Professional Documents

Culture Documents

Perhitungan Base Plate 3

Perhitungan Base Plate 3

Uploaded by

Mashudi AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perhitungan Base Plate 3

Perhitungan Base Plate 3

Uploaded by

Mashudi AliCopyright:

Available Formats

Analysis and Design of Basis

Base Plate

I - Axially Loaded Column :

Length (C) & Width(B) of base plate

uniform stress

f=P/A

f

In columns subjected to axially compression force (P) , the stress under the base

plate of dimensions ( C x B ) is uniformly distributed and equal to

f = P/A where

f is the actual bearing stress under base plate

P is the design compression load

A is the area of base plate in contact with concrete = C x B

Since the allowable bearing stress for concrete (Fp) must be actual bearing stress (f)

Then Fp f = P/A

Knowing that Fp = 0.35 Fc = ( 40 70 ) kg/cm

2

where Fc is design compression strength

of a concrete foundation .

Then 0.35 Fc P/A or A P/0.35 Fc B x C P/ 0.35Fc

Referring to above fig C = 0.95h + 2n

B = 0.80b + 2m

Then ( 0.95h+2n)*(0.80b+2m) P/0.35 Fc

For simplicity assume that m = n

And solve the equation to get m and n

Then substitute in the following equations to get B & C

C = 0.95h + 2n

B = 0.80b + 2m

Thickness (t) of base plate

t (the greater between m or n) *5f/fy

where f actual bearing stress and fy of steel used

II Eccentrically Loaded Columns ( M & P)

Length (C) & Width(B) of base plate

f = P/A+

-

M/Z

1,2

f

2

1

f

X

f

1

a

a

1

f

1

2

f

1,2

M/Z

-

+ f = P/A

X

f

section of max bending moment

I

I I

I

f

X

f = P/A+

-

M/Z

1,2

f

2

1

f

1

a

f

3 3

f

f

3

II II

In columns subjected to axially compression force (P) and bending moment (M) ,

the stress under the base plate of dimensions ( C x B ) is triangular and equal to

f1 = P/A + M/Z

f2 = P/A - M/Z

where

f is the actual bearing stress under base plate

P is the design compression load

M is the design moment

A is the area of base plate in contact with concrete = C x B

Z = BC

2

/6

Assume C = 2 h and use f1 = P/A + M/Z 0.35 Fc to find B

Thickness (t) of base plate

t 6M/Fy

where

Fy = 0.6 fy of steel used

and M is the moment at sec I-I & II-II

the example illustrates how to find M

Welding between column and base plate

The weld between column and base plate is designed to transfer 60% of the axial

load P in addition to the shear force, so :

S (0.6*P + shear) / ( 0.707*Lw*0.5*Fy)

Anchor Bolts

I for axially loaded columns

The anchors are designed to resist shear force only

fv = Vmax/A

Fv = 0.4 Fy fv = Vmax/A

A Vmax/0.4Fy

a .n Vmax / 0.4Fy

where

V is shear force

a is area of each anchor bolt cross section = 3.14 D

2

/4

D is anchor diameter

n is number of bolts used

A is total area of bolts cross sections

II for eccentrically loaded columns

a

1

f

1

2

f

1,2

M/Z

-

+ f = P/A

T1

f = +

-

M/Z

1,2

1

f

f

2

T

Actually only the anchor bolts in the tension zone will resist all the tensile force

(T1) determined from the tension zone of the stress diagram , but to provide some reserve

capacity to the anchorage system to resist considerable lateral force ( shifting of column

laterally) we will assume that the bolts in the tension zone will resist only the tensile

force (T) provided by the bending moment only ( note the axial force reduce the area of

tension zone )

So A = T/0.6Fy a x n = T/0.6Fy

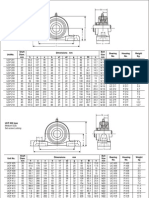

Use the table to find the embedded length (L) of the anchors

Example

Design the base plate , column base plate welding and the anchors number and

diameter for an HEB320 column carrying :

1 axial load only P = 80 tons

2 axial load P = 80 tons and bending moment M = 13 t.m

given that Fc = 180 kg/cm2 & St. 37 is used

solution

1

Base plate design

A P/Fp = 80000/0.35*180 = 80000/63 = 1270 cm

2

C x B 1270 cm

2

( 0.95h+2n)*(0.80b+2m) 1270 cm2

Assume m=n and given for HEB320 h = 320 mm b = 300 mm

4m2 + 108.8 m + 729.6 1270 cm2

Then m = n = 4.3 cm

t 4.35f/fy = 4.35*62.16/2400 = 1.547 cm

then use base plate 400*330*20 mm

welding design

the welding will transfer 60%P

welding length = Lw = 4*30+2*27.9 = 175.8 cm

S (0.6P)/(0.707*Lw*0.5*Fy) = 0.6*80/0.707*175.8*0.5*1.4 = 5.5 cm

Use welding 6 mm

Anchors design

Since there is no shearing force use 2 bolts 25 mm diameter

2

Base plate dimensions design

Fp P/A+ M/Z

0.35*180 = 63 80000/B*C + 6(1300000)/B x C

2

By trial and error let C = 60 cm then B = 56 cm

Base plate thickness design

Consider sec I I

a

1

f

1

2

f

1,2

M/Z

-

+ f = P/A

X

f

section of max bending moment

I

I

f

3

f1 = 80000/60*56 + 6*1300000/56*60

2

= 62.5 kg/cm2

f2 = 80000/60*56 - 6*1300000/56*60

2

= - 14.8 kg/cm2

stress equation is the equation of straight line from the stress diagram goemetry

f = 62.5 1.28X

integrate to find the shear equation

V = 62.5X 1.28X

2

/2

Integrate to find the moment equation

M = 62.5X

2

/2 1.28X

3

/6

The max moment is at sec I-I at X = 0.5*(C -0.95h) = 0.5(60 0.95*32) = 14.8 cm

Substitute in M = 62.5X

2

/2 1.28X

3

/6 for X = 14.8 then

M = 62.5(14.8)

2

/2 - 1.28(14.8)

3

/6 = 6153 kg.cm

Then t = 6*6153/0.6*2400 = 5 cm = 50 mm

Consider sec II-II

I

f at x=14.8 cm is f=62.5-1.28(14.8) = 43.55 kg/cm2 uniformly distributed along the

width of plate at the edge of column

the max moment is at sec II-II M = 43.55(B-0.8b)

2

/2 = 5575.168 kg.cm

then t = 6*5575.168/0.6*2400 = 4.8 cm = 48 mm

take the largest t = 50 mm

then the dimensions of the base plate is 600*560*50

welding design

the welding will transfer 60%P

welding length = Lw = 4*30+2*27.9 = 175.8 cm

S (0.6P)/(0.707*Lw*0.5*Fy) = 0.6*80/0.707*175.8*0.5*1.4 = 5.5 cm

Use welding 6 mm

Anchors design

I

f

X

f = /A P

1,2

+

-

M/Z

f

2

1

f

1

a

II II

f

3

3

f

T = M/d = 1300000/50cm = 26 ton

A = 26000/0.6*3400 = 12.75cm2

Use 3 anchors each side 3a = 12.75 then a = 4.25 cm2 area of each bolt

D=4*a/3.14 = 2.32 cm = 25 mm

Then use 6 bolts 3 each side of diameter 25 mm

Use the above table to find the embedded length

L = 850 mm

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Professional Engineer Summary StatementDocument3 pagesProfessional Engineer Summary StatementkawalhayerNo ratings yet

- List of CollegesDocument3 pagesList of Collegesarchana_anuragi50% (2)

- String Properties: Property DescriptionDocument5 pagesString Properties: Property DescriptionkawalhayerNo ratings yet

- Ik Baba Nanak Si Bai Jeenay Tur Ke Duniya Gaa TiDocument1 pageIk Baba Nanak Si Bai Jeenay Tur Ke Duniya Gaa TikawalhayerNo ratings yet

- Writing Your Three Career EpisodesDocument2 pagesWriting Your Three Career EpisodesizharkhanNo ratings yet

- Indian Lok SabhaDocument1 pageIndian Lok SabhakawalhayerNo ratings yet

- Analysis Basis Base PlateDocument11 pagesAnalysis Basis Base PlatekawalhayerNo ratings yet

- K-Factor Sheet MetalDocument3 pagesK-Factor Sheet MetalkawalhayerNo ratings yet

- TuyereDocument1 pageTuyerekawalhayerNo ratings yet

- UCPs of AsahiDocument4 pagesUCPs of AsahikawalhayerNo ratings yet

- Defectos de LaminadoDocument0 pagesDefectos de Laminadoאבימיי דור אבימיי דורNo ratings yet

- Ias Mechanical EnggDocument2 pagesIas Mechanical EnggkawalhayerNo ratings yet

- DC ChopperDocument63 pagesDC ChopperMalyaj SrivastavaNo ratings yet

- RFID Tag Anti-Collision Protocol Query Tree With Reversed IDsDocument6 pagesRFID Tag Anti-Collision Protocol Query Tree With Reversed IDsvietbkfetNo ratings yet

- TallBuilding BrochureDocument6 pagesTallBuilding BrochureSonny AndalisNo ratings yet

- Trivalent Chromium Passivation - 27!04!11Document7 pagesTrivalent Chromium Passivation - 27!04!11smallik3No ratings yet

- British Army Vehicles and Equipment PDFDocument35 pagesBritish Army Vehicles and Equipment PDFmuya78100% (1)

- Viva Voce QuestionsDocument4 pagesViva Voce QuestionsHumera Fatima100% (2)

- Advanced Earth (Ground) Tester: DescriptionDocument5 pagesAdvanced Earth (Ground) Tester: DescriptionAnwesh Kumar MaddikuntaNo ratings yet

- RTR Bearing PDFDocument52 pagesRTR Bearing PDFkamelNo ratings yet

- Retrofitting The Existing Flare / Burnery For Smoke Less OperationsDocument31 pagesRetrofitting The Existing Flare / Burnery For Smoke Less Operationsmehul10941No ratings yet

- T7 B6 TSA Materials Re Joint Inquiry FDR - 6-27-02 Memo - Mohamed Atta Incident at Miami International Airport 375Document4 pagesT7 B6 TSA Materials Re Joint Inquiry FDR - 6-27-02 Memo - Mohamed Atta Incident at Miami International Airport 3759/11 Document ArchiveNo ratings yet

- Gaa 24350 Aw11 Ii PDFDocument22 pagesGaa 24350 Aw11 Ii PDFEvgeniy100% (1)

- Parker D1VW Directional Control ValvesDocument13 pagesParker D1VW Directional Control ValvesCosma Petru-RaulNo ratings yet

- Hydrotest Report - Fire HoseDocument1 pageHydrotest Report - Fire HoseshivarajNo ratings yet

- DFTDocument32 pagesDFTjeevithpaul100% (1)

- 2000 Series Installation Manual TPD1615E1 PDFDocument136 pages2000 Series Installation Manual TPD1615E1 PDFMostifa Mastafa100% (1)

- Questionnaire For Evaluation of Ball Mills.: ContentsDocument16 pagesQuestionnaire For Evaluation of Ball Mills.: ContentsThaigroup CementNo ratings yet

- Hazard IdentificationDocument5 pagesHazard IdentificationSyakirin SpearsNo ratings yet

- HAZOP Saudi Aramco HAZOP GuidelinesDocument92 pagesHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- Terminating SSL On SAP Web DispatcherDocument15 pagesTerminating SSL On SAP Web DispatcherMaria Joseph VimalNo ratings yet

- Learning MicroStation VBADocument941 pagesLearning MicroStation VBABill100% (3)

- 07-08 Panasonic Wall Split BrochureDocument16 pages07-08 Panasonic Wall Split BrochureAravindan MuthuNo ratings yet

- SonophoresisDocument32 pagesSonophoresisHiren J PatelNo ratings yet

- Research ReportDocument81 pagesResearch ReportSuraj DubeyNo ratings yet

- ElectrostaticsDocument18 pagesElectrostaticsQasim Anwar ChaudaryNo ratings yet

- Entrance Test - LinuxDocument4 pagesEntrance Test - LinuxYudi Muchtar PK SiregarNo ratings yet

- Part Number Description List Price PKG Qty.: Relief Valves Low Flow 1/8 NPT MDocument3 pagesPart Number Description List Price PKG Qty.: Relief Valves Low Flow 1/8 NPT MMuh IchsanudinNo ratings yet

- Advanced Services' Building Core Networks With Boot Camp: Ospf, Is-Is, BGP and MPLSDocument50 pagesAdvanced Services' Building Core Networks With Boot Camp: Ospf, Is-Is, BGP and MPLSaabekhit5601No ratings yet

- Penguard FC Technical Data SheetDocument5 pagesPenguard FC Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Desain Pondasi PileDocument9 pagesDesain Pondasi PilegembulflowNo ratings yet