Professional Documents

Culture Documents

Navgard Installation Manual (Ver.D5)

Navgard Installation Manual (Ver.D5)

Uploaded by

iacovosf836Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Navgard Installation Manual (Ver.D5)

Navgard Installation Manual (Ver.D5)

Uploaded by

iacovosf836Copyright:

Available Formats

OPERATIONS & INSTALLATION MANUAL

Navgard

BNWAS

Revision 2

Copyright 2011 Martek. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored

in a retrieval system, or translated into any language, in any form or by any

means, electronic, mechanical, photocopying, recording, or other-wise, without

prior written permission from Martek.

All copyright, confidential information, patents, design rights and all other in-

tellectual property rights of whatsoever nature contained herein are and shall

remain the sole and exclusive property of Martek Marine Ltd. The information

furnished herein is believed to be accurate and reliable.

However, no responsibility is assumed by Martek for its use, or for any in-

fringements of patents or other rights of third parties resulting from its use.

The Martek name and Martek logo are trademarks or registered trademarks of

Martek Marine Limited.

All other trademarks are the property of their respective owners.

Martek Marine Ltd

Adwick Park Manvers

Rotherham

South Yorkshire

S63 5AB

United Kingdom

Telephone: +44 1709 599222

Fax: +44 1709 871873

Email: service@martek-marine.com

Web: www.martek-marine.com

2 3

Navgard Operations Manual

Customer Feedback Form

Dear Valued Customer,

Martek Marine Ltd is committed to continuously improving the products and

services that we provide you with. We encourage and welcome your comments

and feedback.

If any aspects of our product and/or service have not met or exceeded your

expectations, could you please tell us below? Please feel free to make any

suggestions for improvements or tell us how we could have done better. If we

have performed well in any areas, please also tell us!

Alternatively, please e-mail any comments to service@martek-marine.com

Warranty

Martek Marine Ltd. warrants products as a whole and individually against failure

in the field for 12 months from date of commissioning, or 18 months from date

of shipment from Martek Marine Ltd, whichever is sooner.

The warranty period covers against defects due to component failure or workmanship

when commissioned and/or serviced by Martek Marine Ltd certified engineers.

The following conditions may invalidate your warranty:-

1. If maintenance of the system has not been carried out in line with

requirements as specified in the maintenance section of the manual.

2. If the system has been operated or maintained by untrained crew members.

3. If the system fails as a result of work carried out by a non-certified Martek

Marine Ltd. engineer.

4. If non type approved parts

1

are used within the system.

5. If the system Hardware is reconfigured or upgraded without prior

authorisation by Martek Marine Ltd.

6. If the system Software is modified or affected either directly or indirectly in

anyway without prior authorisation by Martek Marine Ltd.

Martek must be notified of any warranty claims immediately on discovery and

our policy is for a return of equipment back to UK for impartial inspection.

Returns must be accompanied by a returns number which must be obtained

from service@martek-marine.com

In line with the Marine Equipment Directive.

5

Quality Policy

Martek Marine Ltd. is committed to providing our customers with goods and

services of consistent quality and reliability, on time, which is both fit and safe for

their intended use.

We are committed to keeping abreast of new technologies, to anticipate the

changing requirements of our customers, and to meet the changing legislative

requirements for our products. This ensures that we maintain our capability of

meeting the highest standards, and to improve, where possible, the quality of

our service.

The company is committed to maintaining a Quality Management System

and to using suppliers whose quality systems have been accredited to

BS EN ISO 9001:2008.

Our Quality Management System is fully documented, comprehensive and

readily understood. The whole company implements it and it is mandatory that

all company personnel comply with its requirements.

The Company engenders a working environment amongst all its employees such

that they shall have a full commitment to quality and only produce work of the

highest standard.

4

1

Where the client prefers, Martek Marine Ltd. can dispatch a Martek Marine

service engineer and / or replacement equipment to the vessel location on

receipt of a purchase order. If the warranty is upheld only costs associated with

travel and subsistence will be charged, and any purchase orders raised for parts

will be cancelled.

If the cause of the claim is not covered under warranty all associated costs

including parts, labour, travel and expenses, incurred in conjunction with such

repair, replacement or renewal shall be chargeable at Marteks standard

service rates.

6

Table of Contents

QUALITY POLICY 4

WARRANTY 5

1. INTRODUCTION 12

1.1 KEY FEATURES 12

1.1.1 Additional Stage Alarms 12

1.1.2 Emergency Call and Officer Call 12

1.1.3 Additional Interface 12

1.1.4 Inputs from Valid Reset Devices & System Alarms 13

2. NAVGARD COMPONENTS AND FEATURES 14

2.1 OVERALL LAYOUT 14

2.1.1 Wheel House / Bridge 15

2.1.2 Accomodation Decks 15

2.1.3 Remote Locations 15

2.2 PHYSICAL COMPONENTS AND FIELD DEVICES 20

2.2.1 Navgard Control Panel 21

2.2.2 Navgard Reset Pushbuttons 24

2.2.3 PIR (Passive Infra-Red Detectors) Motion Sensors 25

2.2.4 Alarm Sounders 26

2.2.5 Power Supply 27

7

3. NAVGARD OPERATION & MAINTENANCE 28 4. INSTALLATION AND COMMISSIONING 36

3.1 PASSWORD ACCESS CONTROL 28 4.1 INSTALLATION GUIDE 36

3.1.1 Password Level Access 29 4.2 COMMISSIONING GUIDE 38

3.1.2 Battery Reset Password Access 30

APPENDIX A - REQUIREMENTS FOR IMO & IEC 62616 STANDARDS 39

APPENDIX B - COMPONENT DRAWINGS 45

APPENDIX C - COMMISSIONING CHECKLIST 70

VISUAL INSPECTION TEST 70

CONFIGURATION OF CONTROL PANEL 71

TEST CONFIGURATION 73

CABIN CONFIGURATION 73

SYSTEM TEST 74

SYSTEM PARAMETERS 76

COMMUNICATIONS TEST WITH VDR CONNECTED 78

WARRANTY LABELS 79

SIGNATURE OF ACCEPTANCE 79

APPENDIX D - TECHNICAL COMPONENT SPECIFICATION 80

APPENDIX E - PERIPHERAL DEVICES DETAIL 82

360 PIR 82

DIRECTIONAL PIR 84

BEACON SOUNDER 88

ONBOARD PIR 90

35

5 WEEE DIRECTIVE: 94

9

3.3 ERRORS AND ALARMS

3.3.1 General Error

3.3.2 Battery Error

3.3.3 Battery Replacement Required

3.3.4 Mains Power Fail

3.3.5 Tamper Error

3.3.6 Unapproved Battery Error

3.3.7 PIR Error

3.4 MAINTENANCE GUIDE:

8

33

33

33

33

34

34

34

34

3.2 OPERATING MENU 30

3.2.1 Setting the Operational Mode 30

3.2.1.1 AUTO 31

3.2.1.2 ON 31

3.2.1.3 OFF 31

3.2.1.4 PORT SECURITY 31

3.2.2 Setting the Dormant Period 31

3.2.3 Setting the Stage 2-3 Time Difference 31

3.2.4 Setting the Stage 4 32

3.2.5 Setting the Stage 2 Cabin Configuration 32

3.2.6 Dim Button 32

3.2.7 Alarm History 32

TABLE OF FIGURES

FIGURE 1 FIGURE 7

NAVGARD EXAMPLE OF PHYSICAL LAYOUT WITH PIRS 16 NAVGARD EXTERNAL REST PUSHBUTTON SPECIFICATION (101714) 24

FIGURE 2 FIGURE 8

NAVGARD EXAMPLE OF PHYSICAL LAYOUT NO PIRS (LR VESSELS) 18 NAVGARD DIRECTIONAL PIR (101834) SPECIFICATION 25

FIGURE 3 FIGURE 9

NAVGARD CONTROL PANEL BULKHEAD MOUNT (101713) 21 NAVGARD 360 PIR (101060) SPECIFICATION 25

FIGURE 4 FIGURE 10

NAVGARD CONTROL PANEL BULKHEAD MOUNT (101081) BOTTOM 22 NAVGARD SOUNDER SQUARE (101084) SPECIFICATION 26

FIGURE 5 FIGURE 11

NAVGARD CONSOLE COLLAR (101483) 23 NAVGARD SOUNDER/BEACON (101064) SPECIFICATION 26

FIGURE 6 FIGURE 12

NAVGARD INTERNAL RESET PUSHBUTTON SPECIFICATION (101715) 24 CONTROL PANEL FASCIA 29

10 11

1. Introduction

Navgard is designed for maintenance free operation providing fast, accurate 1.1.4 Inputs from Valid Reset Devices & System Alarms

information for the lifetime of the vessel. It is simple to use, straightforward to Navgard provides additional wired inputs to accept a reset signal and transfer

learn and easy to operate. It is fully approved to classification society standards. of alarm conditions from other devices, and the source is flashed on the LCD

display. These might include RADAR or ECDIS.

1.1 Key Features

The Navgard system is designed for use on a ships Bridge. The remote alarm External valid reset inputs must be approved by the appropriate approval body

sounders cover key locations like the officer cabins and engine control room. before being connected to Navgard. This is not the responsibility of Martek

Some optional reset devices are able to be used on the external wings of Marine Ltd.

a bridge.

All control and monitoring equipment are installed in safe areas.

System components are shown in more detail in section 2.2 and

Appendix B.

1.1.1 Additional Stage Alarms

Navgard has an additional Stage 4 Alarm indication. There are three additional

stage alarm outputs for IAS/Alarm management system. A separate Stage 0

output can be used to signal a beacon on the bridge should it be required, this is

linked also to the external bridge wing sounder.

1.1.2 Emergency Call and Officer Call

Navgard has an Officer Call configurable in 4 officer cabins within the

navigation menu.

1.1.3 Additional Interface

An optional additional SD card interface can be supplied to log data of stage

alarms and emergency calls with time stamp.

12 13

2.1.1 Wheel house / Bridge

The Control Panel, Stage 1 Alarm Sounders, Alarm Beacon, Directional PIRs, 360

degree PIRs and push button reset switches are located in the Wheel House /

Bridge. If so required optional external push buttons with built in sounders can

be mounted on the Bridge wing, and are rated accordingly.

2.1.2 Accomodation Decks

The Stage 2 Alarms are located in the accommodation areas. The system

is configurable through the navigation menu, for up to four separate

accommodations as deemed necessary Captain, Officer 1, Officer 2 and Officer

3. (Set as: Cabin 1, 2, 3, 4.)

2.1.3 Remote Locations

Stage 3 Alarm sounder/beacons are located in remote locations and could

include Officers Mess, Crew Mess, Ships Office, CCR and ECR.

15

2. Navgard Components and Features

Navgard comprises of:

Hardware components include Control Panel, reset push buttons, PIR motion

sensors and alarm sounders/beacons.

Navgard Navigation Menu where the operator can configure and control the

operational mode and other device parameters of the system.

All field components used on the vessel are shown as accurate scaled drawings in

Appendix B.

2.1 Overall Layout

There are three areas within the vessel where the system and peripherals

are fitted:-

Wheel house / Bridge

Accommodation

Remote Locations

14

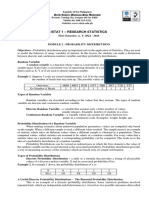

FIGURE 1 - NAVGARD EXAMPLE OF PHYSICAL LAYOUT WITH PIRS

16 17

FIGURE 2 - NAVGARD EXAMPLE OF PHYSICAL LAYOUT NO PIRS (LR VESSELS)

18 19

2.2 Physical Components and Field Devices

Navgard is made up of a number of hardware components including a control

panel, reset pushbutton modules, motion sensors and alarm sounders,

Communication interface, Power supply modules. This section provides both an

overall view of the physical structure of the Navgard system and a description of

the components.

Table 1: Navgard Components

20

2.2.1 Navgard Control Panel

The Navgard Control Panel forms the central console. The control panel is to be

mounted at a suitable location within the ship bridge preferably at a location

where the watch officer is expected to be stationed during normal operations.

M6 screw

fastener

Figure 3: Navgard Control Panel Bulkhead mount (101713)

21

Part Number Description

101713 Navgard Control Panel Bulkhead mount (Document Section 2.2.1)

101715 Navgard Internal Reset Pushbutton (Document Section 2.2.2)

101714 Navgard External Reset Pushbutton (Document Section 2.2.2)

101834

101060

101084

Navgard Directional Passive Infra-red Detectors (Document Section 2.2.3)

Navgard 360 Passive Infra-red Detectors (Document Section 2.2.3)

Navgard Alarm Sounder square (Document Section 2.2.4)

101064 Navgard Alarm Beacon/Sounder (Document Section 2.2.4)

101260 SD Card

101409 SD Card Reader

101716 4 core Marine approved 0.5mm2 cable for installation of peripherals

101483 Navgard console collar

The control panel provides gland entry for cabling (suitable for 4 core 0.5mm

2

& 0.75mm

2

screened) and other interfaces as shown in figure 4 below. The

Control panel houses the on-board PIR, User interface comprising of the LCD

and membrane keypad, LED indicators and the internal assembly comprises

of the PCB and the battery.

Knockouts to accommodate 18 x M20 Gland Entry

Figure 4 Navgard Control Panel Bulkhead mount (101713) Bottom

The control panel can be mounted into a console using the same gland entry for

cabling (suitable for 4 core 0.5mm

2

& 0.75mm

2

screened).

22

Navgard Console collar

Fitted around control panel

Figure 5 - Navgard Console collar (101483)

23

2.2.2 Navgard Reset Pushbuttons 2.2.3 PIR (Passive Infra-Red Detectors) Motion Sensors

The Navgard reset pushbutton module is used to indicate periodically operator The Navgard Motion sensors are used to detect human presence by monitoring

alertness to the system. The reset pushbutton module houses a Red illuminated movement within the bridge area.

pushbutton with 2 normally closed contacts that form part of the tamper loop.

The push button will flash during Stage 0 to alert the Officer in Watch that a reset These motion sensors are be used in Port Security mode where the system

signal must be activated. The Internal reset pushbutton is located in the bridge. operates as an intruder alarm.

The external reset pushbutton is located on the bridge wing. Note: Lloyds register does not accept motion sensors as a valid reset device. It is the responsibility of the

owner to ensure LR class vessels are installed without operational PIRs.

Figure 6 Navgard Internal Reset Pushbutton Figure 7 Navgard External Reset Pushbutton

(101715) (101714)

Figure 8 Navgard Directional PIR Figure 9 Navgard 360 PIR

Note: The maximum number of internal reset push buttons (101715) on the bridge is 6, as stated in the (101834) (101060)

System Layout Drawings in the Appendix B.

Note: The maximum number of external reset push buttons (101714) is two, one for each bridge Note: Where PIRs are allowed the maximum number of PIRs on the bridge is 4, as stated in the

wing, as stated in the System Layout Drawings in the Appendix B. System Layout Drawings in the Appendix B.

24 25

2.2.4 Alarm Sounders 2.2.5 Power Supply

The Navgard alarm sounders are to be configured in Bridge area(s), Officer The Navgard is supplied ready for connection to a DC main and Backup supply.

Cabins, of which a maximum of 4 may be configured, and remote locations which This will provide a 24V DC output to the internal fuse.

might include common area(s), engine control room and Officers mess.

Detailed drawings can be found in Appendix B

The Alarm sounders are configured at 80dB in order to comply with IMO and

IEC standards for volumes levels on the bridge. The tone is selectable during The Navgard System has battery back-up using a Ni-MH Martek Battery pack

commissioning in order to differentiate between different alarm sounds. (101261) which powers the system up to 6 hours in quiescent conditions, and

powers an emergency call or alarm sounders if actuated under battery back-up

conditions, effectively complying with IEC 62616. This is based on the maximum

peripheral loading as per System Layout Drawings in Appendix B.

Figure 10 - Navgard Sounder square Figure 11 - Navgard Sounder/Beacon

(101084) (101064)

Note: The maximum number of Sounder/Beacons in total is 7 for non LR vessels, an additional

2 Sounder Beacons can be used on LR vessels, as stated in the System Layout Drawings in the

Appendix B.

Note: The minimum number of Sounder/Beacons for compliance to the IMO standards is three;

One located in the bridge for Stage 1, one located in accommodation cabins for Stage 2 and one in

remote location for Stage 3.

26 27

3. Navgard Operation & Maintenance

3.1 Password Access Control

Login access controls what you can and cannot do on the Navgard system. There

are two password levels:

Master Level - This system is shipped with a default password 0000 it is the

responsibility of the ships Master to change and control the Master

level password.

Commissioning Level - This system is shipped with a commissioning password

inside a sealed envelope addressed to the commissioning engineer.

Note: If password is lost please contact the Service Department, details can be found on page 2

of the manual.

Figure 12 Control Panel Fascia

3.1.1 Password Level Access

To enter the password press the select button on the main control panel. The

operator has 25 seconds to enter a correct password, or the system will revert

back to the Operational Mode screen on the display.

Note: It is the responsibility of the Master to change the Master password upon successful

commissioning of the system and pass this to the subsequent crew.

Utilise the up and down keys to toggle between digits 0-9. When you arrive at

the correct digit of the password press the select key to move to the next field.

Press back to return to previous field. You must then repeat the process until

all digits of the password are entered.

Upon successful entry of the password, the HMI will display PASSWORD OK

and the Operation Mode screen is displayed.

28 29

3.1.2 Battery Reset Password Access

Notification regarding the requirements to change the internal battery are

automatically triggered by a separate internal clock, initiated during the

commissioning of the system. Indication of battery requiring replacement is done

via a flashing Battery LED on the control panel.

24 months after commissioning your battery must be replaced.

Six months prior to battery replacement becoming due a warning will be

displayed on the control panel.

24 months after system is commissioned or the battery is replaced a battery

replacement overdue warning will be displayed on the control panel.

A password is supplied with the replacement battery, and works in conjunction with

the unique serial chip embedded in each battery, in order that Type Approvals are

not invalidated. Instructions will be sent along with the new battery to reset the

Battery LED on the front of the control panel.

Once the battery is replaced and the correct password is entered the internal clock

will be reset for a further 24 months. The cycle will then repeat.

Note: If a non approved battery is used notification will be via the ERROR LED

3.2 Operating Menu

Once the Master Password is correctly entered the operator can gain access to

the navigational menu of the Navgard system and define Operational mode and

customise timing parameters within the Navgard menus. Press the SELECT key to

toggle between next stage menus.

3.2.1 Setting the Operational Mode

Press SELECT key to enter Operational mode & toggle between the four different

modes of operation by pressing the up and down keys. The four modes are: -

OFF, ON, AUTO & PORT SECURITY.

30

3.2.1.1 AUTO

When AUTO is selected the system runs as per the status of the track control

signal. Either AUTO ON or AUTO OFF will be displayed.

3.2.1.2 ON

The system functions as per stored timing parameters to configure these timings

refer to sections 3.2.2, 3.2.3 & 3.2.4. Alarms are activated within the IMO standards.

3.2.1.3 OFF

System operation is inhibited, apart from Emergency and Officer call functions.

3.2.1.4 PORT SECURITY

The system functions as a standard intruder alarm. Master level Password is utilised

to initiate entry and exit periods. The EXIT ENTRY PERIODS are defined in minutes.

The same time is configured for ENTRY and EXIT. When the user selects the Port

Security Mode within the Operational mode menu the user must exit the bridge

within the selected/configured time. Upon entry the user must then, using the

Master level password, change the Operational Mode to either ON, OFF or AUTO

before the ENTRY expires, otherwise the Navgard will go into alarm mode at Stage 1.

3.2.2 Setting the Dormant Period

The Dormant period is defined in minutes as the maximum length of time before

which a reset signal must be initiated.

The Dormant Period is configured by utilising the up and down keys to increase/

decrease the value indicated. When you have the desired value press the select

key. Only a number between 3-12 minutes is allowable as per the IMO and IEC

specified limits.

3.2.3 Setting the Stage 2-3 Time Difference

The Stage 2-3 time difference is defined in seconds as the time from Stage 2

alarm activating and the Stage 3 alarms being activated, assuming stage 2 is

not acknowledged.

31

The Stage 2-3 time is configured by utilising the up and down keys to increase/decrease

the value indicated. When you have the desired value press the select key. Only a

number between 90-180 seconds is allowable as per the IMO and IEC specified limits.

3.2.4 Setting the Stage 4

Stage 4 is an additional configurable alarm and defined in minutes as the time

from unacknowledged Stage 3 alarm to Stage 4 alarm being initiated. A number

between 12-99 minutes inclusive must be selected. Stage 4 alarms will be active,

assuming Stage 3 is not acknowledged.

The Stage 4 alarm is not a requirement of the IMO or IEC standards.

3.2.5 Setting the Stage 2 cabin configuration

Navgard enables up to 4 officer cabins to be configured to ON * and OFF - mode.

This is configured by utilising the up and down keys to increase/decrease the

value indicated. When you have the desired value press the select key.

For example if Stage 2 cabin configuration is set at -*-- means that cabin 2 only

will be activated during stage 2 alarm. If set at -*-*means that cabin 2 and

cabin 4 will be activated during stage 2 alarm.

3.2.6 Dim Button

The dimming function is operated by pressing the dimming button on the key

board. All panel visual LED indicators and reset push button lamps can be toggled

between a normal and low illuminated state.

3.2.7 Alarm History

All system alarms generated are sent via a serial communication to a VDR

if connected. Also an onboard SD flash memory records errors and faults if

purchased and installed as an option. The SD card is located in the PCB board.

Various indicators are signalled on the control panel that indicate to the

personnel on the bridge that action is required.

32

3.3 Errors and Alarms

3.3.1 General Error

If an error occurs with the operating system, the Error LED will

remain illuminated.

To rectify this, power the system down.

Reinitialise and select Operational Mode as per Section 3.2.1.

Input Dormant Time and Stage 2-3 Time Difference as per Sections 3.2.2 & 3.2.3.

If this does not reset Error LED identify if any of the subsequent errors below

have occurred , if unable to reset Error LED contact Service Department (details

on page 2 of manual).

3.3.2 Battery Error

When service is due or if an unapproved battery is used, the Error LED will flash

and internal buzzer sounds. The LCD display will indicate battery replacement

message. Contact spares@martek-marine.com

3.3.3 Battery Replacement Required

Notification of requirement to change the internal battery is automatically

triggered by an internal clock. The indication does not hamper system operation

but prompts user to replace battery.

If the internal battery (Part number 101261) is not replaced every 24 months,

the Battery LED will flash and Error LED will be illuminated and a notification of

change on the LCD will be displayed.

33

3.3.4 Mains Power Fail

If the mains power fails the battery is used to power the system and this state

is indicated by the POWER LED being switched off and the BATTERY LED being

illuminated. In addition to this the internal buzzer on the PCB is activated until

acknowledgment of failure by pressing the reset on Navgard keypad. The POWER

LED will remain off until main power is restored to the system.

3.3.5 Tamper Error

If the interface to any of the peripherals is disconnected, the Tamper LED will be

illuminated. In addition to this the internal buzzer on the PCB is activated until

acknowledgment of failure by pressing the reset on Navgard keypad. The Tamper

LED will remain illuminated until the cause of the tamper is removed.

3.3.6 Unapproved Battery Error

Post installation if an unapproved battery is used, the Error LED

will be illuminated until an approved battery is connected and battery

is re-commissioned.

3.3.7 PIR Error

The flashing of the Error LED is an indication that no PIRs are fitted or there is a short

circuit on the PIR loop. If constant movement is detected for a period of 30 mins the

flashing Error LED will be displayed also. This can be reset at the control panel.

34

3.4 Maintenance guide

1. The Navgard system requires periodic (24 monthly) replacement of the

battery (part number 101261)

2. It is also recommended that an annual full system integrity check is carried

out to confirm that all sensors are functioning

3. Any damaged/inactive peripherals MUST be replaced by a suitable spare part

by a qualified electrical engineer.

Contact spares@martek-marine.com

4. All cabling and interfaces should be re-checked to confirm system integrity

and any damaged cables must be replaced/re-wired if required by a qualified

electrical engineer.

5. Any changes made above must be tested in line with commissioning checklist

in Appendix C to confirm system operation.

6. Any warranty void marks/visible tampering must be logged to prevent future

disruption and system damage.

35

6. Knock-outs are located in the enclosure base for both bulkhead and console

mount panels for cable entry via M20 cable glands.

7. PIR sensors are identified/installed as per drawings:

(a) Directional PIR c/w JB Dimensional and Wiring Details

Drawing 101378-00

(b) 360 PIR Dimensional Wiring Details Drawing 101060-00

8. Internal /External Push Buttons are identified/installed as per drawings:

(a) Internal Push Button Dimensional and Wiring Details

Drawing 101066-00

(b) External Push Button Dimensional and Wiring Details

Drawing 101061-00.

9. Sounders and sounder/beacons are identified/installed as per drawings:

(a) Square Sounder Dimensional and Wiring Details Drawing 101084-00

(b) Sounder/Beacon Dimension and Wiring Details Drawing 101064-00

Note: A survey of the vessel will be required to determine the position of the peripherals and cable

lengths required.

10. Installation of additional Inputs and Interface to external equipment should

be in accordance with Drawings:

- 001 C0 Interconnection Diagram

- 001 D0 Typical Reset Switch Connection Details

- 001 E0 PIR Series Connection Details

11. Connect a mains power supply 24V DC as per drawing 001-B0 but do not

apply power.

12. Reconfirm the wiring as per the system drawings.

37

For bulkhead mounting place the enclosure against the wall and mark

the four drilling positions with a pen using the holes in the enclosure

mounting brackets as a template. Reference drawing Bulkhead

Mounted Enclosure Detail Drawing 101713-00.

(b) For console mounting make a cut-out in the console to suit based on

dimensions contained in drawing - Console Mounted Enclosure Detail

Drawing 101483-00.

3. Unscrew console case or open Navgard wall mount box to gain access to PCB.

4. Review Navgard Drawing Interconnection Diagram Drawing 001C0.

5. Identify the number of cable entries for each connection on the system. This

will depend on the number and type of peripherals supplied, and any external

reset signals used.

One entry is required for each of the following:

- VDR

- Each push button reset loop

- Each PIR Loop

- Each stage 2 alarm sounder

- Each stage 3 alarm sounder

36

4 Installation and Commissioning

4.1 Installation guide

1. Unpack Navgard System and peripherals verifying all components as per

Packing Specification.

2. Identify intended location for the Navgard Control Panel usually indicated by

prior survey

(a)

13. Visually inspect battery for defects.

14. Connect battery to PCB connector.

15. Verify battery LED is illuminated.

16. Connect the mains power and ensure that the battery LED is extinguished.

Warning: All installation must be done with Marine Approved cabling and by a certified Electrical Engineer.

4.2 Commissioning guide

Following installation of Navgard commissioning must be undertaken.

This can be arranged with Martek Marine Service Department. Contact details

are found on page 2 of this Manual. If commissioning is conducted by a non

Martek Engineer then an electronic copy of the commissioning checklist must be

completed fully and e-mailed/faxed back to Service Department at Martek Marine

(service@martek-marine.com). This indicates the start of the warranty period.

Names and Signatures of the Engineer commissioning the system must be

recorded on the commissioning checklist.

The Original Commissioning Checklist (Appendix C); must be completed and

retained with the Navgard Operation Manual on board.

Warning: Failure to return an electronic copy of the commissioning checklist to Martek will mean

that warranty is not validated, and technical support is not activated.

38 39

Appendix A - Requirements

for IMO & IEC 62616 Standards

Sr No. IMO Document reference Statement

1. Operational Requirement.

IMO MSC.128(75) 4.1.1.1

62616:2010 - 3.1.1

The BNWAS should incorporate the following

operational modes:

- Automatic (Automatically brought into

operation whenever the ships heading

or track control system is activated and

inhibited when not activated)

- Manual ON (In operation constantly)

- Manual OFF (Does not operate under

any circumstances)

2. IMO MSC.128(75) 4.1.2.1

62616:2010 - 3.1.2.1

Once operational, the alarm system should

remain dormant for a period of between 3

and 12 min (Td).

3. IMO MSC.128(75) 4.1.2.2

62616:2010 - 3.1.2.1

At the end of this dormant period, the alarm

system should initiate a visual indication on

the bridge.

4. IMO MSC.128(75) 4.1.2.3

62616:2010 - 3.1.2.2

If not reset, the BNWAS should additionally

sound a first stage audible alarm on the

bridge 15 s after the visual indication is

initiated.

5. IMO MSC.128(75) 4.1.2.4

62616:2010 - 3.1.2.3

If not reset, the BNWAS should additionally

sound a second stage remote audible alarm

in the back-up officers and/or Masters

location 15 s after the first stage audible

alarm is initiated.

6. IMO MSC.128(75) 4.1.2.5

62616:2010 - 3.1.2.4

If not reset, the BNWAS should additionally

sound a third stage remote audible alarm

at the locations of further crew members

capable of taking corrective actions 90 s

after the second stage remote audible alarm

is initiated.

40 41

Sr No. IMO Document reference Statement

12. IMO MSC.128(75) 4.1.3.4

62616:2010 - 3.1.3.3

A continuous activation of any reset device

should not prolong the dormant period

or cause a suppression of the sequence of

indications and alarms.

13. IMO MSC.128(75) 4.1.4

62616:2010 - 3.1.4

Means may be provided on the bridge

to immediately activate the second, and

subsequently third, stage remote audible

alarms by means of an Emergency Call push

button or similar.

14. IMO MSC.128(75) 4.2

Accuracy

62616:2010 - 3.2

The alarm system should be capable of

achieving the timings stated in section 4.1.2

with accuracy of 5% or 5 s, whichever is less,

under all environmental conditions.

15. IMO MSC.128(75) 4.3

Security

62616:2010 - 3.3

The means of selecting the Operational

Mode and the duration of the Dormant

Period should be security protected so that

access to these controls should be restricted

to the Master only.

16. IMO MSC.128(75) 4.4.1

Malfunctions, alarms and

indications

62616:2010 - 3.4

If a malfunction of, or power supply failure

to, the BNWAS is detected, this should be

indicated. Means shall be provided to allow

the repeat of this indication on a central

alarm panel if fitted.

17. IMO MSC.128(75) 5.1.1

ERGONOMIC CRITERIA

Operational controls

62616:2010 4.1a

A protected means of selecting the

operational mode of the BNWAS.

18. IMO MSC.128(75) 5.1.2

62616:2010 4.1b

A protected means of selecting the duration of

the dormant period of the BNWAS.

19. IMO MSC.128(75) 5.1.3

62616:2010 4.1c

A means of activating the Emergency Call

function if this facility is incorporated within

the BNWAS.

7. IMO MSC.128(75) 4.1.2.6

62616:2010 - 3.1.2.5

In vessels other than passenger vessels, the

second or third stage remote audible alarms

may sound in all the above locations at the

same time. If the second stage audible alarm

is sounded in this way, the third stage alarm

may be omitted.

8. IMO MSC.128(75) 4.1.2.7

62616:2010 - 3.1.2.5

In larger vessels, the delay between the

second and third stage alarms may be set

to a longer value on installation, up to a

maximum of 12 min, to allow sufficient time

for the back-up officer and/or Master to

reach the bridge.

9. IMO MSC.128(75) 4.1.3.1

62616:2010 Annex A.2

It should not be possible to initiate the

reset function or cancel any audible alarm

from any device, equipment or system not

physically located in areas of the bridge

providing proper look out.

10. IMO MSC.128(75) 4.1.3.2

62616:2010 - 3.1.3.1

The reset function should, by a single

operator action, cancel the visual indication

and all audible alarms and initiate a further

dormant period. If the reset function is

activated before the end of the dormant

period, the period should be re-initiated to

run for its full duration from the time of

the reset.

11. IMO MSC.128(75) 4.1.3.3

62616:2010 - 3.1.3.2

To initiate the reset function, an input

representing a single operator action by

the OOW is required. This input may be

generated by reset devices forming an

integral part of the BNWAS or by external

inputs from other equipment capable of

registering physical activity and mental

alertness of the OOW.

42 43

Sr No. IMO Document reference Statement

24. IMO MSC.128(75) 5.2.4

62616:2010 4.2.4

The remote audible alarm which sounds in the

locations of the Master, officers and further

crew members capable of taking corrective

action at the end of the bridge audible alarm

period should be easily identifiable by its

sound and should indicate urgency. The

volume of this alarm should be sufficient for

it to be heard throughout the locations above

and to wake sleeping persons.

25. IMO MSC.128(75) 6.2.1

System physical integrity

62616:2010 5.2.1

All items of equipment forming part of the

BNWAS should be tamper-proof so that no

member of the crew may interfere with the

systems operation.

26. IMO MSC.128(75) 6.2.2

62616:2010 5.2.2

Reset devices should be designed and

installed so as to minimize the possibility

of their operation by any means other than

activation by the OOW. Reset devices should

all be of a uniform design and should be

illuminated for identification at night.

27. IMO MSC.128(75) 6.2.3

62616:2010 5.2.2

Alternative reset arrangements may be

incorporated to initiate the reset function

from other equipment on the bridge capable

of registering operator actions in positions

giving proper look out.

28. IMO MSC.128(75) 6.3

Power

62616:2010 5.3

The BNWAS should be powered from the

ships main power supply. The malfunction

indication, and all elements of the Emergency

Call facility, if incorporated, should be

powered from a battery maintained supply.

20. IMO MSC.128(75) 5.1.4

62616:2010 Annex A.3

Means of activating the reset function

should only be available in positions on the

bridge giving proper look out and preferably

adjacent to visual indications. Means of

activating the reset function should be easily

accessible from the conning position, the

workstation for navigating and manoeuvring,

the workstation for monitoring and the

bridge wings.

21. IMO MSC.128(75) 5.2.1

Presentation of information

62616:2010 4.2.1

The operational mode of the equipment

should be indicated to the OOW.

22. IMO MSC.128(75) 5.2.2

62616:2010 4.2.2

62616:2010 Annex A.4

The visual indication initiated at the end of

the dormant period should take the form

of a flashing indication. Flashing indications

should be visible from all operational

positions on the bridge where the OOW may

reasonably be expected to be stationed. The

color of the indication(s) should be chosen

so as not to impair night vision and dimming

facilities should be included.

23. IMO MSC.128(75) 5.2.3

62616:2010 4.2.3

62616:2010 Annex A.5

The first stage audible alarm which sounds on

the bridge at the end of the visual indication

period should have its own characteristic

tone or modulation intended to alert, but

not to startle, the OOW. This alarm should be

audible from all operational positions on the

bridge where the OOW may reasonably be

expected to be stationed. This function may

be engineered using one or more sounding

devices. Tone/modulation characteristics

and volume level should be selectable during

commissioning of the system.

Appendix B - Component Drawings

Layout Drawings

System Diagram 001 AA0 (Page 16)

System Diagram (LR Vessels) 001 BA0 (Page 18)

This appendix contains drawings of Navgard components and layout schematic

Component Drawings

Bulkhead Mounted Enclosure Detail 101081

Console Mounted Enclosure Detail 101080

Directional PIR c/w JB & Wiring Details 101378

RF360 PIR & Wiring Details 101060

Internal Push Button & Wiring Details 101066

Square Sounder & Wiring Details 101084

Sounder/Beacon & Wiring Details 101064

External 150mm Push Button & Wiring Details 101061

Wiring Interface / Panel wiring Drawings

Power supply Arrangement 001 B1

Interconnection Diagram 001 C1

Typical Reset Switch Connection Diagram 001 D1

PIR Series Connection Details 001 E1

44 45

29. IMO MSC.128(75) 7

Interfacing

62616:2010 6.1

Inputs should be available for additional reset

devices for connection to bridge equipment

capable of generating a reset signal by

contacts, equivalent circuits or serial data.

30. IMO MSC.128(75) 7.2

62616:2010 6.2

Output(s) should be available for connection

of additional bridge visual indications and

audible alarms and remote audible alarms.

Component Dwg No 101081

46 47

Component Dwg No 101483

48 49

Component Dwg No 101378

50 51

Component Dwg No 101060

52 53

Component Dwg No 101066

54 55

Component Dwg No 101084

56 57

Please note if sounders supplied are round in

shape please use drawing number 001-M1 (next

page)

Component Dwg No 001-M1

Component Dwg No 101064

58 59

Component Dwg No 101061

60 61

Component Dwg No 001 B1

62 63

Component Dwg No 001 C1

64 65

Component Dwg No 001 D1

Component Dwg No 001 E1

68 69

Appendix C - Commissioning Checklist

This commissioning checklist must be carried out upon completion of installation

of the NAVGARD system.

Visual Inspection Test

70

Configuration of Control Panel

Software Revision number: (displayed during power up)

71

Ref Mechanical Conformance Pass Criteria Sign if OK

2.1 Tug Test cable connections All components are

mechanically acceptable.

2.2 Pushbutton mechanical

check

Ensure all push buttons depress and

return as expected.

2.3 Onboard PIRs No rotation of PIR.

2.4 Ensure fascia

mounting flush

Fascia not raised above recess.

2.5 Connect internal

12v Battery

Connection orientated correctly.

Software version displayed

on HMI.

Power LED remains off.

Battery LED is illuminated.

2.6 24Vdc Ensure the main

supply voltage is of

the correct rating.

Main supply voltage rating

is correct.

2.7 Apply the mains supply

to the unit and ensure

correct operation.

Internal PSU powers up.

PCB powers up.

MARTEK JOB NUMBER:

IMO NUMBER:

SHIPYARD:

VESSEL HULL NOS/NAME:

VESSEL CLASS

COMMISSIONING ENGINEER

1.5 Visually check the surface

of fascia.

Finish on fascia visually acceptable

with no defects or damage and

protective film present.

1.6 Visually check the

Directional PIRs.

All components shipped are visually

acceptable.

1.7 Visually check the 360

PIRs.

All components shipped are visually

acceptable.

1.8 Visually check the

Sounder/Beacons.

All components shipped are visually

acceptable.

1.9 Visually check the

Sounders.

All components shipped are visually

acceptable.

Ref Test Pass Criteria Sign if OK

1.1 Check all fixing

components within each

enclosure are not visual

defective.

All components are visually

acceptable and aligned.

1.2 Check all internal wiring

within the system

enclosures are not visual

defective.

All wiring is visually acceptable.

In accordance with Wiring Details in

Appendix B.

1.3 Check all external wiring

to the power supply is

correct prior to applying

power.

In accordance with Wiring Details in

Appendix B.

1.4 Visually check the

external appearance of

the enclosure to ensure

not visually defective or

damaged.

Finish on cabinet visually

acceptable.

Test Configuration

Cabin Configuration

Configure cabins in the menu as defined above

Activate Officer call Alarm - Verify that cabin alarms work independently. Tick

cabins where alarms activated.

Activate Emergency call Alarm - Verify that all cabins alarm, and alarm

escalates to Stage 3 if reset not activated. Tick cabins where alarms activated.

72 73

Date Test Set up Criteria Use values

3.1 Ensure that all alarm

levels are configured

correctly for test

Dormant Period (3 -12minutes).

Stage 2-3 Time Difference

(90-180 seconds).

Stage 4 (12-99 minutes).

ENTRY / EXIT TIME

(Port Security) (12-99 minutes).

3 minutes

90 seconds

12 minutes

12 minutes

Cabin 1 Cabin 2 Cabin 3 Cabin 4

- -

2.8 Ensure system

powers up.

Internal Power supply LED

illuminates.

Power LED is illiuminated.

Battery LED is extinguished.

NAVGARD is displayed on the HMI

when powered up in off mode.

2.9 Isolate the mains power

from the unit and ensure

that automatic switch

over to batter back-up

occurs.

System continues operation

without interruption.

Power LED on front of unit is

extinguished.

Battery LED on front of unit is

illuminated.

2.10 Reconnect main

power and ensure normal

operation continues.

System continues operation

without interruption.

Power LED is illuminated.

Battery LED on front of unit is

extinguished.

Cabin 1 Cabin 2 Cabin 3 Cabin 4

Cabin 1 Cabin 2 Cabin 3 Cabin 4 Escalates-Stage 3

System Test

Stage 1 Alarms

Stage 3 Alarms

Stage 2 Alarms

74 75

Check reset by

appropriate reset device.

Internal push buttons

External push buttons

Onboard PIR

360 PIR

Directional PIR

Other

Tick as

appropriate

Ref Test Pass Criteria Sign if OK

4.1 Ensure that Stage 1

alarm indications are

generated when the

alarm is not reset.

This should occur 195

seconds after the last

reset.

Check that the alarm

resets by pressing an

appropriate reset device.

Stage 1 alarm LED on system blinks

after 180 seconds when no reset is

activated

After 15 seconds if no reset is

activated the Stage 1 LED changes

to steady state

Bridge Sounder/Beacons is

activated at Stage 1

Ensure that alarms are reset when

using one of the below reset

devices.

Internal push buttons

External push buttons

Onboard PIR

360 PIR

Directional PIR

Other

Tick as

appropriate

Ref Test Pass Criteria Sign if OK

4.3 Ensure that Stage 3

alarm indications are

generated when Stage 1

and Stage 2 alarms are

not reset. This should

occur 300 seconds after

the last reset.

Check that all alarms

reset by pressing an

appropriate reset device.

Stage 3 alarm LED on the system is

illuminated and the cabin sounders/

beacons remain active when the

Stage 3 alarm point is reached

Bridge Sounder/Beacon is activated

during Stage 1 & 2

Cabin Sounder/Beacons are

activated during Stage 2

Ensure that all alarms reset when

using one of the below reset

devices.

Check reset by

appropriate reset device.

Internal push buttons

External push buttons

Onboard PIR

360 PIR

Directional PIR

Other

Tick as

appropriate

Ref Test Pass Criteria Sign if OK

4.2 Ensure that Stage 2

alarm indications are

generated when Stage 1

and alarm is not reset.

This should occur 210

seconds after the last

reset.

Stage 2 alarm LED on the system is

illuminated when the Stage 2 alarm

point is reached

Bridge Sounder/Beacons is

activated during Stage 1 & 2

Cabin Sounder/Beacons are

activated at Stage 2

Ensure that all alarms reset when

using one of the below reset devices.

Reset Alarms

System Parameters

The NAVGARD system functions in 3 different modes of operation

76 77

Ref Test Pass Criteria Sign if OK

4.4 Ensure reset devices

not previously validated

functioning

Ensure alarms count down timer

reset when using each of the below

reset devices.

Internal push buttons

External push buttons

Onboard PIR

360 PIR

Directional PIR

Other

Tick as

appropriate

5.3 Verify functionality of

Off mode

Change operation mode

to Off.

Verify Off LED is illuminated.

No alarms should activate and

system remains dormant.

NAVGARD is displayed on the HMI

Countdown timer is not displayed

5.4 Verify functionality of

Port Security mode

Change mode to Port

security

Enter Entry/Exit time as

2 minutes

Verify Port security LED illuminated.

Verify stage 1 LED blinks for 2

minutes to prompt bridge exit.

PIRs detect intruder after 2

minutes

PCB buzzer sounds to indicate

password required for mode

change.

If mode not changed within 2

minutes Alarm sounds.

5.5 Disable Port Security

mode

Change mode to ON

Alarms reset

Ref Test Pass Criteria Sign if OK

5.1 Verify Auto mode

functionality

Change operation mode

to Auto

Switch track control

ON to initiate a track

control signal to PCB.

Verify Auto LED is illuminated.

System should countdown as

normal.

HMI should display Auto On.

5.2 Switch track control

OFF to inhibit the track

control signal to the PCB.

Verify Auto LED is illuminated.

No alarms should activate and

system remains dormant.

HMI should display Auto Off.

Countdown timer is not displayed.

Communications Test with VDR connected Warranty Labels

Signature of Acceptance

SD Card (if Applicable)

78 79

Ref Test Pass Criteria Sign if OK

6.2 Identify logging on SD

Card of Stage 1, 2 and 3

alarms

No corrupt data and Garbage values

viewed

Ref Test Pass Criteria Sign if OK

6.1 Confirm that data logged

on the VDR is correct

No corrupt data and Garbage values

viewed.

For Example

The NAVGARD VDR output for a stage

0 alarm is:

$BNALR, ,000,V,A,C1=MAN;C2=03;C

3=0; C4=0;C5=0; C6=0*25

Where:

C1 = Mode (AON, AOFF, MAN, PSM)

C2= Dormant Period (3-12)

C3 = Stage Alarm (0, 1, 2, 3)

C4 = Mains Fail (0, 1)

C5 = Tamper (0, 1)

C6 = Emergency/Officer Call = (0, 1)

Martek

Approved Engineer

Other commissioning

Engineer

Client / Surveyor (if

applicable)

Print Name

Signature

Date

Ref Test Pass Criteria Sign if OK

7.1 Add anti-tamper

warranty labels to all

Peripherals and their

respective terminals.

All peripherals should have anti-

tamper warning stickers over access

screws post commissioning.

Any attempts to access these would

result in approvals and system

warranty being void.

7.2 Add anti-tamper

warranty labels to

control panel and their

respective terminals.

No unauthorized access to control

panel.

Any attempts to access these would

result in approvals and system

warranty going void.

Appendix D - Technical Component Specification

80 81

Temperature

Dimensions

(WxHxD)

Cable Entry

IP Rating

Weight

V / mA

Console

panel

-20C to

+70C

291 x 321 x

135mm

18 x M20

IP 54

3.8 kg

24v / 60mA

Bulkhead

panel

-20C to

+70C

250 x 280 x

135mm

18 x M20

IP 54

3.6 kg

24v / 60mA

PIR

Directional

-10C to

+55C

86 x 60 x

38mm

Fixed to JB

1x or 2x M20

IP 22

0.07 kg

12v / 12mA

PIR 360

-35C to

+55C

113 x 30 mm

Push out

IP 44

0.125 kg

12v / 10mA

Internal

Pushbutton

-20C to

+70C

94 x 94 x

81mm

18 x M20

IP 65

0.3 kg

12v

External

Pushbutton

-20C to

+70C

150 x 150 x

120mm

18 x M20

IP 65

1.5 kg

12v

Sounder/

Beacon

-20C to

+70C

92 x 115mm

18 x M20

IP 21

0.3 kg

18-24v /

40mA

Sounder

-20C to

+70C

95 x 95mm

18 x M20

IP 21

0.3 kg

18-24v /

40mA

Appendix E - Peripheral devices Detail

360 PIR

82 83

Directional PIR

84 85

86 87

Beacon Sounder

88 89

Onboard PIR

90 91

Notes Notes

92 93

5 WEEE Directive:

The WEEE Directive aims to both reduce the amount of electrical and electronic

equipment being produced and to encourage everyone to reuse, recycle and recover it.

The WEEE Directive also aims to improve the environmental performance of businesses

that manufacture, supply, use, recycle and recover electrical and electronic equipment.

The Navgard as is exempt from the WEEE directive as any equipment that is installed on a

fixed Installation is exempted.

Notice to European Union Customers

The crossed-out wheeled bin symbol above on the Battery indicates that this equipment

has been put on the market after 13 August 2005, and is included in the scope of the

directive 2002/96/EEC on waste electrical and electronic equipment (WEEE) and of the

national decree(s) which transpose provisions of such directive.

At the end of its lifetime, this device can only be disposed of in compliance with the

provisions of the above mentioned European directive (and following possible revisions)

as well as with the corresponding national regulation. Severe penalties are possible for

unauthorized disposal.

Electrical and Electronic Equipment (EEE) may contain polluting components and

hazardous substances which accumulation could pose serious risk for the environment

and human health.

Thats why local Administrations provide regulations which encourage reuse and

recycling, and prohibit the disposal of WEEE as unsorted municipal waste and require

the collection of such WEEE separately (at specifically authorized treatment facilities).

Manufacturer and authorized distributors are required to supply information about a safe

treatment and disposition of the specific device.

You may also return this equipment to your distributor when purchasing a new one. As

for reuse and recycling, notwithstanding the limits imposed by the nature and the use

of this device, the manufacturer will do his best to develop recovery processes. Please

contact the local distributor for information.

94 95

You might also like

- Configuration ManualDocument46 pagesConfiguration ManualHeber BallesterosNo ratings yet

- 95SA Installation Manual 1010Document89 pages95SA Installation Manual 1010belial111No ratings yet

- Nt920ahr Mkii ManualDocument14 pagesNt920ahr Mkii ManualKuang Ah Hock100% (1)

- (Fluid Mechanics and Its Applications 110) Roelof Vos, Saeed Farokhi (Auth.) - Introduction To Transonic Aerodynamics-Springer Netherlands (2015)Document561 pages(Fluid Mechanics and Its Applications 110) Roelof Vos, Saeed Farokhi (Auth.) - Introduction To Transonic Aerodynamics-Springer Netherlands (2015)Kunal GargNo ratings yet

- Autopilot NP2015/2025: Type 102 - 886 NG001Document105 pagesAutopilot NP2015/2025: Type 102 - 886 NG001Alexey Plekhanov100% (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- MRTS 7M Manual en v5.6.2Document85 pagesMRTS 7M Manual en v5.6.2ИгорьNo ratings yet

- 3566 e 032 A4Document111 pages3566 e 032 A4Arshad JummaniNo ratings yet

- Installation Manual: VDR Voyage Master II, III and IVDocument28 pagesInstallation Manual: VDR Voyage Master II, III and IVJay Sanchaniya100% (1)

- NW4000-10 VDR Ships and Operators Instruction Manual V 2.1.5Document185 pagesNW4000-10 VDR Ships and Operators Instruction Manual V 2.1.5python0202No ratings yet

- TG 8000 GYRO ChecklistDocument3 pagesTG 8000 GYRO ChecklistNishant Pandya0% (1)

- StratumFive - Thrane Thrane TT-3000SSA SSAS ConfigurationDocument1 pageStratumFive - Thrane Thrane TT-3000SSA SSAS ConfigurationRobin LalNo ratings yet

- Navigat Manual MK2Document98 pagesNavigat Manual MK2mohammed_omran_3No ratings yet

- Dr. Benoit Rihoux, Charles C. Ragin Configurational Comparative Methods - Qualitative Comparative Analysis (QCA) and Related Techniques (Applied Social Research Methods)Document118 pagesDr. Benoit Rihoux, Charles C. Ragin Configurational Comparative Methods - Qualitative Comparative Analysis (QCA) and Related Techniques (Applied Social Research Methods)Joana PinaNo ratings yet

- 1-Pearl Building Guide For Consultants English v1.0Document72 pages1-Pearl Building Guide For Consultants English v1.0waboucha100% (2)

- Fiber To Fiber and Fiber To Metal FrictionDocument49 pagesFiber To Fiber and Fiber To Metal FrictionMuhammad Khalil AzharNo ratings yet

- VDR Manual v5.0 (English)Document88 pagesVDR Manual v5.0 (English)Gấu Béo100% (1)

- Installation Manual For DM100Document119 pagesInstallation Manual For DM100joaofelipe.msNo ratings yet

- RT4822 VHF-DSC Installation Manual: SailorDocument20 pagesRT4822 VHF-DSC Installation Manual: Sailorvuhoan84No ratings yet

- NR50 User ManualDocument83 pagesNR50 User ManualArjunroyEdward100% (1)

- 180-AIS Em-Trak A200 InstOper Manual 29-1-2018Document104 pages180-AIS Em-Trak A200 InstOper Manual 29-1-2018QooNo ratings yet

- 2 - JCY-1700S Maintenance Software Manual 7ZPJD0370Document104 pages2 - JCY-1700S Maintenance Software Manual 7ZPJD0370Anonymous gJSJ8MGYFF100% (1)

- Navitron Systems LTD - NT990HDI Technical SpecificationsDocument1 pageNavitron Systems LTD - NT990HDI Technical SpecificationsUFUKKK100% (1)

- JLN-205MKII Installation Manual 7ZPNA3605 PDFDocument54 pagesJLN-205MKII Installation Manual 7ZPNA3605 PDFKuang Ah HockNo ratings yet

- Meridian GyrocompassDocument76 pagesMeridian GyrocompassZaw Khaing WinNo ratings yet

- Jue501 Service Manual 0000000871 - 7zpsc0434Document170 pagesJue501 Service Manual 0000000871 - 7zpsc0434carmine100% (1)

- Saab r4 Gps Pi-15-041-Rev-A-R4-Ais-Service-Bulletin - Gps-Week-RolloverDocument2 pagesSaab r4 Gps Pi-15-041-Rev-A-R4-Ais-Service-Bulletin - Gps-Week-Rollovercan doganNo ratings yet

- 11 - NautoAlarm Serv - Man ++Document22 pages11 - NautoAlarm Serv - Man ++MariosNo ratings yet

- M-2 AIS Installation Manual ContentDocument57 pagesM-2 AIS Installation Manual ContentAdi PrasetyoNo ratings yet

- 707094E0, VDR Users ManualDocument33 pages707094E0, VDR Users Manualdidou135067% (3)

- FURUNO FAR-FR2855 Installation Manual RDP115 Basic DiagramsDocument86 pagesFURUNO FAR-FR2855 Installation Manual RDP115 Basic Diagramstoumassis_pNo ratings yet

- JMA-9800 Instruction ManualDocument372 pagesJMA-9800 Instruction ManualMorseunited100% (1)

- DBS9200336 - Service Manual For Capsule and Backup Disc PDFDocument14 pagesDBS9200336 - Service Manual For Capsule and Backup Disc PDFSergeyNo ratings yet

- Furuno Felcom 18 Installation ManualDocument60 pagesFuruno Felcom 18 Installation ManualtariktunadNo ratings yet

- Furuno Ais Fa100 Service ManualDocument307 pagesFuruno Ais Fa100 Service Manualhomecncrouter0% (1)

- User's Manual: D/S Repeater Converter MKC106ADocument18 pagesUser's Manual: D/S Repeater Converter MKC106AAdi PrasetyoNo ratings yet

- 98-130890-d Installation Manual Sailor 6300 MF-HF DSC 150w-150w Fcc-250w-500wDocument80 pages98-130890-d Installation Manual Sailor 6300 MF-HF DSC 150w-150w Fcc-250w-500wleo.wainer100% (1)

- Simrad Gn33: Instruction ManualDocument154 pagesSimrad Gn33: Instruction ManualOger1No ratings yet

- DBS 00251 Inspectors Manual For Voyage Master II S-VDR PQDocument18 pagesDBS 00251 Inspectors Manual For Voyage Master II S-VDR PQEmannuel SouzaNo ratings yet

- modFELCOM 15 LRIT Checking ProcedureDocument3 pagesmodFELCOM 15 LRIT Checking ProcedurePriteshNo ratings yet

- 36 RH-3032 (Manual)Document71 pages36 RH-3032 (Manual)Nguyen Phuoc HoNo ratings yet

- Furuno VHF Fm-8500Document3 pagesFuruno VHF Fm-8500Simion Cosmin AurelianNo ratings yet

- FA170 Operators Manual ADocument98 pagesFA170 Operators Manual AMahfooz AliNo ratings yet

- Rutter VDR-100 G2 - G3 Diagnostic Checklist - Rev 8.0 PDFDocument11 pagesRutter VDR-100 G2 - G3 Diagnostic Checklist - Rev 8.0 PDFajc2_1984100% (1)

- JMR-7200 - 9200series JAN-7201 - 9201 - 7202 - 9202 (E) 7ZPNA4579F (7版) INSTRUCTION - FUNCTION2 190722Document68 pagesJMR-7200 - 9200series JAN-7201 - 9201 - 7202 - 9202 (E) 7ZPNA4579F (7版) INSTRUCTION - FUNCTION2 190722Macro LoveNo ratings yet

- JTM-30C Configuration & User Manual Rev-I PDFDocument12 pagesJTM-30C Configuration & User Manual Rev-I PDFVladimirs ArzeninovsNo ratings yet

- UAIS DEBEG 3400 Technical ManualDocument72 pagesUAIS DEBEG 3400 Technical Manualborisgolodenko100% (3)

- Navigation Echosounder Laz 5100 PDFDocument79 pagesNavigation Echosounder Laz 5100 PDFMariosNo ratings yet

- Sg12-Se004 (TG-6000 Maintenance Manual)Document132 pagesSg12-Se004 (TG-6000 Maintenance Manual)Leonardo GuzmanNo ratings yet

- NGR-3000 (GPS NAVIGATOR) User's Manual - 20180309 V3.0Document66 pagesNGR-3000 (GPS NAVIGATOR) User's Manual - 20180309 V3.0Mikhail100% (1)

- ECHO - sounder-jmc-model-f-2000-OPER Manual PDFDocument124 pagesECHO - sounder-jmc-model-f-2000-OPER Manual PDFPrinceBabuNo ratings yet

- Weather Facsimile Receiver JRC Jax-9a - Instruction ManualDocument38 pagesWeather Facsimile Receiver JRC Jax-9a - Instruction ManualSamid Softic100% (6)

- Installation Manual RVIDocument9 pagesInstallation Manual RVISachin SikkaNo ratings yet

- Sme44370f VR3000 3000S PDFDocument271 pagesSme44370f VR3000 3000S PDFNishant PandyaNo ratings yet

- Sam Nacos PlatinumDocument38 pagesSam Nacos Platinumburtay3434No ratings yet

- Jlr-8400 (e) 7zpna4701 (1版) Service Manual 190311Document70 pagesJlr-8400 (e) 7zpna4701 (1版) Service Manual 190311mark.lobianoNo ratings yet

- Radarpilot 1100Document7 pagesRadarpilot 1100ioannides_christos100% (1)

- TM SAM MF-HF 5000 Series 150&250W 98 124351Document60 pagesTM SAM MF-HF 5000 Series 150&250W 98 124351citaccitacNo ratings yet

- Rutter VDR 100 G2 User ManualDocument62 pagesRutter VDR 100 G2 User ManualEdwin Nyange0% (1)

- Tn-95-180085-A vhf7222 SW 106Document3 pagesTn-95-180085-A vhf7222 SW 106Sarath PavithranNo ratings yet

- NavNet Service Manual B 7 19 2002 PDFDocument296 pagesNavNet Service Manual B 7 19 2002 PDFErvin Luka TodiNo ratings yet

- R02 MAN IM IND570dyn MLDocument53 pagesR02 MAN IM IND570dyn MLmostafa.othman150No ratings yet

- User's Manual: NVR-7308P8-H2 NVR-7316P8-H2 NVR-7524P8-H4 NVR-7716P16-H2Document54 pagesUser's Manual: NVR-7308P8-H2 NVR-7316P8-H2 NVR-7524P8-H4 NVR-7716P16-H2EdhimingMingNo ratings yet

- Installation Manual. IND9D57 - Dyn-570 Dynamic Weighing SystemDocument27 pagesInstallation Manual. IND9D57 - Dyn-570 Dynamic Weighing SystemCarlos Lasso OrtegaNo ratings yet

- Archl Design LectureDocument38 pagesArchl Design LectureZpartx NikzNo ratings yet

- CD 00281302 - Calculando As GrandezasDocument24 pagesCD 00281302 - Calculando As GrandezasMarcus Zanon100% (1)

- Configuring Roaming User Profiles - Group Policy PDFDocument7 pagesConfiguring Roaming User Profiles - Group Policy PDFEmilio MartinezNo ratings yet

- How John F. Kennedy Changed Decision Making For Us AllDocument4 pagesHow John F. Kennedy Changed Decision Making For Us Allutkarsh bhargavaNo ratings yet

- Module 2 in IStat 1 Probability DistributionDocument6 pagesModule 2 in IStat 1 Probability DistributionJefferson Cadavos CheeNo ratings yet

- Q1 English10 Module 4Document30 pagesQ1 English10 Module 4Janessa Dawn AbayonNo ratings yet

- Data Manual: TMS320F28335, TMS320F28334, TMS320F28332 TMS320F28235, TMS320F28234, TMS320F28232Document199 pagesData Manual: TMS320F28335, TMS320F28334, TMS320F28332 TMS320F28235, TMS320F28234, TMS320F28232Daniela DantasNo ratings yet

- Literacy Day in IndiaDocument10 pagesLiteracy Day in IndiaThe United IndianNo ratings yet

- Sum and Difference of Two SquaresDocument11 pagesSum and Difference of Two SquaresJeffrey Escano FortunadoNo ratings yet

- Dispute Management PDFDocument2 pagesDispute Management PDFPritam PatnaikNo ratings yet

- C - ISR - 60 - SAP Certified Application Associate - Retail With SAP ERP 6.0Document3 pagesC - ISR - 60 - SAP Certified Application Associate - Retail With SAP ERP 6.0amar_india29No ratings yet

- Concrete Pictorial Abstract Approach On Students Attitude and Performance in MathematicsDocument23 pagesConcrete Pictorial Abstract Approach On Students Attitude and Performance in MathematicsArifudin SuryaNo ratings yet

- New Energy Technologies Issue 09Document78 pagesNew Energy Technologies Issue 09blameitontherain9877No ratings yet

- Cpm2 - Paper1Document8 pagesCpm2 - Paper1jupiter or juniperNo ratings yet

- The Silent Death of Americas ChildrenDocument15 pagesThe Silent Death of Americas ChildrenIlaMarie73No ratings yet

- Learning Outcomes For BSC in Mechatronics EngineeringDocument4 pagesLearning Outcomes For BSC in Mechatronics EngineeringKhalaf AborawiNo ratings yet

- 7th Cusp and MarriageDocument3 pages7th Cusp and MarriageKsvenggada RamanNo ratings yet

- Fil 111-TOS Midterm Final Copy 2Document2 pagesFil 111-TOS Midterm Final Copy 2Criselda Garcia SarioNo ratings yet

- The Teacher: Decision MakerDocument24 pagesThe Teacher: Decision Makerapi-353014166No ratings yet

- Chemkin PDFDocument44 pagesChemkin PDFmohamedIGCMONo ratings yet

- Chapter 3Document11 pagesChapter 3farhanyazdaniNo ratings yet

- SofasDocument3 pagesSofaszzmmmoNo ratings yet

- Nature of Science NotesDocument21 pagesNature of Science NotesmceldowneaNo ratings yet

- Census Literacy 2011Document40 pagesCensus Literacy 2011arpit_optimismNo ratings yet

- 6 Editing in ArcGISDocument8 pages6 Editing in ArcGISAnonymous cC2VeA9MBNo ratings yet

- Lean Six Sigma Essential GuideDocument15 pagesLean Six Sigma Essential GuideMarc Silvestre100% (3)