Professional Documents

Culture Documents

Pipe Clamps Technical Appendix: Recommended Distance Between Clamps Thread Chart

Pipe Clamps Technical Appendix: Recommended Distance Between Clamps Thread Chart

Uploaded by

satthukotienOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Clamps Technical Appendix: Recommended Distance Between Clamps Thread Chart

Pipe Clamps Technical Appendix: Recommended Distance Between Clamps Thread Chart

Uploaded by

satthukotienCopyright:

Available Formats

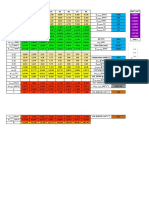

PIPE CLAMPS TECHNICAL APPENDIX

Pipe-O.D. Distance A

[mm] [m]

6,0 12,7 1,0

12,7 22,0 1,2

22,0 32,0 1,5

32,0 38,0 2,0

38,0 57,0 2,7

57,0 75,0 3,0

75,0 76,1 3,5

76,1 88,9 3,7

88,9 102,0 4,0

102,0 114,0 4,5

114,0 168,0 5,0

168,0 219,0 6,0

219,0 324,0 6,7

324,0 356,0 7,0

356,0 406,0 7,5

406,0 419,0 8,2

419,0 508,0 8,5

508,0 521,0 9,0

521,0 558,0 10,0

558,0 800,0 12,5

RECOMMENDED DISTANCE BETWEEN CLAMPS

BASIC MOUNTING INSTRUCTIONS

THREAD CHART

The recommended distances between

clamps stated below are standard values

and are valid for static loads.

Pipe bends should be supported by STAUFF

clamps as near to the bends as possible.

Furthermore, it is recommended to design

these clamps as fixed point clamps.

The first clamp should be placed directly

behind the threaded connection or coupling.

This protects the threaded connection or

coupling from vibrations.

If valves are incorporated in the pipelines, it

is recommended that support is provided in

front of and behind these valves

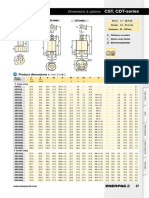

Metric vs. UNC Thread

STAUFF Metric UNC

Group Thread Thread

TWIN SERIES

1D M6

1

/4 20 UNC

2D

3D

M8

5

/16 18 UNC

4D

5D

STAUFF Metric UNC

Group Thread Thread

HEAVY SERIES

3S

4S M10

3

/8 16 UNC

5S

6S M12

7

/16 14 UNC

7S M16

5

/8 11 UNC

8S M20

3

/4 10 UNC

9S M24

7

/8 9 UNC

10S M30 1

1

/8 7 UNC

11S

M30 1

1

/4 7 UNC

12S

A

STAUFF Metric UNC

Group Thread Thread

STANDARD SERIES

1

1A

2

3

4 M6

1

/4 20 UNC

5

6

7

8

You might also like

- SEBF8034 - Valve and Valve Spring Specifications (1Document21 pagesSEBF8034 - Valve and Valve Spring Specifications (1mohamed aliNo ratings yet

- Valve and Valve Spring SpecificationsDocument21 pagesValve and Valve Spring Specificationsbetoven8437100% (1)

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Steel Wire Ropes For General PurposeDocument16 pagesSteel Wire Ropes For General Purposenishio fdNo ratings yet

- Triple RRU SupportDocument2 pagesTriple RRU SupportVitalii LukianchikovNo ratings yet

- CT Straub Geral r03 PortuguesDocument6 pagesCT Straub Geral r03 Portugues084250No ratings yet

- Goetze Series 618Document7 pagesGoetze Series 618George GeorgeNo ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- Brochure MitutoyoDocument32 pagesBrochure Mitutoyod_winarto680100% (1)

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- Tabela Armadura LajesDocument1 pageTabela Armadura Lajespaulo_arrieiroNo ratings yet

- Tabelas Normativas DinDocument2 pagesTabelas Normativas DinDeimos PhobosNo ratings yet

- Engineering Materials PaesDocument353 pagesEngineering Materials PaesjasmenenojasNo ratings yet

- سرسیلندرDocument26 pagesسرسیلندرHossenNo ratings yet

- Planilha Viscosidade Fisica ExperimentalDocument3 pagesPlanilha Viscosidade Fisica ExperimentalDouglas Heringer OuverneyNo ratings yet

- Thermo Scientific Ramsey Series 20: A Belt Scale System For Conveyor Weighing of Bulk MaterialsDocument4 pagesThermo Scientific Ramsey Series 20: A Belt Scale System For Conveyor Weighing of Bulk MaterialsAlex MtNo ratings yet

- Grinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyDocument4 pagesGrinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyСергей КолесниковNo ratings yet

- Muermann b4 Fork End Connector Pin Gusset Plate 460Document1 pageMuermann b4 Fork End Connector Pin Gusset Plate 460Nargis KhanNo ratings yet

- Torque Systems Linear Actuator Product GuideDocument5 pagesTorque Systems Linear Actuator Product GuideElectromateNo ratings yet

- Checkered Plate: Grades AvailableDocument3 pagesCheckered Plate: Grades Availableprajakt_pieNo ratings yet

- Checkered Plate: Grades AvailableDocument3 pagesCheckered Plate: Grades Availablevelmurug_balaNo ratings yet

- Ficha Tecnica Perno M12Document1 pageFicha Tecnica Perno M12CARLOS RODRIGO ROJO ROJONo ratings yet

- NHA Hydraulic Tubing Anchor Data SheetDocument1 pageNHA Hydraulic Tubing Anchor Data Sheet朱向斌No ratings yet

- Eng DS Epp-3192 1907Document2 pagesEng DS Epp-3192 1907Tomi GustomiNo ratings yet

- Or Gland 4Document1 pageOr Gland 4Popa MirceaNo ratings yet

- 3M Cold Shrink Silicone Rubber Outdoor Termination Kit QT-III 7600-S-3W SeriesDocument12 pages3M Cold Shrink Silicone Rubber Outdoor Termination Kit QT-III 7600-S-3W SeriesING CASTILLONo ratings yet

- 8645 enDocument2 pages8645 enhoangmy0106No ratings yet

- d222 en 02 Borehole Rod ExtensometersDocument4 pagesd222 en 02 Borehole Rod ExtensometersViorel LeopaNo ratings yet

- Pti30000 A MSPDocument2 pagesPti30000 A MSPStalin Paul Rodriguez LeonNo ratings yet

- Echipament Sudare Sub Strat de Flux Esab Multitrac A2Document2 pagesEchipament Sudare Sub Strat de Flux Esab Multitrac A2Rogo CatalinNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesHEMANTKHERANo ratings yet

- CMC Zaw I Er Cie Product PortfolioDocument19 pagesCMC Zaw I Er Cie Product PortfolioAmro HassaninNo ratings yet

- 78-8127-6976-4 Rev DDocument16 pages78-8127-6976-4 Rev DAli SurachmanNo ratings yet

- Standard Series Euro Metric Cable GlandsDocument1 pageStandard Series Euro Metric Cable GlandssubramanyaNo ratings yet

- JazeeraDocument38 pagesJazeeraaegon1510No ratings yet

- Especificación QC2 - Martin InglésDocument2 pagesEspecificación QC2 - Martin InglésAntonio Mena MiñoNo ratings yet

- Tubing Drain Sub Data SheetDocument1 pageTubing Drain Sub Data SheetMahmoud NassarNo ratings yet

- 3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsDocument16 pages3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsEliazer GonzalezNo ratings yet

- Rubber TolerancesDocument2 pagesRubber TolerancesmuammeryaziciNo ratings yet

- Only MeDocument3 pagesOnly MeMahesh VaragantiNo ratings yet

- English Catalogue 10 11 LowDocument56 pagesEnglish Catalogue 10 11 LowSepti Diana SariNo ratings yet

- Pneumatic Clamps: DestacoDocument32 pagesPneumatic Clamps: DestacoMarian DunareanuNo ratings yet

- FERRULE Clamp BS 4825 Dimensions Rev.2Document1 pageFERRULE Clamp BS 4825 Dimensions Rev.2Gigin PlusNo ratings yet

- Nevada: Heating UnitsDocument4 pagesNevada: Heating UnitsDanut CatalinNo ratings yet

- Cable Glands: IndustrialDocument1 pageCable Glands: IndustrialM Umar ChatthaNo ratings yet

- Cat 6A S FTP Installation Cable 600MHZ V1901Document2 pagesCat 6A S FTP Installation Cable 600MHZ V1901Trunghieu LeNo ratings yet

- 2.92mm Connector SeriesDocument16 pages2.92mm Connector SeriesCmpterRFNo ratings yet

- Bolt Torque ChartDocument1 pageBolt Torque ChartpererabernardNo ratings yet

- Dist. Elec1Document1 pageDist. Elec1fateruler51No ratings yet

- Enerpac Workholding Catalogue E215eDocument1 pageEnerpac Workholding Catalogue E215eFilipe Pimenta MarquesNo ratings yet

- RD Reflex TolerancesDocument10 pagesRD Reflex TolerancesJonathan LynchNo ratings yet

- CMC Brushless Servo Motor 2011 CatalogDocument4 pagesCMC Brushless Servo Motor 2011 CatalogServo2GoNo ratings yet

- 2.4mm ConnectorDocument15 pages2.4mm ConnectorCmpterRFNo ratings yet

- UNI-Rep L PN16Document2 pagesUNI-Rep L PN16Omar GuillenNo ratings yet

- CCG GlandsDocument1 pageCCG Glandsjimnilsen100% (1)

- Precision Plumbing Price List 12.01.2024Document36 pagesPrecision Plumbing Price List 12.01.2024Anilkumar KolpuruNo ratings yet

- Category 7 File 12Document86 pagesCategory 7 File 12Md Nazir HussainNo ratings yet

- Asme b16.21 GasketDocument12 pagesAsme b16.21 GasketsatthukotienNo ratings yet

- Ansi-Valve Body Material SelectionDocument3 pagesAnsi-Valve Body Material SelectionsatthukotienNo ratings yet