Professional Documents

Culture Documents

Type Inserts With Hole: WNMG 08 04 04-FH

Type Inserts With Hole: WNMG 08 04 04-FH

Uploaded by

TungstenCarbideCopyright:

Available Formats

You might also like

- Steel (TSL) Specification Chemical-Physical270109Document55 pagesSteel (TSL) Specification Chemical-Physical270109dyutimanhazra88% (8)

- GKN Materials and Processes EN PDFDocument40 pagesGKN Materials and Processes EN PDFarnella_h100% (1)

- 01SA0S02Document5 pages01SA0S02raobabar21No ratings yet

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryFrom EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNo ratings yet

- To Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentDocument17 pagesTo Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentRaja GuruNo ratings yet

- Comparison of HILTI and Fisher BoltDocument2 pagesComparison of HILTI and Fisher BoltSuresh D100% (1)

- CCDocument2 pagesCCTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- C006a ADocument152 pagesC006a ASugatSravastiNo ratings yet

- Thread o Ring Flanged FittingDocument4 pagesThread o Ring Flanged FittingsureshisisisNo ratings yet

- Controlled Bolt Tightening ChecklistDocument10 pagesControlled Bolt Tightening Checklistanjangandak2932No ratings yet

- Schneider Electric List Prices Sub-Collection 7 Industry Programmable June 2022 V1 enDocument366 pagesSchneider Electric List Prices Sub-Collection 7 Industry Programmable June 2022 V1 enSidali Hadj BenaliNo ratings yet

- Referencia OsciladoresDocument6 pagesReferencia Osciladoreselectrocla86No ratings yet

- Ms2Mb: Ball Nose End Mill, Medium Cut Length, 2 FluteDocument1 pageMs2Mb: Ball Nose End Mill, Medium Cut Length, 2 FluteTungstenCarbideNo ratings yet

- QSC RMX2450 PDFDocument10 pagesQSC RMX2450 PDFJohnny Tenezaca Duarte0% (1)

- Es LFB6080G2Document2 pagesEs LFB6080G2WattsNo ratings yet

- 1 231085 000061246568 09082018 CCDocument1,043 pages1 231085 000061246568 09082018 CCVergaraJuan0% (1)

- Process Vessels and Storage Vessels: Drawing N°Document7 pagesProcess Vessels and Storage Vessels: Drawing N°Rodrigo BeldaNo ratings yet

- Proximity SwitchesDocument3 pagesProximity Switchesvijaykumar.narayanaswamyNo ratings yet

- Válvula Expansão 2 5TR (Emerson A-Series)Document3 pagesVálvula Expansão 2 5TR (Emerson A-Series)rcbandeiraNo ratings yet

- MES Id PKG Dvce Custsize Qtylayer Opercur STP TTL STP Delqcum DelqDocument25 pagesMES Id PKG Dvce Custsize Qtylayer Opercur STP TTL STP Delqcum DelqamirulamirNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- Vc4Mb: Ball Nose, Medium Cut Length, 4 FL UteDocument1 pageVc4Mb: Ball Nose, Medium Cut Length, 4 FL UteTungstenCarbideNo ratings yet

- EA Catalog PDFDocument16 pagesEA Catalog PDFLeo Joon YanNo ratings yet

- Catalogo Sap Nov-11 Excel1 1Document953 pagesCatalogo Sap Nov-11 Excel1 1Jorge Luis Campos Sinarahua100% (1)

- Obl - NXTDocument3 pagesObl - NXTKumar DevvratNo ratings yet

- WELDING ConsumableDocument12 pagesWELDING ConsumableMuhammad Fitransyah Syamsuar Putra100% (2)

- Daftar InventarisDocument73 pagesDaftar InventarisroxalNo ratings yet

- 23Document2 pages23Muco MucaviNo ratings yet

- ABB PriceDocument60 pagesABB PriceMustapha AlyNo ratings yet

- CL29M6P8X - XAO Electrical Parts List 12Document10 pagesCL29M6P8X - XAO Electrical Parts List 12ITOGAMYNo ratings yet

- Saw Cutting ChartDocument4 pagesSaw Cutting ChartHammondMachineNo ratings yet

- A01 Bastidor Inferior 8697-2Document1 pageA01 Bastidor Inferior 8697-2Dmmxy14No ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- QSC RMX5050Document8 pagesQSC RMX5050Yonatan Rivadeneyra100% (1)

- Dbtv2501 Series A: Service ManualDocument35 pagesDbtv2501 Series A: Service ManualTrevor PatonNo ratings yet

- IGBT, FETMOSFETSaDocument7 pagesIGBT, FETMOSFETSaDan Jeric Arcega RustiaNo ratings yet

- Ferramentas HSK TDocument0 pagesFerramentas HSK Tandreia_janaina9629No ratings yet

- Commercial ComponentsDocument0 pagesCommercial ComponentsChevronelleNo ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- Ms2Sb: Ball Nose End Mill, Short Cut Length, 2 FluteDocument2 pagesMs2Sb: Ball Nose End Mill, Short Cut Length, 2 FluteTungstenCarbideNo ratings yet

- Book 1Document3 pagesBook 1Jose Enrique Salais SigalaNo ratings yet

- InertiaDynamics CB Couplings SpecsheetDocument9 pagesInertiaDynamics CB Couplings SpecsheetElectromateNo ratings yet

- Technical Manual: Five-Channel Power AmplifierDocument8 pagesTechnical Manual: Five-Channel Power Amplifierudal64No ratings yet

- PNL WH 03Document9 pagesPNL WH 03Reasat AzimNo ratings yet

- Copia de INVENTARIO 02 Al 04 de Septiembre BOLEITADocument39 pagesCopia de INVENTARIO 02 Al 04 de Septiembre BOLEITAFreybert PalaciosNo ratings yet

- Accesorios 31-05-2019Document30 pagesAccesorios 31-05-2019representaciones gh 2018No ratings yet

- Import Sample ReportDocument36 pagesImport Sample Reportaarzu.aliro1No ratings yet

- 4 4 PDFDocument21 pages4 4 PDFdothaoNo ratings yet

- Directory Data File Name DescriptionDocument52 pagesDirectory Data File Name DescriptionTIPAZONo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Type Inserts With Hole: TEGX 16 03 02 RDocument1 pageType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- CCDocument2 pagesCCTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- Type Inserts With Hole: DEGX 15 04 02 R-FDocument1 pageType Inserts With Hole: DEGX 15 04 02 R-FTungstenCarbideNo ratings yet

- CPDocument1 pageCPTungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- VQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesDocument1 pageVQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesTungstenCarbideNo ratings yet

- Reinforced Thermoplastic Pipe For Oil and Gas: Saudi Aramco Journal of Technology September 2003Document9 pagesReinforced Thermoplastic Pipe For Oil and Gas: Saudi Aramco Journal of Technology September 2003shizu monNo ratings yet

- Tables For EN 10216-2 PDFDocument18 pagesTables For EN 10216-2 PDFAli BariNo ratings yet

- ANSI Color CodesDocument2 pagesANSI Color CodesluinksNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- XI - Chemistry - HssLiVE - Anil - 14 - ENVIRONMENTAL CHEMISTRYDocument4 pagesXI - Chemistry - HssLiVE - Anil - 14 - ENVIRONMENTAL CHEMISTRYbansallove2008No ratings yet

- 2016 Specimen Paper 3Document10 pages2016 Specimen Paper 3sarabNo ratings yet

- Activity Ionic BondDocument6 pagesActivity Ionic BondMichelle CaliuagNo ratings yet

- Minerals: Editorial For Special Issue "Critical Metals in Hydrothermal Ores: Resources, Recovery, and Challenges"Document6 pagesMinerals: Editorial For Special Issue "Critical Metals in Hydrothermal Ores: Resources, Recovery, and Challenges"Benito Quispe A.No ratings yet

- PI - Technicoll - 9260 - GB - TDS PVAcDocument2 pagesPI - Technicoll - 9260 - GB - TDS PVAcThịnh HuỳnhNo ratings yet

- Somi Conveyer Beltings LTDDocument74 pagesSomi Conveyer Beltings LTDAnirudhNo ratings yet

- Gantrez S97 - Anti-Fog Additive For Window and Glass CleanersDocument2 pagesGantrez S97 - Anti-Fog Additive For Window and Glass Cleanersmarsam sttifNo ratings yet

- Work Sheet Acid Base and Salt Class 7Document4 pagesWork Sheet Acid Base and Salt Class 7Pramila PorwalNo ratings yet

- Boron 15crmo3 PDFDocument9 pagesBoron 15crmo3 PDFSuriyachai NiamsornNo ratings yet

- Introduction of Dung Quat RefineryDocument67 pagesIntroduction of Dung Quat RefineryKamejoku NguyenNo ratings yet

- HyyyyyyyyyDocument5 pagesHyyyyyyyyyrim deNo ratings yet

- Drawing (p15 Ace 857)Document14 pagesDrawing (p15 Ace 857)ritoh8657No ratings yet

- Hydrazine HydrateDocument1 pageHydrazine HydratemanushanthanNo ratings yet

- Thin Film DepositionDocument13 pagesThin Film DepositionMustakim MdNo ratings yet

- Loctite Ea 9396 AeroDocument4 pagesLoctite Ea 9396 AerobenNo ratings yet

- Araoka 2018Document9 pagesAraoka 2018barzi fadhilNo ratings yet

- 7.15a - Welding, Brazing, Soldering and BondingDocument22 pages7.15a - Welding, Brazing, Soldering and BondingAslam AwanNo ratings yet

- D 3023 - 98 Stain TestDocument3 pagesD 3023 - 98 Stain TestJohnNo ratings yet

- 316 Stainless Steel Material Property Data Sheet - Product Availability and Request A QuoteDocument2 pages316 Stainless Steel Material Property Data Sheet - Product Availability and Request A QuoteTonais JimNo ratings yet

- Zam Tech Brochure PDFDocument60 pagesZam Tech Brochure PDFTowkir AhmmadNo ratings yet

- G CHE101L G I E: Eneral Chemistry Lab Component Uided Nquiry XperimentsDocument6 pagesG CHE101L G I E: Eneral Chemistry Lab Component Uided Nquiry XperimentsEmran HossainNo ratings yet

- by Nvs Teacher Coordination CompoundsDocument138 pagesby Nvs Teacher Coordination CompoundsDarshan PatilNo ratings yet

- Chemistry Question and Answer 2013-2017Document52 pagesChemistry Question and Answer 2013-2017Chikuta ShingaliliNo ratings yet

- BS 729Document12 pagesBS 729Arun NagrathNo ratings yet

Type Inserts With Hole: WNMG 08 04 04-FH

Type Inserts With Hole: WNMG 08 04 04-FH

Uploaded by

TungstenCarbideOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type Inserts With Hole: WNMG 08 04 04-FH

Type Inserts With Hole: WNMG 08 04 04-FH

Uploaded by

TungstenCarbideCopyright:

Available Formats

A091

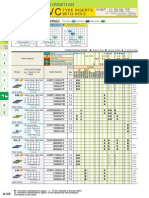

WNMG 08 04 04- FH

WN

80

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

FH

WNMG 080404-FH 0.4 a a a

C021

E015

E039

080408-FH 0.8 a [ a a a

FS

WNMG 080404-FS 0.4 [ a

C021

E015

E039

080408-FS 0.8 [ a

FY

WNMG 080404-FY 0.4 a

C021

E015

E039

080408-FY 0.8 [ a a

LP

WNMG060404-LP 0.4 a a a a

C021

E015

E039

060408-LP 0.8 a a a a

06T304-LP 0.4 a a a a

06T308-LP 0.8 a a a a

080404-LP 0.4 a a a a

080408-LP 0.8 a a a a

080412-LP 1.2 a a a

LM

WNMG 060404-LM 0.4 a a a

C021

E015

E039

060408-LM 0.8 a a a

080404-LM 0.4 a a a

080408-LM 0.8 a a a

SH

WNMG 06T304-SH 0.4 a a a

C021

E015

E037

E039

06T308-SH 0.8 a a a

060404-SH 0.4 a a a

060408-SH 0.8 a a a

080404-SH 0.4 a a a a a

080408-SH 0.8 a a [ a a a

080412-SH 1.2 a a [ a a

NEW

NEW

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

P P M P K

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7 0.1 0.3 0.5 0.7

FY

SY

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

RP

FH

MP

LP

RM

MM

LM

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

SW

MW

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

MA GH

NEG

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Size Thickness Corner Radius

*

Please refer to page A002.

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

WITHOUT

HOLE

Chip Breaker

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Finish Cutting

Finish Cutting

Finish Cutting

Light Cutting

Light Cutting

Light Cutting

Carbon Steel Alloy Steel

Mild Steel

Mild Steel

a

p

(

m

m

)

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

f (mm/rev)

Carbon Steel Alloy Steel

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

a

p

(

m

m

)

f (mm/rev)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A040

GRADES A030

IDENTIFICATION A002

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

Carbon Steel Alloy Steel (Wiper)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Standard

Flat Top

A092

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

SA

WNMG 080404-SA 0.4 a a [ a

C021

E015

E039

080408-SA 0.8 a a [ a

080412-SA 1.2 a a [ a

SW

WNMG 060404-SW 0.4 a a [ a a

C021

E015

E039

060408-SW 0.8 a a [ a a

080404-SW 0.4 a a [ a a a a

080408-SW 0.8 a a [ a a a a

080412-SW 1.2 a a [ a a a

SY

WNMG080404-SY 0.4 a

C021

E015

E039

080408-SY 0.8 [ a a a

C

WNMG 080404-C 0.4 [[

C021

E015

E039

080408-C 0.8 [

MJ

WNMG 080408-MJ 0.8 a a a

C021

E015

E039

080412-MJ 1.2 a a a

080416-MJ 1.6 a a a

MP

WNMG 06T304-MP 0.4 a a a [ a

C021

E015

E037

E039

06T308-MP 0.8 a a a [ a

06T312-MP 1.2 a a a [ a

060404-MP 0.4 a a a [ a

060408-MP 0.8 a a a [ a

060412-MP 1.2 a a a [ a

080404-MP 0.4 a a a [ a a

080408-MP 0.8 a a a [ a a

080412-MP 1.2 a a a [ a a

080416-MP 1.6 a a a [ a

WNMG 08 04 04- SA

WN

80

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

P P M P K

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7 0.1 0.3 0.5 0.7

FY

SY

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

RP

FH

MP

LP

RM

MM

LM

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

SW

MW

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

MA GH

NEG

TURNI NG I NSERTS

[

NEGATI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

Size Thickness Corner Radius

*

Please refer to page A002.

WITHOUT

HOLE

Light Cutting

Light Cutting

(Wiper)

Light Cutting

Light Cutting

Light Cutting

Medium Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

Mild Steel

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

Diffcult-to-Cut Materials

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

TYPE I NSERTS

WI TH HOLE

Chip Breaker

CHIP CONTROL RANGE FOR WORK MATERIALS

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

*

Please refer to A028 before using the SW breaker (wiper insert).

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

*

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

Carbon Steel Alloy Steel (Wiper)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Standard

Flat Top

A093

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

MM

WNMG 060408-MM 0.8 a a a

C021

E015

E039

060412-MM 1.2 a a a

080408-MM 0.8 a a a

080412-MM 1.2 a a a

GM

WNMG 060404-GM 0.4 a a a

C021

E015

E039

060408-GM 0.8 a a a

080404-GM 0.4 a a a

080408-GM 0.8 a a a

080412-GM 1.2 a a a

MA

WNMG 06T304-MA 0.4 a a a

C021

E015

E037

E039

06T308-MA 0.8 a a a

06T312-MA 1.2 a a a

060404-MA 0.4 a a a

060408-MA 0.8 a a a a a a a

060412-MA 1.2 a a a a a a a

080404-MA 0.4 a a a [ a a [ a a a a

080408-MA 0.8 a a a [ a a a [ a a a a a

080412-MA 1.2 a a a [ a a a [ a a a a a

080416-MA 1.6 a a a

100612-MA 1.2 [ a

MH

WNMG 080404-MH 0.4 a a [

C021

E015

E039

080408-MH 0.8 a a [ a [ a

080412-MH 1.2 a a [ a a

WNMG 080404 0.4 a a a [ a a a a

C021

E015

E039

080408 0.8 a a a [ a a a a a a

080412 1.2 a a a [ a a a a

080416 1.6 a

MW

WNMG 060408-MW 0.8 a a a [ a a

C021

E015

E039

060412-MW 1.2 a a a a

080408-MW 0.8 a a a [ [ a a

080412-MW 1.2 a a [ a a

MS

WNMG 06T304-MS 0.4 a [ a

C021

E015

E037

E039

06T308-MS 0.8 a [ a

060404-MS 0.4 a [ a

060408-MS 0.8 a [ a

080404-MS 0.4 a [ [ a

080408-MS 0.8 a [ [ a a a a a a

080412-MS 1.2 a a a a a

NEW

NEW

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

NEG

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

WITHOUT

HOLE

*

Please refer to A028 before using the MW breaker (wiper insert).

Medium Cutting

Medium Cutting

Medium Cutting

Medium Cutting

Standard

Medium Cutting

Medium Cutting

(Wiper)

Medium Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

a

p

(

m

m

)

f (mm/rev)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

*

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A040

GRADES A030

IDENTIFICATION A002

Diffcult-to-Cut Materials

A094

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

RP

WNMG 080408-RP 0.8 a a a

C021

E015

E039

080412-RP 1.2 a a a

RM

WNMG 060408-RM 0.8 a a a

C021

E015

E039

060412-RM 1.2 a a a

080408-RM 0.8 a a a

080412-RM 1.2 a a a

GH

WNMG 080408-GH 0.8 a a [ [ a a a

C021

E015

E039

080412-GH 1.2 a a [ a a a

GJ

WNMG 080408-GJ 0.8 a a a

C021

E015

E039

080412-GJ 1.2 a a a

080416-GJ 1.6 a a a

100612-GJ 1.2 a a

WNMA 080404 0.4 a a a

C021

E015

E039

080408 0.8 a a a

080412 1.2 a a

080416 1.6 a

NEW

WNMG 08 04 08- RP

WN

80

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

NEW

P P M P K

7

5

3

1

0

0.1 0.3 0.5 0.7

7

5

3

1

0

0.1 0.3 0.5 0.7

7

5

3

1

0

0.1 0.3 0.5 0.7

7

5

3

1

0

0.1 0.3 0.5 0.7

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7 0.1 0.3 0.5 0.7

FY

SY

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

RP

FH

MP

LP

RM

MM

LM

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

SW

MW

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

MA GH

8

6

4

2

0

0.1 0.3 0.5 0.7

NEG

TURNI NG I NSERTS

[

NEGATI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

Size Thickness Corner Radius

*

Please refer to page A002.

WITH

HOLE

Rough Cutting

Rough Cutting

Rough Cutting

Rough Cutting

Flat Top

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Diffcult-to-Cut Materials

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

Cast Iron

Cast Iron

a

p

(

m

m

)

f (mm/rev)

TYPE I NSERTS

WI TH HOLE

Chip Breaker

CHIP CONTROL RANGE FOR WORK MATERIALS

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

CHIP BREAKERS A040

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Mild Steel Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

Carbon Steel Alloy Steel (Wiper)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Standard

Flat Top

You might also like

- Steel (TSL) Specification Chemical-Physical270109Document55 pagesSteel (TSL) Specification Chemical-Physical270109dyutimanhazra88% (8)

- GKN Materials and Processes EN PDFDocument40 pagesGKN Materials and Processes EN PDFarnella_h100% (1)

- 01SA0S02Document5 pages01SA0S02raobabar21No ratings yet

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryFrom EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNo ratings yet

- To Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentDocument17 pagesTo Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentRaja GuruNo ratings yet

- Comparison of HILTI and Fisher BoltDocument2 pagesComparison of HILTI and Fisher BoltSuresh D100% (1)

- CCDocument2 pagesCCTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- C006a ADocument152 pagesC006a ASugatSravastiNo ratings yet

- Thread o Ring Flanged FittingDocument4 pagesThread o Ring Flanged FittingsureshisisisNo ratings yet

- Controlled Bolt Tightening ChecklistDocument10 pagesControlled Bolt Tightening Checklistanjangandak2932No ratings yet

- Schneider Electric List Prices Sub-Collection 7 Industry Programmable June 2022 V1 enDocument366 pagesSchneider Electric List Prices Sub-Collection 7 Industry Programmable June 2022 V1 enSidali Hadj BenaliNo ratings yet

- Referencia OsciladoresDocument6 pagesReferencia Osciladoreselectrocla86No ratings yet

- Ms2Mb: Ball Nose End Mill, Medium Cut Length, 2 FluteDocument1 pageMs2Mb: Ball Nose End Mill, Medium Cut Length, 2 FluteTungstenCarbideNo ratings yet

- QSC RMX2450 PDFDocument10 pagesQSC RMX2450 PDFJohnny Tenezaca Duarte0% (1)

- Es LFB6080G2Document2 pagesEs LFB6080G2WattsNo ratings yet

- 1 231085 000061246568 09082018 CCDocument1,043 pages1 231085 000061246568 09082018 CCVergaraJuan0% (1)

- Process Vessels and Storage Vessels: Drawing N°Document7 pagesProcess Vessels and Storage Vessels: Drawing N°Rodrigo BeldaNo ratings yet

- Proximity SwitchesDocument3 pagesProximity Switchesvijaykumar.narayanaswamyNo ratings yet

- Válvula Expansão 2 5TR (Emerson A-Series)Document3 pagesVálvula Expansão 2 5TR (Emerson A-Series)rcbandeiraNo ratings yet

- MES Id PKG Dvce Custsize Qtylayer Opercur STP TTL STP Delqcum DelqDocument25 pagesMES Id PKG Dvce Custsize Qtylayer Opercur STP TTL STP Delqcum DelqamirulamirNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- Vc4Mb: Ball Nose, Medium Cut Length, 4 FL UteDocument1 pageVc4Mb: Ball Nose, Medium Cut Length, 4 FL UteTungstenCarbideNo ratings yet

- EA Catalog PDFDocument16 pagesEA Catalog PDFLeo Joon YanNo ratings yet

- Catalogo Sap Nov-11 Excel1 1Document953 pagesCatalogo Sap Nov-11 Excel1 1Jorge Luis Campos Sinarahua100% (1)

- Obl - NXTDocument3 pagesObl - NXTKumar DevvratNo ratings yet

- WELDING ConsumableDocument12 pagesWELDING ConsumableMuhammad Fitransyah Syamsuar Putra100% (2)

- Daftar InventarisDocument73 pagesDaftar InventarisroxalNo ratings yet

- 23Document2 pages23Muco MucaviNo ratings yet

- ABB PriceDocument60 pagesABB PriceMustapha AlyNo ratings yet

- CL29M6P8X - XAO Electrical Parts List 12Document10 pagesCL29M6P8X - XAO Electrical Parts List 12ITOGAMYNo ratings yet

- Saw Cutting ChartDocument4 pagesSaw Cutting ChartHammondMachineNo ratings yet

- A01 Bastidor Inferior 8697-2Document1 pageA01 Bastidor Inferior 8697-2Dmmxy14No ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- QSC RMX5050Document8 pagesQSC RMX5050Yonatan Rivadeneyra100% (1)

- Dbtv2501 Series A: Service ManualDocument35 pagesDbtv2501 Series A: Service ManualTrevor PatonNo ratings yet

- IGBT, FETMOSFETSaDocument7 pagesIGBT, FETMOSFETSaDan Jeric Arcega RustiaNo ratings yet

- Ferramentas HSK TDocument0 pagesFerramentas HSK Tandreia_janaina9629No ratings yet

- Commercial ComponentsDocument0 pagesCommercial ComponentsChevronelleNo ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- Ms2Sb: Ball Nose End Mill, Short Cut Length, 2 FluteDocument2 pagesMs2Sb: Ball Nose End Mill, Short Cut Length, 2 FluteTungstenCarbideNo ratings yet

- Book 1Document3 pagesBook 1Jose Enrique Salais SigalaNo ratings yet

- InertiaDynamics CB Couplings SpecsheetDocument9 pagesInertiaDynamics CB Couplings SpecsheetElectromateNo ratings yet

- Technical Manual: Five-Channel Power AmplifierDocument8 pagesTechnical Manual: Five-Channel Power Amplifierudal64No ratings yet

- PNL WH 03Document9 pagesPNL WH 03Reasat AzimNo ratings yet

- Copia de INVENTARIO 02 Al 04 de Septiembre BOLEITADocument39 pagesCopia de INVENTARIO 02 Al 04 de Septiembre BOLEITAFreybert PalaciosNo ratings yet

- Accesorios 31-05-2019Document30 pagesAccesorios 31-05-2019representaciones gh 2018No ratings yet

- Import Sample ReportDocument36 pagesImport Sample Reportaarzu.aliro1No ratings yet

- 4 4 PDFDocument21 pages4 4 PDFdothaoNo ratings yet

- Directory Data File Name DescriptionDocument52 pagesDirectory Data File Name DescriptionTIPAZONo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Through Holes Steam Oxide External Cooling: Series 4402Document8 pagesThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNo ratings yet

- CC CC: Type Inserts With HoleDocument4 pagesCC CC: Type Inserts With HoleTungstenCarbideNo ratings yet

- CBN InsertsDocument27 pagesCBN InsertsTungstenCarbideNo ratings yet

- Gy2g0200d020n-Mf VP10RTDocument6 pagesGy2g0200d020n-Mf VP10RTTungstenCarbideNo ratings yet

- CCMXDocument1 pageCCMXTungstenCarbideNo ratings yet

- Any Size Kits Are All $400.00: Steel ApplicationsDocument2 pagesAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Type Inserts With Hole: TEGX 16 03 02 RDocument1 pageType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNo ratings yet

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocument2 pagesAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNo ratings yet

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocument1 pageType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNo ratings yet

- Type Inserts With Hole: VNMG 16 04 02-FHDocument3 pagesType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNo ratings yet

- Aemw150304er Up20mDocument1 pageAemw150304er Up20mTungstenCarbideNo ratings yet

- Type Inserts With Hole: XCMT 15 03 02-SVXDocument1 pageType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNo ratings yet

- Type Inserts With Hole: VDGX 16 03 02 RDocument1 pageType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: WCGT 02 01 02 RDocument1 pageType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNo ratings yet

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocument1 pageType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNo ratings yet

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocument1 pageType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNo ratings yet

- Type Inserts With Hole: VBMT 11 03 04 - SVDocument2 pagesType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNo ratings yet

- Type Inserts With Hole: VCMT 11 03 02-FPDocument2 pagesType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TPMH 08 02 02-FVDocument3 pagesType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNo ratings yet

- Type Inserts With Hole: SCMT 09 T3 04-FPDocument2 pagesType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Type Inserts With Hole: SPMT 09 03 04Document1 pageType Inserts With Hole: SPMT 09 03 04TungstenCarbideNo ratings yet

- CCDocument2 pagesCCTungstenCarbideNo ratings yet

- Type Inserts With Hole: DNMG 15 04 02-FHDocument5 pagesType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNo ratings yet

- Type Inserts With Hole: RCGT 08 03 M0-AZDocument1 pageType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNo ratings yet

- Type Inserts With Hole: DEGX 15 04 02 R-FDocument1 pageType Inserts With Hole: DEGX 15 04 02 R-FTungstenCarbideNo ratings yet

- CPDocument1 pageCPTungstenCarbideNo ratings yet

- Type Inserts Without Hole: Posi 6ºDocument1 pageType Inserts Without Hole: Posi 6ºTungstenCarbideNo ratings yet

- VQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesDocument1 pageVQ-SVR: Roughing End Mill, Short Length of Cut, 4 FL Ute, Irregular Helix FL UtesTungstenCarbideNo ratings yet

- Reinforced Thermoplastic Pipe For Oil and Gas: Saudi Aramco Journal of Technology September 2003Document9 pagesReinforced Thermoplastic Pipe For Oil and Gas: Saudi Aramco Journal of Technology September 2003shizu monNo ratings yet

- Tables For EN 10216-2 PDFDocument18 pagesTables For EN 10216-2 PDFAli BariNo ratings yet

- ANSI Color CodesDocument2 pagesANSI Color CodesluinksNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- XI - Chemistry - HssLiVE - Anil - 14 - ENVIRONMENTAL CHEMISTRYDocument4 pagesXI - Chemistry - HssLiVE - Anil - 14 - ENVIRONMENTAL CHEMISTRYbansallove2008No ratings yet

- 2016 Specimen Paper 3Document10 pages2016 Specimen Paper 3sarabNo ratings yet

- Activity Ionic BondDocument6 pagesActivity Ionic BondMichelle CaliuagNo ratings yet

- Minerals: Editorial For Special Issue "Critical Metals in Hydrothermal Ores: Resources, Recovery, and Challenges"Document6 pagesMinerals: Editorial For Special Issue "Critical Metals in Hydrothermal Ores: Resources, Recovery, and Challenges"Benito Quispe A.No ratings yet

- PI - Technicoll - 9260 - GB - TDS PVAcDocument2 pagesPI - Technicoll - 9260 - GB - TDS PVAcThịnh HuỳnhNo ratings yet

- Somi Conveyer Beltings LTDDocument74 pagesSomi Conveyer Beltings LTDAnirudhNo ratings yet

- Gantrez S97 - Anti-Fog Additive For Window and Glass CleanersDocument2 pagesGantrez S97 - Anti-Fog Additive For Window and Glass Cleanersmarsam sttifNo ratings yet

- Work Sheet Acid Base and Salt Class 7Document4 pagesWork Sheet Acid Base and Salt Class 7Pramila PorwalNo ratings yet

- Boron 15crmo3 PDFDocument9 pagesBoron 15crmo3 PDFSuriyachai NiamsornNo ratings yet

- Introduction of Dung Quat RefineryDocument67 pagesIntroduction of Dung Quat RefineryKamejoku NguyenNo ratings yet

- HyyyyyyyyyDocument5 pagesHyyyyyyyyyrim deNo ratings yet

- Drawing (p15 Ace 857)Document14 pagesDrawing (p15 Ace 857)ritoh8657No ratings yet

- Hydrazine HydrateDocument1 pageHydrazine HydratemanushanthanNo ratings yet

- Thin Film DepositionDocument13 pagesThin Film DepositionMustakim MdNo ratings yet

- Loctite Ea 9396 AeroDocument4 pagesLoctite Ea 9396 AerobenNo ratings yet

- Araoka 2018Document9 pagesAraoka 2018barzi fadhilNo ratings yet

- 7.15a - Welding, Brazing, Soldering and BondingDocument22 pages7.15a - Welding, Brazing, Soldering and BondingAslam AwanNo ratings yet

- D 3023 - 98 Stain TestDocument3 pagesD 3023 - 98 Stain TestJohnNo ratings yet

- 316 Stainless Steel Material Property Data Sheet - Product Availability and Request A QuoteDocument2 pages316 Stainless Steel Material Property Data Sheet - Product Availability and Request A QuoteTonais JimNo ratings yet

- Zam Tech Brochure PDFDocument60 pagesZam Tech Brochure PDFTowkir AhmmadNo ratings yet

- G CHE101L G I E: Eneral Chemistry Lab Component Uided Nquiry XperimentsDocument6 pagesG CHE101L G I E: Eneral Chemistry Lab Component Uided Nquiry XperimentsEmran HossainNo ratings yet

- by Nvs Teacher Coordination CompoundsDocument138 pagesby Nvs Teacher Coordination CompoundsDarshan PatilNo ratings yet

- Chemistry Question and Answer 2013-2017Document52 pagesChemistry Question and Answer 2013-2017Chikuta ShingaliliNo ratings yet

- BS 729Document12 pagesBS 729Arun NagrathNo ratings yet