Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

115 viewsTurboshaft Engines

Turboshaft Engines

Uploaded by

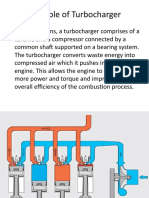

Ankush SharmaA turboshaft engine uses a gas turbine to produce shaft power rather than jet thrust. It works similarly to a turbojet or turboprop by using a compressor, combustor, and turbine to drive an output shaft via additional turbine stages and gearing. Turboshaft engines are commonly used in helicopters, ships, tanks, and stationary equipment because they provide sustained high power output while being small, light, and reliable. A turboshaft engine consists of a gas generator section that produces hot gases to drive a power section with extra turbines and a gearbox to reduce speed for the output shaft. Turboshaft and turboprop engines are similar but turboshafts drive transmissions instead of propellers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 03 Principle of TurbochargerDocument19 pages03 Principle of TurbochargerSky RNo ratings yet

- TurbochargerDocument10 pagesTurbochargernavle krushnaNo ratings yet

- Turbocharger PresentationDocument18 pagesTurbocharger PresentationShrwan Gyawali100% (3)

- What Is Forced Induction?Document15 pagesWhat Is Forced Induction?Fugaru Paul - AlexandruNo ratings yet

- What Is TurbochargerDocument7 pagesWhat Is TurbochargerKomarac DzemilNo ratings yet

- Supercharging and TurbochargingDocument3 pagesSupercharging and Turbocharging13311A0341 S SHIVA SAI KIRANNo ratings yet

- AMTE 213 Gas Turbine EngineDocument6 pagesAMTE 213 Gas Turbine EngineanonimusNo ratings yet

- Pasgt Act 3Document7 pagesPasgt Act 3Ramil SalundagaNo ratings yet

- Types of Gasturbine Engine: Prepared By: Engr. Jan Lester V. MagbagDocument24 pagesTypes of Gasturbine Engine: Prepared By: Engr. Jan Lester V. MagbagJohn Kane Mariano100% (1)

- TURBOCHARGERDocument5 pagesTURBOCHARGERAnand Raju100% (1)

- Definition EssayDocument5 pagesDefinition Essayhondarider909No ratings yet

- Turbo PDFDocument16 pagesTurbo PDFAdnin HakeemNo ratings yet

- TurbochargerDocument21 pagesTurbochargerJo VialNo ratings yet

- Turbo Charging - Introduction and HistoryDocument39 pagesTurbo Charging - Introduction and HistoryeravisrNo ratings yet

- Natural Aspirated EnginesDocument10 pagesNatural Aspirated EnginesakshithaNo ratings yet

- Hybrid TurbochargersDocument7 pagesHybrid Turbochargersanon_47328873429% (7)

- 2.3 Turbo Chargers (WGT, VGT), Engine Emission Control by Three Way Catalytic Converter System, Emission Norms (Euro and BS) .Document20 pages2.3 Turbo Chargers (WGT, VGT), Engine Emission Control by Three Way Catalytic Converter System, Emission Norms (Euro and BS) .DEEPAK S SEC 2020No ratings yet

- Turbocharger and SuperchargerDocument16 pagesTurbocharger and SuperchargerPrajwal ZinjadeNo ratings yet

- Unit 83 Assignment 4Document3 pagesUnit 83 Assignment 4micropig1234No ratings yet

- Powerplant: Dimas Arango Emmauel Hincapie AMT 4 2019Document46 pagesPowerplant: Dimas Arango Emmauel Hincapie AMT 4 2019Emanuel Hincapie MorenoNo ratings yet

- Gas Turbines - Hassan ElBanhawiDocument3 pagesGas Turbines - Hassan ElBanhawijesus_manrique2753No ratings yet

- Turbo Charger LectureDocument6 pagesTurbo Charger LectureAbdelrhman Essam AttiaNo ratings yet

- What Are The Functions of An Exhaust ManifoldDocument5 pagesWhat Are The Functions of An Exhaust Manifoldjameel babooram100% (1)

- AEMSDocument28 pagesAEMSGARVIT SRIVASTAVANo ratings yet

- Bhel TrainingDocument41 pagesBhel TrainingArun AroraNo ratings yet

- University of Engineering & Technology KSK New CampusDocument9 pagesUniversity of Engineering & Technology KSK New CampusAli RazaNo ratings yet

- Unit - 3 Types of Gas Turbine EnginesDocument4 pagesUnit - 3 Types of Gas Turbine EnginesAnonymous VKv75qe98100% (1)

- Mechanical Project TurbochargerDocument12 pagesMechanical Project Turbochargerinduscad100% (6)

- Turbine Gas: Oil Nuclear ReactorDocument65 pagesTurbine Gas: Oil Nuclear ReactorDey TandirerungNo ratings yet

- The Modern Gas TurbineDocument6 pagesThe Modern Gas TurbinelaurciobanuNo ratings yet

- Unit II - Turbo Super ChargerDocument14 pagesUnit II - Turbo Super ChargerdrkbalaNo ratings yet

- Shahid R Peerzade Seminar ReportDocument20 pagesShahid R Peerzade Seminar ReportMahesh R JNo ratings yet

- Turbo ChargerDocument18 pagesTurbo ChargerRangappa swamyNo ratings yet

- GTE Note 4 2023Document9 pagesGTE Note 4 2023ibrahim ibrahimNo ratings yet

- 2 Descripción Motores ReciprocosDocument53 pages2 Descripción Motores ReciprocosAngel Julian HernandezNo ratings yet

- Lesson 1 CorrectionDocument5 pagesLesson 1 CorrectionAlyanna AngelesNo ratings yet

- Design of Turbine BladeDocument15 pagesDesign of Turbine BladeKailash Chauhan100% (1)

- Chapter 2Document13 pagesChapter 2hamadmukhtar95No ratings yet

- Cómo Trabajan Los JetsDocument8 pagesCómo Trabajan Los JetspepenitoNo ratings yet

- Turbo Basics ExplainedDocument5 pagesTurbo Basics ExplainedPawan Kumar SinghNo ratings yet

- Supercharger Turbo 3.31Document6 pagesSupercharger Turbo 3.31larasmoyoNo ratings yet

- Engish 202 Turbocharger Technical DescriptionDocument3 pagesEngish 202 Turbocharger Technical DescriptionMuthukumar GovindasamyNo ratings yet

- Turbo ChargerDocument23 pagesTurbo Chargerselvaraj9223100% (1)

- TurbopropDocument5 pagesTurbopropBijesh JayanNo ratings yet

- Himanshu Singh Turbocharger-SeminarDocument20 pagesHimanshu Singh Turbocharger-SeminarHimanshu SinghNo ratings yet

- KOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentDocument6 pagesKOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentArjun KhindreNo ratings yet

- Race Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeDocument7 pagesRace Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeharryNo ratings yet

- 03-Supercharging and TurbochargersDocument7 pages03-Supercharging and TurbochargersAHMADNo ratings yet

- Jelyn TurboDocument1 pageJelyn TurboRommel BlancoNo ratings yet

- Power TrainDocument11 pagesPower TrainKapil Dev SinghNo ratings yet

- Gas Turbines Applications ReportDocument9 pagesGas Turbines Applications ReportKareem Ibrahim Mohamed NasrNo ratings yet

- 12 TurbochargerDocument14 pages12 TurbochargerDodi SuhendraNo ratings yet

- Engineer M. A. HamidDocument14 pagesEngineer M. A. HamidAbhishekNo ratings yet

- Chapter 12 Supercharging TurbochargingDocument33 pagesChapter 12 Supercharging Turbochargingdesie yalewNo ratings yet

- Module 1Document45 pagesModule 1shubham GoundadkarNo ratings yet

- Operating PrincipleDocument6 pagesOperating PrincipleGedan CristianNo ratings yet

- RAC - Heat Load and Cooling LoadDocument3 pagesRAC - Heat Load and Cooling LoadAnkush Sharma50% (2)

- Loading and Machine Scheduling Problems: Introduction To LectureDocument16 pagesLoading and Machine Scheduling Problems: Introduction To LectureAnkush SharmaNo ratings yet

- Reversible & Irreversible ProcessesDocument4 pagesReversible & Irreversible ProcessesAnkush Sharma100% (1)

- Fundamentals of Work Study and ErgonomicsDocument20 pagesFundamentals of Work Study and ErgonomicsAnkush SharmaNo ratings yet

- Types of CoalDocument2 pagesTypes of CoalAnkush SharmaNo ratings yet

- Reversible & Irreversible ProcessesDocument4 pagesReversible & Irreversible ProcessesAnkush Sharma100% (1)

- Bonda Tribes OdishaDocument1 pageBonda Tribes OdishaAnkush SharmaNo ratings yet

- Clamp MeterDocument3 pagesClamp MeterAnkush SharmaNo ratings yet

- Float CoatDocument2 pagesFloat CoatAnkush SharmaNo ratings yet

Turboshaft Engines

Turboshaft Engines

Uploaded by

Ankush Sharma0 ratings0% found this document useful (0 votes)

115 views1 pageA turboshaft engine uses a gas turbine to produce shaft power rather than jet thrust. It works similarly to a turbojet or turboprop by using a compressor, combustor, and turbine to drive an output shaft via additional turbine stages and gearing. Turboshaft engines are commonly used in helicopters, ships, tanks, and stationary equipment because they provide sustained high power output while being small, light, and reliable. A turboshaft engine consists of a gas generator section that produces hot gases to drive a power section with extra turbines and a gearbox to reduce speed for the output shaft. Turboshaft and turboprop engines are similar but turboshafts drive transmissions instead of propellers

Original Description:

Precise details of aircraft turbo engines.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA turboshaft engine uses a gas turbine to produce shaft power rather than jet thrust. It works similarly to a turbojet or turboprop by using a compressor, combustor, and turbine to drive an output shaft via additional turbine stages and gearing. Turboshaft engines are commonly used in helicopters, ships, tanks, and stationary equipment because they provide sustained high power output while being small, light, and reliable. A turboshaft engine consists of a gas generator section that produces hot gases to drive a power section with extra turbines and a gearbox to reduce speed for the output shaft. Turboshaft and turboprop engines are similar but turboshafts drive transmissions instead of propellers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

115 views1 pageTurboshaft Engines

Turboshaft Engines

Uploaded by

Ankush SharmaA turboshaft engine uses a gas turbine to produce shaft power rather than jet thrust. It works similarly to a turbojet or turboprop by using a compressor, combustor, and turbine to drive an output shaft via additional turbine stages and gearing. Turboshaft engines are commonly used in helicopters, ships, tanks, and stationary equipment because they provide sustained high power output while being small, light, and reliable. A turboshaft engine consists of a gas generator section that produces hot gases to drive a power section with extra turbines and a gearbox to reduce speed for the output shaft. Turboshaft and turboprop engines are similar but turboshafts drive transmissions instead of propellers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

A turboshaft engine is a form of gas turbine which is optimized to produce shaft power rather

than jet thrust.

In concept, turboshaft engines are very similar to turbojets, with additional turbine expansion to

extract heat energy from the exhaust and convert it into output shaft power. They are even more

similar to turboprops, with only minor differences, and a single engine is often sold in both forms.

Turboshaft engines are commonly used in applications that require a sustained high power output,

high reliability, small size, and light weight. These include helicopters, auxiliary power

units, boats and ships, tanks, hovercraft, and stationary equipment.

A turboshaft engine may be made up of two major parts assemblies: the 'gas generator' and the

'power section'. The gas generator consists of the compressor, combustion chambers with ignitors

and fuel nozzles, and one or more stages of turbine. The power section consists of additional stages

of turbines, a gear reduction system, and the shaft output. The gas generator creates the hot

expanding gases to drive the power section. Depending on the design, the engine accessories may

be driven either by the gas generator or by the power section.

The general layout of a turboshaft is similar to that of a turboprop. The main difference is a turboprop

is structurally designed to support the loads created by a rotating propeller, as the propeller is not

attached to anything but the engine itself. In contrast, turboshaft engines usually drive a transmission

which is not structurally attached to the engine. The transmission is attached to the vehicle structure

and supports the loads created instead of the engine. In practice, though, many of the same engines

are built in both turboprop and turboshaft versions, with only minor differences.

You might also like

- 03 Principle of TurbochargerDocument19 pages03 Principle of TurbochargerSky RNo ratings yet

- TurbochargerDocument10 pagesTurbochargernavle krushnaNo ratings yet

- Turbocharger PresentationDocument18 pagesTurbocharger PresentationShrwan Gyawali100% (3)

- What Is Forced Induction?Document15 pagesWhat Is Forced Induction?Fugaru Paul - AlexandruNo ratings yet

- What Is TurbochargerDocument7 pagesWhat Is TurbochargerKomarac DzemilNo ratings yet

- Supercharging and TurbochargingDocument3 pagesSupercharging and Turbocharging13311A0341 S SHIVA SAI KIRANNo ratings yet

- AMTE 213 Gas Turbine EngineDocument6 pagesAMTE 213 Gas Turbine EngineanonimusNo ratings yet

- Pasgt Act 3Document7 pagesPasgt Act 3Ramil SalundagaNo ratings yet

- Types of Gasturbine Engine: Prepared By: Engr. Jan Lester V. MagbagDocument24 pagesTypes of Gasturbine Engine: Prepared By: Engr. Jan Lester V. MagbagJohn Kane Mariano100% (1)

- TURBOCHARGERDocument5 pagesTURBOCHARGERAnand Raju100% (1)

- Definition EssayDocument5 pagesDefinition Essayhondarider909No ratings yet

- Turbo PDFDocument16 pagesTurbo PDFAdnin HakeemNo ratings yet

- TurbochargerDocument21 pagesTurbochargerJo VialNo ratings yet

- Turbo Charging - Introduction and HistoryDocument39 pagesTurbo Charging - Introduction and HistoryeravisrNo ratings yet

- Natural Aspirated EnginesDocument10 pagesNatural Aspirated EnginesakshithaNo ratings yet

- Hybrid TurbochargersDocument7 pagesHybrid Turbochargersanon_47328873429% (7)

- 2.3 Turbo Chargers (WGT, VGT), Engine Emission Control by Three Way Catalytic Converter System, Emission Norms (Euro and BS) .Document20 pages2.3 Turbo Chargers (WGT, VGT), Engine Emission Control by Three Way Catalytic Converter System, Emission Norms (Euro and BS) .DEEPAK S SEC 2020No ratings yet

- Turbocharger and SuperchargerDocument16 pagesTurbocharger and SuperchargerPrajwal ZinjadeNo ratings yet

- Unit 83 Assignment 4Document3 pagesUnit 83 Assignment 4micropig1234No ratings yet

- Powerplant: Dimas Arango Emmauel Hincapie AMT 4 2019Document46 pagesPowerplant: Dimas Arango Emmauel Hincapie AMT 4 2019Emanuel Hincapie MorenoNo ratings yet

- Gas Turbines - Hassan ElBanhawiDocument3 pagesGas Turbines - Hassan ElBanhawijesus_manrique2753No ratings yet

- Turbo Charger LectureDocument6 pagesTurbo Charger LectureAbdelrhman Essam AttiaNo ratings yet

- What Are The Functions of An Exhaust ManifoldDocument5 pagesWhat Are The Functions of An Exhaust Manifoldjameel babooram100% (1)

- AEMSDocument28 pagesAEMSGARVIT SRIVASTAVANo ratings yet

- Bhel TrainingDocument41 pagesBhel TrainingArun AroraNo ratings yet

- University of Engineering & Technology KSK New CampusDocument9 pagesUniversity of Engineering & Technology KSK New CampusAli RazaNo ratings yet

- Unit - 3 Types of Gas Turbine EnginesDocument4 pagesUnit - 3 Types of Gas Turbine EnginesAnonymous VKv75qe98100% (1)

- Mechanical Project TurbochargerDocument12 pagesMechanical Project Turbochargerinduscad100% (6)

- Turbine Gas: Oil Nuclear ReactorDocument65 pagesTurbine Gas: Oil Nuclear ReactorDey TandirerungNo ratings yet

- The Modern Gas TurbineDocument6 pagesThe Modern Gas TurbinelaurciobanuNo ratings yet

- Unit II - Turbo Super ChargerDocument14 pagesUnit II - Turbo Super ChargerdrkbalaNo ratings yet

- Shahid R Peerzade Seminar ReportDocument20 pagesShahid R Peerzade Seminar ReportMahesh R JNo ratings yet

- Turbo ChargerDocument18 pagesTurbo ChargerRangappa swamyNo ratings yet

- GTE Note 4 2023Document9 pagesGTE Note 4 2023ibrahim ibrahimNo ratings yet

- 2 Descripción Motores ReciprocosDocument53 pages2 Descripción Motores ReciprocosAngel Julian HernandezNo ratings yet

- Lesson 1 CorrectionDocument5 pagesLesson 1 CorrectionAlyanna AngelesNo ratings yet

- Design of Turbine BladeDocument15 pagesDesign of Turbine BladeKailash Chauhan100% (1)

- Chapter 2Document13 pagesChapter 2hamadmukhtar95No ratings yet

- Cómo Trabajan Los JetsDocument8 pagesCómo Trabajan Los JetspepenitoNo ratings yet

- Turbo Basics ExplainedDocument5 pagesTurbo Basics ExplainedPawan Kumar SinghNo ratings yet

- Supercharger Turbo 3.31Document6 pagesSupercharger Turbo 3.31larasmoyoNo ratings yet

- Engish 202 Turbocharger Technical DescriptionDocument3 pagesEngish 202 Turbocharger Technical DescriptionMuthukumar GovindasamyNo ratings yet

- Turbo ChargerDocument23 pagesTurbo Chargerselvaraj9223100% (1)

- TurbopropDocument5 pagesTurbopropBijesh JayanNo ratings yet

- Himanshu Singh Turbocharger-SeminarDocument20 pagesHimanshu Singh Turbocharger-SeminarHimanshu SinghNo ratings yet

- KOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentDocument6 pagesKOGLEN-A Rotating Internal Combustion Engine: Engines Under DevelopmentArjun KhindreNo ratings yet

- Race Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeDocument7 pagesRace Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeharryNo ratings yet

- 03-Supercharging and TurbochargersDocument7 pages03-Supercharging and TurbochargersAHMADNo ratings yet

- Jelyn TurboDocument1 pageJelyn TurboRommel BlancoNo ratings yet

- Power TrainDocument11 pagesPower TrainKapil Dev SinghNo ratings yet

- Gas Turbines Applications ReportDocument9 pagesGas Turbines Applications ReportKareem Ibrahim Mohamed NasrNo ratings yet

- 12 TurbochargerDocument14 pages12 TurbochargerDodi SuhendraNo ratings yet

- Engineer M. A. HamidDocument14 pagesEngineer M. A. HamidAbhishekNo ratings yet

- Chapter 12 Supercharging TurbochargingDocument33 pagesChapter 12 Supercharging Turbochargingdesie yalewNo ratings yet

- Module 1Document45 pagesModule 1shubham GoundadkarNo ratings yet

- Operating PrincipleDocument6 pagesOperating PrincipleGedan CristianNo ratings yet

- RAC - Heat Load and Cooling LoadDocument3 pagesRAC - Heat Load and Cooling LoadAnkush Sharma50% (2)

- Loading and Machine Scheduling Problems: Introduction To LectureDocument16 pagesLoading and Machine Scheduling Problems: Introduction To LectureAnkush SharmaNo ratings yet

- Reversible & Irreversible ProcessesDocument4 pagesReversible & Irreversible ProcessesAnkush Sharma100% (1)

- Fundamentals of Work Study and ErgonomicsDocument20 pagesFundamentals of Work Study and ErgonomicsAnkush SharmaNo ratings yet

- Types of CoalDocument2 pagesTypes of CoalAnkush SharmaNo ratings yet

- Reversible & Irreversible ProcessesDocument4 pagesReversible & Irreversible ProcessesAnkush Sharma100% (1)

- Bonda Tribes OdishaDocument1 pageBonda Tribes OdishaAnkush SharmaNo ratings yet

- Clamp MeterDocument3 pagesClamp MeterAnkush SharmaNo ratings yet

- Float CoatDocument2 pagesFloat CoatAnkush SharmaNo ratings yet