Professional Documents

Culture Documents

Design Reportof Baja Sae India 2010

Design Reportof Baja Sae India 2010

Uploaded by

Deepak LambaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Reportof Baja Sae India 2010

Design Reportof Baja Sae India 2010

Uploaded by

Deepak LambaCopyright:

Available Formats

Institute Of Technology And Management

Gurgoan, Haryana

SAE Baja Asia 2010

The Techie Tyros

Design Report 2010

DESIGNED BY

Vikrant Dalal

Vice-captain and Head of Design Team

#TTT-3

SAE BAJA ASIA 2010 Design Report

Vikrant Dalal

Vice-captain, Head of Design Team

Copyright 2009 SAE International

1.0 ABSTRACT

The objective of the Baja competition is to design a Baja

all-terrain vehicle that embodies innovation, simplicity

and functionality, delivering high performance and safety

at a reasonable price. This report details the

considerations, functions and processes behind the

separate vehicle subassembly

2.0 INTRODUCTION

Baja-2010 is an international competition sponsored by

the Society of Automotive Engineers (SAE). Engineering

students are given a challenge to design, simulate and

manufacture a fun to drive, versatile, safe, durable, and

high performance off road vehicle.

The Techie Tyros 2010 Baja team consists of 22

undergraduate students in Automotive and Mechanical

Engineering. The goal of the 2010 car is to improve on

some of the key areas that have caused the team

problems over the last few competition years. These

areas are: suspension, steering, driveline, hub and

fabrication tolerances. It was decided that, while making

components lightweight is important, strength and

durability of key components would not be sacrificed for

weight reduction. All subassemblies and components

were researched and designed to meet pre-established

team expectations.

For designing, simulation, analysis and optimization of

the vehicle components various software such as Pro-E

(design and analysis), Cosmos (analysis and

simulation), Optimum K and suspension analyzer

(Suspension design and analysis), ADAMS and IPG car

maker (vehicle dynamics) are used.

The design targets of our vehicle for Baja 2010 are as

follows:

1. Maximum speed 60 km/hr

2. Weight of vehicle 270 kg

3. Ground clearance 20 cm or 8 inch

4. Track width 140 cm or 56 inch approx

5. Wheel base 130 cm or 52 inch approx

6. Braking distance 1400 cm

7. Turning radius 240 cm or 96 inch

3.0 MAIN SECTION

The design of Baja 2010 is divided into follow section:

1. CHASIS AND ANALYSIS

2. ENGINE AND TRANSMISSION

3. TYRES

4. BRAKES

5. STEERING

6. SUSPENSION

7. HUB DESIGN

3.1 CHASIS AND ANALYSIS

The kind of body we are required to manufacture is a

unitized body. The roll cage is of utmost importance for

us as it would be the one which would provide safety to

the driver, mounting points for various systems and even

ergonomics and looks to the vehicle.

3.1.1 MATERIAL

The material used in vehicle must fulfill the SAE Baja

requirements. The proper equilibrium should be acquired

between the design requirements, cost and weight to

achieve an unbeaten design. The available materials

that fulfil the requirements are AISI 1018, 1020, IS1239

part-1 and 4130.A comparison was done to select the

material by considering various properties and cost of

each material.

Table 1: Material property

MATERIAL

YIELD

STRENGTH

(KSI)

MODULUS

OF

ELASTICITY

(KSI)

COST

PER

METER

(RS)

ELONGATION

AT YIELD POINT

(%)

AISI 1018

53.7

29700

600

15

AISI 1020

42.7

29700

2200

36

IS 1239

59.12

29700

765

18.5

AISI 4130

65.1

29700

2500

25.5

Graph 1: Weight and Cost comparison

AISI 4130 and IS 1239 part-1 having good yield strength

will allow the usage of tubing with smaller wall thickness.

This will in turn reduce the weight of our chassis. Also

4130 and IS 1239 part-1 are more ductile than other

materials so it will deform more before its ultimate

failure. But cost of per meter length of 4130 is 2.5 times

more expensive IS 1239 part-1. So considering the

above said factors we have chosen IS 1239 part-1 pipes

to be used for our chassis.

3.1.2 FEA ANALYSIS

The initial design is shown in the Figure 1. Some notable

features are the fact that the design consists of 4 main

members: the roll hoop, the horizontal hoop, and the two

perimeter hoops. As mentioned above the design was

made using the Pro-E solid modelling package.

Figure 1: Roll cage model in Pro-E

In order to optimized the strength, durability and weight

of Chassis cosmos was used to analyze the chassis for

all six loading condition. The six analysis tests conditions

are front impact, side impact, rollover impact, heave and

the loading on the frame from the front and rear shocks

After running all five analyses it was found that there is a

need of additional member. After having added these

members, a second analysis using identical loading

constraints was completed and results of these tests are

shown in table 2.

For front collision test stress diagram and displacement

diagram is shown in figure 2 and 3.

Table 2: FEA Analysis results

Type of case Force applied Result

Front Collision 4500 KN Passed

Side Collision 1200 N Passed

Rollover 1800 N Passed

Front Bump 810 N Passed

Figure 2: Stress analysis for front collision

Figure 3: Stress displacement for front collision

76

77

78

79

80

81

82

83

0

500

1000

1500

2000

2500

3000

AISI 1080AISI 1020 IS 1234 AISI 4130

W

i

g

h

t

(

K

G

)

C

o

s

t

(

R

s

)

cost(*10) weight

Comparison between previous years roll cage

design is done and the results are shown in table3.

Table 3: Comparison of pervious 3 years design

2007-BAJA

ROLLCAGE

DESIGN

2008-BAJA

ROLLCAGE

DESIGN

2010-BAJA

ROLLCAGE

DESIGN

SAFETY

Poor

High

High

COMFORT

Average

High

High

ERGONOMIC

Poor

Good

Very good

SPECE FOR

ELECTRONIC

DEVICES

More

Less

Sufficient

WIEGHT

To heavy

Medium

Light

COST OF

ROLLCAGE

High

Low to

high

Low

STANDARDIZATION

9/10

4/10

8/10

3.2 ENGINE AND TRANSMISSION

A quick look at the engine:

Power - 8 kW at 4400 rpm

Max Torque 19 Nm at 3000 rpm

Engine was given to us. Thus we had a little choice while

working on engine. Configuration of our vehicle would be

rear engine rear wheel drive. We decided to keep the

maximum speed of the vehicle at 60 km/hr as the vehicle

is not about larger speed but greater torque and stability.

As per the rules of the competition, the engine cannot be

modified in any way. This restriction causes the design

emphasis to be placed on the choice of transmission.

For the transmission we have several options:

A manual transmission (4 or 5 speed): this system would

allow the driver to select the right gear from the available

gears allowing more control over the vehicle. This is

seen on most manual cars with a standard H pattern.

A sequential transmission: this is similar to the manual

transmission, but the H pattern is eliminated and

replaced with a different shifting pattern. For example in

a race car, the motion of the shift lever is either push

forward to up-shift or pull backward to downshift.

These transmissions are usually found in either

motorcycles or all terrain vehicles. This type is most

suitable of our vehicle as it has good sensitive i.e. why

we are using M&M champion transmission. To increase

the torque following options were available:

1. Manipulation of power transmission outside the gear

box using gears, sprockets and chain.

2. Engaging the reverse gear lever while driving in all

the forward gears and using the first gear in forward

as reverse gear.

3. Using the transmission system in normal conditions.

We decided to work on the 3rd option due to following

reason:

1. We were able to check the weight

2. Reduce the cost of the vehicle as we avoided

the use of additional gears, sprockets and

chains.

3. We used standard parts, thus increased the

reliability of the transmission system.

To find the speed of the vehicle corresponding to

different gear ratios, the formulae used is

Velocity on road =

2NR60

1000

Where,

G=gear ratio

N=revolutions per minute

R=outer radius of the tire in meters.

Some of our calculations for normal orientation are as

follows:

Table 4: Normal orientation

Final

Gear

Ratios

Speed

(km/hr)

Speed (km/hr)

D=22 D=24

inch inch

First 31.45:1 0.65D 14 16

Second 18.70:1 1.109D 24 27

Third 11.40:1 1.82D 40 44

Forth 7.35:1 2.82D 60 68

Reverse 55.08:1 0.38D 10 9

Hence for maximum speed of 60 km/hr, we selected

tires of 22 inch outer diameter.

Further, for better economy, we assume engine rpm to

be ranging from 2750 to 3250 as maximum torque

produced by the engine is at 3000 rpm. In between this

range the torque produced by the engine is almost

constant. Thus, for better economy, the range of speed

in each gear, for the driving tires of O.D. 22 inches;

operating in normal forward orientation is:

First - 10 to 12 km/hr

Second - 15 to 18 km/hr

Third - 25 to 33 km/hr

Forth - 40 to 51 km/hr

Reverse - 8 to 11 km/hr

Apart from this, for mounting the engine we are going to

use neoprene rubber mountings.

3.3 TIRES

Selecting the tires is one of the most important things as

the whole vehicle is in contact with the road on these 4

points or rather patches. Also for designing an all terrain

vehicle tires form the most important part. They should

be such that they are able to provide enough traction on

all kind of surfaces so as to transmit the torque available

at the wheels without causing slipping.

Front

Outer diameter of tire 21 inch

Outer diameter of rim 10 inch

Tread width 6 inch

Aspect ratio 0.68

Number of plies 6

Rear

Outer diameter of tire 22 inch

Outer diameter of rim 10 inch

Tread width 8 inch

Aspect ratio 0.75

Number of plies 6

One of the most important parameter for the selection of

the outer diameter of the tires in rear was the maximum

speed of the vehicle. The relation between outer

diameter of the tires and the vehicle speed is as given

below:

Velocity on road =

For the normal orientation of the transmission system

and maximum speed of the vehicle as 60 km/hr radius

comes out to be 11 inches. Apart from outer radius of

the tire, other factors for the selection of tires include

tread width, tread design, side wall width, load handling

capacity, number of plies and treads on side wall etc

which define the traction ability, tire resistance to wear

and puncture and performance of the tire on various

terrains.

Reason:

1. Built with a 6 ply rating and a reinforced casing

makes these one of the most puncture resistant tires

in the market today.

2. Large shoulder knobs wrap down the sidewall to

provide excellent side to pull out of the ruts without

causing sidewall failure.

3. The deep tread and open wing design provides

excellent clean-out with each lug and an improved

traction.

4. Special natural compound delivers added traction.

5. Smaller tires in front results in a smaller magnitude

of moment on the wishbones due to cornering forces

during steering.

6. Use of the larger outer diameter tire at the rear helps

to provide good ground clearance and also 8 inch

treads provides good traction to the power wheels.

3.4 BRAKES

The criterion for designing the brakes stated as per the

rule book is that all the four wheels should lock

simultaneously as the brake pedal is pressed.

For designing the braking system this year, we

calculated the weight of our vehicle in static condition as

well as in dynamic condition as per the deceleration (0.6

g) and stopping distance. In static condition it is around

60kg on each front tire and 110kg each on the rear tire.

But in dynamic conditions, we consider weight to be

85kg on each tire, the front and the rear. We have

calculated the dynamic weight using the formulae as

given below:

Front axle dynamic load =

1

+

Rear axle dynamic load =

1

Where,

W1=Weight on the front axle in the static condition.

W2=Weight on the rear axle in the static condition.

g = Acceleration due to gravity.

W= Total weight of the vehicle.

H=Height of center of the gravity.

L= Length of the wheel base.

Deceleration of the vehicle is .

We planned to use disc brake in all four wheels. Initially

we thought of using disc brake in front and drum brakes

in rear but problem with drum brake is of locking .For

achieving the condition for locking at once on the

application of brake paddle, it is preferred to use disc in

all four wheels. Some formulas that we used for

designing our brakes:

T (disc) =

1

1

+

2

2

T (disc) = 2 .

Where,

T (disc) = Frictional torque on the disc

f = deceleration

W = weight of the body

R = Effective radius of disc

R1= Radius of front tire

R2= Radius of rear tire

P = Pressure applied by the TMC.

= Coefficient of friction

R=Radius of the disc

A= Area of the caliper for disc brake

P= Pressure applied by the master cylinder.

Using these formulae, we have done our calculation and

selected our brakes. Some of calculations are shown in

the table 5:

Table 5: Brake pedal force calculation

F

kg

Pr

D1

mm

D2

mm

R

inch

R1

inch

R2

inch

3.0 3.21 16.25 16 98 10.5 11

2.5 3.86 16.25 16 98 10.5 11

3.0 3.84 17.78 16 98 10.5 11

3.8 3 17.78 16 98 10.5 11

3.2 3.58 17.78 16 98 10.5 11

3.0 4.44 19.05 16 98 10.5 11

3.2 3 16.25 16 98 10.5 11

Where the parameters shown above are as under:

F=Pedal force required for braking (kg)

Pr = Pedal ratio

D1=Diameter of the TMC (mm)

D2=Diameter of caliper cylinder for the disc (mm)

R = Effective radius of the disc

R1=Outer radius of the front tires (inch)

R2=Outer radius of the rear tires (inch)

The above highlighted specifications have been selected

for our vehicle. We selected these as per our design of

the braking system for 5.9 m/s^2 deceleration.

3.5 STEERING SYSTEM

After a comparative study on different steering which are

available in the market it was found that the best suitable

steering for our vehicle is central roller and rack. Table 6

shows results of our study on steering.

Table 6: Steering comparison

Types of

steering

cost weight Sensitivity

and

response

efficiency

Rack and

pinion

low light poor fine

Central

roller and

rack

low light good good

Recirculating

ball type

high medium poor Very good

Worm and

roller

medium heavy poor medium

Worm and

sector

medium heavy Very poor good

Central roller and rack.

Turning radius 8 feet.

No. of teeth on the Rack bar =36

Length of rack = 144mm

The ratio of the rack and pinion = 12:1

The axial pitch of the Rack bar = 6 mm

Steering ratio 7.8:1

No. of universal joints in column = 2

Column inclination from horizontal- 45 degree

Removable steering wheel assembly for the ease of

driver exit in time specified as per the rulebook.

No. of the tie rods = 2.

Figure 4: Central roller and rack

While designing the steering system the constraints that

we possessed were centre alignment of steering system,

track width, human effort at the steering wheel and the

desired response of the steering system.

Apart from deciding the steering ratio we have not been

able to design the linkages, tie rods etc as presently we

do not have the gear box of steering.

The formulae used for steering calculations are:

= + +

= +

Where,

C Length of tie rod

X, Y lengths as shown in fig 5

p, q angles as shown in fig 5

a length of steering knuckle from center of tire

b Perpendicular distance of steering knuckle from pivot

point as shown in fig 5.

FIGURE 5: Steering knuckle

3.6 SUSPENSIONS

Suspension is the term given to the system of springs,

shock absorbers and linkages that connects a vehicle to

its wheels. The suspension systems not only help in the

proper functioning of the car's handling and braking, but

also keep vehicle occupants comfortable and make your

drive smooth and pleasant. It also protects the vehicle

from wear and tear.

This year we are going to use equal wishbone

suspension in both front and rear because of the

following reasons:-

* Double wishbone designs allow the us to carefully

control the motion of the wheel throughout suspension

travel, controlling such parameters as camber angle,

caster angle, toe pattern, scrub radius more.

* In a double wishbone suspension it is fairly easy to

work out the effect of moving each joint, so you can tune

the kinematics of the suspension easily and optimize

wheel motion.

*Double wishbones are usually considered to have

superior dynamic characteristics, load handling

capability and are still found on higher performance

vehicles.

Spring Design started with some arbitrary parameters

within the constraints

Constraints: Weight, ground clearance required and

space limitations

Estimated weight of

vehicle

250 kg approx.

Driver with

accessories

90 kg approx.

Total weight with

driver

340 kg approx.

Unsprung mass 75 kg approx.

Sprung mass 265 kg (at max. with

driver)

Now according to design for rear wheel drive 40% of the

total weight will be distributed at the front portion and the

remaining 60% of the weight will be at the back or rear

end.

From the above estimated weight we find that weight

distribution at one side of front end will be approximately

70 kg and at one side of rear end will be approximately

105 kg. So, all the calculations will be done taking this

weight distribution only.

3.6.1 FRONT SUSPENSIONS

The spring damper would be placed at the centre of the

upper wishbone as shown in the figure 5.

Taking ground clearance to be around 8 inches and load

of 70 kg on each tire. Thus static load on each spring

would be 140 kg as spring is mounted at the centre of

the wishbone

Figure 6: Front suspension on optimum k

Front spring design specification of our vehicle is shown

in the table 7.

Table 7: Front suspension spring details

Length of spring 171 mm

Total length(spring +

damper)

291mm

Wire diameter 7mm

Mean coil diameter 51mm

Allowed travel of spring 100mm

Stiffness 20N/mm

Pitch 19mm

No. of active turns 10

Total no. of turns 12

3.6.2 REAR SUSPENSION

Here also the constraints were ground clearance 8

inches, vehicle weight 110 kg on each tire and

movement of transmission shaft as shown in figure 7; full

angle being 15 degree, full jounce 3 degree and full

rebound 12 degree

In here, we keep the mounting point of the spring on the

upper wishbone and at its end. The rear suspension

system is as shown in figure 7.

Figure 7: Rear suspension on optimum k

For the smaller half drive shaft, the distance between

spring mounting point and shaft hinge point is 12 inch

approximately. Thus, for 15 degree spring movement is

80 mm as calculated by the formulae:

LENGTH OF ARC = RADIUS * ANGLE SUBTENDED

So for 1 degree movement of shaft deflection of spring is

5.3 mm

Rear spring specification after designing the rear

suspension is shown in table 8.

Table 8: Rear suspension spring details

Length of spring 230 mm

Total length(spring +

damper)

490mm

Wire diameter 11mm

Mean coil diameter 80mm

Allowed travel of spring 72mm

Stiffness 30N/mm

Pitch 19mm

No. of active turns 10

Total no. of turns 12

Initial compression (after driver is seated) = 33.3mm

From initial compression we conclude that the

movement of shaft required is 6.3 degrees

3.6.3 DESIGN AND ANALYSIS OF WISH

BONES

FRONT SUSPENSION

REAR SUSPENSION

3.7 HUB DESIGN

The hub assembly has a very important contribution

towards vehicles weight. So to achieve our main

objective of reducing the overall weight of our vehicle we

have to reduce the weight of wheel assembly. We have

a detailed study of previous years wheel assembly. It

was made up of mild steel that why weight of the

assembly is extremely heavy. This year we have

decided to use aluminium alloy for the manufacture of

our hub .we are also using some standard part such as

disc, spline cut alto shaft etc to reduce the cost of our

hub assembly. Wight of this year hub assembly is about

3kgs and 400gms which is 4 times less than previous

year

TABLE 9: Hub weight comparison

Hub assembly weight of

2010

3kg and 440gms

Hub assembly weight of

2009

14kgs and 780gms

Hub assembly weight of

2007

22kgs and 340gms

FIGURE 8: Hub design on pro-e

4.0 CONCLUSION

As discussed earlier, our approach is to design for the

worst and still optimize so that we avoid over designing.

This would help us to reduce the cost.

The approach that we followed is iterative in nature and

processes like reverse engineering are adopted in order

to select various systems from the ones, existing in the

market. This step would ensure standardization and

reliability would follow as a by part.

Our top priority would always be the safety of the driver

and working in this direction, we will strive to add

aesthetic value and a sense of ergonomics to the

vehicle.

5.0 ACKNOWLEDGMENTS

The design process is not a single handed effort and so

it is my team, whom I wanted to thank for standing with

me under all circumstances. I would also like to express

my gratitude towards our Mechanical department and on

the whole towards the college for supporting us and

believing in us. SAE has provided us with an excellent

platform for learning and showcasing real life projects.

While working on the project, it was really heartening to

see that the people from industry were willing to help us

and they provided us with their precious time.

6.0 REFERENCES

1. S.S.Rattan ,2005,Theory of Machines

2. V.B. Bhandari ,2007,Design of Machine

Elements

3. SAE , 2008 ,Advanced Vehicle Technology

4. Thomas D. Gillespie ,2008 ,Fundamentals Of

Vehicle Dynamics

7.0 CONTACT

Vikrant Dalal

Mechanical Engineering student

Institute of Technology and Management,

Gurgaon

Web site www.thetechietyros.com

Email I.D. vikrantdalal@yahoo.co.in

Address: V.P.O Goela Khurd, Najafgarh New Delhi

110071

engine

Type 4-stroke, gasoline

Lombardini engine

Displacement 305 cc

Compression Ratio 8:1

Power 8 KW

Torque 19 NM at 3000 rpm

Drive Train

Transmission 4 speed manual constant

mesh gear box with 1

reverse

Company Mahindra alpha champion

Chassis/Suspension

Chassis Type IS 1239 Steel Pipes

Overall Length 1400 mm.

Wheel Base 1150 mm.

Overall Width 1600 mm.

Front Suspension Double Wishbone

Rear Suspension Double Wishbone

Ground Clearance 250 mm

Shocks coil-over

Front Travel 200 mm. (75 mm rebound

and 125 mm jounce )

Rear Travel 100 mm (75 mm rebound

and 25 mm jounce )

Vehicle Weight 270 kg

Wheels/Tires

Front Tires 21 in. x 6 in. ITP Holeshots

Front Wheels 10 in.

Rear Tires 22 in. x 8 in. ITP Holeshots

Rear Wheels 10 in.

Performance

Approach Angle 80 degrees

Departure Angle 60 degrees

Top Speed 60 km/hr

Rear Wheel Torque 1584 NM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- API 571 Comparison SheetDocument6 pagesAPI 571 Comparison SheetJeyakandan Marudiah100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Baja Sae India Design ReportDocument13 pagesBaja Sae India Design Reportgobajasaeindia93% (15)

- Baja Sae India Design ReportDocument13 pagesBaja Sae India Design Reportgobajasaeindia93% (15)

- 2014 Kawasaki Ninja 300 AbsDocument157 pages2014 Kawasaki Ninja 300 AbsAdonias NiyurukundoNo ratings yet

- AST Installation GuideDocument59 pagesAST Installation GuidegobajasaeindiaNo ratings yet

- Adhesives Retain With Confidence Tech ArticleDocument4 pagesAdhesives Retain With Confidence Tech ArticlegobajasaeindiaNo ratings yet

- DrdoDocument2 pagesDrdogobajasaeindiaNo ratings yet

- Exhaust Muffler Design PrinciplesDocument9 pagesExhaust Muffler Design Principlespaulomareze67% (3)

- QuotationDocument32 pagesQuotationgobajasaeindiaNo ratings yet

- QuotationDocument32 pagesQuotationgobajasaeindiaNo ratings yet

- Sae Baja India 2010 Design Report - VAJRADocument8 pagesSae Baja India 2010 Design Report - VAJRAgobajasaeindia100% (3)

- Design Report of Sae Baja IndiaDocument9 pagesDesign Report of Sae Baja Indiagobajasaeindia67% (3)

- Sae Baja India Presentation For Round 1Document53 pagesSae Baja India Presentation For Round 1gobajasaeindia75% (4)

- Railway Cased CrossingDocument1 pageRailway Cased Crossingbinay kumarNo ratings yet

- Bombas Por ClaseDocument20 pagesBombas Por Clasegabriels251No ratings yet

- Design Calculations For Cabana Roof StructureDocument4 pagesDesign Calculations For Cabana Roof Structuremsiddiq1No ratings yet

- Antox 71 E Pickling Paste PDFDocument2 pagesAntox 71 E Pickling Paste PDFasaasd100% (1)

- Guide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)Document1 pageGuide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)anon_673643629No ratings yet

- Practical Guidelines For Electrical Area Classification inDocument11 pagesPractical Guidelines For Electrical Area Classification inaliris322No ratings yet

- Wheat MillingDocument7 pagesWheat MillingEdward Appenteng MensahNo ratings yet

- 34-V0107 Multispeed PDFDocument8 pages34-V0107 Multispeed PDFAlberto SanchezNo ratings yet

- JHJBJDocument5 pagesJHJBJarvindNo ratings yet

- The Elements and Principles of Design With ExamplesDocument74 pagesThe Elements and Principles of Design With ExamplesAr Abhinav SrivastavNo ratings yet

- Eye/Face Washes G1750: Guardian EquipmentDocument2 pagesEye/Face Washes G1750: Guardian Equipmenteisenbarger5607No ratings yet

- Danox 20db 1Document3 pagesDanox 20db 1Badri RachedNo ratings yet

- Ada 325265Document457 pagesAda 325265hychongNo ratings yet

- Penstock CaalculationDocument3 pagesPenstock CaalculationGertjan DuniceriNo ratings yet

- I MouseDocument22 pagesI Mouseapi-374496394% (16)

- Study On Performance Evaluation of Automotive RadiDocument11 pagesStudy On Performance Evaluation of Automotive RadiNabajyoti DeyNo ratings yet

- Fosroc Supercast SW30 TDSDocument2 pagesFosroc Supercast SW30 TDSAnonymous dyoHdLP100% (1)

- XTR106!4!20mA Current Transmitter With Bridge Excitation and Linearization Datasheet (RevDocument11 pagesXTR106!4!20mA Current Transmitter With Bridge Excitation and Linearization Datasheet (RevNathália MegdaNo ratings yet

- Kinematics of A Particle - MiscellaneousDocument14 pagesKinematics of A Particle - MiscellaneousJee AspirantNo ratings yet

- BMW E46ICBodyDocument25 pagesBMW E46ICBodySalisburNo ratings yet

- Measurements and InstrumentationsDocument2 pagesMeasurements and InstrumentationsmaheshboobalanNo ratings yet

- Pedel Powered Zeolite (Vacuum) RefrigeratorDocument7 pagesPedel Powered Zeolite (Vacuum) RefrigeratorAvikantNo ratings yet

- DECEMBER 2018 Surplus Record Machinery & Equipment DirectoryDocument717 pagesDECEMBER 2018 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Hydrogen Fuel Cell Vehicles: Seminar Co-Ordinator Prashant ChauhanDocument23 pagesHydrogen Fuel Cell Vehicles: Seminar Co-Ordinator Prashant Chauhananubhav srivastavaNo ratings yet

- C - 1531 RLDocument11 pagesC - 1531 RLPand AemonaEonNo ratings yet

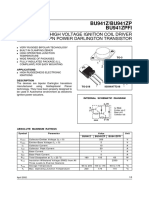

- BU941ZDocument8 pagesBU941ZGustavo Alberto RizzaNo ratings yet

- 72-112 Hokuloa 8.5 X 11 Download Able BrochureDocument9 pages72-112 Hokuloa 8.5 X 11 Download Able BrochuressoesmanNo ratings yet

- M.Srinivasan: ObjectiveDocument4 pagesM.Srinivasan: ObjectivemathisriniNo ratings yet