Professional Documents

Culture Documents

Hybrid Tech Eat On Fuel Cell

Hybrid Tech Eat On Fuel Cell

Uploaded by

Andreia SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hybrid Tech Eat On Fuel Cell

Hybrid Tech Eat On Fuel Cell

Uploaded by

Andreia SilvaCopyright:

Available Formats

By Jeffrey D.

Sokol

Note:

This writing is not a finished product. This is what we have down so far, and there are

more little details regarding the testing to come shortly. These are the basics of how this

cell works. I have been sponsored by George Wiseman of Eagle Research and

www.WaterTorch.com in the sense that he has spent hours of his valuable instructing me

on how to get this information out to the public to keep it from being suppressed. lease

also note that George Wiseman is !"T yet E!#"R$I!G %ybridTech Energy, only

advising our release to the public. George has not yet seen or tested this information, and

only knows what he has been told regarding the technology.

The inventor of this cell is #r. $teven Eaton. #r. Eaton is a !uclear hysicist, who

worked for the !$& for '( years before forced retirement due to a heart issue, which has

been fully repaired. %e has had many accomplishments in hysics including being

credited with the inventing of early warning nuclear detection devices being used

worldwide in power plants today, among other notable accomplishments with the !$&.

#r. Eaton has agreed to work with %ybridTech Energy to publish and manufacture his

invention.

Why its important:

The cell is a )'.* volt design, to be used anywhere. What makes it so ama+ing, is that the

inventor, #r. $teven Eaton, has designed it so that physics work with the cell, instead of

against it. The cell is incredibly efficient, able to produce appro,imately * liters per

minute, with less than )* amps, with absolutely -ER" electrolyte. The cell in previous

testing has not reached over .. degrees.

revious models were completed, producing ' lpm with )/ amps each. ( of those units

were fitted to run a (.** kw Troy 0ilt Generator. The generator ran )//1 on 2 34 of

%%" gas, which was produced by the Troy 0ilt Generator itself, and ran light bulbs and

other shop devices. The only thing that bogged it down was a large bench grinder

drawing 5.6 amps on top of the '// watts being taken from ' light bulbs. The key here,

is that electricity was being produced with )//1 water for fuel technology, no gasoline

or any other fossil fuels. The Troy 0ilt generated enough power off of %%" gas, to

operate the %%" cells, and provide e,tra power for small household items.

This newest design will be finished and tested very soon, which is the one you see below.

#r. Eaton has designed it to be even more efficient than it7s predecessors. Each unit

providing * liters per minute, drawing less than )* amps, will be mounted on the

generator. We will mount ' units onto the generator for verification by several notable

people in this field of study. The main point of this writing is to protect T%I$ #E$IG!

that has already worked.

The final designs will be very similar to this one, with only longer tubes if necessary, 6 to

)) inches are suggested by the numbers, but we used the material that was available at the

time to produce this unit.

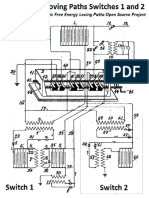

This paper is the basic idea of the system, and why it works. The basis of this design is

the voltage separation, the fact that it self8circulates, and the spacing between the anode

and cathode is only )9(':.

lease replicate this design for you own use, and prove this to yourself. The specs on

everything are included below.

This description of this ama+ing cell is for informational purposes. lease save, and

spread this information. This information is copyrighted, and may only be reproduced

and manufactured commercially with the written permission of %ybridTech Energy and

#r. $teven Eaton who currently holds it as atent ending status. %owever, all you have

to do is ask and give us credit, we want the information out there. ; complete %%"

ebook will be produced and sold very ine,pensively with the finished designs. It will be

a <lickbank product, so become an affiliate and sell the plans when it is time.

Cell:

The cell is composed of a series of tubes, and end plates, all metal material is ()23

stainless steel.

The tubes are specially made ()23 stainless, and are designed so that only )9(': of

clearance is available between the anode and cathodes. The tubes are =: long.

It is made in three parts, of ). tubes each. Each of the three parts, contains>

) End late with ?: holes, and @6A ?: "#, =9)2: I# tubes welded to the end plate.

) End late with (9.: holes, and @6A (9.: "# tubes, welded to the end plate.

The (9.: tubes are assembled with )9(': spacers, before they are welded to the end

plates. The (9. : tubes in the photo are wrapped in monofilament for testing purposes, .

/)* diameter. We have since drilled . holes in each tube, four holes on the top, and four

on the bottom. lastic plugs with )9(': heads are then inserted into the holes.

;fter spacers are in place and welding is complete, insert the (9.: tubes into the ?:

tubes. If everything is done properly, it should fit in a fairly snug fashion and the two

sets of tubes should not be touching. #o not push the tubes all the way to the ne,t contact

plate, there should be appro,imately ?: from the contact end plate, to the tubes of the

oppositely charged set of tubes. This will allow for the water to be sucked in from

underneath and flow through the tubes efficiently. This is a very important part of the

overall efficiency of the system, the fact that it flows on it7s own, at over ' gpm.

4ake sure you check for continuity before setting up connections.

Bsing a 4IG welder will turn your ()23 stainless to basically mild steel. This isn7t good

for electrolysis. Bse a TIG "!3C.

Each of the three parts, are wired to the other in a series. This spreads out the )'.* or so

volts, to each cell part, giving them appro,imately 5.' volts per set of ). tubes.

If everything is properly assembled, the cell should function to produce appro,imately *

liters per minute of %%" gas, at under )* amps.

$i+e of E!# 3;TE$. 4achine ready.

4"RE I!&"R4;TI"! T" <"4E. T%I$ I$ T%E 0;$I< I!&" "& T%E #E$IG!

;!# %"W IT W"RD$. This will be enough to get anyone started in producing an

e,tremely efficient cell, that will have engines running )//1 on water, that reEuires no

electrolyte for operation. %ybridTech Energy will begin manufacturing the finished

product very soon in our 3afayette, 3ouisiana production facility, or with our 0ra+ilian

affiliates.

lease reproduce this technology to prove it to yourself. If you can improve upon it,

please tell us so we can all have the information. This technology will run gasoline

generators on )//1 distilled water, with energy left over to run household items.

<omplete details of the efficiency will be reported after an . hour bench test. If the

numbers from #r. Eaton are correct, as they have been so far in his ). months of RF#

into this particular fuel cell design which keeps improving, then the %%" unit should

produce * 34, with less than )./ watts. ( of these units will draw *5/ watts, and

produce )* liters per minute of %%" gas. This should be more than enough to securely

power that (.** kw generator almost to capacity. What about a natural gas or propane

generatorGG I bet it would be more fuel efficient for %%", increasing the benefits.

Thank you for your time, and please stay tuned. Email me with Euestions to

%ybridTechEnergyHgmail.com. We will try to get a video produced with the generator

running on %%" very soon.

;RT II

$E<$ on arts

;ll metals are ()23 grade $$.

Electrodes are (9.: "#. I ./(/. 0rush finish sanded.

<athodes are =9)2 "#. I ./(/ brush finish sanded

<ontact plates are ./5/ factory e,truded finish. $pec. bored to clearance H ?7

&or cathode and (9. for electrode I,@6A per plate. 2 plates per unit.

0uss plates @welded contactsA are factory e,truded finish. ?: , ./5/. ;nd adJusted for

length according to

Electroly+er tube lengths.

Terminal buss plates are adJusted accordingly with length of electroly+er tubes with

Right angle bends K: from terminus and bored to receive (9. , '8L: $$ fine thread

%e, head bolt.

$ection dividers are ./)/ oly styrene , )8=9.: , length of electroly+er assy.

;ll assy. ;re spec welded by T.I.G. process annealing, specified no filler.

Electroly+er tubes to contact plates spec. H ' annealed tack per Junction.

0uss and terminal plates are spec. seam welded to contact plate assy.

Elecrode to cathode spacers are cast acrylic with )9)2: , (9)2 shafts and )9.:

an heads. )9(': thick heads.

<onnection 0uss 0ar

4y&ree<opyright.com Registered F rotected

4<!> <EW&384;!RE8(2!&B

You might also like

- MA - Glovo Business CaseDocument2 pagesMA - Glovo Business CaseAdam Ghouloulou0% (1)

- Poor Man Hydrogen Generator on Demand: Smcs Hho Stephens Multi Cell Systems Hydrogen Generator on DemandFrom EverandPoor Man Hydrogen Generator on Demand: Smcs Hho Stephens Multi Cell Systems Hydrogen Generator on DemandRating: 5 out of 5 stars5/5 (2)

- ERR Power Station Project BookletDocument18 pagesERR Power Station Project BookletAnonymous C0KBah6TEqNo ratings yet

- Setting Mikrotik LoadBalance 3 ISP No Lopping Ping Imut Full ScriptDocument2 pagesSetting Mikrotik LoadBalance 3 ISP No Lopping Ping Imut Full ScriptZhon Ocas100% (1)

- Bill Williams Gas Splitter Dry CellDocument4 pagesBill Williams Gas Splitter Dry CellCiprian ALNo ratings yet

- Site Map Site Search: Neutral Plates - QuestionsDocument2 pagesSite Map Site Search: Neutral Plates - QuestionsChandra NurikoNo ratings yet

- Numerical Study Ofa Tesla TurbineDocument8 pagesNumerical Study Ofa Tesla TurbineRavi ScoobyNo ratings yet

- A Unique Discrete Zero-Crossing DetectorDocument2 pagesA Unique Discrete Zero-Crossing DetectorCristian LiviuNo ratings yet

- GEET Fuel Processor Plans: WARNING: This Information Is Clasified As EXPERIMENTAL!Document10 pagesGEET Fuel Processor Plans: WARNING: This Information Is Clasified As EXPERIMENTAL!John BlackNo ratings yet

- Starlite PDFDocument35 pagesStarlite PDFPuturrú De FuáNo ratings yet

- Booklet PDFDocument31 pagesBooklet PDFKeith PittmanNo ratings yet

- TM355: Communications Technology: Take Home Exam For Final Assignment 2020-2021/ FallDocument7 pagesTM355: Communications Technology: Take Home Exam For Final Assignment 2020-2021/ FallHusseinJdeedNo ratings yet

- Study of Marketing Mix of Maruti Suzuki - BBA Marketing Summer Training Project Report PDFDocument95 pagesStudy of Marketing Mix of Maruti Suzuki - BBA Marketing Summer Training Project Report PDFRj Bîmålkümãr75% (4)

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinFrom EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNo ratings yet

- Energie - Rick Friedrich - Open Path EnergyDocument25 pagesEnergie - Rick Friedrich - Open Path EnergyIvan Ugidos MartinezNo ratings yet

- MAGLEV Wind Mill Power GenerationDocument16 pagesMAGLEV Wind Mill Power GenerationNagabhushanaNo ratings yet

- CommaxDocument24 pagesCommaxEduard PopescuNo ratings yet

- How To Make 250 To 5000 Watts PWM DC AC 220V Power InverterDocument22 pagesHow To Make 250 To 5000 Watts PWM DC AC 220V Power Invertermaster chibuking100% (2)

- Furnace Boosting DesignDocument8 pagesFurnace Boosting Designasitchawla100% (1)

- Geet Reactor RodDocument11 pagesGeet Reactor RodthenjhomebuyerNo ratings yet

- Power Generation by Foot Step Method - Rack and PinionDocument13 pagesPower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Us 4936961Document8 pagesUs 4936961PratikNo ratings yet

- Tesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megDocument9 pagesTesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megNISHANT KumarNo ratings yet

- Les Banki Circuit Updated Version August 16Document12 pagesLes Banki Circuit Updated Version August 16petar2009100% (2)

- Barbosa 150426021227 Conversion Gate01Document6 pagesBarbosa 150426021227 Conversion Gate01zac2351No ratings yet

- Alcohol Fuel 2001Document3 pagesAlcohol Fuel 2001tibork1No ratings yet

- Bsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Document120 pagesBsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Jumpman OutletNo ratings yet

- Ijiset V6 I8 18Document5 pagesIjiset V6 I8 18TeotiaNo ratings yet

- HPT (Ieee, 2005)Document7 pagesHPT (Ieee, 2005)Muhammad Hadi MustajabNo ratings yet

- Fluid Flywheel: Auto MechDocument6 pagesFluid Flywheel: Auto MechsalmapratyushNo ratings yet

- Dony WatssDocument49 pagesDony WatssvbugaianNo ratings yet

- Top 10 OU Revised 3.1docxDocument11 pagesTop 10 OU Revised 3.1docxBill ClarkeNo ratings yet

- Pulse Charging Capacitors Through InductorsDocument5 pagesPulse Charging Capacitors Through InductorsJamtse GyatsoNo ratings yet

- Switching A Normal' Load. Energizing A Load Begins With A Switching Device in The OpenDocument5 pagesSwitching A Normal' Load. Energizing A Load Begins With A Switching Device in The OpendenramrNo ratings yet

- Hendershot BookDocument52 pagesHendershot BookboboNo ratings yet

- Samsung CL29K3W Chassis KS3ADocument92 pagesSamsung CL29K3W Chassis KS3AHernan Ortiz EnamoradoNo ratings yet

- 25mV Joule Thief Powered by Peltier Merely Using Our Body Heat - Free Energy 24 - 7Document1 page25mV Joule Thief Powered by Peltier Merely Using Our Body Heat - Free Energy 24 - 7Luis MiglioreroNo ratings yet

- Chapter 13Document61 pagesChapter 13Stevan FarkasNo ratings yet

- Axial Flux Permanent Magnet Generators For Pico-HydropowerDocument8 pagesAxial Flux Permanent Magnet Generators For Pico-HydropowerEngineers Without Borders UKNo ratings yet

- Tensor DL DS ManualDocument162 pagesTensor DL DS ManualJoao RobertoNo ratings yet

- Deva Glide ManualDocument20 pagesDeva Glide ManualshibumbNo ratings yet

- Coconut Cooking Oil Is A Powerful VirusDocument9 pagesCoconut Cooking Oil Is A Powerful ViruskishbudNo ratings yet

- As Works (Devays) of (Tarielya) To (Kapanadze) .: Moral AspectDocument64 pagesAs Works (Devays) of (Tarielya) To (Kapanadze) .: Moral AspectchigoNo ratings yet

- US20140111054A1-Generator Cu Bobine Îmbunătățite Pentru Ai Spori Proprietățile electrodinamice-US20140111054ADocument21 pagesUS20140111054A1-Generator Cu Bobine Îmbunătățite Pentru Ai Spori Proprietățile electrodinamice-US20140111054AbluesurviverNo ratings yet

- Roto Verter - Rv-9Document38 pagesRoto Verter - Rv-9chigoNo ratings yet

- Motionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreDocument6 pagesMotionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreRolling76No ratings yet

- Paul Brown Nuclear Battery Patent 1989 PDFDocument10 pagesPaul Brown Nuclear Battery Patent 1989 PDFЛето Жаркое100% (1)

- Hyenergy: Cleaner, Greener, Cheaper FuelDocument11 pagesHyenergy: Cleaner, Greener, Cheaper FuelHHO MartNo ratings yet

- No. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaDocument4 pagesNo. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaAtharva Deshpande100% (1)

- Car That Runs On Tap Water - Plasma Spark - Oct 2005 - Hydrogen Fuel - Free Energy - Stanley MeyerDocument139 pagesCar That Runs On Tap Water - Plasma Spark - Oct 2005 - Hydrogen Fuel - Free Energy - Stanley MeyerGheorghe SilviuNo ratings yet

- Part 3 Zpe PDFDocument11 pagesPart 3 Zpe PDFAnonymous u5128WZ1KNo ratings yet

- Hydroxy BoostersDocument269 pagesHydroxy Boostersapi-3725726100% (4)

- Development and Evaluation of Fuel-Less Power GeneratorDocument5 pagesDevelopment and Evaluation of Fuel-Less Power GeneratorVoundai MahamatNo ratings yet

- Kapanadze, Stepanov, Barbosa-Leal and The Secret of Free EnergyDocument1 pageKapanadze, Stepanov, Barbosa-Leal and The Secret of Free Energymitza22No ratings yet

- 14744-Texto Del Artículo-72648-1-10-20190408Document12 pages14744-Texto Del Artículo-72648-1-10-20190408GeorgeNo ratings yet

- ELECTRETDocument3 pagesELECTRETchvar80100% (1)

- VladimirUtkin NewestDocument75 pagesVladimirUtkin Newestandy1144552No ratings yet

- Muammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesDocument29 pagesMuammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesMohd Fakhri0% (1)

- Necklace Hho 5Document89 pagesNecklace Hho 5RuddyMartiniNo ratings yet

- Hector Posts Volume2Document118 pagesHector Posts Volume2Vincent J. CataldiNo ratings yet

- Hector Posts Volume5Document140 pagesHector Posts Volume5Vincent J. CataldiNo ratings yet

- Nuclear BatteryDocument22 pagesNuclear BatteryPrayag P NairNo ratings yet

- Solid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld EnergyDocument2 pagesSolid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld Energyfsilassie8012No ratings yet

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsFrom EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsNo ratings yet

- Safe Energy Forever: + Pure water for the world and a cure for cancerFrom EverandSafe Energy Forever: + Pure water for the world and a cure for cancerNo ratings yet

- Lab Report2 Keil SimulatorDocument11 pagesLab Report2 Keil SimulatorKhubaib WaqarNo ratings yet

- HUC Program Grading SchemeDocument1 pageHUC Program Grading SchemeThanis RaoNo ratings yet

- Swot Analysis 123Document15 pagesSwot Analysis 123Roif SamsulNo ratings yet

- Lab 1.1 - 1.1.7 Lab - Basic Switch ConfigurationDocument13 pagesLab 1.1 - 1.1.7 Lab - Basic Switch ConfigurationHeng PhinNo ratings yet

- Worksheet: Rosales National High School Senior DepartmentDocument1 pageWorksheet: Rosales National High School Senior DepartmentGhaniella B. JulianNo ratings yet

- Code Black Personal ThreatDocument2 pagesCode Black Personal ThreatpatientsafetyNo ratings yet

- Error Analysis in Physics PDFDocument2 pagesError Analysis in Physics PDFKrystal0% (1)

- PPM Case Study AnswersDocument15 pagesPPM Case Study AnswersMohamed Kadri100% (2)

- Viichy France and The Resistance Culture & IdeologyDocument301 pagesViichy France and The Resistance Culture & IdeologyandybgNo ratings yet

- Notes 4 - Stresses in SoilsDocument45 pagesNotes 4 - Stresses in SoilsWen Sen SimNo ratings yet

- TR - Dressmaking NC IIDocument60 pagesTR - Dressmaking NC IIMR. CHRISTIAN DACORONNo ratings yet

- 3 Combine Wiring Diagram Pad BDocument7 pages3 Combine Wiring Diagram Pad BDimas FirmanNo ratings yet

- List of Delegates - Sep. 14 Bali 2017: Publist Salut. Surname First Name Company Title Phone Email EscortDocument6 pagesList of Delegates - Sep. 14 Bali 2017: Publist Salut. Surname First Name Company Title Phone Email EscortNetty yuliartiNo ratings yet

- Avenida de Balide - Antigo Comarca Balide, Dili TLF.: (+670) 3310315 11111Document2 pagesAvenida de Balide - Antigo Comarca Balide, Dili TLF.: (+670) 3310315 11111iduyNo ratings yet

- Hempathane HS 55610Document4 pagesHempathane HS 55610Hussein MohamedNo ratings yet

- Box Culvert / U-Drain Section Design: File:///conversion/tmp/scratch/488560866Document9 pagesBox Culvert / U-Drain Section Design: File:///conversion/tmp/scratch/488560866azwanNo ratings yet

- Shravni Ragoor ResDocument1 pageShravni Ragoor Resapi-705833851No ratings yet

- Reverberi Sterilix - Service ManualDocument19 pagesReverberi Sterilix - Service ManualMoyses MoyNo ratings yet

- 2019 Summer Model Answer Paper (Msbte Study Resources)Document34 pages2019 Summer Model Answer Paper (Msbte Study Resources)arvi.sardarNo ratings yet

- Bryce Boerste - Personal College Essay - Draft 2Document3 pagesBryce Boerste - Personal College Essay - Draft 2api-492128881No ratings yet

- Robinsons Daiso v. CIRDocument35 pagesRobinsons Daiso v. CIRaudreydql5No ratings yet

- Logging InnovationDocument8 pagesLogging InnovationAnkit ChourasiaNo ratings yet

- KWL Comprehension Strategy Handout Copy 2 0 PDFDocument20 pagesKWL Comprehension Strategy Handout Copy 2 0 PDFMuhammad FauziNo ratings yet

- Guía Didáctica - Profesionalización Inglés A1Document60 pagesGuía Didáctica - Profesionalización Inglés A1Fernanda AndradeNo ratings yet

- Family EngagementDocument8 pagesFamily Engagementapi-559316869No ratings yet