Professional Documents

Culture Documents

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

Uploaded by

jacquesmayol0 ratings0% found this document useful (0 votes)

31 views3 pagesThis document provides a welding procedure specification (WPS) for sleeve, fillet, and butt welds on pipes with diameters between 2.375" and 12.75" and thicknesses between 0.154" and 0.750" using shielded metal arc welding (SMAW) with E-6010 and E-7018 electrodes. The WPS specifies requirements for joint design, filler materials, base materials, welding positions, preheat and interpass temperatures, electrical characteristics, and typical welding parameters. It also describes qualification test parameters and results that were conducted according to API 1104 Appendix B and the Los Alamos National Laboratory welding standards manual.

Original Description:

Original Title

API-1000-13

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a welding procedure specification (WPS) for sleeve, fillet, and butt welds on pipes with diameters between 2.375" and 12.75" and thicknesses between 0.154" and 0.750" using shielded metal arc welding (SMAW) with E-6010 and E-7018 electrodes. The WPS specifies requirements for joint design, filler materials, base materials, welding positions, preheat and interpass temperatures, electrical characteristics, and typical welding parameters. It also describes qualification test parameters and results that were conducted according to API 1104 Appendix B and the Los Alamos National Laboratory welding standards manual.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

31 views3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

Uploaded by

jacquesmayolThis document provides a welding procedure specification (WPS) for sleeve, fillet, and butt welds on pipes with diameters between 2.375" and 12.75" and thicknesses between 0.154" and 0.750" using shielded metal arc welding (SMAW) with E-6010 and E-7018 electrodes. The WPS specifies requirements for joint design, filler materials, base materials, welding positions, preheat and interpass temperatures, electrical characteristics, and typical welding parameters. It also describes qualification test parameters and results that were conducted according to API 1104 Appendix B and the Los Alamos National Laboratory welding standards manual.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

API WELDING PROCEDURE SPECIFICATION

WPS: API 1000-13 REV. NO.: 0 PROCESS: SMAW DATE: 10/11/2005

API-1104 QUALIFIED RANGES

Diameter: 2.375 od. thru 12.75 od. Filler Metal Group: API Group 3

Thickness: .154 thru .750 Joint Type: Sleeve/fillet/butt full penetration

Material: Yield less than 42 Kpi

Positions: Fixed: All Rolled: Progression: V/Up & Down

NOTE: This WPS shall be used in conjunction with the applicable sections of the Los Alamos National

Laboratories Welding Standards Manual (GWS)

WELD JOINT: Type: Sleeve/fillet/butt ~371/2 Class: Full & Partial Penetration

Joint Description: Sleeve weld for In-service hot-tap (per 1104 App. B) (Mueller stop/plug fitting)

Sketch Number: See pg. 2 for typical sketch and bead sequence.

FILLER MATERIALS: API Group No.: 3 AWS Class: E-6010 & E-7018

SFA Class: 5.1/5.5 F No.: 3/4 Sizes (s): 1/8 5/32 5/32

Number of Beads: See pg. 2 for typical number and of beads

BASE MATERIALS: Spec: ASTM A-53 or A-106 Gr. B to Spec: ASTM A-53 or A-106 Gr. B

Thickness Welded: .154 - .750 to .154 - .750

Pipe Diameter: 2.375 OD. thru 12.75 OD. pipe to Pipe Diameter Less than 12.75 OD.

ASME P No.: 1 Group: 1 to P No.: 1 Group: 1

POSITIONS: Fixed: All positions PWHT: Time @ F Temp.: N/A

Progression: V/Up/Dn (E-7018 & E-6010) Temperature Range F: N/A

PREHEAT: X Minimum Temp F: ~70F GAS: Shielding: N/A Backing: N/A

NOTE: See time between passes. Composition: N/A

INTERPASS TEMP.: ~70F Flow Rate: CFH N/A

ELECTRICAL CHARACTERISTICS:

Current: DC Polarity: EP Ranges Amps: 65 - 140

Transfer Mode: N/A WFS/IPM: N/A Volts: 22 - 30

Electrode size and Type 3/32 1//8 5/32 E70xx E-6010 Travel/IPM 5 - 13

MAX. TIME BETWEEN PASSES: 5 minutes between root pass and second (hot) pass.

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

WPS No.: API-1000-13 Rev. No.: 0 Date: 10/11/2005

WELDING TECHNIQUE:

Line-Up Clamp: Fit-up dogs removed after tack welding by grinding.

Stringer or Weave Bead: (S) S (W) Single Pass Multi Pass M

Cleaning and/or Grinding: Stiff wire brush or power grinder

PROCEDURE QUALIFIED FOR: Charpy V Notch N/A NDTT N/A DT N/A

Maximum K/J Heat Input: N/A

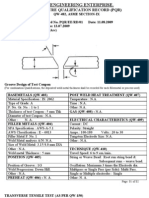

JOINT SKETCH AND BEAD NUMBER AND SEQUENCE

NOTE: Weld layers are representative only actual number of passes and layer sequence may vary

due to variation in joint design, thickness and fit-up.

TYPICAL WELDING PARAMETERS

Pass

Number

Filler/ Electrode

Size

Amps

Volts

Travel

Speed

Other

1 E-6010 1/8 70 -115 24 - 29 5 10

2 E-6010 5/32 80 -130 24 - 30 6 12

3 E-7018 3/32 125 135 24 - 30 6 10

4 E-7018 1/8 125 150 24 - 30 6 13

5 E-7018 5/32 125 180 26 - 32 8 13

6 Rem. >>>>>> >>>>> >>>>> >>>>> >>>>>

7 Rem. >>>>>> >>>>> >>>>> >>>>> >>>>>

8 Rem. >>>>>> >>>>> >>>>> >>>>> >>>>>

PREPARED BY: KG Fellers DATE: 10/03/2005

Signature on file

APPROVED BY: Tobin Oruch DATE: 10/25/2005

Signature on file

QA REVIEW BY: Larry Souza DATE: 10/26/2005

Signature on file

0 3/32 land

~1/18-5/32 gap

t thickness varies

Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specifications

API-1000-13 REV.: 0 PAGE 3 OF 3 DATE: 06/02/2005

API WELDING SPECIFICATION PROCEDURE

TEST PARAMETERS

Full Pene. Butt/Fillets 10 Joint Type:

Diameter:

.365 wall (3/8in.) 1/8 & 5/32 E-6010 1/8 & 5/32 E-7018

Thickness:

Filler:

ASTM A-106/53 Gr B ~70F IPT ~73F

Material:

Preheat:

6F Girth welds and 2G Fixed (Modified

to 45 angle)

DCEP Amps: 70-125

Position:

Current:

E-7018 V/Up E-6010 V/Up/Dn. root 22-26 Progression:

Volts:

GUIDED BEND TESTS

No. Type Result No. Type Result

1. Side Acc. 5. Side Acc.

2. Side Acc. 6. Side Acc.

3. Side Acc. 7. Side Acc.

4. Side Acc. 8. Side Acc.

TENSILE TESTS

No. Specimen

Type

Area

Sq./ in

Applied

Load

Ultimate

Tensile

Character of failure and location

1. Figure 4 0.3721 28057.62 75408.51 BM

2. Figure 4 0.3684 27372.56 74297.56 BM

NICK-BREAK TESTS

No. Type Remarks on Nick-Break tests

1. Figure 5 Clean (Minor atomic H) Cup & Cone

2. Figure 5 Clean (Minor atomic H) Cup & Cone

Welders Name: Brett McNeil Z No.: 09815 Stamp: ________

Procedure developed and conducted by: By: KG Fellers _________________Date:_10/20/2005_____________

Signature on File

We certify that the statements herein are correct and that the tests were conducted in accordance with API-

1104 App. B and LANL Welding Program Chapter 13 Engineering Standards Manual

Authorized by: Kelly Bingham ______________________________________ Date: 10/20/2005

Signature on File

You might also like

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Aramco Hot Tap Welding Procedure Rev. 1Document3 pagesAramco Hot Tap Welding Procedure Rev. 1arockiyathass100% (10)

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (3)

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure Specificationsamini_mohiNo ratings yet

- API-1000-12 Rev 0Document3 pagesAPI-1000-12 Rev 0Kiriakos PappoutasNo ratings yet

- API-1000-12 Rev 0 PDFDocument3 pagesAPI-1000-12 Rev 0 PDFBob LeeNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- API-1000-12 Rev 0Document3 pagesAPI-1000-12 Rev 0mohamedNo ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsAnonymous 6LwW4qi6TiNo ratings yet

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsMohamed100% (1)

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- API-1000-11 Rev 0 PDFDocument3 pagesAPI-1000-11 Rev 0 PDF213eknoNo ratings yet

- Revisi API - 1000 PDFDocument3 pagesRevisi API - 1000 PDF213eknoNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- WPS-PQR For Split TeeDocument9 pagesWPS-PQR For Split TeemaheshmalaichamyNo ratings yet

- Unique 4Document23 pagesUnique 4kavitapatil12No ratings yet

- TopCorbelco - WPS FCAW Sa 516 GR 70Document6 pagesTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisNo ratings yet

- Technical Data Sheet: Art. NR.: Type: Main Switch - Disconnect SwitchDocument3 pagesTechnical Data Sheet: Art. NR.: Type: Main Switch - Disconnect SwitchMauricio ChinarelliNo ratings yet

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- Wps Vosl-Pl-1 Pipeline Rev.2 XDocument11 pagesWps Vosl-Pl-1 Pipeline Rev.2 XVijo Jose100% (1)

- 16 Electrode QualificationDocument11 pages16 Electrode QualificationAkhilesh Kumar67% (3)

- Micom p139 Over Current RelayDocument4 pagesMicom p139 Over Current Relayanoop_jan139885100% (1)

- Appendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Document14 pagesAppendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Fadil WimalaNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- 28 LaDocument3 pages28 Lagsinghal121No ratings yet

- Wps ModelDocument13 pagesWps ModelMuhammedShafeeq50% (2)

- Site Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)Document3 pagesSite Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)m khNo ratings yet

- MIL Control Valve Specification and Sizing CalculationDocument34 pagesMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Topcor Belco: Welding Procedure Specification (WPS)Document9 pagesTopcor Belco: Welding Procedure Specification (WPS)Madhan RamamoorthyNo ratings yet

- Post Weld Head Treament Piping-ProcedureDocument12 pagesPost Weld Head Treament Piping-ProcedureAnh Võ100% (1)

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Webco 3rd Party Monitoring Audit Report - Rev 9 18 2015Document7 pagesWebco 3rd Party Monitoring Audit Report - Rev 9 18 2015virous08No ratings yet

- 5 Clamps Connectors 220 400kv SsDocument12 pages5 Clamps Connectors 220 400kv SsJaswanth SaiNo ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Annex BDocument14 pagesAnnex BPercy Junior Berrios Muñoz100% (1)

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormDocument5 pagesCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877No ratings yet

- Document No PCPL-0532-4-407-04-12-1 Battery Charger Data Sheet Section - 4 PAGE: 1 of 7 Data Sheet A-1Document7 pagesDocument No PCPL-0532-4-407-04-12-1 Battery Charger Data Sheet Section - 4 PAGE: 1 of 7 Data Sheet A-1tceterexNo ratings yet

- VKVC Launcher-Receiver PDFDocument3 pagesVKVC Launcher-Receiver PDFKRUNAL SHAHNo ratings yet

- Plug ValvesDocument14 pagesPlug Valvesashish.mathur1100% (1)

- Fire Test Cert API 607 6th Ed 8in 900cls Ball ValveDocument17 pagesFire Test Cert API 607 6th Ed 8in 900cls Ball Valvestrahor7492100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Seismic Analysis of Steel Liquid Storage Tanks by Api-650Document129 pagesSeismic Analysis of Steel Liquid Storage Tanks by Api-650haschere67% (3)

- Cruiser Lines PlansDocument1 pageCruiser Lines PlansjacquesmayolNo ratings yet

- Api 570 Quiz-2Document34 pagesApi 570 Quiz-2jacquesmayol0% (1)

- Featured (/featured/) Write An Instructable (/about/create - JSP) (/)Document9 pagesFeatured (/featured/) Write An Instructable (/about/create - JSP) (/)jacquesmayolNo ratings yet

- ASTM F1554 - Portland BoltDocument1 pageASTM F1554 - Portland BoltjacquesmayolNo ratings yet

- API 570 QuizDocument6 pagesAPI 570 Quizjacquesmayol100% (1)

- SSPC InfoDocument3 pagesSSPC InfojacquesmayolNo ratings yet

- Surface CoatingDocument18 pagesSurface Coatingaaftab ahmed100% (1)

- Brockwayfull PDFDocument38 pagesBrockwayfull PDFjacquesmayolNo ratings yet

- Delftship ManualDocument81 pagesDelftship ManualjacquesmayolNo ratings yet

- Kinegrams ProjectDocument3 pagesKinegrams ProjectjacquesmayolNo ratings yet

- Bosch Multi Functional CatalogDocument2 pagesBosch Multi Functional CatalogjacquesmayolNo ratings yet

- Figure #2: The Parts For The Drilling Jig After Cutting To SizeDocument7 pagesFigure #2: The Parts For The Drilling Jig After Cutting To SizejacquesmayolNo ratings yet