Professional Documents

Culture Documents

B65 Micro Concrete Mix Design

B65 Micro Concrete Mix Design

Uploaded by

sadi3013Copyright:

Available Formats

You might also like

- Specification of Cyclopean ConcreteDocument5 pagesSpecification of Cyclopean ConcreteSeptian Anggoro100% (11)

- Borewell Yield MeasurementDocument2 pagesBorewell Yield Measurementsadi301378% (9)

- RMC Lab ManualDocument66 pagesRMC Lab ManualVaishnaviNo ratings yet

- Concrete Block Paving Drainage PDFDocument6 pagesConcrete Block Paving Drainage PDFDaniel ReynoldsNo ratings yet

- Irs T 40-1985Document4 pagesIrs T 40-1985vpmohammedNo ratings yet

- Concrete Mix Design SpreadsheetDocument4 pagesConcrete Mix Design SpreadsheetSmith SivaNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Replacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Document27 pagesReplacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Parashu Ram Neo100% (1)

- Aac Blocks PPT 1Document13 pagesAac Blocks PPT 1Bhagyashree VenturesNo ratings yet

- Use of Chemical and Mineral Admixtures in ConcreteDocument17 pagesUse of Chemical and Mineral Admixtures in ConcreteManmohan Sharma50% (2)

- Is 15622-2006 PDFDocument17 pagesIs 15622-2006 PDFravi03121100% (2)

- Evaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteDocument62 pagesEvaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteRomeo R Chinguel DelgadoNo ratings yet

- BASF Introduces Smart Dynamic ConcreteDocument4 pagesBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignIvo StanilovNo ratings yet

- 456 CodeDocument66 pages456 CodeDebesh KuanrNo ratings yet

- Consistency Test of Cement: ResultsDocument11 pagesConsistency Test of Cement: Resultsnira365No ratings yet

- 17.sec.1700 (Structural Concrete)Document16 pages17.sec.1700 (Structural Concrete)aalignup arc & const. pvt ltdNo ratings yet

- Concrete Technology (Lab Manual)Document23 pagesConcrete Technology (Lab Manual)VipulShukla100% (3)

- High Performance ConcreteDocument49 pagesHigh Performance ConcreteHorng Zaii100% (1)

- DLCDocument14 pagesDLCvijayNo ratings yet

- Testing of Sand Quality at Construction Site For ConcreteDocument6 pagesTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNo ratings yet

- Self Compacting ConcreteDocument46 pagesSelf Compacting ConcreteEngr Shahzad Hashim100% (1)

- On Modified BitumenDocument19 pagesOn Modified BitumenTejeshwini SNo ratings yet

- Mix Design For M35 Grade of ConcreteDocument3 pagesMix Design For M35 Grade of ConcreteRajesh PentapalliNo ratings yet

- Design & Cost Analysis of Self-Compacting Concrete For Mivan ShutteringDocument5 pagesDesign & Cost Analysis of Self-Compacting Concrete For Mivan Shutteringraj221No ratings yet

- M40 Mix DesignDocument13 pagesM40 Mix DesignVk Rai100% (1)

- Self Compacting ConcreteDocument48 pagesSelf Compacting Concreteshweta sharmaNo ratings yet

- Project On Comparison of Strength of Concrete of M Sand and River Sand.Document18 pagesProject On Comparison of Strength of Concrete of M Sand and River Sand.Jiya Oza100% (1)

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusDocument4 pagesExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusRajesh Babu100% (1)

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocument3 pagesM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanNo ratings yet

- Replacement of Cement Using Fly AshDocument22 pagesReplacement of Cement Using Fly Ashkaushal yadavNo ratings yet

- Ferrochrome Slag Test PDFDocument34 pagesFerrochrome Slag Test PDFpriya maran100% (1)

- Road Surfacing: STP LimitedDocument8 pagesRoad Surfacing: STP LimitedRana MahatoNo ratings yet

- Morth 1300 Brick MasonryDocument7 pagesMorth 1300 Brick MasonryRameshNo ratings yet

- Studies On Cement Grouted Bituminous Macadam For Indian RoadsDocument19 pagesStudies On Cement Grouted Bituminous Macadam For Indian Roadsyawhgih100% (1)

- Presentation On Fly-Ash Paver BlockDocument31 pagesPresentation On Fly-Ash Paver BlockBaharulHussain75% (8)

- Building Materials Final Solution After Cor.Document64 pagesBuilding Materials Final Solution After Cor.TarunNo ratings yet

- An Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderDocument5 pagesAn Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Is 3812 2 2003Document14 pagesIs 3812 2 2003VijayKatariaNo ratings yet

- Cement TestDocument20 pagesCement TestKCC Buildcon Purnea Lab100% (3)

- Design Mix M 25 PPC - CP2659-41Document2 pagesDesign Mix M 25 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- Lab Concrete Mix Design C25aDocument17 pagesLab Concrete Mix Design C25aSoundar PachiappanNo ratings yet

- Asphtlatoseal NewDocument41 pagesAsphtlatoseal Newnagaraj_qce3499100% (1)

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- BS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesDocument10 pagesBS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesSarifNo ratings yet

- Testing of Cement: Free Powerpoint Templates Free Powerpoint TemplatesDocument23 pagesTesting of Cement: Free Powerpoint Templates Free Powerpoint TemplatesVivekChaudharyNo ratings yet

- Self Compacting ConcreteDocument27 pagesSelf Compacting ConcreteJatin MaggoNo ratings yet

- Info On Paver BlocksDocument6 pagesInfo On Paver BlocksGaneshNo ratings yet

- (With Flyash) : M-20 KERBDocument8 pages(With Flyash) : M-20 KERBNaveen SinghNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- Design of M100 Grade ACI MethodDocument3 pagesDesign of M100 Grade ACI MethodGaurav PatilNo ratings yet

- Concrete TechnologyDocument103 pagesConcrete TechnologyBaskar Singh G100% (1)

- NDT Rebound Hammer Test ReportsDocument7 pagesNDT Rebound Hammer Test ReportsPrasanta ParidaNo ratings yet

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyNo ratings yet

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- Midterm, Topic 2, ConcreteDocument22 pagesMidterm, Topic 2, ConcreteDhave Airen DomingoNo ratings yet

- Utilization of Porous Concrete in Ground Water Recharge: Deepika K P, Zaiba FathimaDocument3 pagesUtilization of Porous Concrete in Ground Water Recharge: Deepika K P, Zaiba FathimaMohan kumar R.kNo ratings yet

- Cc-Mix DesignDocument37 pagesCc-Mix DesignManoj Kumar SinghNo ratings yet

- CHBDocument6 pagesCHBkharlj3604No ratings yet

- 1 KonningsDocument32 pages1 Konningssadi3013No ratings yet

- 11-Influence of Porosity On Compressive and Tensile Strength of Cement MortarDocument6 pages11-Influence of Porosity On Compressive and Tensile Strength of Cement Mortarsadi3013No ratings yet

- Damp Proof Asian Paints PDFDocument2 pagesDamp Proof Asian Paints PDFsadi3013No ratings yet

- Plastic Shrinkage CracksDocument7 pagesPlastic Shrinkage CracksvkmsNo ratings yet

- 02-NCSCM Volume 2 - Techical Specifications PDFDocument498 pages02-NCSCM Volume 2 - Techical Specifications PDFsadi3013No ratings yet

- Figure 1: Major Design Criteria Applied To Metallic Civil Aircraft StructureDocument9 pagesFigure 1: Major Design Criteria Applied To Metallic Civil Aircraft Structurepanda33upNo ratings yet

B65 Micro Concrete Mix Design

B65 Micro Concrete Mix Design

Uploaded by

sadi3013Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B65 Micro Concrete Mix Design

B65 Micro Concrete Mix Design

Uploaded by

sadi3013Copyright:

Available Formats

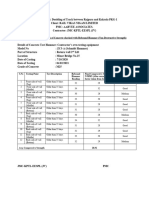

B65

Micro Concrete Mix Design

Recommended Micro Concrete Mix

2:1 Sand:Cement ratio with the following mix proportions

Cement 556 kg/ m

SandFine sharp washed. Zone 3 to 4 1,112 kg/ m

Water (mixing water:cement ratio 0.7, 387 kg/ m

varies to suit sand grading)

Typical Strength Range 3040 N/mm

Recommended Sand

Washed river or sea sand that is well graded within B.S. 822 Zone F. The sand grading line

should fall inside the green zone on the graph below.

Flow Cone

The water:cement ratio varies with the exact granulometry of the

sand used and should be determined on site using the Proserve

Flow Cone.

The water: cement ratio is adjusted to give a discharge time of 27-

33 seconds

Sieve Size (mm)

5 mm 2.36 mm

10 %

30 %

40 %

50 %

60 %

70 %

80 %

90 %

100 %

20 %

0.3 mm 0.6mm 1.18 mm 0.075 mm 0.15 mm 0

P

e

r

c

e

n

t

a

g

e

P

a

s

s

i

n

g

(

%

)

Proserve Flow Cone

Volume 1.75 litres

S

t

r

e

n

g

t

h

(

k

N

/

m

m

)

Free Water Bleed & Strength

Days

Fabric Formwork

41.4

27.6

13.8

0 14 28

Conventional

Formwork

The porous fabric allows the concrete to

bleed, giving off its free water and thus

reduces the pressures acting upon it. This

allows the strength of the concrete to be

higher than normal for a given concrete

mix whilst retaining fluidity during

placement

Proserve Ltd.

80 Priory Road,

Kenilworth,

Warwickshire, CV8 1LQ,

England

UK: 01926 512222

Int: 00 44 1926 512222

office@proserveltd.co.uk

www.proserveltd.co.uk

Fabriform

You might also like

- Specification of Cyclopean ConcreteDocument5 pagesSpecification of Cyclopean ConcreteSeptian Anggoro100% (11)

- Borewell Yield MeasurementDocument2 pagesBorewell Yield Measurementsadi301378% (9)

- RMC Lab ManualDocument66 pagesRMC Lab ManualVaishnaviNo ratings yet

- Concrete Block Paving Drainage PDFDocument6 pagesConcrete Block Paving Drainage PDFDaniel ReynoldsNo ratings yet

- Irs T 40-1985Document4 pagesIrs T 40-1985vpmohammedNo ratings yet

- Concrete Mix Design SpreadsheetDocument4 pagesConcrete Mix Design SpreadsheetSmith SivaNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Replacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Document27 pagesReplacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Parashu Ram Neo100% (1)

- Aac Blocks PPT 1Document13 pagesAac Blocks PPT 1Bhagyashree VenturesNo ratings yet

- Use of Chemical and Mineral Admixtures in ConcreteDocument17 pagesUse of Chemical and Mineral Admixtures in ConcreteManmohan Sharma50% (2)

- Is 15622-2006 PDFDocument17 pagesIs 15622-2006 PDFravi03121100% (2)

- Evaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteDocument62 pagesEvaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteRomeo R Chinguel DelgadoNo ratings yet

- BASF Introduces Smart Dynamic ConcreteDocument4 pagesBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignIvo StanilovNo ratings yet

- 456 CodeDocument66 pages456 CodeDebesh KuanrNo ratings yet

- Consistency Test of Cement: ResultsDocument11 pagesConsistency Test of Cement: Resultsnira365No ratings yet

- 17.sec.1700 (Structural Concrete)Document16 pages17.sec.1700 (Structural Concrete)aalignup arc & const. pvt ltdNo ratings yet

- Concrete Technology (Lab Manual)Document23 pagesConcrete Technology (Lab Manual)VipulShukla100% (3)

- High Performance ConcreteDocument49 pagesHigh Performance ConcreteHorng Zaii100% (1)

- DLCDocument14 pagesDLCvijayNo ratings yet

- Testing of Sand Quality at Construction Site For ConcreteDocument6 pagesTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNo ratings yet

- Self Compacting ConcreteDocument46 pagesSelf Compacting ConcreteEngr Shahzad Hashim100% (1)

- On Modified BitumenDocument19 pagesOn Modified BitumenTejeshwini SNo ratings yet

- Mix Design For M35 Grade of ConcreteDocument3 pagesMix Design For M35 Grade of ConcreteRajesh PentapalliNo ratings yet

- Design & Cost Analysis of Self-Compacting Concrete For Mivan ShutteringDocument5 pagesDesign & Cost Analysis of Self-Compacting Concrete For Mivan Shutteringraj221No ratings yet

- M40 Mix DesignDocument13 pagesM40 Mix DesignVk Rai100% (1)

- Self Compacting ConcreteDocument48 pagesSelf Compacting Concreteshweta sharmaNo ratings yet

- Project On Comparison of Strength of Concrete of M Sand and River Sand.Document18 pagesProject On Comparison of Strength of Concrete of M Sand and River Sand.Jiya Oza100% (1)

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusDocument4 pagesExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusRajesh Babu100% (1)

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocument3 pagesM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanNo ratings yet

- Replacement of Cement Using Fly AshDocument22 pagesReplacement of Cement Using Fly Ashkaushal yadavNo ratings yet

- Ferrochrome Slag Test PDFDocument34 pagesFerrochrome Slag Test PDFpriya maran100% (1)

- Road Surfacing: STP LimitedDocument8 pagesRoad Surfacing: STP LimitedRana MahatoNo ratings yet

- Morth 1300 Brick MasonryDocument7 pagesMorth 1300 Brick MasonryRameshNo ratings yet

- Studies On Cement Grouted Bituminous Macadam For Indian RoadsDocument19 pagesStudies On Cement Grouted Bituminous Macadam For Indian Roadsyawhgih100% (1)

- Presentation On Fly-Ash Paver BlockDocument31 pagesPresentation On Fly-Ash Paver BlockBaharulHussain75% (8)

- Building Materials Final Solution After Cor.Document64 pagesBuilding Materials Final Solution After Cor.TarunNo ratings yet

- An Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderDocument5 pagesAn Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Is 3812 2 2003Document14 pagesIs 3812 2 2003VijayKatariaNo ratings yet

- Cement TestDocument20 pagesCement TestKCC Buildcon Purnea Lab100% (3)

- Design Mix M 25 PPC - CP2659-41Document2 pagesDesign Mix M 25 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- Lab Concrete Mix Design C25aDocument17 pagesLab Concrete Mix Design C25aSoundar PachiappanNo ratings yet

- Asphtlatoseal NewDocument41 pagesAsphtlatoseal Newnagaraj_qce3499100% (1)

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- BS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesDocument10 pagesBS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesSarifNo ratings yet

- Testing of Cement: Free Powerpoint Templates Free Powerpoint TemplatesDocument23 pagesTesting of Cement: Free Powerpoint Templates Free Powerpoint TemplatesVivekChaudharyNo ratings yet

- Self Compacting ConcreteDocument27 pagesSelf Compacting ConcreteJatin MaggoNo ratings yet

- Info On Paver BlocksDocument6 pagesInfo On Paver BlocksGaneshNo ratings yet

- (With Flyash) : M-20 KERBDocument8 pages(With Flyash) : M-20 KERBNaveen SinghNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- Design of M100 Grade ACI MethodDocument3 pagesDesign of M100 Grade ACI MethodGaurav PatilNo ratings yet

- Concrete TechnologyDocument103 pagesConcrete TechnologyBaskar Singh G100% (1)

- NDT Rebound Hammer Test ReportsDocument7 pagesNDT Rebound Hammer Test ReportsPrasanta ParidaNo ratings yet

- Is Concrete Mix DesignDocument21 pagesIs Concrete Mix DesignahmedanyNo ratings yet

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- Midterm, Topic 2, ConcreteDocument22 pagesMidterm, Topic 2, ConcreteDhave Airen DomingoNo ratings yet

- Utilization of Porous Concrete in Ground Water Recharge: Deepika K P, Zaiba FathimaDocument3 pagesUtilization of Porous Concrete in Ground Water Recharge: Deepika K P, Zaiba FathimaMohan kumar R.kNo ratings yet

- Cc-Mix DesignDocument37 pagesCc-Mix DesignManoj Kumar SinghNo ratings yet

- CHBDocument6 pagesCHBkharlj3604No ratings yet

- 1 KonningsDocument32 pages1 Konningssadi3013No ratings yet

- 11-Influence of Porosity On Compressive and Tensile Strength of Cement MortarDocument6 pages11-Influence of Porosity On Compressive and Tensile Strength of Cement Mortarsadi3013No ratings yet

- Damp Proof Asian Paints PDFDocument2 pagesDamp Proof Asian Paints PDFsadi3013No ratings yet

- Plastic Shrinkage CracksDocument7 pagesPlastic Shrinkage CracksvkmsNo ratings yet

- 02-NCSCM Volume 2 - Techical Specifications PDFDocument498 pages02-NCSCM Volume 2 - Techical Specifications PDFsadi3013No ratings yet

- Figure 1: Major Design Criteria Applied To Metallic Civil Aircraft StructureDocument9 pagesFigure 1: Major Design Criteria Applied To Metallic Civil Aircraft Structurepanda33upNo ratings yet