Professional Documents

Culture Documents

PK - FKK.PPM - Manual Makmal Che565 (0) : Chemical Engineering Laboratory Iii

PK - FKK.PPM - Manual Makmal Che565 (0) : Chemical Engineering Laboratory Iii

Uploaded by

mnizamarzukiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PK - FKK.PPM - Manual Makmal Che565 (0) : Chemical Engineering Laboratory Iii

PK - FKK.PPM - Manual Makmal Che565 (0) : Chemical Engineering Laboratory Iii

Uploaded by

mnizamarzukiCopyright:

Available Formats

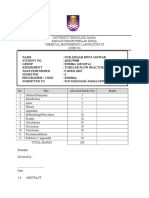

UNIVERSITI TEKNOLOGI MARA

FAKULTI KEJURUTERAAN KIMA

CHEMICAL ENGINEERING LABORATORY III

(CHE575)

NAME : RM SYIBLI MILASI B R MUHAMAD FAKIH

STUDENT NO. : 200424!2!

E"#ERIMENT : CONTINUOUS STIRRED TANK REACTOR (CSTR) IN SERIES

DATE PERFORMED : 7

TH

FEBUARY 200

SEMESTER :

DISEMBER 2005 APRIL 2006

#ROGRAMME $ CODE :

Bachelor of Engineering (Hons. in !he"ical Engineering

$ EH220

Remarks:

Checked by: Rechecked by:

DR.RUZITAH

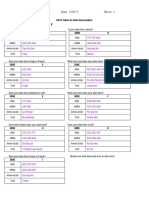

No. Ti!e A!!ocaed marks " Marks "

# Absrac$%&mmary '

( I)rod&cio) '

* Aims$Ob+eci,es '

- Theory '

' Proced&res *

. A//ara&s '

0 Res&!s (1

2 Ca!c&!aio)s #1

3 Disc&ssio)s (1

#1 Co)c!&sio)s #1

## Recomme)daio)s '

#( Re4ere)ces '

#* A//e)dices (

TOTA5 #11

P6.F66.PPM.MANUA5 MA6MA5 CHE'.'

718

TABLE OF CONTENTS

ABSTRACT$SUMMARY99999999999.9.*

INTRODUCTION9999999999999.........*:-

OBJECTIVES99999999999999999-

THEORY99999999999999999......-:2

#ROCEDURES999999999999999..2:#1

A##ARATUS99999999999999999.#1

RESULTS99999999999999999##:#(

SAM#LE OF CALCULATIONS999999999#*

DISCUSSION999999999999999.#-:#'

CONCLUSION9999999999999999.#'

RECOMMENDATION9999999999999.#.

REFERENCES9999999999999999.#.

A##ENDICES9999999999999999...#0

S#MMAR$

Our experiment involves a continuous stirred tank reactor (CSTR) in series. Our

system consists of 3 agitated, glass reactor vessels in series. lt!oug! t!e concentration is

uniform for eac! reactor "ut t!ere is a c!ange in concentration as fluids move over from

reactor to reactor.

Our o"#ective in t!is experiment is to determine t!e concentration response to a

step c!ange and pulse input and also to determine t!e effect of residence time on t!e

response curve.

$

st

t!e deionised %ater are filled in t!e "ot! t%o tanks %it! t!e sodium c!loride

%ere diluted in t!e tank one. T!en deionised %ater from t!e tank t%o %ill flo% t!roug! to

fill up t!e t!ree reactors. T!e flo% rate of t!e deionised %ater is set to $&' ml(min to

prevent from over flo%. T!e only readings %ere taken at time t

o

after %e get t!e readings

of t!e conductivity are sta"le enoug! %!ere t!e readings of t!e conductivity are )uit

similar from one to anot!er. fter t!at, readings are continuously taken every 3 minutes

until to t!e point t!at t!e conductivity values for t!e t!ree reactors are closed to eac!

ot!er. T!en t!e grap! of t!e conductivity versus time %as plotted

T!e grap! t!at !as "een plotted is accordingly to t!e t!eory. *rom t!e grap! %e

can determine t!e effect of t!e step c!ange and pulse input to t!e concentration.

I%&R'D#!&I'%

+n t!e ma#ority of industrial c!emical process, a reactor is t!e key item of

e)uipment in %!ic! ra% materials undergo a c!emical c!ange to form desired product.

T!e design and operation of c!emical reactors is t!us crucial to t!e %!ole success of t!e

industrial operation.

Reactors can %idely form, depending on t!e nature of t!e feed materials and t!e

products. ,nderstanding non-steady "e!avior of process e)uipment is necessary for

design and operation of automatic control systems. One particular type of process

e)uipment is t!e continuous stirred tank reactor. +n t!is reactor, it is important to

determine t!e system response to a c!ange in concentration. T!is response of

concentration versus time is an indication of t!e ideality of t!e system.

'B(E!&I)ES

$. To determine t!e effect of step c!anges and pulse input to t!e concentration.

.. To determine t!e effect residence time on t!e response curve.

&HE'R$

;e)era! Mo!e <a!a)ce E=&aio)

Ass&m/io)s

#8 %eady sae here4ore

(8 >e!! mi?ed here4ore rA is he same hro&@ho& he reacor

Rearra)@i)@ he @e)eraio)

I) erms o4 co),ersio)

Reacors i) %eries

;i,e) :rA as a 4&)cio) o4 co),ersio)A A :rA B 47C8A o)e ca) a!so desi@) a)y

se=&e)ce o4 reacors i) series /ro,ided here are )o side sreams by de4i)i)@ he

o,era!! co),ersio) a a)y /oi).

Mo!e <a!a)ce o) Reacor #

Mo!e <a!a)ce o) Reacor (

;i,e) :rA B 47C8 he 5e,e)s/ie! P!o ca) be &sed o 4i)d he reacor ,o!&me

For a PFR beDee) Do C%TRs

E44ec o4 %e/ Cha)@e i) I)/& Co)ce)raio) o he Co)ce)raio) o4 %o!&e i)

%irred Ta)k Reacors i) %eries.

>he) a se/ cha)@e o4 so!&e co)ce)raio) is i)rod&ced a he 4eed o4 a)k #A

he a)k i) series Di!! e?/erie)ce a ra)sie) beha,ior as a Fi@&re 0 be!oD. The

res/o)se Di!! be de/e)de) o) he reside)ce ime o4 each reacor i) series.

Co)ce)raio) Co)ce)raio)

::::::::::::::::::::::::::::::::::

Time Time

Fi@&re 2a. %e/ cha)@e i)/& Fi@&re 2b . Tra)sie) res/o)se o4

a)k i) series o he se/ i)/&.

E44ec o4 P&!se i) I)/& Co)ce)raio) o he Co)ce)raio) o4 %o!&e i) %irred

Ta)k i) %eries.

Reacor #

Reacor (

Reacor *

R%&'()* (

R%&'()* +

R%&'()* *

>he) a /&!se i)/& o4 so!&e co)ce)raio) is i)rod&ced a he 4eed o4 a)k #A he

ra)sie) beha,ior Di!! be di44ere) ha) he se/ cha)@e i)/& d&e o he

dimi)ishi)@ co)ce)raio) 4rom he i)/& a4er /&!si)@ as described i) Fi@&re 2.

T,-% T,-%

F,./*% !&: #/01% ,23/( F,./*% !4: T*&21,%2( *%13)21% )5

(&26 ,2 1%*,%1 () (7% 3/01% ,23/(.

PR'!ED#RES

E*+eri"en, -. &he Effec, of S,e+ !hange In+/,

+n t!is experiment a step-c!ange input %ould "e introduced and t!e progression of t!e

tracer %ill "e monitored via t!e conductivity measurements in all t!e t!ree reactors.

Tank $ and tank . %as filled up %it! .'/ feeds deionised %ater.

3''g of Sodium C!loride %as dissolved in tank $until t!e salts dissolve entirely

and t!e solution is !omogenous.

T!ree %ay valve (03) %as set to position . so t!at deionised %ater from tank .

%ill flo% into reactor $.

1ump . %as s%itc!ed on to fill up all t!ree reactors %it! deionised %ater.

T!e flo% rate (*l$) %as set to $&' ml(min "y ad#usting t!e needles valve (02). 3o

C

)

2

'

%

2

(

*

&

(

,

)

2

C

)

2

'

%

2

(

*

&

(

,

)

2

not use too !ig! flo% rate to avoid t!e over flo% and make sure no air "u""les

trapped in t!e piping. T!e stirrers $, . and 3 %ere s%itc!ed on.

T!e deionised %ater %as continued pumped for a"out $' minute until t!e

conductivity readings for all t!ree reactors %ere sta"le at lo% values.

T!e values of conductivity %ere recorded at t

'

.

T!e pump . %as s%itc!ed off after & minutes. T!e valve (03) %as s%itc!ed to

position $ and t!e pump $ %as s%itc!ed on. T!e timer %as started.

T!e conductivity values for eac! reactor %ere recorded every t!ree minutes.

Record t!e conductivity values %ere continued until reading for reactor 3 closed

to reactor $.

1ump . %as s%itc!ed off and t!e valve (02) %as closed.

ll li)uids in reactors %ere drained "y opening valves 0& and 04.

E*+eri"en, 2. &he Effec, of P/lse In+/,

+n t!is experiment a pulse input %ould "e introduced and t!e progression of t!e tracer

%ill "e monitored via t!e conductivity measurements in all t!e t!ree reactors.

Tank $ and tank . %as filled up %it! .'/ feeds deionised %ater.

3''g of Sodium C!loride %as dissolved in tank $until t!e salts dissolve entirely

and t!e solution is !omogenous.

T!ree %ay valve (03) %as set to position . so t!at deionised %ater from tank .

%ill flo% into reactor $.

1ump . %as s%itc!ed on to fill up all t!ree reactors %it! deionised %ater.

T!e flo% rate (*l$) %as set to $&' ml(min "y ad#usting t!e needles valve (02). 3o

not use too !ig! flo% rate to avoid t!e over flo% and make sure no air "u""les

trapped in t!e piping. T!e stirrers $, . and 3 %ere s%itc!ed on.

T!e deionised %ater %as continued pumped for a"out $' minute until t!e

conductivity readings for all t!ree reactors %ere sta"le at lo% values.

T!e values of conductivity %ere recorded at t

'

.

T!e pump . %as s%itc!ed off after & minutes. T!e valve (03) %as s%itc!ed to

position $ and t!e pump $ %as s%itc!ed on. T!e timer %as started.

/et t!e pump $ to operate for & minute, and t!en s%itc!ed off pump $. S%itc!ed

t!e t!ree %ays valve (03) "ack to position .. T!e pump . %as s%itc!ed on.

T!e conductivity values for eac! reactor %ere recorded every t!ree minutes.

Record t!e conductivity values %ere continued until reading for reactor 3 closed

to reactor $.

1ump . %as s%itc!ed off and t!e valve (02) %as closed.

ll li)uids in reactors %ere drained "y opening valves 0& and 04.

APPARA&#S

#. Disi!!aio) Daer

(. %odi&m Ch!oride

*. Co)i)&o&s reacor i) series

-. %irrer sysem

'. Feed a)ks

.. >ase a)k

0. Dead ime coi!

2. Com/&eriEe sysem

3. %o/ Dach

CO5T+5,O,S/6 ST+RR73 T58 R7CTOR (CSTR)

SAMPLE '0 !AL!#LA&I'%

0

i

9 *

'

(:

,i

- :

,i-$

) ( (-r

)

i

;!ere 0i 9 volume of reactor i

*

,i

9 molal flo% rate of into t!e first reactor

:

,i

9 fractional conversion of in t!e reactor i

:

,i-$

9 fractional conversion of in t!e reactor i-$

*or first order reaction, -r

9 k C

,+

9 kC

'

($ < :

,i

)

v 9 volumetric flo% rate of 9 $&'mil(min 9 '.$& liter(min

*or t!e first reactor= (0 9 .' lit)

(-r

)$ 9 (kC

)

$

9 kC

,$

9 k C

'

($ < :

,$

)

C

'

9 *

'

( v

i.e., *

'

9 vC

'

:

,i-$

9 :

,'

9 '

T!erefore,

Tank $

0i 9 *

'

(:

,i

< :

,i-$

) ( (-r

)

i

.' 9 '.$& (:

,$

< ') ( ('.$&> x ($ < :

,$

))

:

,$

9 '.?&

Tank .

0i 9 *

'

(:

,i

< :

,i-$

) ( (-r

)

i

.' 9 '.$& (:

,$

< '.?&) ( ('.$&> x ($ < :

,$

))

:

,$

9 '.??@

Tank 3

0i 9 *

'

(:

,i

< :

,i-$

) ( (-r

)

i

.' 9 '.$& (:

,$

< '.??@) ( ('.$&> x ($ < :

,$

))

:

,$

9 '.??>

Disc/ssion

+n t!is experiment our o"#ective is to determine t!e effect of step c!ange and

pulse input to t!e concentration in a continues stirred tank reactor in series. *or t!at %e

!ave . experiment $

st

t!e step c!ange and .

nd

is t!e pulse input.

;e take t!e reading of t!e conductivity for t!e 3 different tanks for every 3

minutes and plotted grap! conductivity versus time. *or t!e $

st

experiment t!e flo% rate

%as $&' ml(min and %e take .> readings. ;e can see t!e effect of t!e step c!ange to t!e

concentration from t!e grap!. Step c!ange is a sudden c!ange in a process varia"le. *or

t!is experiment our varia"le t!at "een c!ange is t!e input. Reactor feedstock is suddenly

s%itc!ed from one supply to anot!er, causing sudden c!anges in feed concentration,

flo%, etc.

s %e kno% t!e concentration can "e calculated using electrical conductivity

measurements and cali"ration supplied. T!e concentration is directly proportional to t!e

conductivity.

T!e affect of t!e step c!ange to t!e concentration for t!e 3 reactors are t!e same.

;!en t!e step c!ange of solute concentration %as introduced at t!e feed of tank $, t!e

tank %ill experience a transient "e!avior as s!o%n in t!e result. T!e concentration of in

t!e reactor %ill increase in a period of time until it !as reac!ed a constant concentration.

*or every reactor it !as its o%n concentration. Reactor $ !as t!e !ig!est concentration

follo%ing tank . and 3. T!e concentration if increasing "ecause of t!e feed rate t!at "een

opened %as t!e tank $ t!at contain t!e dissolve c!loride.

*or t!e .

nd

experiment t!e procedure is t!e same as experiment $ except %e

c!ange t!e pump from $ to . and t!e flo% rate %as .''mil(min. *or t!is experiment %e

%ant to see t!e effect of t!e pulse input. ;!en %e !ave plotted t!e grap! %e get a

different result from t!e step c!ange. T!e pulse input caused t!e concentration c!ange

drastically for every tank. *or tank $ t!e concentration decreased rapidly until it reac!es

a constant value. *or tank . t!e concentrations $st increase in a period of time t!en start

decreasing until it reac!es a constant value. *or tank 3 t!e concentrations also increase

and decrease "ut not rapidly. T!ere are only a small different for every readings.

T!e decreasing in t!e concentration !appen "ecause t!e feed %as from tank . t!at

contain only dissolve %ater %it!out any sodium c!loride.

!oncl/sions

*rom t!e experiment result it s!o%s t!at a step c!ange in input and a pulse in

input !ave its o%n effect to t!e concentration. 7ac! of t!is experiment !as its o%n

transient "e!avior. ;e compare t!e $

st

grap! and t!e .

nd

grap!.

*or t!e $

st

grap! t!e c!ange of t!e concentration for t!e 3 tank is almost t!e same.

*or t!e .

nd

grap! every tank !as its o%n c!ange of concentration. *rom "ot! experiment

%e can conclude t!at c!ange in input and pulse input !as an effect to t!e concentration.

*or t!e step c!ange it %ill increase t!e concentration until it reac!es a constant value and

for pulse input it %ill first increase t!en decrease until it reac!es a constant value. T!e

feed of t!e systems effect t!e concentration in t!e reactor, if t!e feed contain a

concentration t!en t!e concentration in t!e tank %ill increase and if t!e feed only contain

deionised %ater t!en t!e concentration %ill decrease.

7very reactor !as its o%n concentration, "ecause of t!at %e conclude t!at t!e

residence time for eac! reactor is different. T!e value of t!e residence time depends on

%!at !appens in t!e reactor.

Reco""en1a,ions

fter %e !ave finis!ed t!is experiment, %e find t!at are several factors in t!is

experiment t!at can "e fixed to make sure t!at t!e experiment runs "etter. T!is is some of

my recommendation for t!is experiment=

;!en %e are doing t!e experiment t!e program t!at used to record t!e data %as

not function. T!is cause us a !ig! error in reading t!e data. Ay recommendation

is to make sure "etter maintainers of t!e apparatus.

T!e instruction in t!e la" manual for num"er $,. and 3 for "ot! experiment is not

clear and after %e doing t!e experiment it seems t!at %e did not follo% t!e

procedures $,. and 3. ;e #ust #ump to step num"er 2, it cause us a %aste of time

and confusion. Ay recommendation is to make sure t!at t!e procedure is exactly

t!e same as %!at %e do in t!e experiment.

Reference

5e,e)s/ie!A OA Chemical Reaction EngineeringA Foh) >i!eyA #30(

Rober H.PerryA Do) >.;ree)A Perrys Chemical Engineers HandbookA

Mc;raD Hi!!A#332.

%mihAF.MA Chemical Engineering Kinetics, Mc;raD Hi!!A #32#.

A++en1ics

C1 C2

C3

Fi@&re '

T83% )5 R%&'()* C7&*&'(%*,1(,'1

Co)i)&o&s!y %irred

Ta)k Reacor 7C%TR8

R&) a seady sae Dih co)i)&o&s 4!oD o4 reaca)s a)d

/rod&csG he 4eed ass&mes a uniform com/osiio)

hro&@ho& he reacorA exit sream has he same com/osiio)

as i) he a)k

K,291 )5

#7&1%1

#*%1%2(

U1&.% A9:&2(&.%1 D,1&9:&2(&.%1

#. 5i=&id /hase

(. ;as:!i=&id

r?)s

*. %o!id:!i=&id

r?)s

#. >he) a@iaio) is

re=&ired

(. %eries

co)4i@&raio)s 4or

di44ere)

co)ce)raio)

sreams

#. Co)i)&o&s o/eraio)

(. ;ood temperature

control

*. Easi!y ada/s o Do

/hase r&)s

-. ;ood co)ro!

'. %im/!iciy o4

construction

. 5oD o/erai)@ 7!abor8

cos

#. 5oDes co),ersio)

/er &)i ,o!&me

(. <y:/assi)@ a)d

cha))e!i)@ /ossib!e

Dih /oor a@iaio)

You might also like

- Data Tables For Alien Gene AnalysisDocument3 pagesData Tables For Alien Gene Analysisapi-382372564100% (3)

- CSTR Lab ReportDocument16 pagesCSTR Lab Reportleenzalal100% (5)

- CSTR Lab Report .Document18 pagesCSTR Lab Report .Emily Swan50% (4)

- Continuous Distillation ColumnDocument31 pagesContinuous Distillation ColumnRichard Obinna100% (2)

- MCAT Prep Organic Equation SheetDocument6 pagesMCAT Prep Organic Equation SheetChris_Barber09No ratings yet

- Laboratory ReportDocument31 pagesLaboratory ReportJim100% (2)

- Title Page: The Total Mass Flow Rate of A SystemDocument35 pagesTitle Page: The Total Mass Flow Rate of A SystemJimNo ratings yet

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Lab CSTR in SeriesDocument13 pagesLab CSTR in SeriesKhairul Zakirin78% (9)

- Experiment 1 CSTR DynamicsDocument24 pagesExperiment 1 CSTR DynamicsFarhan Hazeeq50% (2)

- Lab Report CSTR in SeriesDocument13 pagesLab Report CSTR in SeriesNisha Sharif100% (1)

- CSTR Lab ReportDocument10 pagesCSTR Lab ReportErraFatihaNo ratings yet

- Lab Report Batch Reactor GGDocument25 pagesLab Report Batch Reactor GGFrost Orchid100% (1)

- Distillation Column Lab ReportDocument14 pagesDistillation Column Lab ReportWahida Shukori67% (3)

- Continuous Stirrer Tank Reactors in Series.Document54 pagesContinuous Stirrer Tank Reactors in Series.Farrukh Shahzad60% (5)

- Abstract For CSTR Lab ReportDocument4 pagesAbstract For CSTR Lab ReportNabilah SyaheeraNo ratings yet

- CSTRDocument12 pagesCSTRsamueloNo ratings yet

- Tubular ReactorDocument20 pagesTubular ReactorMuhamad Hafifi AjwadNo ratings yet

- LabDocument16 pagesLabMuhamad Hafifi AjwadNo ratings yet

- S7 11012021 Acid Base Titrations WS With ANSWERSDocument7 pagesS7 11012021 Acid Base Titrations WS With ANSWERSFatima Ahmed-VeriterNo ratings yet

- Lube Oil Flushing Procedure - Rev 0Document22 pagesLube Oil Flushing Procedure - Rev 0Yusuf67% (3)

- CSTR in SeriesDocument16 pagesCSTR in SeriesAhmadAzriMohamad50% (2)

- Experiment CSTR 40LDocument18 pagesExperiment CSTR 40LSaber Minato Azrul100% (2)

- Continuous Stirred Tank Reactor (CSTR) in SeriesDocument15 pagesContinuous Stirred Tank Reactor (CSTR) in SeriesHaizul Radzi33% (3)

- CSTRDocument15 pagesCSTRbilisfreak100% (3)

- Stirred Tank in Series ReportDocument20 pagesStirred Tank in Series ReportEmonbeifo EfosasereNo ratings yet

- 5 - (CSTR Bp143)Document12 pages5 - (CSTR Bp143)Aisyah Addia AzizanNo ratings yet

- CSTR SeriesDocument14 pagesCSTR SeriesElina Nes100% (1)

- Tubular Flow Reactor ReportDocument19 pagesTubular Flow Reactor ReportN Afiqah Razak100% (1)

- CSTR in SeriesDocument12 pagesCSTR in Seriesmnizamarzuki0% (2)

- Stirred Tank ReactorDocument32 pagesStirred Tank ReactorChristopher Emeka Ominyi100% (1)

- Lab RPRT (CSTR)Document21 pagesLab RPRT (CSTR)Black White80% (5)

- CHE506 - Lab Report On Continuous Stirre PDFDocument29 pagesCHE506 - Lab Report On Continuous Stirre PDFMuhammad AimanNo ratings yet

- Results and Discussion of CSTR in SeriesDocument3 pagesResults and Discussion of CSTR in SeriesleenzalalNo ratings yet

- Chemical Reaction Engineering 40 L CSTR SaponificationDocument21 pagesChemical Reaction Engineering 40 L CSTR SaponificationMohamad Turmizi Jaafar67% (3)

- CSTRDocument19 pagesCSTRAmir Al-AimanNo ratings yet

- CSTR ReportDocument21 pagesCSTR ReportJonathon Douglas100% (1)

- CSTRDocument25 pagesCSTRAinul Mardhiah Abdul Rahim100% (1)

- CHE504 - Lab Report On Distillation ColuDocument27 pagesCHE504 - Lab Report On Distillation ColuMuhammad Irfan MalikNo ratings yet

- Lab ManualDocument24 pagesLab ManualAasia FarrukhNo ratings yet

- C4 Lab ReportDocument11 pagesC4 Lab ReportchaitanyaNo ratings yet

- Che244 Exp 1Document6 pagesChe244 Exp 1NABILA AFIEQAH NASRUDINNo ratings yet

- Batch ReactorDocument4 pagesBatch ReactorFoo Xiao BingNo ratings yet

- CEV452 Lab 2 Distillation ColumnDocument22 pagesCEV452 Lab 2 Distillation ColumnAjlaa Rahim100% (1)

- Chemical Engineering Laboratory Ii: /DT Term Is Zero SinceDocument9 pagesChemical Engineering Laboratory Ii: /DT Term Is Zero SinceKayathre Raveendran100% (1)

- CSTR Lab ReportDocument14 pagesCSTR Lab ReportAmy Farhana33% (3)

- Lab 10-Batch ReactorDocument22 pagesLab 10-Batch Reactorniraj_bairagiNo ratings yet

- Lab Report 7Document39 pagesLab Report 7Fatinnnnnn100% (2)

- Chapter 1 - Part IDocument46 pagesChapter 1 - Part IMaisarah RazaliNo ratings yet

- CSTRDocument18 pagesCSTRbond45930% (1)

- Lab 1 - CSTRDocument22 pagesLab 1 - CSTRnur athilahNo ratings yet

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 pagesPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- Batch Reactor PDFDocument29 pagesBatch Reactor PDFSaranya KannanNo ratings yet

- Experiment 6 CSTRDocument9 pagesExperiment 6 CSTRRicky JayNo ratings yet

- CSTRDocument21 pagesCSTRirfan hilmanNo ratings yet

- CSTR FinalDocument36 pagesCSTR FinalMuhammad Yar KhanNo ratings yet

- Continuous Stirred Tank Reactor (CSTR)Document6 pagesContinuous Stirred Tank Reactor (CSTR)Elaine PuiNo ratings yet

- Report CSTRDocument14 pagesReport CSTRniraj_bairagiNo ratings yet

- Lab 4Document18 pagesLab 4Amir Al-AimanNo ratings yet

- Fundamentals of Chemical Reaction EngineeringFrom EverandFundamentals of Chemical Reaction EngineeringRating: 2.5 out of 5 stars2.5/5 (3)

- Lab ReportDocument12 pagesLab ReportkaimanwatsoNNo ratings yet

- TFR ExperimentDocument25 pagesTFR ExperimentSiti Norbaya100% (1)

- TubularDocument15 pagesTubularSharing CaringNo ratings yet

- Lab ReportDocument25 pagesLab ReportafiqahanuwarNo ratings yet

- Tubular Reactor bp101bDocument17 pagesTubular Reactor bp101bMuhamad Hafifi AjwadNo ratings yet

- Report PFRDocument21 pagesReport PFRMuhamad Hafifi Ajwad100% (2)

- Sigma Bond: From Wikipedia, The Free EncyclopediaDocument8 pagesSigma Bond: From Wikipedia, The Free EncyclopediaMuhamad Hafifi AjwadNo ratings yet

- GRI - CBM Gas in Placasdfe AnalysisDocument146 pagesGRI - CBM Gas in Placasdfe Analysisnimbo100% (1)

- E527-12 Standard Practice For Numbering Metals and Alloys in The Unified Numbering System (UNS) PDFDocument7 pagesE527-12 Standard Practice For Numbering Metals and Alloys in The Unified Numbering System (UNS) PDFUTTAM JAINNo ratings yet

- Chapter 3 EvapotranspirationDocument20 pagesChapter 3 EvapotranspirationnimcanNo ratings yet

- Synthesis of Modified Silane Acrylic Resins and Their Physical Properties As Weather-Resistant CoatingsDocument14 pagesSynthesis of Modified Silane Acrylic Resins and Their Physical Properties As Weather-Resistant CoatingszainNo ratings yet

- Basics of Magnetic Resonance ImagingDocument17 pagesBasics of Magnetic Resonance ImagingIrinaMariaStrugariNo ratings yet

- DPP 01 Chemical Bonding MridulPandey MergedDocument4 pagesDPP 01 Chemical Bonding MridulPandey Mergedsaurabh shaurya guptaNo ratings yet

- Lab #06Document22 pagesLab #06ldlewisNo ratings yet

- Mobilgear 600 XP 680 Msds - 638450Document11 pagesMobilgear 600 XP 680 Msds - 638450Nguyen DatNo ratings yet

- Amino Acids, Peptides, and Proteins I 2013Document36 pagesAmino Acids, Peptides, and Proteins I 2013ender arslanNo ratings yet

- Ucrete RG: Heavy Duty Polyurethane Concrete For Forming Cove Bases and Renovating WallsDocument3 pagesUcrete RG: Heavy Duty Polyurethane Concrete For Forming Cove Bases and Renovating Wallssyifa latifa zahidaNo ratings yet

- Toluene (010822004)Document1 pageToluene (010822004)Harry SitumorangNo ratings yet

- Research Report 296Document53 pagesResearch Report 296marcela walterosNo ratings yet

- Laser Cutting TechnologyDocument264 pagesLaser Cutting Technologykkangari100% (4)

- Alcohols and PhenolsDocument72 pagesAlcohols and PhenolsChandra ReddyNo ratings yet

- Venturi ScrubberDocument3 pagesVenturi ScrubberRoger FernandezNo ratings yet

- Fundamental Operations in Compunding, PPTDocument32 pagesFundamental Operations in Compunding, PPTdoctorneha6691% (22)

- Chem 1206 - Chapt 1Document5 pagesChem 1206 - Chapt 1Djaimee Joyce NimesNo ratings yet

- Sintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)Document13 pagesSintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)volkanNo ratings yet

- Fick'S Law of DiffusionDocument10 pagesFick'S Law of DiffusiondhruvNo ratings yet

- Chesterton 891Document2 pagesChesterton 891aiindustriyahoocoidNo ratings yet

- Worksheet 1 - Measurements in Chemistry (Questions)Document5 pagesWorksheet 1 - Measurements in Chemistry (Questions)kangalbert86No ratings yet

- Chicken EggshellsDocument27 pagesChicken EggshellsBenmar L. OrterasNo ratings yet

- Furstenberg-Hagg Et Al. 2013. Plant Defense Against Insect Herbivores.Document56 pagesFurstenberg-Hagg Et Al. 2013. Plant Defense Against Insect Herbivores.J Alberto LucasNo ratings yet

- Aiadrveng: ScuijahDocument3 pagesAiadrveng: ScuijahAtom SuwiJakNo ratings yet

- f7 9 2 f780 f781 f782Document16 pagesf7 9 2 f780 f781 f782abcdsefNo ratings yet

- Centrifugation in The Pharmaceutical IndustryDocument12 pagesCentrifugation in The Pharmaceutical Industrymamun_ruNo ratings yet