Professional Documents

Culture Documents

Engineering Data Screen Openings For Basket Strainers: Purpose Filtration Level

Engineering Data Screen Openings For Basket Strainers: Purpose Filtration Level

Uploaded by

onin007Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Data Screen Openings For Basket Strainers: Purpose Filtration Level

Engineering Data Screen Openings For Basket Strainers: Purpose Filtration Level

Uploaded by

onin007Copyright:

Available Formats

14 Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax.

1-866-872-0073

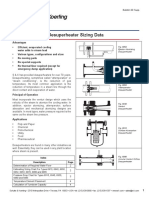

Engineering Data

Screen Openings for Basket Strainers

Purpose

If the basket strainer is being used for protection rather than

direct filtration, IFCs standard screens will suffice in most applications.

Service

With services that require extremely sturdy screens, such as

high pressure/ temperature applications or services with

high viscosities, IFC recommends that perforated screens

without mesh liners be used. If mesh is required to obtain a

certain level of filtration, then IFC recommends a trapped

perf./mesh/perf. combination.

Filtration Level

When choosing a perf. or a mesh/perf. combination attention

should be given to ensure overstraining does not occur. As a

general rule the specified level of filtration should be no

smaller than half the size of the particle to be removed. If too

fine a filtration is specified the pressure drop through the

strainer will increase very rapidly, possibly causing damage to

the basket.

1

/

4

D

i

a

.

-

4

0

%

O

.

A

.

3

/

1

6

D

i

a

.

-

5

0

%

O

.

A

.

5

/

3

2

D

i

a

.

-

5

8

%

O

.

A

1

/

8

D

i

a

.

-

4

0

%

O

.

A

.

3

/

3

2

D

i

a

.

-

3

9

%

O

.

A

1

/

1

6

D

i

a

.

-

3

7

%

O

.

A

.

3

/

6

4

D

i

a

.

-

3

6

%

O

.

A

.

1

/

4

D

i

a

.

-

4

0

%

O

.

A

.

0

.

0

2

7

D

i

a

.

-

2

3

%

O

.

A

.

2

0

M

e

s

h

-

4

9

%

O

.

A

.

0

.

0

3

5

O

p

e

n

i

n

g

s

3

0

M

e

s

h

-

4

5

%

O

.

A

.

0

.

0

2

2

O

p

e

n

i

n

g

s

4

0

M

e

s

h

-

4

1

%

O

.

A

.

0

.

0

1

6

O

p

e

n

i

n

g

s

6

0

M

e

s

h

-

3

8

%

O

.

A

.

0

.

0

1

0

O

p

e

n

i

n

g

s

8

0

M

e

s

h

-

3

6

%

O

.

A

.

0

.

0

0

8

O

p

e

n

i

n

g

s

1

0

0

M

e

s

h

-

3

0

%

O

.

A

.

0

.

0

0

6

O

p

e

n

i

n

g

s

Notes: 1. Screen openings other than those shown above are readily available. IFC inventories

various mesh sizes as fine as 5 micron and perforated plate as coarse as 1/2 Dia.

2. Screens are available in a wide range of materials. IFC inventories various screen material in

carbon steel, stainless steel (304, 316), alloy 20, monel 400, hastalloy C and titanium grade 2.

3. Custom manufactured screens are available upon request. Please consult factory.

Factors To Consider

Screen Types/Dimensions

15 Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

Engineering Data

Basket Strainer Pressure Drop-Liquids

FLOW RATE (GPM)

1

0.1

10

1

10 100

P

R

E

S

S

U

R

E

D

R

O

P

(

P

S

I

D

)

3

/

4

1

1

1

/

4

1

1

/

2

1

/

2

2

1

1

/

4

1

1

/

2

FLOW RATE (GPM)

10

0.1

10

1

100 1000 10000

P

R

E

S

S

U

R

E

D

R

O

P

(

P

S

I

D

)

4 5 8

1

0

2 3 6

1

2

1

6

1

8

2

0

2

4

1

4

Notes: 1. Pressure drop curves are based on water flow with standard screens.

See page 16 for correction factors to be used with other fluids and/or screen openings.

2. For Style 1 basket strainers multiply value obtained in figure 2 by 1.15 to obtain clean pressure drop.

FIGURE 1

FIGURE 2

Threaded Basket Strainer Pressure Drop - Liquids (Sizes

1

/

2

- 1

1

/

2

)

Flanged Basket Strainer Pressure Drop - Liquids (Sizes 2 - 24 )

16 Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

Engineering Data

Screen Correction Factor Chart

*Multiply values obtained from figure 1 thru 2 by the appropriate values shown below

A) As shown in the above example, the corrected pressure drop (P2) = 1.08 psig

B) Since S.G. = 1, P3 = P2 = 1.08 psig

C) Using chart #2 P4 = 0.35 x P3 = 0.38 psig

D) P5 = 1.08 - 0.38 = 0.70 psig

E) Using chart #3 P6 = 0.38 x 1.6 = 0.61 psig

F) Again using chart #3 P7 = 0.70 x 6.5 = 4.55 psig

G) Total pressure drop P8 = 0.61 + 4.55 = 5.16 psig

Example:

Strainer Size: 2 Style 2

Filtration: 100 mesh lined 1/8 perf.

Flow rate: 70 GPM

Specific Gravity: 1

Viscosity: 100 cP

SCREEN OPENINGS

Perforated Plate Mesh lined standard screens

Size % Screen Material Open Area % Screen Material Open Area

Range 60% 50% 40% 30% 20% 50% 40% 30%

1

/

4

- 1

1

/

2

0.45 0.55 0.7 1 1.15 1.05 1.05 1.2

2 - 16 0.65 0.8 1 1.4 2.15 1.05 1.05 1.2

How to Use:

1) Using figures 1 or 2 determine the pressure drop (P1) through the strainer with water flow and standard screens.

2) If non-standard screens (i.e. 40 mesh, etc.) are being used apply factors in chart #1 to determine corrected pressure drop (P2).

3) Multiply P1 or P2 (is used) by the specific gravity of the fluid actually flowing through the strainer to get P3.

4) Using chart #2 multiply P3 by the appropriate Component Factor (CF) to get P4.

5) Let P5 = P3 - P4.

6) Multiply P4 by the appropriate Body Loss Factor (BF) in chart #3 to get P6.

7) Multiply P5 by the appropriate Screen Loss factor (PF or MF) in chart #3 to get P7.

8) Total pressure drop P8 = P6 + P7.

Chart #1

A) Using figure 1 the pressure drop is determined to be 0.9 psig with IFCs standard screen.

B) Looking at page 14 we find that the % Open area of 100 mesh is 30%.

C) Using chart 1 we read the correction factor to be 1.2 for 100 mesh lined 1/8 perf.

D) Total pressure drop equals 0.9 x 1.2 = 1.08 psig clean.

Example:

Strainer Size: 2 Style 2

Filtration: 100 Mesh lined 1/8 perf.

Flow rate: 70 GPM

Service: Water

Notes: 1. See page 14 for % Open Areas of IFC inventoried perforated plate.

2. Standard screens for sizes 1/4 to 1-1/2 is approximately a 30% open area screen media.

3. Standard screens for sizes 2 and larger is approximately a 40% open area screen media.

* For use see instructions below.

Chart #2

Chart #3

Size Component

Range f actor (CF)

1

/

4

- 1

1

/

2

0.25

2 - 16 0.35

Viscosity Body Loss Screen Loss Factor

Cp Factor Perf alone 20 mesh 30 & 40 mesh 60 to 300 mesh

(BF) (PF) lined (MF) lined (MF) lined (MF)

10 1 1.15 1.3 1.4 1.5

25 1.2 1.25 2 2.2 2.5

100 1.6 1.4 3 4 6.5

200 2.2 1.5 4.5 7 11.5

500 4.4 1.6 10 15 25

1000 8 1.7 15 30 50

2000 15.2 1.9 30 60 100

For Non-Standard and Mesh Lined Screens

Viscosity and Density Correction Factor Chart

17 Tel. 905-335-8777 Fax. 905-335-0977 Toll Free Tel. 1-866-872-0072 Toll Free Fax. 1-866-872-0073

Engineering Data

Correction Factors For Clogged Screens

Example #2

Strainer Size: 12

IFC Series: B150F(Style 2)

Filtration:

3

/

16

perf.

Flow rate: 3000 GPM

Service: Water

% Clogged: 70%

Ratio of Free Screen Area to Pipe Area

% Clogged 10:1 8:1 6:1 4:1 3:1 2:1 1:1

10% - - - - - - 3.15

20% - - - - - 1.15 3.9

30% - - - - - 1.4 5

40% - - - - - 1.8 6.65

50% - - - - 1.25 2.5 9.45

60% - - - 1.15 1.8 3.7 14.5

70% - - - 1.75 2.95 6.4 26

80% - 1.1 1.75 3.6 6.25 14 58

90% 2.3 3.45 6 13.5 24 55 -

A) Using figure #1 the pressure drop is determined to be 1.0 psig with IFCs standard screen.

B) Looking at page 14 we find that the % Open area (OA) of

3

/

16

perf. is 50%.

C) Using chart #1 we read the correction factor to be 0.8 for

3

/

16

perf.

D) Total clean pressure drop equals 1.0 x 0.8 = 0.8 psig.

E) Since a non-standard screen is being used we must calculate the ratio free area to pipe

area using the above formula.

F) Looking at page 27 we find AG = 693.85 in2,Ap = 113.10 in2.

G) The ratio free area to pipe area is calculated as 3.07:1. (3:1 approx.)

H) Using chart #4 we read the correction factor to be 2.95 at 70% clogged.

I) Total pressure drop equals 0.8 x 2.95 = 2.36 psig when 70% clogged.

A) Using figure #1 the pressure drop is determined to be 2.0 psig with IFCs standard screen.

B) Looking at page 19 the ratio of free area to pipe area for a 10 IFCseries B150F (Style 1)

strainer is equal to 2.1:1 (2:1 approx.).

C) Using chart #4 we read the correction factor to be 3.7 at 60% clogged.

D) Total pressure drop equals 2.0 x 3.7 = 7.4 psig when 60% clogged.

Example #1

Strainer Size: 10

IFC Series: B150F(Style 2)

Filtration:

1

/

8

perf.

Flow rate: 3000 GPM

Service: Water

% Clogged: 60%

Notes: 1. See page 14 for the ratio of free area to pipe area for IFC Basket Strainers equipped with standard screens.

2. For screens other than IFCs standard use the following formula to calculate the ratio free area to pipe area:

where; R = Ratio free area to pipe area

Ag = Gross screen area, sq. in. (See page 19)

OA = Open area of screen media, % (See page 14, i.e.

1

/

16

perf. = 37%)

Ap = Nominal area of pipe fitting, sq. in. (See page 19)

R =

Ag x OA

100Ap

Chart #4

* Multiply values obtained from figures 1 thru 2 and charts #1, #2 and #3 (if used) by the appropriate values shown below

You might also like

- How To Use Vertical Thermosyphon Reboiler CalculatorDocument2 pagesHow To Use Vertical Thermosyphon Reboiler CalculatorMahesh KumarNo ratings yet

- Complete Test FourDocument27 pagesComplete Test FourGladysRios'No ratings yet

- Sizing SF 6 Inch Y-Strainer-1Document11 pagesSizing SF 6 Inch Y-Strainer-1BIDDU GHOSHNo ratings yet

- Nozzle CriteriaDocument2 pagesNozzle CriteriaKhalil LasferNo ratings yet

- Strainer SizingDocument20 pagesStrainer Sizingaliscribd46No ratings yet

- Dense Medium Cyclone Selection - It All Adds UpDocument18 pagesDense Medium Cyclone Selection - It All Adds UpLuis VelasquezNo ratings yet

- For Exchanger Tube Rupture PDFDocument3 pagesFor Exchanger Tube Rupture PDFNikhil DivateNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Separator Sizing SpreadsheetDocument10 pagesSeparator Sizing SpreadsheetEmmanuel ByensitaNo ratings yet

- RT PDFDocument2 pagesRT PDFsri9987No ratings yet

- 25nb y StrainerDocument1 page25nb y StrainerKailas NimbalkarNo ratings yet

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhNo ratings yet

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different StandardsAMRUTA PATILNo ratings yet

- Mixer SizingDocument0 pagesMixer SizingIlija RunjajicNo ratings yet

- 2A P220 Accumulator Process Data Sheet PDFDocument3 pages2A P220 Accumulator Process Data Sheet PDFAhmed MusallamNo ratings yet

- Mr. C.H.Park / Project Manager 03-May-06Document30 pagesMr. C.H.Park / Project Manager 03-May-06Ali YassineNo ratings yet

- Tube Rupture (Two Phase - API App-D Method)Document5 pagesTube Rupture (Two Phase - API App-D Method)Indra Kurniawan WijayaNo ratings yet

- Arts NPSH TutorialDocument3 pagesArts NPSH TutorialDidier SanonNo ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDocument7 pagesPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryNo ratings yet

- Relief Load CalculationDocument8 pagesRelief Load CalculationMuthuKumar ArunachalamNo ratings yet

- 6DSUPP Desuperheater Supplement BrochureDocument4 pages6DSUPP Desuperheater Supplement BrochureПавел ЛукьяновNo ratings yet

- BAsket Strainer Sizing HaywardDocument1 pageBAsket Strainer Sizing Haywardmarcoo8No ratings yet

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorencia0% (1)

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavNo ratings yet

- 2.CV SizingDocument33 pages2.CV Sizingyamen-691904No ratings yet

- Distillation Column InternalsDocument7 pagesDistillation Column InternalsRicardo BecNo ratings yet

- Orifice Calculation Parameter Case 1 Case 2 Case 3 Case 4 Case 5 Fluid PropertiesDocument1 pageOrifice Calculation Parameter Case 1 Case 2 Case 3 Case 4 Case 5 Fluid Propertiesaw_aeNo ratings yet

- Template (Vessel Sizing-2phase)Document2 pagesTemplate (Vessel Sizing-2phase)mNo ratings yet

- Volume and Wetted Area of Partially Filled Horizontal VesselsDocument11 pagesVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaNo ratings yet

- Line Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsDocument2 pagesLine Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsRawlinson TolentinoNo ratings yet

- Thermosyphon Reboiler Hydraulics: ResultDocument5 pagesThermosyphon Reboiler Hydraulics: ResultVaishnavi RaghavNo ratings yet

- Coalescer PallDocument16 pagesCoalescer PallJeEJyZaNo ratings yet

- PVRV Sizing Calculations Crude Oil Stroage Tank 007486 T 01Document2 pagesPVRV Sizing Calculations Crude Oil Stroage Tank 007486 T 01Olumuyiwa FasehunNo ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Estimation For Instrument Air Consumption of Pneumatic InstrumentDocument2 pagesEstimation For Instrument Air Consumption of Pneumatic Instrumentmyself_ritesh100% (1)

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 pagesAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangNo ratings yet

- Molcular Sieve 13X LTGDocument2 pagesMolcular Sieve 13X LTGkanu PatelNo ratings yet

- Eductor SizingDocument2 pagesEductor SizingbudiprasNo ratings yet

- Tank Emergency VentingDocument1 pageTank Emergency VentingSaeid Rahimi MofradNo ratings yet

- Sizing Separators and Accumulators PDFDocument4 pagesSizing Separators and Accumulators PDFjt_breakdanceNo ratings yet

- Control Valve SizingDocument21 pagesControl Valve Sizingtiwarishailendra2198No ratings yet

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 pagesOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulNo ratings yet

- A New Pressure Drop Model For Structured Packing H.A. Kooijman PDFDocument10 pagesA New Pressure Drop Model For Structured Packing H.A. Kooijman PDFMichael Sutherland100% (1)

- Line SizingDocument13 pagesLine Sizingadil alameenNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Demister EfficiencyDocument9 pagesDemister EfficiencyHastelloy Monel100% (1)

- A Guideline For Design Pressure - Part 1Document4 pagesA Guideline For Design Pressure - Part 1Said Ahmed SalemNo ratings yet

- Fabrication Strainers Mesh SizingDocument6 pagesFabrication Strainers Mesh SizingArun GuptaNo ratings yet

- Screen Openings For Y-StrainersDocument6 pagesScreen Openings For Y-Strainersboom10No ratings yet

- Sizing of StrainerDocument20 pagesSizing of StrainerMASOMESE KIKILENo ratings yet

- 33 - STR990-1 - Pressure Drop Data YDocument2 pages33 - STR990-1 - Pressure Drop Data YblindjaxxNo ratings yet

- Strainer Drop PressureDocument2 pagesStrainer Drop PressureJose Manuel Cervantes0% (1)

- Using Flange Joint in Duct SiystemDocument23 pagesUsing Flange Joint in Duct Siystematamete100% (1)

- T S T I: Emporary Trainer Echnical NformationDocument7 pagesT S T I: Emporary Trainer Echnical NformationTg TarroNo ratings yet

- Pressure Drop - COLTON Strainers PDFDocument2 pagesPressure Drop - COLTON Strainers PDFcavillalobosb8167No ratings yet

- Models - Cfd.water Purification ReactorDocument11 pagesModels - Cfd.water Purification ReactorzaidNo ratings yet

- Pipenet Vision Training Manual Standard: Chapter 4 Page 1 of 36 REVISION 2.1, SEP 2010Document36 pagesPipenet Vision Training Manual Standard: Chapter 4 Page 1 of 36 REVISION 2.1, SEP 2010ToyinNo ratings yet

- Drilling PPDocument26 pagesDrilling PPAnonymous T32l1R100% (1)

- FLUENT - Tutorial - VOF - Drop Ejection From A Printhead NozzleDocument11 pagesFLUENT - Tutorial - VOF - Drop Ejection From A Printhead Nozzlemootaz_ahmed464No ratings yet

- Brake System 1 PDFDocument43 pagesBrake System 1 PDFKarthi KeyanNo ratings yet

- A New Hybrid Thermal Comfort Guideline For The Netherlands (ISSO 74: 2014)Document12 pagesA New Hybrid Thermal Comfort Guideline For The Netherlands (ISSO 74: 2014)ramy86No ratings yet

- Unit 9 Coordination QN BankDocument6 pagesUnit 9 Coordination QN BankDharaneesh S.k.No ratings yet

- Chemistry of The Ironmaking by Blast Furnace Process - IspatguruDocument7 pagesChemistry of The Ironmaking by Blast Furnace Process - IspatguruSanjeev Sahu100% (1)

- Experiment (13) : Flow ChannelDocument10 pagesExperiment (13) : Flow ChannelSaikumar GadaleNo ratings yet

- MULTIPLE APPLICATIONS OF GEOCHEMICAL PRODUCTION ALLpdfDocument2 pagesMULTIPLE APPLICATIONS OF GEOCHEMICAL PRODUCTION ALLpdfrahulscribd007No ratings yet

- 12.7, 12.8, 12.9, 12.10, 12.14 PDFDocument5 pages12.7, 12.8, 12.9, 12.10, 12.14 PDFSaiAditya11No ratings yet

- Review Synthesis Properties and Practical ApplicationDocument23 pagesReview Synthesis Properties and Practical ApplicationRasha El-GhazawyNo ratings yet

- Chapter 3: Oxidation and Reduction Form 5 Chemistry Title: Rusting As A Redox ReactionDocument3 pagesChapter 3: Oxidation and Reduction Form 5 Chemistry Title: Rusting As A Redox Reactionryder1man6433No ratings yet

- Beer Lambert LawDocument5 pagesBeer Lambert LawPriya SharmaNo ratings yet

- Akta Pure Chromatography SystemDocument14 pagesAkta Pure Chromatography SystemCeli OlmedoNo ratings yet

- Resource 20240531183309 Class X, Holidays HW, 2024-2025Document8 pagesResource 20240531183309 Class X, Holidays HW, 2024-2025kirna516No ratings yet

- R Series User Manual ENDocument99 pagesR Series User Manual ENeka_setyowati0No ratings yet

- Fluid Mechanics, Lecture 3Document22 pagesFluid Mechanics, Lecture 3Adhi FebrianNo ratings yet

- Overall Order of Irreversible Reactions From The Half-Life TDocument15 pagesOverall Order of Irreversible Reactions From The Half-Life Talice AnnabelleNo ratings yet

- National Comfort Institute - Measure and Interpret Static PressuresDocument5 pagesNational Comfort Institute - Measure and Interpret Static PressurescrisNo ratings yet

- Bab 2 - Coal Handling PlantDocument10 pagesBab 2 - Coal Handling PlantmasgrahaNo ratings yet

- W.M.van Boggelen AAC Innovations From A Life Cycle PerspectiveDocument10 pagesW.M.van Boggelen AAC Innovations From A Life Cycle PerspectiveEfrain TlacaelelNo ratings yet

- Bottom Hole PressureDocument12 pagesBottom Hole PressurebrayangtNo ratings yet

- Stirred Tank Reactors FinalDocument65 pagesStirred Tank Reactors Finalhap1313100% (1)

- If T Food ExperimentsDocument63 pagesIf T Food ExperimentsMuhammad Sohail AkramNo ratings yet

- Interactive Textbook 3 PDF Mixtures3 3Document9 pagesInteractive Textbook 3 PDF Mixtures3 3api-240094705No ratings yet

- What Is "Wandering" in Literature and Literary Criticism?Document2 pagesWhat Is "Wandering" in Literature and Literary Criticism?Julian ScuttsNo ratings yet

- Anionici PDFDocument1 pageAnionici PDFAnonymous HKuYF6kNo ratings yet

- Lembar Kerja Percobaan 1 No. Gambar Struktur 2D Dan Nama IUPAC Parameter Fisika Kimia Struktur 3D Yang Telah DiminisasiDocument3 pagesLembar Kerja Percobaan 1 No. Gambar Struktur 2D Dan Nama IUPAC Parameter Fisika Kimia Struktur 3D Yang Telah DiminisasiNur AmaliaNo ratings yet

- Implementation of The Adventure of Element Game As Learning Media During Covid-19 PandemyDocument8 pagesImplementation of The Adventure of Element Game As Learning Media During Covid-19 PandemyruslyhidayahNo ratings yet

- QBE2002-PDocument4 pagesQBE2002-PAnonymous 7z6OzoNo ratings yet