit or that

dead time is handled in software. If active breaking is used it can be desired to use PWM channels for both high and

low side of the drivers to distribute the power dissipation more evenly over the effect transistors. However, in most

applications this is not required.

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

6

A single ADC channel is used to measure the current flow. The ADC has a resolution of 10 bits and uses an external

2.5V reference; this gives an accuracy of approximately 2.4mV, which is sufficient for over-current detection as the

voltage over a 0.22 shunt resistor is 220mV when 1A flows through it. If required the ADC can be triggered by the

PWM to measure current when not switching or run continuously with a given sampling frequency. A second ADC

channel is used to measure an analog voltage (e.g. a potentiometer) used as speed reference for adjusting the motor

speed.

The Hall sensor outputs are connected to three pins on PORTB, which all features interrupt on level change (pin

change interrupt). In case the Hall sensors outputs change their logic levels, an interrupt is executed and the

commutation state corresponding to the new Hall sensor output is determined. Note that the lowest pins on a PORT are

used intentionally to speed optimize the decoding of the Hall signals.

An overview of the resources used is listed in Table 1-1, more details can be found in the software documentation

(readme.html).

Table 1-1. Resources used for motor control.

Resource Usage

ADC0 and ADC4 Speed reference and current measurements

PORTD[3] Timer Counter 2: OC2B Control of low side drivers (WL)

PORTD[5,6] Timer Counter 0: OC0[A,B] Control of low side drivers (VL, UL)

PORTD[7,4,2] Control of high side drivers (UH, VH, WH)

It is worth mentioning that the hardware resources for UART, SPI and TWI communication are still available if required.

Note that the increased response time to hall sensor change should be considered if interrupts are used for

communication (or other peripherals).

1.3 Software Description

All code is implemented in C language using the IAR EWAVR 4.12A compiler (free up to 4kB of binary output). The

source code is documented using Doxygen - refer to the readme.html file found along with the source code for code

documentation. The readme.html will open the html based code documentation.

The most important function, the Pin Change Interrupt routine, handling the commutation change upon a change in the

Hall sensor output, is described by the flowchart found in Figure 1-5.

Note that the implementation locks a number of registers for certain variables to ensure fast execution of the interrupt

handling the commutation. The compiler rarely uses the registers locked - unless standard libraries functions for

handling strings are used. If a conflict should emerge this, it can be taken care of by recompiling the standard libraries.

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

7

Figure 1-5. Flowchart of the pin change interrupts handling the communication.

Read Hall signals

Pin change interrupt

Change PWM output

configuration according to

commutation table.

(uses pointer with hall signal

as offset)

Change high side control

signals according to

commutation table.

(Uses pointer with hall signal

as offset)

Update Count variable used to

monitor the motor speed

Exit

Note that the pointer used to

control the commutation can

point to either a Clock-Wise or

a Counter Clock-Wise

commutation table. The table

holds information about high

side driving and configuration

of both timer 0 and timer 2

1.4 Performance of Current Implementation

8-bit resolution on the speed control (limited by PWM resolution)

Code size is 427 bytes (high code size optimization)

Response time to Hall sensor signal changes is below 5s

Pin-Change interrupt routine (Hall input) takes app 50 CPU cycles. At 8MHz this gives a giving a theoretical

maximum of 1600k RPM (8MHz/(50 cycles x 6 commutation states) x 60 sec/min) - if over-current control and

communication is not considered

Atmel AVR443: Sensor-based Control of Three Phase Brushless DC Motor [APPLICATION NOTE]

2596CAVR07/2013

8

2. Revision History

Doc. Rev. Date Comments

2596C 07/2013 Syntax correction and new document template

2596B 02/2006 Doxygen comments updated and corrected

2596A Initial document release

Atmel Corporation

1600 Technology Drive

San Jose, CA 95110

USA

Tel: (+1)(408) 441-0311

Fax: (+1)(408) 487-2600

www.atmel.com

Atmel Asia Limited

Unit 01-5 & 16, 19F

BEA Tower, Millennium City 5

418 Kwun Tong Road

Kwun Tong, Kowloon

HONG KONG

Tel: (+852) 2245-6100

Fax: (+852) 2722-1369

Atmel Munich GmbH

Business Campus

Parkring 4

D-85748 Garching b. Munich

GERMANY

Tel: (+49) 89-31970-0

Fax: (+49) 89-3194621

Atmel Japan G.K.

16F Shin-Osaki Kangyo Building

1-6-4 Osaki, Shinagawa-ku

Tokyo 141-0032

JAPAN

Tel: (+81)(3) 6417-0300

Fax: (+81)(3) 6417-0370

2013 Atmel Corporation. All rights reserved. / Rev.: 2596CAVR07/2013

Atmel

, Atmel logo and combinations thereof, AVR

, Enabling Unlimited Possibilities

, and others are registered trademarks or trademarks of Atmel Corporation

or its subsidiaries. Other terms and product names may be trademarks of others.

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any intellectual property right is granted by this

document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN THE ATMEL TERMS AND CONDITIONS OF SALES LOCATED ON THE ATMEL WEBSITE, ATMEL ASSUMES

NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT,

CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS AND PROFITS, BUSINESS INTERRUPTION, OR LOSS OF

INFORMATION) ARISING OUT OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications and products descriptions at any time

without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in,

automotive applications. Atmel products are not intended, authorized, or warranted for use as components in applications intended to support or sustain life.

You might also like

- Class 2 Electrical Oral QuestionsDocument6 pagesClass 2 Electrical Oral QuestionsArun Paul Rayen100% (1)

- Controls For Electric & Gas Forklifts, Golf CartsDocument124 pagesControls For Electric & Gas Forklifts, Golf CartsFaizal Jamal60% (10)

- Sensorbased Control of Three Phase Brushless DC Motor PDFDocument8 pagesSensorbased Control of Three Phase Brushless DC Motor PDFmike_helplineNo ratings yet

- AVR492: Brushless DC Motor Control Using AT90PWM3: Application NoteDocument26 pagesAVR492: Brushless DC Motor Control Using AT90PWM3: Application NotenicoletabytaxNo ratings yet

- AVR194 Brushless DC Motor Control Using ATMega32M1Document16 pagesAVR194 Brushless DC Motor Control Using ATMega32M1u776287No ratings yet

- Experiment Number: 9 AIM:-To Speed Control of Three Phase BLDC Motor. Theory: - 2.1 BLDC MotorDocument7 pagesExperiment Number: 9 AIM:-To Speed Control of Three Phase BLDC Motor. Theory: - 2.1 BLDC MotorDineshKanawatNo ratings yet

- The Voltech Handbook of PWM Motor DrivesDocument53 pagesThe Voltech Handbook of PWM Motor DrivesPovaS100% (1)

- Scalar Speed Control of Induction MotorsDocument21 pagesScalar Speed Control of Induction MotorsRami100% (1)

- An Introduction To Brushless DC Motor ControlDocument33 pagesAn Introduction To Brushless DC Motor ControlIgor TrimcevskiNo ratings yet

- Atmel 8311 AVR1607 Brushless DC Motor Control in Sensor Mode Using ATxmega128A1 and ATAVRMC323 Application NoteDocument18 pagesAtmel 8311 AVR1607 Brushless DC Motor Control in Sensor Mode Using ATxmega128A1 and ATAVRMC323 Application NoteRoberto CasperNo ratings yet

- Basic BLDC ControllerDocument9 pagesBasic BLDC ControllerRen KiyoshiiNo ratings yet

- Ijert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariDocument4 pagesIjert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariAvinash Babu KmNo ratings yet

- Embedded BLCDDocument24 pagesEmbedded BLCDDhananjay PatilNo ratings yet

- Speed Control of 3Ø AC Induction Motor Using VSI & MicrocontrollerDocument32 pagesSpeed Control of 3Ø AC Induction Motor Using VSI & MicrocontrollerVijay PrabhuNo ratings yet

- Industrial Drives Lab File PDFDocument19 pagesIndustrial Drives Lab File PDFMayankJainNo ratings yet

- Speed Control For Brushless DC MotorsDocument50 pagesSpeed Control For Brushless DC MotorsMiladShahabiNo ratings yet

- Infant Monitoring System Using Co2 Sensor-Project ReportDocument59 pagesInfant Monitoring System Using Co2 Sensor-Project ReportRajesh Kumar0% (1)

- Microcontroller Based Constant Speed Low Cost Energy Efficient BLDC Motor Drive Using Proteus VSM SoftwareDocument7 pagesMicrocontroller Based Constant Speed Low Cost Energy Efficient BLDC Motor Drive Using Proteus VSM SoftwaremakroumNo ratings yet

- 00908a - Using The DsPIC30F For Vector Control of An ACIMDocument76 pages00908a - Using The DsPIC30F For Vector Control of An ACIMJandfor Tansfg ErrottNo ratings yet

- Giri 1Document18 pagesGiri 1GiridharNo ratings yet

- Speed Control of A Single Phase Induction Motor: Knob, Which Is CommonlyDocument16 pagesSpeed Control of A Single Phase Induction Motor: Knob, Which Is CommonlygalaxyNo ratings yet

- Unit Iii Induction Motor Drives: Dept. of EEEDocument17 pagesUnit Iii Induction Motor Drives: Dept. of EEEmanoj kumarNo ratings yet

- Ijett V53P221Document6 pagesIjett V53P221Rifky WahyudaNo ratings yet

- Brushless DC MotorsDocument7 pagesBrushless DC Motorsnelu969No ratings yet

- Variable-Frequency Inverter For Speed Control of A Three-Phase MotorDocument7 pagesVariable-Frequency Inverter For Speed Control of A Three-Phase Motorsadegh karamyNo ratings yet

- Introduction To: Hurst Brushless DC MotorsDocument1 pageIntroduction To: Hurst Brushless DC MotorsMehmet KırgözoğluNo ratings yet

- A New Topology For Unipolar Brushless DC Motor DriveDocument55 pagesA New Topology For Unipolar Brushless DC Motor Drivesrikaanth06No ratings yet

- AC Induction Motor Volts Per Hertz Control, Driven by eTPU On MCF523xDocument38 pagesAC Induction Motor Volts Per Hertz Control, Driven by eTPU On MCF523xElias CarvalhoNo ratings yet

- Ijetae 0812 25 PDFDocument10 pagesIjetae 0812 25 PDFvishiwizardNo ratings yet

- DC Motor Speed Control Using PWMDocument14 pagesDC Motor Speed Control Using PWMVincent KorieNo ratings yet

- Servo MotorsDocument3 pagesServo MotorsGrinerd GreatNo ratings yet

- Chapter 3 - Actuators-1Document42 pagesChapter 3 - Actuators-1NguyenNo ratings yet

- Analysis and Control of Four Quadrant Operation of Three Phase Brushless DC (BLDC) Motor DriveDocument5 pagesAnalysis and Control of Four Quadrant Operation of Three Phase Brushless DC (BLDC) Motor DriveInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Subject (UNREG08) - Sensorless Motor ControlDocument7 pagesSubject (UNREG08) - Sensorless Motor ControlsorrowarNo ratings yet

- Final Report Acs 12Document36 pagesFinal Report Acs 12Abhishek SinghNo ratings yet

- Brushed DC Sensorless FeedbackDocument3 pagesBrushed DC Sensorless FeedbackHoon Miew JieNo ratings yet

- Sensorless BLDC ControlDocument36 pagesSensorless BLDC ControlPaolo TripicchioNo ratings yet

- Speed Control of Three Phase Induction MotorDocument8 pagesSpeed Control of Three Phase Induction MotorsasNo ratings yet

- Three-Phase BLDC Sensorless Motor Control ApplicationDocument30 pagesThree-Phase BLDC Sensorless Motor Control Applicationthierry42No ratings yet

- Implementing Embedded Speed Control For Brushless DC Motors Part1Document8 pagesImplementing Embedded Speed Control For Brushless DC Motors Part1charliesteven100% (2)

- AN296285 BLDC Driver For Automotive Fuel PumpsDocument28 pagesAN296285 BLDC Driver For Automotive Fuel PumpslcisnydeksdtaujutlNo ratings yet

- Development of A BLDC Motor Drive With Improved Output CharacteristicsDocument4 pagesDevelopment of A BLDC Motor Drive With Improved Output CharacteristicskurlshNo ratings yet

- Soft StarterDocument6 pagesSoft StartergamasistemNo ratings yet

- Simulation of Brushless DC Motor For Performance Analysis Using MATLAB SIMULINK EnvironmentDocument4 pagesSimulation of Brushless DC Motor For Performance Analysis Using MATLAB SIMULINK EnvironmentnandhakumarmeNo ratings yet

- 3 Phase Ac Motor Control With VHZ Speed Closed Loop Using The 56f800eDocument36 pages3 Phase Ac Motor Control With VHZ Speed Closed Loop Using The 56f800ePrabhu RajNo ratings yet

- Implementation of Brushless DC Motor Speed Control PDFDocument7 pagesImplementation of Brushless DC Motor Speed Control PDFDane DaneNo ratings yet

- Field Oriented Control For Space Vector Modulation Based Brushless DC Motor DriveDocument8 pagesField Oriented Control For Space Vector Modulation Based Brushless DC Motor DriveSushant MandalNo ratings yet

- PWM Switching Strategy For Torque Ripple Minimization in BLDC MotorDocument6 pagesPWM Switching Strategy For Torque Ripple Minimization in BLDC MotorekaliappanNo ratings yet

- Figure 1. Simple VFD / Fan ApplicationDocument7 pagesFigure 1. Simple VFD / Fan ApplicationTapas PalNo ratings yet

- Motor BrushlessDocument5 pagesMotor BrushlessHector CarrilloNo ratings yet

- SFC OperationDocument10 pagesSFC OperationKelvin LiewNo ratings yet

- 2008 - A Low Cost Drive Strategy For BLDC Motor With Low Torque RipplesDocument4 pages2008 - A Low Cost Drive Strategy For BLDC Motor With Low Torque RipplesgrcatuNo ratings yet

- Experiment No. 09 - Speed ControlDocument6 pagesExperiment No. 09 - Speed Controlabheetpethe.scoe.entcNo ratings yet

- AC Drive Theory and Application: Benefits of Using AC DrivesDocument8 pagesAC Drive Theory and Application: Benefits of Using AC DrivesRaghu KodiNo ratings yet

- Motor Starting MethodsDocument3 pagesMotor Starting MethodsDineesh SankaranarayananNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Electrical Machines: Lecture Notes for Electrical Machines CourseFrom EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNo ratings yet

- Serpi Star ND Range UserguideDocument6 pagesSerpi Star ND Range UserguideBogdan CosteaNo ratings yet

- BafuchsanDocument147 pagesBafuchsanBogdan CosteaNo ratings yet

- 3-Phase Sensorless BLDC Motor Control Development Kit With MC9S12G128 MCUDocument40 pages3-Phase Sensorless BLDC Motor Control Development Kit With MC9S12G128 MCUBogdan CosteaNo ratings yet

- Using DS18B20 Temp Sensor On AVRDocument16 pagesUsing DS18B20 Temp Sensor On AVRjoprinzNo ratings yet

- IEEMA Basics of Dual Ratio Transformers PDFDocument3 pagesIEEMA Basics of Dual Ratio Transformers PDFKelly chatNo ratings yet

- Manual de Servicio SR - L - 626 - 628 - 676 - 678 - EV PDFDocument62 pagesManual de Servicio SR - L - 626 - 628 - 676 - 678 - EV PDFMario Agustín PaisNo ratings yet

- LP 18eel58 Pe Lab B SectionDocument5 pagesLP 18eel58 Pe Lab B SectionChithra ManivelanNo ratings yet

- Earthing Grid Vs Earthing Rod SystemDocument5 pagesEarthing Grid Vs Earthing Rod SystemAhmed HatemNo ratings yet

- C Audio - Ra1001 Ra2001 Ra3001 Power AmplifierDocument9 pagesC Audio - Ra1001 Ra2001 Ra3001 Power AmplifierSadie SomersNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFJORGENo ratings yet

- Chapter 3 Msbte Asked QuestionsDocument10 pagesChapter 3 Msbte Asked Questionsrutu surve (Ru.)No ratings yet

- F0126405 PB OLTCsDocument24 pagesF0126405 PB OLTCsshahramkh59100% (1)

- PX4212 4Document2 pagesPX4212 4kalpanaNo ratings yet

- Clipper CircuitsDocument9 pagesClipper CircuitsMitali SinghNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

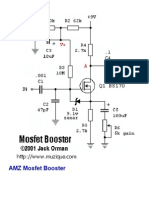

- MosFET Booster ExplicacionDocument4 pagesMosFET Booster ExplicacionGustavoTfLaNo ratings yet

- Growatt 33000-40000 PDFDocument2 pagesGrowatt 33000-40000 PDFAlfredo Rodriguez MuñozNo ratings yet

- Addressable Panel-Installation-ManualDocument26 pagesAddressable Panel-Installation-ManualEufemiano Noble JrNo ratings yet

- Hubbard Coil. VAZNODocument12 pagesHubbard Coil. VAZNOTomislav JovanovicNo ratings yet

- Quiz1 AnalogIC ECE4A - SetADocument8 pagesQuiz1 AnalogIC ECE4A - SetANiel Joshua I. LozadaNo ratings yet

- L&T Busbar Trunking SystemDocument19 pagesL&T Busbar Trunking SystemUmerNo ratings yet

- Eaton EBM 240VDocument34 pagesEaton EBM 240VLeonardoAcevedoNo ratings yet

- Science 10 12.2 Electric Motor and GeneratorsDocument36 pagesScience 10 12.2 Electric Motor and GeneratorsYuriNo ratings yet

- Power Quality (8EP04) : Unit No. 5 Wiring and GroundingDocument37 pagesPower Quality (8EP04) : Unit No. 5 Wiring and GroundingAkshay MalkhedeNo ratings yet

- Ds LEIAN DCDU 12B SpecificationDocument9 pagesDs LEIAN DCDU 12B SpecificationDr.Ahmed GhareebNo ratings yet

- Buku Standarisasi Spek Mtu PLN - SK Dir 216 (Bus VT)Document1 pageBuku Standarisasi Spek Mtu PLN - SK Dir 216 (Bus VT)PontasNo ratings yet

- Chapter 2 Single Phase Full Wave Diode RectifierDocument11 pagesChapter 2 Single Phase Full Wave Diode RectifierfahrizaNo ratings yet

- Model: Ls-806 "Striker"Document3 pagesModel: Ls-806 "Striker"private 2No ratings yet

- Bitx Version 3 Linear Amplifier AssemblyDocument14 pagesBitx Version 3 Linear Amplifier Assemblyapi-26282181100% (1)

- Tech 2Document6 pagesTech 2Karlo Sam DiegoNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- Fotocelda Sun Tech - FP7600Document1 pageFotocelda Sun Tech - FP7600Paola DamiánNo ratings yet