Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

29 viewsDatasheet Resistor2

Datasheet Resistor2

Uploaded by

Petrus PurbadiThe document summarizes specifications for a 250 Watt, 100 ohm flanged resistor model RFP-250-100RM. Key details include:

- It has a thick film resistive element on a beryllium oxide ceramic substrate with an alumina ceramic cover and copper mounting flange.

- Electrical specifications are a resistance value of 100 ohms ±5%, frequency range of DC-2 GHz, and power rating of 250 Watts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Go RFP 400 50RDocument2 pagesGo RFP 400 50RYusuf ÜnlüNo ratings yet

- Sony HCD-GNX60Document76 pagesSony HCD-GNX60kalentoneschatNo ratings yet

- ACS100 Manual EngDocument52 pagesACS100 Manual EngMárcio FernandesNo ratings yet

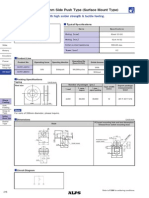

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Do Not Duplicate: S651PDY24A Example of Model Number S651 Specifications Drawing Number. PD Sensing ElementDocument1 pageDo Not Duplicate: S651PDY24A Example of Model Number S651 Specifications Drawing Number. PD Sensing ElementMaxim VolkovNo ratings yet

- Abb VariadorDocument52 pagesAbb VariadorPa TricioNo ratings yet

- 4.5mm Square Compact (Snap-In Type)Document3 pages4.5mm Square Compact (Snap-In Type)shyhuNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Gaas Phemt Mmic Medium Power Amplifier, 17.5 - 25.5 GHZ: Features Typical ApplicationsDocument6 pagesGaas Phemt Mmic Medium Power Amplifier, 17.5 - 25.5 GHZ: Features Typical ApplicationssmhzzNo ratings yet

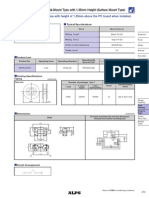

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

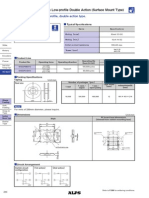

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- Tall Height (4.3mm and 5.0mm) and Surface Mount TypeDocument3 pagesTall Height (4.3mm and 5.0mm) and Surface Mount TypeshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Soldering Thermometer & TesterDocument12 pagesSoldering Thermometer & TesterFerdinand EstanislaoNo ratings yet

- 1N4620Document4 pages1N4620Deepa DevarajNo ratings yet

- 04 Lloyd Insulation SDocument39 pages04 Lloyd Insulation SBalson VijaishNo ratings yet

- Features Typical Applications: Gaas Mmic Low Noise Amplifier, 24 - 30 GHZDocument6 pagesFeatures Typical Applications: Gaas Mmic Low Noise Amplifier, 24 - 30 GHZsmhzzNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Post WeldDocument4 pagesPost WelddanemsalNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- A New Die Material For Longer Service LifeDocument12 pagesA New Die Material For Longer Service LifeLuis SantosNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- Quiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelDocument3 pagesQuiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelshyhuNo ratings yet

- S355MCDocument2 pagesS355MCRodrigo Eduardo GomesNo ratings yet

- Fusibles SMDDocument28 pagesFusibles SMDmarquitos550bNo ratings yet

- 6mm Square Dust-Proof (Snap-In Type)Document3 pages6mm Square Dust-Proof (Snap-In Type)shyhuNo ratings yet

- PCB ConnectorsDocument83 pagesPCB ConnectorsMuhammad ZakaNo ratings yet

- Antenna Kathrein 800 10541Document3 pagesAntenna Kathrein 800 10541golden_hunter_1980No ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- lm2937 DatasheetDocument30 pageslm2937 Datasheetanon_660018118No ratings yet

- Condor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) ADocument2 pagesCondor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) AEldar IsgenderovNo ratings yet

- SD40ADocument2 pagesSD40AaquilesreinaNo ratings yet

- Model 2269 Insulated Double Banana Jack: FeaturesDocument1 pageModel 2269 Insulated Double Banana Jack: Featuresmaxi_mikeNo ratings yet

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothNo ratings yet

- Description Function Application: SolenoidsDocument2 pagesDescription Function Application: SolenoidsJuned VhoraNo ratings yet

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YDocument3 pagesHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanNo ratings yet

- Trendmaster® 2000 Thermocouple - Install Guide PDFDocument4 pagesTrendmaster® 2000 Thermocouple - Install Guide PDFchicaokNo ratings yet

- TEP0089U Terminator ZT SpecDocument1 pageTEP0089U Terminator ZT SpecMuhammad SafeerNo ratings yet

- Three Core Cables To BS 6622Document8 pagesThree Core Cables To BS 6622rose chenNo ratings yet

- DC - AC Solenoids: in High-Duty and Low-Watt-DesignDocument4 pagesDC - AC Solenoids: in High-Duty and Low-Watt-DesignVíctor VelosoNo ratings yet

- 1N4728A - 1N4764A 1W Zener DiodesDocument4 pages1N4728A - 1N4764A 1W Zener DiodessergiogasNo ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- SB50 Anderson ConnectorsDocument6 pagesSB50 Anderson ConnectorsNeville DickensNo ratings yet

- Kelvin Test Socket: FeaturesDocument2 pagesKelvin Test Socket: FeaturesKeith TienNo ratings yet

- 2.4mm ConnectorDocument15 pages2.4mm ConnectorCmpterRFNo ratings yet

- 2.92mm Connector SeriesDocument16 pages2.92mm Connector SeriesCmpterRFNo ratings yet

- Armox WeldingDocument2 pagesArmox WeldingsudhavelNo ratings yet

- Domex 100 XF Data SheetDocument2 pagesDomex 100 XF Data Sheetzubblwump5063No ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 045Document2 pages045Ghichajiwala_A_5413No ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocument4 pages12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuNo ratings yet

Datasheet Resistor2

Datasheet Resistor2

Uploaded by

Petrus Purbadi0 ratings0% found this document useful (0 votes)

29 views2 pagesThe document summarizes specifications for a 250 Watt, 100 ohm flanged resistor model RFP-250-100RM. Key details include:

- It has a thick film resistive element on a beryllium oxide ceramic substrate with an alumina ceramic cover and copper mounting flange.

- Electrical specifications are a resistance value of 100 ohms ±5%, frequency range of DC-2 GHz, and power rating of 250 Watts.

Original Description:

Original Title

datasheet resistor2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes specifications for a 250 Watt, 100 ohm flanged resistor model RFP-250-100RM. Key details include:

- It has a thick film resistive element on a beryllium oxide ceramic substrate with an alumina ceramic cover and copper mounting flange.

- Electrical specifications are a resistance value of 100 ohms ±5%, frequency range of DC-2 GHz, and power rating of 250 Watts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

29 views2 pagesDatasheet Resistor2

Datasheet Resistor2

Uploaded by

Petrus PurbadiThe document summarizes specifications for a 250 Watt, 100 ohm flanged resistor model RFP-250-100RM. Key details include:

- It has a thick film resistive element on a beryllium oxide ceramic substrate with an alumina ceramic cover and copper mounting flange.

- Electrical specifications are a resistance value of 100 ohms ±5%, frequency range of DC-2 GHz, and power rating of 250 Watts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

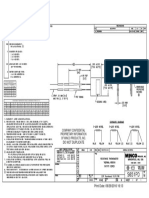

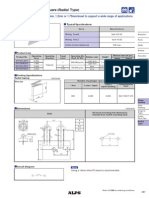

General Specifications

Flanged Resistors

250 Watts, 100

Model RFP-250-100RM

Resistive Element: Thick film

Substrate: Beryllium oxide ceramic

Cover: Alumina ceramic

Mounting Flange: Copper, nickel plated per

QQ-N-290

Lead(s): 99.99% pure silver (.005 thk)

Outline Drawing

.120 DIA THRU.

(2 PLACES)

.303

.210

MAX.

.187

.125

.110

.120

.975

.488

.375

.1875

.725 .125

.370

RM

RFP

250-100

F

l

a

n

g

e

d

R

e

s

i

s

t

o

r

s

Features

DC - 2.0 GHz

250 Watts

BeO Ceramic

Welded Silver Leads

Non-Nichrome Resistive

Element

100% Tested

1 Sales Desk USA: Voice: (800) 544-2414 Fax: (315) 432-9121

Sales Desk Europe: Voice: (+44) 23 92 232392 Fax: (+44) 23 92 251369

Notes: Tolerance is .010, unless otherwise specified. Operating

temperature is -55C to +150C (see chart). Designed to meet or

exceed applicable portions of MIL-E-5400. All dimensions are in

inches. Lead length 0.15 minimum.

Specifications subject to change without notice.

Electrical Specifications

Resistance Value: 100 ohms, 5%

Frequency Range: DC - 2.0 GHz

Power: 250 Watts

Capacitance: 3.3 pF

VER. 12/5/01

F

l

a

n

g

e

d

R

e

s

i

s

t

o

r

s

Model RFP-250-100RM

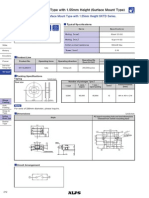

Typical Performance

2

Sales Desk USA: Voice: (800) 544-2414 Fax: (315) 432-9121

Sales Desk Europe: Voice: (+44) 23 92 232392 Fax: (+44) 23 92 251369

Power Derating

Suggested Mounting Procedures

MIN. .025

(2 PLACES)

SUGGESTED STRESS RELIEF METHODS

BOARD LOWER

THAN LEAD. WITH LEAD.

BOARD EVEN

SCALE:

1. Make sure that the devices are mounted on flat surfaces

(.001 under the device) to optimize the heat transfer.

2. Drill & tap the heatsink for the appropriate thread size to

be used.

3. Coat heatsink with a minimum amount of high quality

silicone grease (.001 max. thickness).

4. Position device on mounting surface and secure using

socket head screws, flat & split washers. Torque screws to

the appropriate value. Make sure that the device is flat

against the heatsink. (Care should be taken to avoid

upward pressure of the leads towards the lid).

5. Solder leads in place using an SN63 type solder with a

controlled temperature iron (210C).

SCALE:

BOARD HIGHER

THAN LEAD. THAN LEAD.

BOARD LOWER

NOT RECOMMENDED APPLICATION

CASE TEMPERATURE C

%

O

F

R

A

T

E

D

P

O

W

E

R

150 125 100 75 50 25

100

75

25

50

0

You might also like

- Go RFP 400 50RDocument2 pagesGo RFP 400 50RYusuf ÜnlüNo ratings yet

- Sony HCD-GNX60Document76 pagesSony HCD-GNX60kalentoneschatNo ratings yet

- ACS100 Manual EngDocument52 pagesACS100 Manual EngMárcio FernandesNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Do Not Duplicate: S651PDY24A Example of Model Number S651 Specifications Drawing Number. PD Sensing ElementDocument1 pageDo Not Duplicate: S651PDY24A Example of Model Number S651 Specifications Drawing Number. PD Sensing ElementMaxim VolkovNo ratings yet

- Abb VariadorDocument52 pagesAbb VariadorPa TricioNo ratings yet

- 4.5mm Square Compact (Snap-In Type)Document3 pages4.5mm Square Compact (Snap-In Type)shyhuNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Gaas Phemt Mmic Medium Power Amplifier, 17.5 - 25.5 GHZ: Features Typical ApplicationsDocument6 pagesGaas Phemt Mmic Medium Power Amplifier, 17.5 - 25.5 GHZ: Features Typical ApplicationssmhzzNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- Tall Height (4.3mm and 5.0mm) and Surface Mount TypeDocument3 pagesTall Height (4.3mm and 5.0mm) and Surface Mount TypeshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Soldering Thermometer & TesterDocument12 pagesSoldering Thermometer & TesterFerdinand EstanislaoNo ratings yet

- 1N4620Document4 pages1N4620Deepa DevarajNo ratings yet

- 04 Lloyd Insulation SDocument39 pages04 Lloyd Insulation SBalson VijaishNo ratings yet

- Features Typical Applications: Gaas Mmic Low Noise Amplifier, 24 - 30 GHZDocument6 pagesFeatures Typical Applications: Gaas Mmic Low Noise Amplifier, 24 - 30 GHZsmhzzNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Post WeldDocument4 pagesPost WelddanemsalNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- A New Die Material For Longer Service LifeDocument12 pagesA New Die Material For Longer Service LifeLuis SantosNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- Quiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelDocument3 pagesQuiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelshyhuNo ratings yet

- S355MCDocument2 pagesS355MCRodrigo Eduardo GomesNo ratings yet

- Fusibles SMDDocument28 pagesFusibles SMDmarquitos550bNo ratings yet

- 6mm Square Dust-Proof (Snap-In Type)Document3 pages6mm Square Dust-Proof (Snap-In Type)shyhuNo ratings yet

- PCB ConnectorsDocument83 pagesPCB ConnectorsMuhammad ZakaNo ratings yet

- Antenna Kathrein 800 10541Document3 pagesAntenna Kathrein 800 10541golden_hunter_1980No ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- lm2937 DatasheetDocument30 pageslm2937 Datasheetanon_660018118No ratings yet

- Condor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) ADocument2 pagesCondor Technology: Datasheet: Electrical Smart Heater For Space Heating, Model SM - ( ) AEldar IsgenderovNo ratings yet

- SD40ADocument2 pagesSD40AaquilesreinaNo ratings yet

- Model 2269 Insulated Double Banana Jack: FeaturesDocument1 pageModel 2269 Insulated Double Banana Jack: Featuresmaxi_mikeNo ratings yet

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothNo ratings yet

- Description Function Application: SolenoidsDocument2 pagesDescription Function Application: SolenoidsJuned VhoraNo ratings yet

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YDocument3 pagesHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanNo ratings yet

- Trendmaster® 2000 Thermocouple - Install Guide PDFDocument4 pagesTrendmaster® 2000 Thermocouple - Install Guide PDFchicaokNo ratings yet

- TEP0089U Terminator ZT SpecDocument1 pageTEP0089U Terminator ZT SpecMuhammad SafeerNo ratings yet

- Three Core Cables To BS 6622Document8 pagesThree Core Cables To BS 6622rose chenNo ratings yet

- DC - AC Solenoids: in High-Duty and Low-Watt-DesignDocument4 pagesDC - AC Solenoids: in High-Duty and Low-Watt-DesignVíctor VelosoNo ratings yet

- 1N4728A - 1N4764A 1W Zener DiodesDocument4 pages1N4728A - 1N4764A 1W Zener DiodessergiogasNo ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- SB50 Anderson ConnectorsDocument6 pagesSB50 Anderson ConnectorsNeville DickensNo ratings yet

- Kelvin Test Socket: FeaturesDocument2 pagesKelvin Test Socket: FeaturesKeith TienNo ratings yet

- 2.4mm ConnectorDocument15 pages2.4mm ConnectorCmpterRFNo ratings yet

- 2.92mm Connector SeriesDocument16 pages2.92mm Connector SeriesCmpterRFNo ratings yet

- Armox WeldingDocument2 pagesArmox WeldingsudhavelNo ratings yet

- Domex 100 XF Data SheetDocument2 pagesDomex 100 XF Data Sheetzubblwump5063No ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 045Document2 pages045Ghichajiwala_A_5413No ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocument4 pages12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuNo ratings yet