Professional Documents

Culture Documents

Conveyor Systems

Conveyor Systems

Uploaded by

Milan ZlatkovicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conveyor Systems

Conveyor Systems

Uploaded by

Milan ZlatkovicCopyright:

Available Formats

EISENMANN

Conveyor Systems

EISENMANN designs and builds plants for surface finish-

ing, material flow automation, environmental technology,

firing lines for ceramics and special installations for

coating, recycling, thermal treatment and energy recovery.

Approximately 2,800 employees worldwide, half of them

engineers or technicians, develop new ideas in the areas

of production, painting, assembly and distribution.

Among them are experts and specialists with solid know-

how in various areas of expertise and industry sectors.

This is an advantage that results in customized concepts

with state-of-the-art technology and a high degree of

economic efficiency.

Another result of our efficient production and assembly

strategies: Our production centers are tailored to the

individual requirements of our customers. We design a

plant configuration especially adapted to your needs.

When complex systems are involved, we

assemble the entire plant in our factory

before delivering it, and we put the system

to the acid test. Only when the pre-

assembled function modules have passed

the test run, will they be handed over to

the customer. This method saves consider-

able time and cost for assembly and

commissioning on site and enables the

installation in your plant without even

interrupting your production process.

Of course, we will assist you after commis-

sioning at your demand: Our Aftersales

Service provides professional maintenance,

short repair times and immediate provision

of spare parts.

Contents

Total logistics 2

Electric monorail systems 3 - 5

Electro pallet conveyors 6

Pallet conveying systems 7

Power&Free conveyors 8

Custom conveyors 9

In-floor conveyors 10

Assembly conveyors 10

EISENMANN technology center in Holzgerlingen

1

This is EISENMANN

EISENMANN works for you as

a logistics specialist or as a

general contractor.

EISENMANN is among the world's

leading suppliers of individual and

system components for material

flow automation.

As a general contractor, we design

and build turnkey systems, includ-

ing building engineering. Our pro-

duct line has evolved from experi-

ence gained with numerous systems

built for a broad range of industries

and companies throughout the

world. Among them are the auto-

motive industry and its suppliers,

food and consumer products compa-

nies, manufacturing and service

industries, printers industry, etc.

Our Capabilities Profile

Consulting and planning

Simulation

Customer specific product

and system development

Engineering and manufacturing

Pre-assembly and test run

Installation and start-up

of all mechanical and control

system components

Training

Maintenance and global service

EISENMANN has the right custom-

ized solution for every material

flow task. Out portfolio includes

the entire spectrum of advanced

conveyor, as well as complete system

solut-ions for manufacturing, assem-

bly, warehousing, and shipping.

General Contracting

Project planning

Overall coordination

Specific coordination

Project management

Scheduling and schedule control

Capacity planning and control

Quality assurance

Floor Conveyor Technology

In-floor conveyors

Pallet and container conveyors

Roller conveyors

Skillet conveyor systems

Skid conveyor technology

Slat and belt conveyors

Electro pallet conveyors

Storage system integration (AS/RS)

Overhead Conveying

Overhead chain conveyors

Power&Free conveyors

Electric monorail systems (EMS)

Electric monorail systems and electric pallet conveyors, a conveying system

which is highly intelligent and very flexible.

2

Products Overview

3

Beverage Industry

The electric monorail system (EMS) is a fast and intelli-

gent means of transport with high throughputs. This is

why beverage manufacturers have a speci al preference

for this form of materials handling.

Photo, top: At VELTINS, an EMS masters the 300 m slope

up and down between goods receiving and empties sort-

ing and back to the bottling stations without requiring

additional support to get up the slope.

Photo, centre: EMS track in the logistics centre of

SINEBRYCHOFF, the Scandinavian brewery group.

The EMS serves to connect the bottling lines with the

high-bay storage area and transportation from there

to picking and loading on trucks (goods dispatching).

Photo, left: This mineral water bottler solves its entire

in-house flow of material for full goods and empties

pallets with the EMS. The system overcomes differences

in height over several storeys through a fast lifter; the

EMS bridge connects filling and shipping areas situated

far apart from each other.

Electrical Monorail System

4

Warehouse and Shipping

Photo, top: To handle the high throughput rates from

production to the warehouse and goods dispatching, this

producer of hygienic products decided for the EISENMANN

electric monorail system.

Photo, top: Pick-to-light directly at the EMS. This

picking centre was implemented for the first time at

a Swedish furniture giant.

Photo, left: The VarioTow towing system, newly-

developed by EISENMANN, supports goods distribution

in forwarding and goods distribution centres. Here,

the classical manual carriage is simply towed by the

EMS chassis to its destination.

Electrical Monorail System

5

EMS with Wireless Power Transmission

Left: Electric monorail system in the assembly plant for

airplane components. Instead of using contact bus bars,

the energy and data transmission takes place entirely

inductively without any direct contact.

EMS for Airline Catering

Right: Electric monorail system connects trolley retrieval

with the kitchen and picking in the Catering area of

leading international airlines worldwide.

Roses Moved Rapidly

With 180 m per minute, the quickest EMS in the world:

The "Aalsmeer Shuttle" transports flowers and potted

plants via an 18 km-long track from the auction halls

to the shipment halls of individual wholesalers.

Electrical Monorail System

Electro Pallet Conveyors EPC

This floor-based conveying system, which uses important

components from the electric monorail system, is the

ideal alternative to continuous conveyors. The EPC can

be used flexibly for all floor conveyors and enables

lengthwise and crosswise movements through a clever

switching technique.

Depending on space conditions, loads and throughput,

one-rail systems (as in the top photo) or two-rail

systems can be used.

Photo, right: Two-rail EPC at a Spanish logisti cs services

provider to connect high-bay storage areas and picking

stations.

6

Electro Pallet Conveyors

7

Flexibility through modular construction: EISENMANN's pallet conveyor systems can manage all kinds of pallets.

EISENMANN pallet conveyor systems ensure efficient

handling of goods. Mesh boxes or pallets - with our

systems, transport units with a wei ght of up to

1,500 kg reach the right destination at the right time!

Together with turntables, corner transfer units, shuttles

and other peripheral units, the roller conveyor or the

chain conveyor make the perfect system.

Pallet Conveyor System

Conveyor for Heating Systems

P&F conveyor moves burner housings

efficiently through the paint shop.

Sorting Storage

At this automotive supplier, the P&F provides the

conveyance needs for painting, work-in-process

storage and sortation buffers from which the parts

are transported to the assembly lines.

Robust & Flexible

A Power&Free system transports

tightly packed hangers with shelf

elements through pretreatment

and dip coating in a paint shop.

The dipping process takes place

in phased mode with lowered

Free rail.

8

Power & Free Conveyors

Custom Conveyors

Rail Transport with Inductive Energy

This shuttle with inductive energy and information

transmission links receiving with the storage-and-

retrieval unit in the warehouse.

Safe Handling for Roller Containers

Special floor conveyor systems from EISENMANN

automate the handling of roller containers in

different processes (sorting, buffering, decoupling

and separating).

Container Conveyor Technology for Small

Parts Transport

The ideal system for the automatic small parts storage:

Conveyor systems for lightweight plastic containers and

cardboard boxes up to 50 kg in the logistics center of a

publishing house.

Tray Conveyor for Spare Parts Handling

Efficient roundabout: Up to 240 tr ays with spare parts

for electric motors and gears pass the picking stations

each hour in this huge spare parts center in South

Germany.

9

Push Platform

Moving assembly lines have long been standard in the

final assembly of cars. But in other areas as well such

as in module assembly (photo above), push platform

conveyor systems have been brought into use.

10

Assembly Conveyors

Heavy Load EMS

Electric monorail systems for use in vehi cle assembly.

Lifting chain hangers enable lowering and raising into

ergonomically favourable assembly positions.

In-Floor Conveyors

Furniture Factory

The 400 m-long in-floor conveyor in this kitchen furni-

ture factory connects the production to the shipping

department. At the same time, the conveyor acts as a

distribution loop to assemble complete customer orders.

Parcel Service at the Freight Terminal

At this terminal, several hundred tons of goods are

sorted and distributed according to their destination

with an in-floor conveyor. The 600 m conveyor

connects the truck dispatch stations directly to the

rail yard.

D

i

g

i

M

a

i

2

0

0

8

EISENMANN Anlagenbau GmbH & Co. KG

EISENMANN Service GmbH & Co. KG

Tbinger Str. 81 71032 Bblingen Germany

Daimlerstr. 5 71088 Holzgerlingen Germany

Phone +49 7031 78-0 Fax +49 7031 78-1000

info@eisenmann.com service@eisenmann.com

www.eisenmann.com

EISENMANN

You might also like

- Goyen CleaningsystemsnozzlesDocument16 pagesGoyen CleaningsystemsnozzlesSteve Bourdon LafleurNo ratings yet

- Pulveriseren Atriton PDFDocument8 pagesPulveriseren Atriton PDFEmre AfacanNo ratings yet

- Belt DryerDocument16 pagesBelt Dryerthomas_v501925No ratings yet

- FMC 105-TUP Bucket Elevator and Bucket CatalogDocument33 pagesFMC 105-TUP Bucket Elevator and Bucket Catalogemuno008No ratings yet

- FLS, Eng RequirementsDocument9 pagesFLS, Eng RequirementsDeepak DasNo ratings yet

- FMC 105-TUP Bucket Elevator and Bucket CatalogDocument33 pagesFMC 105-TUP Bucket Elevator and Bucket CatalogErsin SucuNo ratings yet

- Drive Coupling SKFDocument19 pagesDrive Coupling SKFFrank MwafulirwaNo ratings yet

- Dust Collection MaintenanceDocument21 pagesDust Collection MaintenanceLinus RidgeNo ratings yet

- 94-Chain Conveyors & ElevatorsDocument6 pages94-Chain Conveyors & ElevatorsWuttSuNo ratings yet

- Expandable MandrelsDocument3 pagesExpandable Mandrelsali-masoodNo ratings yet

- FAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgDocument4 pagesFAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgriteshsamantrayNo ratings yet

- Marg Conveyor Bag Handling PresentationDocument8 pagesMarg Conveyor Bag Handling PresentationMarg ConveyorsNo ratings yet

- Catalog of Impel's Conveyor Rollers For Gravity Conveyor With SpecificationDocument11 pagesCatalog of Impel's Conveyor Rollers For Gravity Conveyor With SpecificationImpel IntralogisticsNo ratings yet

- Omega H ClassDocument8 pagesOmega H Classskimmer05No ratings yet

- Insert Able Jet Pulse FilterDocument4 pagesInsert Able Jet Pulse FilterM.IBRAHEEMNo ratings yet

- Dyna PoreDocument12 pagesDyna PoreaminNo ratings yet

- Leistritz PDFDocument8 pagesLeistritz PDFJose MarquezNo ratings yet

- Screw Conveyor Engineering Guide Pt1Document17 pagesScrew Conveyor Engineering Guide Pt1vijayendraNo ratings yet

- 90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorDocument7 pages90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorImpel IntralogisticsNo ratings yet

- Great Benefits of Using Bhs Econtors Single Diaphragm CouplingsDocument6 pagesGreat Benefits of Using Bhs Econtors Single Diaphragm CouplingslubricacionNo ratings yet

- Hengyang Rotary DryerDocument8 pagesHengyang Rotary DryerLi GaryNo ratings yet

- U LectureDocument234 pagesU LectureTran DucNo ratings yet

- Air Slide Version 24 Sept 03Document6 pagesAir Slide Version 24 Sept 03Ahmed Mostafa AL-AboudyNo ratings yet

- Sedis Conveyor Chains Catalogue PDFDocument236 pagesSedis Conveyor Chains Catalogue PDFAlexNo ratings yet

- Pallet Handling Technology: High Throughput RatesDocument6 pagesPallet Handling Technology: High Throughput RatesBülent KabadayiNo ratings yet

- Presentación Equipo 2Document62 pagesPresentación Equipo 2Ruben Lopez RicoNo ratings yet

- OM CT 002 01 Chain Transfer Owners Manual PDFDocument33 pagesOM CT 002 01 Chain Transfer Owners Manual PDFMujibur RahmanNo ratings yet

- Habasit Conveyor SelectionDocument78 pagesHabasit Conveyor SelectionAnand PatelNo ratings yet

- TR521 Tier 4i - 1112 - WebDocument6 pagesTR521 Tier 4i - 1112 - WebBrunoNo ratings yet

- Tramco Bucket Elevator Manual Us en 900202 r0Document44 pagesTramco Bucket Elevator Manual Us en 900202 r0tuhintahmidNo ratings yet

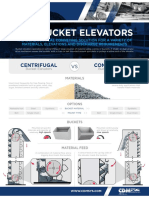

- CDM Bucket Elevators: Centrifugal ContinuousDocument2 pagesCDM Bucket Elevators: Centrifugal ContinuousOcta IrawanNo ratings yet

- Gravity ConveyorsDocument49 pagesGravity ConveyorsAdriel Aron DiazNo ratings yet

- FAG Generation C Deep Groove Ball BearingsDocument8 pagesFAG Generation C Deep Groove Ball BearingsAlvaro MunozNo ratings yet

- Accessories HydraulicsDocument47 pagesAccessories HydraulicsawfahaddadinNo ratings yet

- PaletDocument70 pagesPaletargaNo ratings yet

- Print Close: Machine DesignDocument5 pagesPrint Close: Machine DesignAnonymous CYdagINo ratings yet

- Ypt Paletli Brosur 3 PDFDocument4 pagesYpt Paletli Brosur 3 PDFarsanioseNo ratings yet

- Presentation On Manual LoadersDocument16 pagesPresentation On Manual LoadersViswanad Ravilla100% (1)

- Standard Conveyor SystemsDocument132 pagesStandard Conveyor SystemsFaisal RosidNo ratings yet

- How To Remove Autorun Inf Virus OpenDocument6 pagesHow To Remove Autorun Inf Virus OpenIsaac TataNo ratings yet

- Pan Conveyors PDFDocument20 pagesPan Conveyors PDFChristian Makande100% (2)

- Material Handling Equipment SteelDocument114 pagesMaterial Handling Equipment SteelZahir Khira100% (1)

- Gate ValvesDocument2 pagesGate Valves@sssNo ratings yet

- Bühler Chain CatalogDocument32 pagesBühler Chain CatalogenricoorNo ratings yet

- Final Sprocket New 24Document65 pagesFinal Sprocket New 24Madhu M ReddyNo ratings yet

- Large Size Conveyor ChainDocument156 pagesLarge Size Conveyor ChainManatchaiSanNo ratings yet

- Chains CalculationDocument29 pagesChains CalculationMOHITNo ratings yet

- Troughed Belt IntroDocument5 pagesTroughed Belt IntroAbas S. AcmadNo ratings yet

- Conveyor BeltDocument2 pagesConveyor BeltSholhan AzizNo ratings yet

- Air Operated Grease Ratio Pumps 50-1Document3 pagesAir Operated Grease Ratio Pumps 50-1balasubramanyam kotaNo ratings yet

- EleconDocument72 pagesEleconPranit BangeraNo ratings yet

- FEECO Complete OfferingsDocument8 pagesFEECO Complete OfferingsawfahNo ratings yet

- DIN 22.102 - Gumene Transportne TrakeDocument4 pagesDIN 22.102 - Gumene Transportne TrakeThomas WilliamsNo ratings yet

- SEW Eurodrive EMS Systems PDFDocument15 pagesSEW Eurodrive EMS Systems PDFRikardo AlexisNo ratings yet

- KAT0400-0001-E Product Overview Conveyor SystemsDocument16 pagesKAT0400-0001-E Product Overview Conveyor Systemspithaloka100% (1)

- Data-Sheet Siemens Mobility Vectron enDocument4 pagesData-Sheet Siemens Mobility Vectron enAnonymous HiQx2gF100% (1)

- Ucm03 072352Document8 pagesUcm03 072352Ivan ErmolaevNo ratings yet

- Rails and Rolled Products: For Railway ApplicationsDocument16 pagesRails and Rolled Products: For Railway ApplicationsMarin Laurentiu100% (1)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Check Weigher: Revolutionizing Quality Control with Computer VisionFrom EverandCheck Weigher: Revolutionizing Quality Control with Computer VisionNo ratings yet

- Hertzian Contact Stress Calculator.Document3 pagesHertzian Contact Stress Calculator.Nitesh Kumar SoniNo ratings yet

- Cleat Pad: Sr. Activity New Plan Date RemarksDocument2 pagesCleat Pad: Sr. Activity New Plan Date RemarksNitesh Kumar SoniNo ratings yet

- 2564 PDFDocument3 pages2564 PDFNitesh Kumar SoniNo ratings yet

- Casting Design As Influenced by Foundry Practice 7.28.08 PDFDocument80 pagesCasting Design As Influenced by Foundry Practice 7.28.08 PDFNitesh Kumar SoniNo ratings yet

- Heat Exchanger - 2Document19 pagesHeat Exchanger - 2Nitesh Kumar SoniNo ratings yet

- How To Use Coil Springs and Precautions: Radial Bearing (Class 0) Tolerances and AllowancesDocument1 pageHow To Use Coil Springs and Precautions: Radial Bearing (Class 0) Tolerances and AllowancesNitesh Kumar SoniNo ratings yet

- Resume: Skills and To Deliver To Best of My AbilityDocument3 pagesResume: Skills and To Deliver To Best of My AbilityNitesh Kumar SoniNo ratings yet

- Item No. Part Number Qty. 1 NH00000237053 1Document9 pagesItem No. Part Number Qty. 1 NH00000237053 1Nitesh Kumar SoniNo ratings yet

- Op PDFDocument247 pagesOp PDFNitesh Kumar SoniNo ratings yet

- Types of Rolling Element Bearings: Cylindrical Roller Bearings With CageDocument1 pageTypes of Rolling Element Bearings: Cylindrical Roller Bearings With CageNitesh Kumar SoniNo ratings yet

- Nitesh 1 Year B.E MechanicalDocument2 pagesNitesh 1 Year B.E MechanicalNitesh Kumar SoniNo ratings yet

- Date Time IN Time Out Duration RemarkDocument24 pagesDate Time IN Time Out Duration RemarkNitesh Kumar SoniNo ratings yet

- Tool Design Data Book PDFDocument124 pagesTool Design Data Book PDFbmvinay74% (19)

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (University of Technology of Madhya Pradesh)Document2 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (University of Technology of Madhya Pradesh)Nitesh Kumar SoniNo ratings yet

- Neelesh Kumar Soni: Career ObjectivesDocument3 pagesNeelesh Kumar Soni: Career ObjectivesNitesh Kumar SoniNo ratings yet