Professional Documents

Culture Documents

Tang Jian An

Tang Jian An

Uploaded by

Nadiah Abdul RahamanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tang Jian An

Tang Jian An

Uploaded by

Nadiah Abdul RahamanCopyright:

Available Formats

COMPRESSIVE STRENGTH OF NORMAL STRENGTH CONCRETE (NSC) USING

BRITISH STANDARD, EURO CODE AND NON- DESTRUCTIVE TEST

APPROACHES

TANG RAN AN

A thesis submitted in partial fulfillment of the requirements for the award

of degree of Bachelor of Civil Engineering.

Faculty of Civil Engineering and Earth Resources

Universiti Malaysia Pahang

NOVEMBER 2010

ABSTRACT

Concrete is a very important material and widely used in construction industry. It

offers stability and design flexibility for the residential marketplace and environmental

advantages through every stage of manufacturing and use. Locally, the characteristic

compressive strength is usually measured based on

150 mm cubes according to BS

approach. But in future, the design compressive strength is usually based on the standard

150 x 300 mm cylinders as recommendation by Eurocode. Compression Test, Rebound

Hammer Test and Ultrasonic Pulse Velocity Test method are used to determine the

compressive strength. Each of the method gives the different method to measure

compressive strength value. Experimental results indicate that the ratio of cylinder to

cube samples was ranging between 0.70 and 0.83. It was found, that on average, the

ratio of the compressive strength of 150 x 300 mm cylinders to 150 mm cubes was 0.79.

Rebound Hammer method was preferable to be used for Non Destructive Test due to the

slightly differences of compressive strength value compared to Ultrasonic Pulse

Velocity method. A comparison of the compressive strength between Compression Test

method on cube, Rebound Hammer method and Ultrasonic Pulse Velocity method on

prism was performed. These types of methods were chosen because it represented

Destructive and Non Destructive test that are most commonly used locally in the

construction industry and research.

V

ABSTRAK

Konkrit merupakan bahan yang sangat penting dan digunakan secara meluas

dalam industri pembinaan. Konkrit memberi kestabilan dan rekabentuk yang fleksibel

untuk pasaran perumahan tempatan dan kebaikan alam sekitar melalui setiap fasa a

pembuatan dan kegunaannya. Ciri- ciri kekuatan mampatan di tempatan biasanya

disukat berdasalkan kiub bersaiz 150mm yang mana mengunakan piawaian British.

Tetapi, dalam era mendatang, kekuatan mampatan rekabentuk selalunya berdasalkan

piawaian silinder yang bersaiz 150 x 300 mm seperti yang dicadangkan oleh Eurocode.

Kaedah ujian Mampatan,ujian Rebound Hammer dan ujian Ultrasonic Pulse Velocity

digunakan untuk menentukan kekuatan mampatan.konkrit Setiap kaedah memberi

kaedah yang berlainan untuk mengukur nilai kekuatan mampatan. Keputusan kajian

menunjukan nisbah silinder kepada kiub adalah antara 0.70 dan 0.83. Keputusan kajian

didapati bahawa purata nisbah bagi kekuatan mampatan untuk 150 x 300 mm silinder

kepada 150mm kiub adalah 0.79. Kaedah Rebound Hammer lebih sesuai digunakan

sebagai Ujian Tanpa Musnah disebabkan perbezaan kekuatan mampatan yang sedikit

berbanding dengan Kaedah Ultrasonic Pulse Velocity. Perbandingan daya mampatan

antara kaedah ujian mampatan, kaedah ujian Rebound Hammer dan kaedah ujian

Ultrasonic Pulse Velocity pada prisma dilakukan. Jenis kaedah ujian mi dipilih kerana

ujian Musnah dan Tanpa Musnah yang paling sering digunakan secara tempatan dalam

industri pembinaan dan kajian penyelidikan.

v i

TABLE OF CONTENT

CHAPTER

TITLE

PAGE

TITLE

i

DECLARATION

i i

DEDICATION

i i i

ACKNOWLEDGEMENT

i v

ABSTRACT

v

ABSTRAK

v i

TABLE OF CONTENTS

v i i

LIST OF TABLES

x i

LIST OF FIGURES

x i i

LIST OF SYMBOLS

x i v

INTRODUCTION

1.1General

1

1.2Problem Statements

2

1.3Objectives of Study

3

1.4Scopes of Study

4

2LITERATURE RI VIEW

2.1 Introduction

5

2.2 Compressive Strength of Concrete

6

2.3 Relationship between Cube Concrete and Cylinder6

Concrete

2.4 Effect of Placement Direction on Compressive8

vii

viii

- -

Strength for Normal Strength Concrete and High

Strength Concrete

2.5

Non Destructive Test: Rebound Hammer

1 0

2.6

Non Destructive Test :Ultrasonic Pulse Velocity

ii

2.7 Cement

1 1

2.8 Water

1 3

2.9 Aggregate

1 3

2.9.1 Coarse Aggregate

1 4

2.9.1 1 Natural Crushed Stone

1 4

2.9.1 .2 Natural Gravel

i

2.9.1 .3 Artificial Coarse Aggregate

1 5

2.9.1 .4 Heavyweight and Nuclear- Shielding

1 5

Aggregate

2.9.2 Fine Aggregate

1 5

2.1 0

Characteristic Strength of Concrete

is

2.1 1 Workability

1 7

2.1 2 Consistency

1 8

2.1 3 Bleeding

1 8

2.1 4 Curing

1 8

2.1 4 .1 Water Curing (WAC)

1 9

2.1 4 .2 Wrapped Curing (WRC)

1 9

2.1 4 .3 Dry Air Curing (DAC)

1 9

2.1 4 .4 Effect of Curing on Compressive Strength

20

Concrete

2.1 5

Type of Failures of Cube Concrete

20

i x

3

METHODOLOGY-

3.1 Introducti on

2 2

3.2 Ex peri mental Program

2 3

3.3

Materi al Selecti on

2 4

3.3. 1 . Cement

2 4

3.3.2 Water

25

3.3.3 Aggregate

25

3.4 Preparati ons of Speci mens

2 7

3.4 .1 Concrete Mi x Desi gn

2 8

3.4 .2 Batchi ng, Mi x i ng and Casti ng

2 9

3.4 .3 Number of Speci mens

30

3.5 Mould

30

3.5.1 Cyli nder Mould

31

3.5.2 Cube Mould

31

3.5.3 Pri sm Mould

32

3.6 Curi ng

33

3.7 Mechani cal Properti es Testi ng Method

34

3.7 .1 Compressi ve Strength Test

34

3.7 .1.1 Compressi ve Strength Test of Cube

35

and Cyli nder Speci men

3.7 .2 Rebound Hammer Test Speci men

35

3.7 .3 Ultrasoni c Pulse Veloci ty Test

36

3.8 Analysi s of Data

37

3.8 .1 Calculati on of Compressi ve Strength Test

37

3.8 .2 Calculati on of Ultrasoni c Pulse Veloci ty Test

38

x

4

RESULTA ND DISCUSSION

4.1 General

3 9

4.2

Results on Compressive Strength

40

4.2.1 Compressive Strength between Cube and

41

Cylinder at Grade 20

4.2.2 Compressive Strength between Cube and

42

Cylinder at Grade 3 0

4.2.3 Compressive Strength between Cube and

44

Cylinder at Grade 20 and Grade 3 0

4.3

Result of Rebound Hammer Test

47

4.4

Result of Ultrasonic Pulse Velocity (UPV)

5 0

4.5

Summary on Compression Test, Rebound

5 3

Hammer Test and Ultrasonic Pulse Velocity Test

at Days 7 and Days 28

5

CONCLUSIONS AND RECOMMENDATIONS

5 .1 Introduction

5 7

5 .2 Conclusion

5 7

5 .3 Recommendation

5 8

REFERENCES

5 9

APPENDIX A

6 2

APPENDIX B

6 7

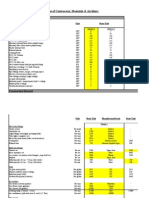

LIST OF TABLES

TABLE NO. TITLE

PAGE

2.1

Strength and Elastic Properties of British Standard and

16

Euro Code 2

3.1

Proportion of Material for Concrete Mix Design

28

Grade 20 and Grade 30

3.2 Detail of Specimen Testing

30

4.1

Cube and Cylinder Strength of Grade 20 and Grade 30

40

at 7 and 28 days.

4.2

Average Compressive Strength of Cube 150mm and 45

Cylinder 150 X 300mm

4.3

Result for Rebound Hammer Test at 7 and 28 Days

48

4.4 Result for Rebound Hammer Test at 7 and 28 Days

48

4.5

Result for Ultrasonic Pulse Velocity Test (UPV)

5 1

at 7 Days

4.6

Result for Ultrasonic Pulse Velocity Test (UPV)

5 2

at 28 Days.

4.7

Compression Test, Rebound Hammer Test and

5 4

Ultrasonic Pulse Velocity Test (UPV) at days

7 and 28 days.

xi

LIST OF FIGURES

FIGURE NO.

TITLE

PAGE

2.1

Cube strength against the cylinder compressive strength

7

for representative specimen sizes.

2.2(a)

Relationship between compressive strengths against

9

diameter cube of Normal Strength Concrete.

2.2(b)

Relationship between compressive strengths against

9

diameter Cube of High Strength Concrete.

2.3

Compressive strength against the specific surface of

12

cement

2.4 Typical short term stress strain curves for normal

17

strength concrete in compression.

2.5

Effect of curing on the compressive strength of concrete

20

2.6 Satisfactory failures

21

2.7 Unsatisfactory failures

21

3.1 Experimental Process flows

23

3.2 Cement

24

3.3 Coarse Aggregate

26

3.4 Fine Aggregate

26

3.5 Mechanical Sieve Shaker

27

3.6 Automatic Concrete Mixer

29

3.7 Slump Test

29

3.8 Concrete cylinder mould

31

3.9 Cube mould

32

xli

3.10

-Concrete-Prism Mould

32

3.11 Curing tank

, 33

3.12

Compressive Strength Machine

34

3.13 Rebound Hammer

36

3.14

Pundit Pulse Velocity Meter

37

4 .1

Compression strength of 7 and 2 8 days between the

4 2

Cube and Cylinder strength at Grade 2 0.

4 .2

Compression strength of 7 and 2 8 days between the

4 3

Cube and Cylinder strength at Grade 30

4 .3

Compression strength of 7 and 2 8 days between the

4 4

Cube and Cylinder strength at Grade 2 0 and Grade 30

4 .4

Compressive strength of concrete '150 mm cubes

4 5

versus 150 x 300 mm cylinders

4.5

Failure of cube specimen during 7 and 2 8 days.

4 6

4 .6

Failure of cylinder specimen during 7 and 2 8 days.

4 7

4 .7

Rebound Hammer Test at 7 and 2 8 days for Grade 2 0

4 9

and Grade 30

4 .8

Rebound Hammer Test

4 9

4 .9

Result of Ultrasonic Pulse Velocity Test at 7 and 2 8

53

days for Grade 2 0 and Grade 30.

4 .10

Ultrasonic Pulse Velocity Test (UPV)

53

4 .11

Concrete strength of Compression Test, Ultrasonic

54

Pulse Velocity Test and Rebound Hammer Test for

Grade 2 0 and Grade 30 at 7 days

4 .12

Concrete strength of Compression Test, Ultrasonic

55

Pulse Velocity Test and Rebound Hammer Test for

Grade 2 0 and Grade 30 at days 2 8

xlii

LIST OF SYMBOLS

fck

-Characteristic cylinder strength

fYd

- Design yield strength

fc -Concrete strength

-Partial safety factor

T -Time in second

V -Velocity

cm -Centimeter

mm -Millimeter

km -Kilometer

UPV -Ultrasonic Pulse Velocity

NSC -Normal Strength Concrete

NDT -Non Destructive Test

ASTM -American Society of Testing Material

xiv

CHAPTER 1

INTRODUCTION

1.1General

Concrete is a construction material composed of cement (commonly Portland

cement) as well as other cementations' materials such as fly ash and slag cement,

aggregate (generally a coarse aggregate such as gravel, limestone, or granite, plus a fine

aggregate such as sand), water, and chemical admixtures. Concrete is a very important

material and widely used in construction industry. It offers stability and design

flexibility for the residential marketplace and environmental advantages through every

stage of manufacturing and use. There are many advantages of concrete such as built-in-

fire resistance, high compressive strength and low maintenance.

Various methods of concrete testing are carried out to ensure that it remains of

adequate strength and durability. Testing method such as Non-destructive method,

British Standard and Euro code are used to determine the compressive strength. Each of

the method gives the different type of compressive strength value. In most structures,

concrete is often subjected to biaxial states of stress, and the behavior of the material

under these types of loadings must be well understood.

2

It is therefore not surprising that numerous investigations into the behavior and

strength of Normal Strength Concrete (NSC) under biaxial stresses have been done in

the past 40 years. On the other hand, High Performance Concrete difference from

Normal Strength Concrete in several.

In normal strength concrete, the micro cracks form when the compressive stress

reaches until 40% of the strength. The cracks interconnect when the stress reaches 80-

90% of the strength. The fracture surface in NSC is rough. The fracture develops along

the transition zone between the matrix and aggregates. Fewer aggregate particles are

broken. Marcio (2 002 )

1.2Problem Statements

Eurocode 2 (EC2 ) defined as a set of ten Eurocode programme in European

Standard that contains the design standard for concrete structures. EC2 gives many

benefits such as less restrictive than British Standard, extensive and comprehensive,

logic and organized to avoid repetition and the new EC2 are claimed to be the most

technically advanced codes in the world. In Europe, all the public works must allow the

Eurocodes to be used for structural design. (Moss et.al

2 004)

According to the grade of concrete, EC2 allows benefits to be derived from using

which BS8 110 does not. Concrete strengths are referred to by cylinder strength, which

are typically 10-2 0% less than the corresponding cube strengths. The maximum

characteristic cylinder strength,

fk

permitted is 90 N/mm2 which corresponds to

characteristic cube strength of 105 N/mm2 .

A basic material partial safety factor,

7m

of EC2 for concrete is 1.5 compared to

reinforcing steel in B S 8 110 which the material partial safety factor was reduced from

1.15 to 1.05 several year ago.

3

This is unlikely to have any practical impact however as steel intended to meet -

the existing yield strength of 460N/mm2

assumed by BS8 110 is likely to be able to meet

the 500N/mm2

assumption made by EC2 , so that the design yield strength,

fyd

will be

virtually identical (Moss et.al 2 002 ).

Use of the EC2 will provide more opportunity for United Kingdom (UK)

designers to work throughout Europe and for Europeans to work in the UK (Moss et.al

2 004).

Similarly to the Malaysian designer whose are going to work in Europe gives

advantages when design compressive strength of the building. Most importantly,

Eurocode going to introduced all over the world included Malaysia.

So the compressive strength of Eurocode when applying concrete design in

Malaysia building due to the different climate and material used compare to the

Eurocode in European is questionable.

1.3Objective of Study

This project has three main objectives which are:-

i.

To determine compressive strength of Normal Strength Concrete (NSC) using

British Standard and Euro Code method.

ii. To check the strength using Non Destructive Test (NDT).

iii. To compare compressive strength using different method of testing.

4

1.4Scope of Study

The scopes of this study are:

Normal strength concrete covered are 20 N/mm

2 and 30 N/mm2

ii.

Non Destructive Test used are Rebound Hammer and Ultrasonic Pulse Velocity.

iii.

Sample will be cured in water for duration of 7 and 28 days.

iv.

All the testing will be carried out at the 7 and 28 days of concrete.

V.

Compressive strength test will be conducted to BS 1881 :PART 116:1983 and

ASTM:C 39/C 39m-04

CHAPTER 2

LITERATURE REVIEW

2.1Introduction

Based on the Balaguru et.al (1992) research, with the rapid development in

concrete technology, concrete of strength over 100 MPa can be easily produced with

ordinary materials and conventional mix methods. Clarke (1994) stated that high

strength normal or high strength lightweight concrete offers more options for the design

of tall buildings and long-span bridges.

According to the Zhou et.al. (1994) in Fracture mechanical properties of high

strength concrete with varying silica fume contents and aggregates , the main concern

with high strength concrete is the increasing brittleness with the increasing strength.

Therefore, it becomes a more acute problem to improve the ductility of high strength

concrete.

Most accumulated experience in normal strength "bre-reinforced" concrete may

well be applicable to high strength concrete but the effectiveness of "bre reinforcement"

in high strength concrete may be different and thus needs to be investigated.

2.2Compressive Strength of Concrete -

According to Seong et.al . (2005), the compressive strength of concrete is used as

the most basic and important material property when reinforced concrete structures are

designed. It has become a problem to use this value, however, because the control

specimen sizes and shapes may be different from country to country.

The ultimate strength of concrete is influenced by the water-cementitious ratio

(w/cm), the design constituents, and the mixing, placement and curing methods

employed. All things being equal, concrete with a lower water-cement (cementitious)

ratio makes a stronger concrete than that with a higher ratio.

In this study, the effect of specimen sizes, specimen shapes, and placement

directions on compressive strength of concrete specimens was experimentally

investigated based on fracture mechanic. The analysis results show that the effect of

specimen sizes, specimen shapes, and placement directions on ultimate strength is

present. In addition, correlations between compressive strengths with size, shape, and

placement direction of the specimen are investigated.

2.3 Relationship between Cube Concrete and Cylinder Concrete

According to Seong et.al (2005), relationship between specimen shapes shows

the cube strength against the cylinder compressive strength for representative specimen

sizes.

7

lot.

60

so

I

( b ) % : 1 1

-

- 0.069 * OAS .'-y.O.9I x + 10.49

___

20400060100 0 2040606010

I 50i300 mm cylinder strength (MPn)

4

I 50x300 mm cylinder strength (MPs)

lot' lot.

(c)

CL

so

I ___

20L 20

y..0.969 7.47

i 0 * 9.00

C..

0 20406080100 0 20406080100

100x200 mm cylinder strength (MPa)

1006200 mm Cylinder strength (MPa)

Figure 2.1 : Cube strength against the cylinder compressive strength for representative

specimen sizes. (Seong et.al . ,2005)

In these figures, solid lines and dashed lines indicate the best-fit lines obtained

from the linear regression analyses and the lines of equality y = x, respectively. In

addition, the equations shown are obtained from the linear regression analyses with test

data points.

Figure 2.1 divided into 4 types of specimens size that is (a) Relationship between

compressive strengths of 150 mm cube and 0150 mm

x

300 mm cylinder; (b)

relationship between compressive strengths of 100 mm cube and 0150 mm

x

300 mm

cylinder; (c) relationship between compressive strengths of 100 mm cube and

0100 mm

x

200 mm cylinder; (d) relationship between compressive strengths of

150 mm cube and 0100 mm

x

200 mm cylinder.

8

The 15 mmcube strength, - whenplottedagainst the corresponding

0150 mm

x

300 mmcylinder strengthas showninFigure 2.1a), shows that cube

strengthis higher for lower grades of concrete.

At approximately 65MPa, however, the twostrengths become identical. After

that point, standardcylinders indicate a slightly higher strengththanthat of the

correspondingcubes.

Meanwhile, the relationshipbetweenprisms andcylinders canbe analogized

fromsome literatures. Namely, Markeset andHillerborg(1995) experimentally showed

that the post-peak energy per unit area is independent of the specimenlengthwhenthe

slenderness is greater thanapproximately 2.50 for concrete -cylinders.

JansenandShah(1997) alsoexperimentally showedthat pre-peak energy per

unit cross-sectional area increases proportionally withspecimenlengthandpost-peak

energy per unit cross-sectional area does not change withspecimenlengthfor lengths

greater than20.0 cminconcrete cylinders.

Kimet al. (2001) concludedthat flexural compressive strengthdoes not change

for specimens havinga lengthgreater than30.0 cmfor C-shapedconcrete specimens

havinga rectangular cross-section. Fromthese contents, it canbe concludedthat the

relationshipbetweenprisms andcylinders will be similar withthe relationshipbetween

cubes andcylinders.

2.4Effect of Placement Direction on Compressive Strength for Normal Strength

Concrete and High Strength Concrete

According to the Seong.et.al

(2005), Figure 2.2 a) and b) show cube placement

direction is parallel to the loading direction; the compressive strength is higher than the

normal case. For Normal Strength Concrete, the size effect difference with displacement

direction is not distinct compared to HSC. The reason is that, for NSC, the general

fracture mechanism based on the movement of water is changed by the end restraint

effect occurred due to the machine platen as well as the failure pattern (in this study, it is

a crushing failure).

Accordingly, the strengths of-both specimens become a similar value. And, when

the compressive test for cubes is performed, since the loading direction is normal to the

placement direction, no homogeneous characteristics occurred due to the settlement

difference of materials is additionally reflected on the reduction of the strength. Namely,

the size effect of cubes is more apparent compared to cylinders regardless of strength

level.

(a)CoNorent

1,4

cpNstth

j

CUD

-.U

I)

O9-------.,.

-,0.8..,i----,-.

051015202$05101520

d(crn)

d(cmj

Figure 2.2: a) Relationship between compressive strengths against diameter cube of

Normal Strength Concrete. b) Relationship between compressive strengths against

diameter cube of High Strength Concrete (Seong.et.al , 2005)

1 0

25 Non Destructive Test: Rebound Hammer

According to the British Standard Institution, the use of rebound hammers is for

testing the hardness of concrete. It describes the areas of application of rebound

hammers, their accuracy, the calibration procedure, the procedure for obtaining a

correlation between hardness and strength, the conditions of the concrete.

According to Hisham (20 0 0 ), the term "nondestructive" is given to any test that

does not damage or affect the structural behavior of the elements and also leaves the

structure in an acceptable condition for the client. According to Malhotra (1 976), Non

destructive methods normally used for concrete testing and evaluation. However, a

successful nondestructive test is the one that can be applied to concrete structures in the

field and be portable and easily operated with the least amount of cost.

Hardness measurements can be used in the production of concrete where it may

be desirable to establish the uniformity of products or similar elements in a structure in

situ at a constant age, temperature, maturity and moisture condition. Measurements can

also be used to define areas of different quality prior to testing by other methods,

possibly using destructive tests. Hardness measurements provide information on the

quality of the surface layer (about 30 mm deep) of the concrete only. Rebound hammers

are unsuitable for detecting strength variations caused by different degrees of

compaction. If the concrete is not fully compacted strength cannot be reliably estimated.

A wet surface gives lower rebound hammer readings than a dry surface. This effect can

be considerable and a reduction in rebound number of 20 % is typical for structural

concrete, although some types of concrete can give greater differences.

Tests on molded surfaces are generally to be preferred. Lack of quantitative

evidence on how different surfaces behave under a hardness test can lead to considerable

errors if results are compared. In such cases separate calibrations are necessary.

I

2.6Non Destructive Test: Ultrasonic Pulse Velocity

Ultrasonic pulse velocity equipment measures the transit time of a pulse between

transducers placed on the surface of a body of concrete. The pulse velocity can then be

calculated using the measured path length through the concrete. The pulse velocity

depends upon the dynamic Young's modulus, dynamic Poisson's ratio and density of the

medium.

According to the BS 1881-201(1986), the principal advantages of ultrasonic

pulse velocity measurement are that it is totally non-destructive, quick to use and reflects

the properties of the interior of a body of concrete. It is particularly valuable in

circumstances where a considerable number of readings is required for the assessment of

uniformity of hardened concrete.

According to Manish and Gupta (2005), numerous attempts to use Ultrasonic

Pulse Velocity (UPV) as a measure of compressive strength of concrete have been made

due to obvious advantages of non-destructive testing methods.

2.7Cement

Generally, cement can be described as a material with bonding agent and

cohesive properties, which it make it proficient of bonding mineral fragments into a

solid hole. Portland cement is hydraulic cement that hardens by interacting with water

and forms a water resisting compound when it receives its final set. Portland cements are

highly durable and produce high compressive strengths in mortars and concrete.

Portland cement is made of finely powdered crystalline minerals composed primarily of

calcium and aluminum silicates

1 2

The strength of cement paste is the result of a process of hydration. The early

strength of Portland cement, is higher with higher percentages of C3 S. If moist curing is

continuous, later strength level becomes greater with higher percentages of C 2 S. C3 S

contributes to the strength developed during first day after placing the concrete because

it is the earliest to hydrate.

The size of the cement particles has a strong influence on the rate of reaction of

cement with water. For a given weight of finely ground cement, the surface area of the

particles is greater than that of the coarsely ground cement. Finely ground cement is

desirable in that they increase strength, especially at the early age, by the way increase

workability.

These result in a greater rate of reaction with water and a more rapid hardening

process for larger surfaces areas. This is one of the reasons for the use of high early

strength type m cement. It gives in 3 days the strength that type I gives 7days, primarily

because of the finer size of its particles. Figure 2 .3 show that specific surface in square

centimeters per gram of cement, on the compressive strength of concrete at four

different ages.

'V'"

rAO

a

6.000----

"-- I

41.4

-

-iU

28-DAVAGE

n::::

J AGE

: : :

<Tf

J ]

1 5 0

20 0 25 0 3 0 0

SPECIFIC SURFACE, m2/kg of CEMENT

Figure2.3:

Compressive strength against the specific surface of cement (Charles,2 007)

1 3

2.8 Water

According to the Charles (2007), water used for mixing concrete should be free

from impurities that could adversely affect the process of hydration and, consequently,

the properties of concrete. BS EN 1 008 specifies requirements for the water and gives.

procedures for checking its suitability for use in concrete.

Drinking water is suitable, and it's usually simply to obtain from local water

utility. Some recycled water is being increasing by used in the interest of reducing the

environment impact of the concrete production. Some organic matter can cause

retardation, whilst chloride may not only accelerate the stiffening process but also cause

embedded steel.

According to Nawy (2000), gradual evaporation of excess water from mix, pores

are produced in the hardened concrete. If the pores are evenly distributed, they could

give improved characteristic to the product. Very even distribution of pores by artificial

introduction of finely divided uniformly distributed air bubbles throughout the product is

possible by adding air-entraining agents. Air entrainment increases workability,

decreases density, increases durability and frost resistances, reduces bleeding and

segregation, and reduces the required sand content in the mixture. Optimum air content

is 9% of mortar fraction of the concrete. Air entraining in excess of 5-6% of the total

mix proportionally reduced concrete strength proportionally.

2.9Aggregate

Aggregate are those parts of the concrete that constitute the bulk of the finished

product. They comprises 60-80% of the volume of the concrete and have to be so graded

that the entire mass of concrete acts as a relatively solid, homogeneous, dense

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pollak Residence - Progres SetDocument32 pagesPollak Residence - Progres SetLuci MenaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Proposal Stressing BECAKAYU 2A Ujung L 32.90 M - H 1.85M PAYN 6 - 7 TengahDocument46 pagesProposal Stressing BECAKAYU 2A Ujung L 32.90 M - H 1.85M PAYN 6 - 7 TengahMuhammad Zulfikar FauziNo ratings yet

- Dam DesignDocument176 pagesDam DesignAnonymous CPEha1db7UNo ratings yet

- Vedafeu Range HDDocument28 pagesVedafeu Range HDDan STEFANNo ratings yet

- The Influence of High Volume of Fly Ash and Slag On The Compressive StrengthDocument8 pagesThe Influence of High Volume of Fly Ash and Slag On The Compressive StrengthSyamsudin rudiNo ratings yet

- 1.5 Types of Portland CementDocument16 pages1.5 Types of Portland Cementm_zaimieNo ratings yet

- Astm C939 PDFDocument4 pagesAstm C939 PDFSrihariKyatamNo ratings yet

- Antisol - WB: Curing Priming/Sealing and Surface Hardener Compound For Freshly Laid ConcreteDocument2 pagesAntisol - WB: Curing Priming/Sealing and Surface Hardener Compound For Freshly Laid ConcreteDilon TkhomaNo ratings yet

- House Building Cost DataDocument17 pagesHouse Building Cost Datasyed usman wazir100% (7)

- Cast-In Place ConcreteDocument217 pagesCast-In Place ConcreteFarid ObandoNo ratings yet

- Building Construction MCQs 1 To 54Document11 pagesBuilding Construction MCQs 1 To 54rk05pittaNo ratings yet

- Post-Tensioned Anchorage Zone - A ReviewDocument18 pagesPost-Tensioned Anchorage Zone - A ReviewPartha Pratim RoyNo ratings yet

- Evaluation of Compressive StrengthDocument11 pagesEvaluation of Compressive StrengthJayChristian QuimsonNo ratings yet

- Soil Stabilization Using LimeDocument55 pagesSoil Stabilization Using LimekoppolusrinivasuluNo ratings yet

- Freeze-Thaw and De-Icing Salt Durability of Solid Concrete Interlocking Paving UnitsDocument2 pagesFreeze-Thaw and De-Icing Salt Durability of Solid Concrete Interlocking Paving Unitsmahmoud hakimNo ratings yet

- BOQ & Resource Assignment-Initials !Document2 pagesBOQ & Resource Assignment-Initials !Anteneh tesfayeNo ratings yet

- Precious Metals Recovery BrochureDocument32 pagesPrecious Metals Recovery BrochureNelson GutierrezNo ratings yet

- Daniel Tian Li: Concrete Column Design Based On ACI 318-05Document3 pagesDaniel Tian Li: Concrete Column Design Based On ACI 318-05Mirko Aliaga100% (1)

- Sikaplast®-5202 NS: Product Data SheetDocument2 pagesSikaplast®-5202 NS: Product Data Sheetrajesh kumar100% (1)

- Strut and Tie Models ACIDocument13 pagesStrut and Tie Models ACIRômulo Menck RomanichenNo ratings yet

- Reinforced Cement Concrete - Introduction - Study NotesDocument16 pagesReinforced Cement Concrete - Introduction - Study Notessachinxyz9661No ratings yet

- Mivan Formwork SystemDocument16 pagesMivan Formwork SystemVijayanandNo ratings yet

- HOLLOW-CORE SLAB SYSTEMS Information ManDocument36 pagesHOLLOW-CORE SLAB SYSTEMS Information ManEng.wissam Safaa100% (1)

- Waterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaDocument6 pagesWaterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaThink itNo ratings yet

- Parametric Optimizationof RCCantilever RetainingwallsDocument8 pagesParametric Optimizationof RCCantilever RetainingwallsShamsher SadiqNo ratings yet

- GRAVITY DAM Part 2 - Stability Analysis Load Combinations - Keerthana Thayalan - AcademiaDocument12 pagesGRAVITY DAM Part 2 - Stability Analysis Load Combinations - Keerthana Thayalan - AcademiaGaddam Padmaja ReddyNo ratings yet

- Design Guide Basement WaterproofingDocument22 pagesDesign Guide Basement WaterproofingSevrinNo ratings yet

- Chapter 5 Buildability - 0Document87 pagesChapter 5 Buildability - 0Judy TanNo ratings yet

- BIPSEDocument5 pagesBIPSEsundram singhNo ratings yet

- ETABS Manual by AtkinsDocument46 pagesETABS Manual by AtkinsRudy Kusardi60% (5)