Professional Documents

Culture Documents

Acid Storage

Acid Storage

Uploaded by

Chelsea SkinnerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acid Storage

Acid Storage

Uploaded by

Chelsea SkinnerCopyright:

Available Formats

Department Editor: Kate Torzewski

Acid Storage

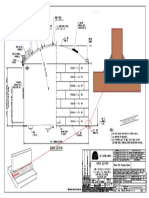

M

ost common acids can be stored in

horizontal or vertical ASME-type

tanks, as shown in the gures to the

right, or vertical API-type tanks. Horizontal,

carbon-steel ASME-type tanks of 10,000

40,000 gal capacity should have a plate

thickness of 3/8 in. with dished heads of

the same thickness. The thickness includes

a corrosion allowance of 1/4 in., which

provides a tank life of 1520 years.

Sulfuric acid (H

2

SO

4

)

Storage. This acid is prone to enter into

reactions that generate hydrogen, so in

addition to keeping the vessel vented

adequately, exclude potential sources of

ignition from the vicinity.

Materials of construction. Carbon

steel is satisfactory for concentrated

technical grades of sulfuric acid at

normal atmospheric temperature. H

2

SO

4

solutions that are more dilute corrode

carbon steel severely. To avoid inadver-

tent dilution of concentrated acid, keep

acid away from contact with moist air.

Polyvinyl chloride pipe is recommended

for ordinary sulfuric acid, but for oleum,

Type 316 stainless steel or carbon-steel

lined with a uorocarbon is best.

Phosphoric acid (H

3

PO

4

)

Storage. The tank bottom should be rolled

to a height of 3 in. (upward). This allows

welds to freely expand or contract. Corner

welds should be avoided, as undue stresses

can occur and aggravate corrosion [2].

Depending on the acid grade, the freezing

point varies and may necessitate heating to

avoid freeze-up in storage. In any case, to

avoid corrosion, high-pressure steam should

not be used; steam coils located several

inches below the bottom of the tank are

recommended. The space below the tank

bottom should be enclosed to permit heat-

ing of the air to 50C, and the tank walls

should be insulated.

Materials of construction. Tanks can

be fabricated of Type 316 extra-low-carbon

stainless steel, rubber--lined carbon steel or

berglass-reinforced plastic. Carbon steel

should not be used, as it will corrode.

Hydrochloric acid (HCl)

Storage. HCl of all strengths should be

stored in tanks similar to those men-

tioned above. Containment areas should

be provided around tanks, and storage

facilities should include a pressure- and

vacuum-relief service, primary and

redundant level indicators, a high-level

alarm, an overow line, an emergency

block valve at the tank outlet nozzle and

a vent-fume scrubber.

Materials of construction. These

storage tanks should be fabricated of rub-

ber-lined carbon steel, glass-lined carbon

steel or ber-reinforced polymer (FRP). Soft

natural-rubber compounds are used as lin-

ers for concentrated acid storage tanks at

temperatures up to 60C with a minimum

lining thickness of 3/16 in. Semi-hard

rubber is used for lining equipment and

piping for acid up to 70C with FRP tanks

of vinyl-ester resin.

Nitric acid (HNO

3

)

Storage. Storage tanks for HNO

3

of less

than 95 wt.% concentration should be

designed for at least a slight pressure and

vacuum, permitting the venting of nitrogen-

oxide fumes to collection and disposal

equipment, such as a scrubber or a are.

When locating the tank vent and overow

pipe, consider that escaping vapors and

liquid can corrode exterior welds as the

acid is diluted with atmospheric moisture.

Materials of construction. For concen-

trations up to 95 wt.% at ambient tempera-

ture, storage units should be fabricated of

Type 304L stainless steel. For concentra-

tions of 95 wt.% and above, Type 3003

aluminum alloy should be used. Acid in

the range of 5255 wt.% should be stored

in tanks of Type 347 stainless steel using

No. 12 gage sheet. Above 90 wt.%, cor-

rosion allowance in the tank-wall thickness

may be necessary. Glass-lined carbon

steel tanks are satisfactory for all acid

grades.

Hydrofuoric acid (HF)

Storage. Because of anhydrous HFs high

vapor pressure, tanks are designed for a

minimum pressure of 60 psig and have

X-rayed and stress-relieved welds. Tanks

holding 70 wt.% HF are also designed per

ASME code, or for lower pressure, as its

vapor pressure is much lower than that of an-

hydrous HF. These tanks should be equipped

with a relief device, and discharge piping

should be routed to a scrubber. Aqueous HF

tanks should have a vent, with the vent line

also going to the scrubber.

Materials of construction. Carbon-steel

storage tanks can be used for anhydrous HF

at temperatures up to 66C and 70 wt.%

HF. Acid of concentrations greater than 60

wt.% may be handled in steel up to a tem-

perature of 38C. In steel tanks, hydrogen

blistering may be caused by the accumula-

tion of H

2

, so periodic tank inspections are

required to evaluate blistering.

References

1. Grossel, S., Safe Efcient Handling of Acids,

Chem. Eng. December 1998, pp. 104112.

2. Anon., Phosphoric Acid, Rhone-Poulene Basic

Chemicals Co., Shelton, Conn. (1992).

2A*

Weld lines

* Minimum width of the shell course at each saddle. Width may be increased if more economical for shell course layout.

Knuckle radius line

2A*

DImension all nozzle

locations from this line

Standard flanged

and dished heads

Manhole Vent

A A

Top plate of saddle

welded to shell

6 in. typical

Nominal capacity level

Bottom

outlet

baffle

Channel

legs

Submerged

fill pipe

Grounding

clip

Name

plate

R

=

O

D

(

a

p

p

r

o

x

)

1

5

i

n

.

OD

You might also like

- 4 - TEMA StandardDocument16 pages4 - TEMA StandardM.H vafaeiNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Pressure VesselDocument46 pagesPressure VesselHaftamu HilufNo ratings yet

- Tank GADocument1 pageTank GASubramanian100% (1)

- Cone To Shell ReinforcementDocument4 pagesCone To Shell ReinforcementSajal KulshresthaNo ratings yet

- Bunded Steel Fuel Tanks - SmallDocument1 pageBunded Steel Fuel Tanks - SmallNAHASALI11No ratings yet

- Application For The Static Equipment Design EngineerDocument3 pagesApplication For The Static Equipment Design EngineerTejas ShahNo ratings yet

- Instructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Document287 pagesInstructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Tania HuqNo ratings yet

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- STHE Design (Training Material)Document37 pagesSTHE Design (Training Material)Herman_ms2000100% (2)

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishNo ratings yet

- Piping For PDFDocument1 pagePiping For PDFSumañ DašNo ratings yet

- Page No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressDocument93 pagesPage No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressSiva baalanNo ratings yet

- Grand Prix Engg.: Tag No. 90-EH-02Document6 pagesGrand Prix Engg.: Tag No. 90-EH-02Abhay UpadhyayNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelsudokuNo ratings yet

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 pageShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNo ratings yet

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- 03 Metal Packing Support PlatesDocument3 pages03 Metal Packing Support PlatesypatelsNo ratings yet

- Cone Layout Development by Marking and Calculation Method With Practical ExampleDocument12 pagesCone Layout Development by Marking and Calculation Method With Practical ExampleOkayNo ratings yet

- Annex V External PressureDocument26 pagesAnnex V External PressureJohnny Villarroel100% (1)

- Vessel With Large Opening: PVE SamplesDocument25 pagesVessel With Large Opening: PVE SamplesSivateja NallamothuNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- 10inch Inlet DiffuserDocument1 page10inch Inlet DiffuserJulian Vega DiazNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Tank Cleaning - Catalog 75 PDFDocument116 pagesTank Cleaning - Catalog 75 PDFClaimir GuinzelliNo ratings yet

- PTB E4.18.5 Fixed TubesheetDocument83 pagesPTB E4.18.5 Fixed TubesheetNicolaSaviliNo ratings yet

- WRC 107 WRC 297 Co MP PDFDocument11 pagesWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

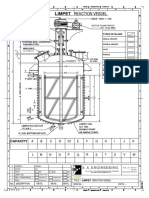

- Limpet Reaction Vessel PDFDocument1 pageLimpet Reaction Vessel PDFarajamani78No ratings yet

- Beam Design CalculationDocument33 pagesBeam Design CalculationsmijusNo ratings yet

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- DheerajDocument7 pagesDheerajSaksham KakarNo ratings yet

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- 1 Process VesselsDocument4 pages1 Process VesselsARIANA NICOLE RELIGIOSONo ratings yet

- Ideas To Achieve Optimal Combination of Axial & Cross FlowDocument28 pagesIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianNo ratings yet

- 299 Elliptical Head Design Tool Ver E4 01Document1 page299 Elliptical Head Design Tool Ver E4 01Noman Abu-FarhaNo ratings yet

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- CV - Omid KhodadadfarDocument4 pagesCV - Omid KhodadadfarGurvir SinghNo ratings yet

- Kherdi Chiplun Indus. Area: North DirectionDocument1 pageKherdi Chiplun Indus. Area: North DirectionPrathameshNo ratings yet

- Material Requisition For Expansion Joint - Rev7Document5 pagesMaterial Requisition For Expansion Joint - Rev7altipatlarNo ratings yet

- TEMA Shell Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNo ratings yet

- Molasses Tank 18092020Document31 pagesMolasses Tank 18092020Keshav GopaulNo ratings yet

- PV Elite BrocDocument6 pagesPV Elite BrocprasadgssNo ratings yet

- Hemispherical HeadDocument5 pagesHemispherical HeadPuRuiSen HelathchemicalNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingSourav HaitNo ratings yet

- Stress RelievingDocument1 pageStress RelievingCruz Gabriel Rosetti100% (1)

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- Sa 387Document29 pagesSa 387Ali VarmazyarNo ratings yet

- Cone Bottom Thickness & Structure Calculation For Elevated Supported Bottom Cone Tank Document NameDocument1 pageCone Bottom Thickness & Structure Calculation For Elevated Supported Bottom Cone Tank Document NameSachin5586100% (1)

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat ExchangerMohammed BaquarNo ratings yet

- Acid Storage DesignDocument1 pageAcid Storage DesignEugenio OlivaresNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument3 pagesPolythionic Acid Stress Corrosion Crackingvajidqc100% (1)

- KOROSIDocument35 pagesKOROSISaiful BahriNo ratings yet

- Equipment Design HW01Document4 pagesEquipment Design HW01Grin NikiforovNo ratings yet

- Stainless SteelsDocument3 pagesStainless SteelsAbdul WahabNo ratings yet

- Cracking of Boiler TubesDocument8 pagesCracking of Boiler Tubeslambu_ladNo ratings yet

- Polythionic Acid Stress Corrosion CrackingDocument2 pagesPolythionic Acid Stress Corrosion CrackingVajid MadathilNo ratings yet

- Implementing A Corrosion Under Insulation ProgramDocument4 pagesImplementing A Corrosion Under Insulation ProgramChelsea Skinner100% (1)

- Soda AshDocument1 pageSoda AshChelsea Skinner100% (1)

- Piping System Leak Detection and MonitoringDocument7 pagesPiping System Leak Detection and MonitoringChelsea SkinnerNo ratings yet

- Safety - Lessons Relearned - Confined SpaceDocument5 pagesSafety - Lessons Relearned - Confined SpaceChelsea SkinnerNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- Methyl ChlorideDocument1 pageMethyl ChlorideChelsea SkinnerNo ratings yet

- Acids HandlingDocument8 pagesAcids HandlingChelsea SkinnerNo ratings yet

- CEPCI CalculationDocument9 pagesCEPCI CalculationChelsea SkinnerNo ratings yet

- Acids HandlingDocument8 pagesAcids HandlingChelsea SkinnerNo ratings yet