Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

115 viewsInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00

Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00

Uploaded by

ramabhplThis document contains a cost breakdown for manufacturing a piston component. It lists the raw materials, machining operations, times, costs, and prices. The total component cost is Rs. 117.55 and total cycle time is 11.57 minutes. It provides detailed information on the machining processes, including the cutting parameters, for turning, drilling, and other operations needed to produce the piston from raw stock.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Injection Molding: Part Cost EstimatorDocument3 pagesInjection Molding: Part Cost Estimatorpchakkrapani100% (1)

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- Learning Objectives: 3.1 Basic Weld JointsDocument15 pagesLearning Objectives: 3.1 Basic Weld Jointsramabhpl100% (1)

- SHT Metal EstimatorDocument7 pagesSHT Metal Estimatorkarthikkumarfeb6No ratings yet

- Tool Design Calculation: Cutting ForceDocument4 pagesTool Design Calculation: Cutting ForceRaja SathishNo ratings yet

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- Compression Molding Machine PriceDocument13 pagesCompression Molding Machine PriceSalma FarooqNo ratings yet

- Catalogue HyvaDocument222 pagesCatalogue HyvaEdgar Rojas Espejo100% (2)

- Api 579-1 - Asme FFS-1 PaDocument14 pagesApi 579-1 - Asme FFS-1 PaZdravko Ivancic20% (5)

- PlasticDocument172 pagesPlasticNGOC HUYNHNo ratings yet

- Collapse of Flats at Ronan Point, Canning TownDocument83 pagesCollapse of Flats at Ronan Point, Canning TownAman 'kebe' KebedeNo ratings yet

- F1 Car Project ProposalDocument4 pagesF1 Car Project ProposalFirdaus IliasNo ratings yet

- Template For Quoting Sheet Metal PartsDocument100 pagesTemplate For Quoting Sheet Metal PartsCarlos RetamozaNo ratings yet

- Partcost With Freight Table Rev. 7Document3 pagesPartcost With Freight Table Rev. 7RJLockNo ratings yet

- Design and Analysis of Progressive Tool For An Automobile ComponentDocument9 pagesDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- Material: NRE Pricing Sheet Quantity CostDocument1 pageMaterial: NRE Pricing Sheet Quantity CostAnonymous VRspXsmNo ratings yet

- Tonnage CalculatorDocument2 pagesTonnage CalculatorLoveofyouth ReddyNo ratings yet

- Compound Die PDFDocument4 pagesCompound Die PDFNhan Le100% (1)

- Cupola Melting CostDocument3 pagesCupola Melting CostnirevievNo ratings yet

- CostTable Fasteners 2022Document17 pagesCostTable Fasteners 2022shaffin jeba shinuNo ratings yet

- Cost-Benefit AnalysisDocument2 pagesCost-Benefit AnalysisNISREEN WAYANo ratings yet

- E-Coat Inputs: A) Part InformationDocument5 pagesE-Coat Inputs: A) Part InformationAnjan MalusareNo ratings yet

- Machine Cost & Set Up TimeDocument11 pagesMachine Cost & Set Up TimeGanesh SunderNo ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- EA Plasma, Laser, OxyfuelDocument5 pagesEA Plasma, Laser, OxyfuelSaravanan VelayuthamNo ratings yet

- Costing Sheet 500632403736Document6 pagesCosting Sheet 500632403736Sourabh PradhanNo ratings yet

- Machining Line Quote-NewDocument1 pageMachining Line Quote-NewJimmyNo ratings yet

- How To Calculate The Tonnage of Die Casting MachineDocument2 pagesHow To Calculate The Tonnage of Die Casting MachineRafał LesiczkaNo ratings yet

- NTTF Press Tool Standards Ebook GeneralDocument207 pagesNTTF Press Tool Standards Ebook GeneralRagunathan G100% (1)

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- CSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListDocument1 pageCSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListJosemar PorfirioNo ratings yet

- Injection Timing Calculator 2020Document43 pagesInjection Timing Calculator 2020Tim JuddNo ratings yet

- Zuhaltekraftberechnung: Teilbezeichnung Auslegung 1 - FachDocument2 pagesZuhaltekraftberechnung: Teilbezeichnung Auslegung 1 - FachARUN KUMAR KoterimadathilNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Bob 0601 2015 00Document12 pagesBob 0601 2015 00Prashant MoreNo ratings yet

- Piercing Process Cost CalculationDocument3 pagesPiercing Process Cost CalculationVenkateswaran venkateswaranNo ratings yet

- F A X TSS: Cutting ForceDocument3 pagesF A X TSS: Cutting ForcesachinNo ratings yet

- 14.72 KL PP FRP TankDocument24 pages14.72 KL PP FRP TankmaheshdgavaliNo ratings yet

- Stamping Blank and Tonnage CalculatorDocument10 pagesStamping Blank and Tonnage CalculatorDhanus KodiNo ratings yet

- Investment Casting Cycle TimeDocument12 pagesInvestment Casting Cycle TimemaheshNo ratings yet

- 2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeDocument1 page2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeKARTICK PRASADNo ratings yet

- Ijme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Document10 pagesIjme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Impact JournalsNo ratings yet

- Cost Working of Mechanical Press: Description General Formula CostDocument4 pagesCost Working of Mechanical Press: Description General Formula Costazadsingh1No ratings yet

- Project Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceDocument2 pagesProject Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceNihar RanjanNo ratings yet

- Inj Mold CalculateDocument9 pagesInj Mold CalculateGiap NguyenNo ratings yet

- 04 421 40033 Clutch CoverDocument1 page04 421 40033 Clutch CoverPress TechNo ratings yet

- Project: TML (Emc) : Part No 1A014117 Customer TMLDocument2 pagesProject: TML (Emc) : Part No 1A014117 Customer TMLShrikant YashNo ratings yet

- Tonase Dan Kebutuhan Material CV04A Dan RF45Document2 pagesTonase Dan Kebutuhan Material CV04A Dan RF45Bagas Lesta CoratiesNo ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Costing Calculations:: Date: 12/5/2016 Revision: R0 Costing 336Document9 pagesCosting Calculations:: Date: 12/5/2016 Revision: R0 Costing 336Rakesh SharmaNo ratings yet

- Costing Sheet - 1835 - ExtrusionDocument3 pagesCosting Sheet - 1835 - ExtrusionER RAKESHNo ratings yet

- Costing Format - Press ToolDocument6 pagesCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Effeciency CalculationDocument26 pagesEffeciency CalculationAshish SawantNo ratings yet

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocument19 pagesSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uNo ratings yet

- Costing FormatDocument3 pagesCosting FormatdavNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Die Casting Die Parameter - Calculation - GuidelineDocument8 pagesDie Casting Die Parameter - Calculation - GuidelineVenkateswaran venkateswaranNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- TML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeDocument7 pagesTML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeChandrajeet ShelkeNo ratings yet

- DT50U PartsDocument74 pagesDT50U PartshuckinnzNo ratings yet

- Front End Tipping SolutionsDocument16 pagesFront End Tipping SolutionsramabhplNo ratings yet

- Cushioning CalculationDocument2 pagesCushioning CalculationramabhplNo ratings yet

- Leroy Somer Electrical MotorDocument132 pagesLeroy Somer Electrical Motorramabhpl100% (1)

- METRIC THREADS - CHART For Higher SizesDocument2 pagesMETRIC THREADS - CHART For Higher SizesramabhplNo ratings yet

- 2016 Hydraulic Cylinders Industry ReportDocument35 pages2016 Hydraulic Cylinders Industry Reportramabhpl100% (1)

- A005 AtosDocument4 pagesA005 AtosramabhplNo ratings yet

- PV SeriesDocument43 pagesPV SeriesramabhplNo ratings yet

- BreatherDocument4 pagesBreatherramabhplNo ratings yet

- Sweet Spot Front Axle Assembly: Boundary/Block DiagramDocument1 pageSweet Spot Front Axle Assembly: Boundary/Block DiagramramabhplNo ratings yet

- Trelleborg DAS SealDocument3 pagesTrelleborg DAS SealramabhplNo ratings yet

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Ressia at Elmina Gardens - City of Elmina - Way of LivingDocument15 pagesRessia at Elmina Gardens - City of Elmina - Way of LivingSime Darby PropertyNo ratings yet

- ElectricalDocument18 pagesElectricalLimuel Espiritu100% (1)

- Welding Washers For Steel DeckDocument2 pagesWelding Washers For Steel DecktylerlhsmithNo ratings yet

- PCB Designing and Fabrication P.C.B. (Printed Circuit Board)Document2 pagesPCB Designing and Fabrication P.C.B. (Printed Circuit Board)Ashwani DhimanNo ratings yet

- 3M Work Gloves BrochureDocument4 pages3M Work Gloves BrochureherminNo ratings yet

- Cathodic Protection System For Offshore StructureDocument13 pagesCathodic Protection System For Offshore StructureheikelNo ratings yet

- Flowfit CylindersDocument4 pagesFlowfit CylinderspvssrhNo ratings yet

- 1 - Skills and Knowledge of Cost EngineeringDocument17 pages1 - Skills and Knowledge of Cost EngineeringSherazNo ratings yet

- Total Balance ConcreteDocument2 pagesTotal Balance ConcreteNICMAILNo ratings yet

- Super Heavy AerbDocument42 pagesSuper Heavy Aerbarpitmehta85051No ratings yet

- Manual Masina de Spalat Rufe Incorporabila BekoDocument72 pagesManual Masina de Spalat Rufe Incorporabila BekoPerfectreviewNo ratings yet

- GB 50011-2010-EnDocument240 pagesGB 50011-2010-Enrahman fatah0% (1)

- TE-6070V Sampler Calibration Worksheet: Site and Calibration Information (Using G-Factor)Document3 pagesTE-6070V Sampler Calibration Worksheet: Site and Calibration Information (Using G-Factor)EDWARDNo ratings yet

- Motor Diesel F5L912Document35 pagesMotor Diesel F5L912Anonymous iu95trpxN100% (1)

- America's Secret Space Program and The Super ValkyrieDocument9 pagesAmerica's Secret Space Program and The Super ValkyrieVen Geancia0% (1)

- N2XH IEC 60502-1 XLPE FRNC 0.6/1kV CableDocument4 pagesN2XH IEC 60502-1 XLPE FRNC 0.6/1kV Cableesilva2021No ratings yet

- This PDF Document Is A Partial Sample Chapter From The Book..Document9 pagesThis PDF Document Is A Partial Sample Chapter From The Book..Anonymous VRspXsmNo ratings yet

- WeishauptDocument24 pagesWeishauptpatitay036817No ratings yet

- Datasheet 5451 and 5452 QSIIDocument6 pagesDatasheet 5451 and 5452 QSIIvictornoesgrunfeldNo ratings yet

- Development of Hybrid BT Cotton in China A Successful Integration of Transgenic Technology and Conventional TechniquesDocument5 pagesDevelopment of Hybrid BT Cotton in China A Successful Integration of Transgenic Technology and Conventional Techniqueszhongshunmao1541No ratings yet

- Security Survey of SITEDocument4 pagesSecurity Survey of SITEbcsharma_2009100% (1)

- 2020 ProposalDocument14 pages2020 Proposalapi-338285899No ratings yet

- Ehouse MCC Switchgear BuildingDocument15 pagesEhouse MCC Switchgear BuildingSARAVANA100% (1)

- Technical Manual 50UB-2014Document41 pagesTechnical Manual 50UB-2014SHNODANo ratings yet

- Bulb Flat, Steel Bulb Flats, hp100x8 Bulb Bar PDFDocument4 pagesBulb Flat, Steel Bulb Flats, hp100x8 Bulb Bar PDF9245126694No ratings yet

- Hollow Structural Section NSMPDocument16 pagesHollow Structural Section NSMPAngelo MoralNo ratings yet

Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00

Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00

Uploaded by

ramabhpl0 ratings0% found this document useful (0 votes)

115 views2 pagesThis document contains a cost breakdown for manufacturing a piston component. It lists the raw materials, machining operations, times, costs, and prices. The total component cost is Rs. 117.55 and total cycle time is 11.57 minutes. It provides detailed information on the machining processes, including the cutting parameters, for turning, drilling, and other operations needed to produce the piston from raw stock.

Original Description:

Costing sheet sample

Original Title

725-24-600-12

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a cost breakdown for manufacturing a piston component. It lists the raw materials, machining operations, times, costs, and prices. The total component cost is Rs. 117.55 and total cycle time is 11.57 minutes. It provides detailed information on the machining processes, including the cutting parameters, for turning, drilling, and other operations needed to produce the piston from raw stock.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

115 views2 pagesInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00

Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00

Uploaded by

ramabhplThis document contains a cost breakdown for manufacturing a piston component. It lists the raw materials, machining operations, times, costs, and prices. The total component cost is Rs. 117.55 and total cycle time is 11.57 minutes. It provides detailed information on the machining processes, including the cutting parameters, for turning, drilling, and other operations needed to produce the piston from raw stock.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 2

DANA Description

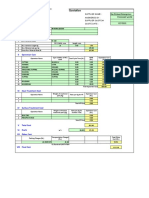

725-24-600-12 Cylinder Details EAU 12800 I USD 53.75 INR

Sno. Part Description Part No. Material Qty UM Unit Cost Ext. Cost M.H.F Stroke-A C S

Component

Cost

Shell

Mat.

Cost

Rod Mat.

Cost

Drain

Tube

Cylinder

Mat. Cost

BURDEN LABOR

TOTAL

WORKS

COST

EAU Packing

Selling

Price

add3.75%-

EOU Tax

Ex-Works

Chennai

1 Shell Material 68 X 80 Variable mtr 1,140.00 Variable 210 0 0 1,339 599 1,160 3,098 402 13 3,513 5,164 191.05 5,354.60

2 Rod Material C45 - 36 dia QT+ IH Variable mtr 1,400.00 Variable 3,513 38% 4,997 184.89 5,181.87

3 Mounting plate OPTION 1 2 kg CASTING 1 ea 400.00 400.00 3 55 165 130 X 110 X 25 THK 3,513 35% 4,766 176.36 4,942.71

4 Piston SHRINK FIT c45 1 ea 118 118 GASCUTTING 20

5 Retainer SNAP IN TYPE cast bar 1 ea 288.10 288.10 MILLING 100

6 M18 port 1 ea 20.00 20.00 DRILL 50

7 HEAD 1 ea 254.32 254.32

8 RETAINING WIRE 1 ea 10.00 10.00 TOTAL 335

9 CIRCLIP 1 ea 10.00 10.00 Quoted Rs Per Cylinder.

10 Piston Cap seal 1 ea 30.00 30.00

11 energizer 1 ea 10.00 10.00

12 rod wear ring 1 ea 20.00 20.00

13 Rod Seal 2 ea 25.00 50.00 0.6 955

14 Wiper 2 ea 27.00 54.00 1591.6667

15 o-ring 1 ea 10.00 10.00

16 Bu ring 1 ea 10.00 10.00

17 Plastic cover FOR PORTS 2 ea 2.00 4.00

Frt for Imported Parts 25% 51.00

TIME IN MINS MACHINE RATE MACHINING COST

PAINTING 50

Shell Material 2 2800 93.3

Rod 5 800 66.7

SHRINK FIT COST 2 400 13.3

WELDING 8 600 80 TARGET

ASSEMBLY 10 250 41.7

TESTING 2 800 26.67

PACKING 30.00

Tulip rate for L & t(50 mic) is 1591

OPTION2

PLATE

Customer Drawing No. STEERING PHC Drawing no. Prepared by RAMASWAMY

Cylinder Part

No.

INTERNAL COSTING SHEET

Customer Name 68 X 36 X 210 Mounting Details PLATE Reference Date 28-Jun-12

PISTON

Material: Date

WO No. : Part No.

Operation

D = Job/Drill

dia

mm

d =

Minor

dia mm

Surface area

in cm

2

Cutting rate

Vz cm

2/

min

Dc = Cutter

dia

mm

No. of

inserts

Feed /

Tooth

(mm)

S=Speed

mtr/ min

N =spindle

speed

rpm

f=Feed

mm/rev

L= Length of

travel mm

No of

pass

depth of

cut mm

Cycle Time

min

SET UP : 1 Machine : BANDSAW

N= (S*1000)/

3.14*D C = L/f*N

1 BANDSAW CUTTING 75 0 44.15625 40 0 0 0 0 0 0.0 0 1 1.10

SETUP TIME 1 MINS 1.10 MINS

SET UP : 2 Machine : CNC LATHE

1 Face cleaning 75 0 0 0 0 0 0 109 463 0.6 47.5 1 0.17

2 OD TURNING 75 0 0 0 0 0 0 109 463 0.6 40 2 0.29

3 PRE-DRILL FOR 30 DIA 6 0 0 0 0 0 0 0 1050 0.075 0 1 80 1.02

4 PRE-DRILL FOR 30 DIA 16 0 0 0 0 0 0 0 425 0.25 0 1 80 0.75

5 PRE-DRILL FOR 30 DIA 20 0 0 0 0 0 0 0 350 0.25 0 1 80 0.91

6 PRE-DRILL FOR 30 DIA 28 0 0 0 0 0 0 0 265 0.35 0 1 80 0.86

7 36 DIA BORE 36 0 0 0 0 0 0 109 964 0.6 50 5 0.43

8 CHAMFER ID 36 0 0 0 0 0 0 109 964 0.2 30 1 0.16

SETUP TIME 1 MINS 4.59 MINS

SET UP : 3 Machine : CNC LATHE

1 Face cleaning 75 0 0 0 0 0 0 109 463 0.6 47.5 1 0.17

2 CHAMFER ID 36 0 0 0 0 0 0 109 964 0.2 30 1 0.16

SETUP TIME 1 MINS 0.33 MINS

SET UP : 4 Machine : CNC LATHE

1 OD TURNING 75 0 0 0 0 0 0 109 463 0.6 45 2 0.32

2 OD TURNING GROOVE 75 0 0 0 0 0 0 109 463 0.6 40 4 0.58

3 CHAMFER OD 75 0 0 0 0 0 0 109 463 0.2 30 2 0.65

SETUP TIME 1 MINS 1.55 MINS

7.57 MINS

4.00 MINS

11.57 MINS

0.19 HRS

40.23 RS

62.00 RS

102.22 RS

15.33 RS

0.00 RS

117.55 RS TOTAL PART COST

TOTAL CYCLE TIME IN MINS

TOTAL CYCLE TIME IN HRS

MACHINING COST

MATERIAL COST

TOTAL COST

Profit 15%

Component Description: PISTON

RAW LENGTH

COST/METER

MACHINING TIME

SETTING / LOADING & UNLOADING TIME PER PIECE

INTERNAL CYCLE TIME ANALYSIS

Issue: 1

C1018 RAW MATL WT: 1.03 KG

Page 2

You might also like

- Injection Molding: Part Cost EstimatorDocument3 pagesInjection Molding: Part Cost Estimatorpchakkrapani100% (1)

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Cost BreakupDocument6 pagesCost Breakuppiyush sharma100% (1)

- Learning Objectives: 3.1 Basic Weld JointsDocument15 pagesLearning Objectives: 3.1 Basic Weld Jointsramabhpl100% (1)

- SHT Metal EstimatorDocument7 pagesSHT Metal Estimatorkarthikkumarfeb6No ratings yet

- Tool Design Calculation: Cutting ForceDocument4 pagesTool Design Calculation: Cutting ForceRaja SathishNo ratings yet

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- Compression Molding Machine PriceDocument13 pagesCompression Molding Machine PriceSalma FarooqNo ratings yet

- Catalogue HyvaDocument222 pagesCatalogue HyvaEdgar Rojas Espejo100% (2)

- Api 579-1 - Asme FFS-1 PaDocument14 pagesApi 579-1 - Asme FFS-1 PaZdravko Ivancic20% (5)

- PlasticDocument172 pagesPlasticNGOC HUYNHNo ratings yet

- Collapse of Flats at Ronan Point, Canning TownDocument83 pagesCollapse of Flats at Ronan Point, Canning TownAman 'kebe' KebedeNo ratings yet

- F1 Car Project ProposalDocument4 pagesF1 Car Project ProposalFirdaus IliasNo ratings yet

- Template For Quoting Sheet Metal PartsDocument100 pagesTemplate For Quoting Sheet Metal PartsCarlos RetamozaNo ratings yet

- Partcost With Freight Table Rev. 7Document3 pagesPartcost With Freight Table Rev. 7RJLockNo ratings yet

- Design and Analysis of Progressive Tool For An Automobile ComponentDocument9 pagesDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- Material: NRE Pricing Sheet Quantity CostDocument1 pageMaterial: NRE Pricing Sheet Quantity CostAnonymous VRspXsmNo ratings yet

- Tonnage CalculatorDocument2 pagesTonnage CalculatorLoveofyouth ReddyNo ratings yet

- Compound Die PDFDocument4 pagesCompound Die PDFNhan Le100% (1)

- Cupola Melting CostDocument3 pagesCupola Melting CostnirevievNo ratings yet

- CostTable Fasteners 2022Document17 pagesCostTable Fasteners 2022shaffin jeba shinuNo ratings yet

- Cost-Benefit AnalysisDocument2 pagesCost-Benefit AnalysisNISREEN WAYANo ratings yet

- E-Coat Inputs: A) Part InformationDocument5 pagesE-Coat Inputs: A) Part InformationAnjan MalusareNo ratings yet

- Machine Cost & Set Up TimeDocument11 pagesMachine Cost & Set Up TimeGanesh SunderNo ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- EA Plasma, Laser, OxyfuelDocument5 pagesEA Plasma, Laser, OxyfuelSaravanan VelayuthamNo ratings yet

- Costing Sheet 500632403736Document6 pagesCosting Sheet 500632403736Sourabh PradhanNo ratings yet

- Machining Line Quote-NewDocument1 pageMachining Line Quote-NewJimmyNo ratings yet

- How To Calculate The Tonnage of Die Casting MachineDocument2 pagesHow To Calculate The Tonnage of Die Casting MachineRafał LesiczkaNo ratings yet

- NTTF Press Tool Standards Ebook GeneralDocument207 pagesNTTF Press Tool Standards Ebook GeneralRagunathan G100% (1)

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- CSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListDocument1 pageCSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListJosemar PorfirioNo ratings yet

- Injection Timing Calculator 2020Document43 pagesInjection Timing Calculator 2020Tim JuddNo ratings yet

- Zuhaltekraftberechnung: Teilbezeichnung Auslegung 1 - FachDocument2 pagesZuhaltekraftberechnung: Teilbezeichnung Auslegung 1 - FachARUN KUMAR KoterimadathilNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Bob 0601 2015 00Document12 pagesBob 0601 2015 00Prashant MoreNo ratings yet

- Piercing Process Cost CalculationDocument3 pagesPiercing Process Cost CalculationVenkateswaran venkateswaranNo ratings yet

- F A X TSS: Cutting ForceDocument3 pagesF A X TSS: Cutting ForcesachinNo ratings yet

- 14.72 KL PP FRP TankDocument24 pages14.72 KL PP FRP TankmaheshdgavaliNo ratings yet

- Stamping Blank and Tonnage CalculatorDocument10 pagesStamping Blank and Tonnage CalculatorDhanus KodiNo ratings yet

- Investment Casting Cycle TimeDocument12 pagesInvestment Casting Cycle TimemaheshNo ratings yet

- 2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeDocument1 page2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeKARTICK PRASADNo ratings yet

- Ijme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Document10 pagesIjme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Impact JournalsNo ratings yet

- Cost Working of Mechanical Press: Description General Formula CostDocument4 pagesCost Working of Mechanical Press: Description General Formula Costazadsingh1No ratings yet

- Project Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceDocument2 pagesProject Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceNihar RanjanNo ratings yet

- Inj Mold CalculateDocument9 pagesInj Mold CalculateGiap NguyenNo ratings yet

- 04 421 40033 Clutch CoverDocument1 page04 421 40033 Clutch CoverPress TechNo ratings yet

- Project: TML (Emc) : Part No 1A014117 Customer TMLDocument2 pagesProject: TML (Emc) : Part No 1A014117 Customer TMLShrikant YashNo ratings yet

- Tonase Dan Kebutuhan Material CV04A Dan RF45Document2 pagesTonase Dan Kebutuhan Material CV04A Dan RF45Bagas Lesta CoratiesNo ratings yet

- FES MTG Welding Fixture F7222910Document11 pagesFES MTG Welding Fixture F7222910Sekar NaikNo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Costing Calculations:: Date: 12/5/2016 Revision: R0 Costing 336Document9 pagesCosting Calculations:: Date: 12/5/2016 Revision: R0 Costing 336Rakesh SharmaNo ratings yet

- Costing Sheet - 1835 - ExtrusionDocument3 pagesCosting Sheet - 1835 - ExtrusionER RAKESHNo ratings yet

- Costing Format - Press ToolDocument6 pagesCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Effeciency CalculationDocument26 pagesEffeciency CalculationAshish SawantNo ratings yet

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocument19 pagesSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uNo ratings yet

- Costing FormatDocument3 pagesCosting FormatdavNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Die Casting Die Parameter - Calculation - GuidelineDocument8 pagesDie Casting Die Parameter - Calculation - GuidelineVenkateswaran venkateswaranNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- TML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeDocument7 pagesTML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeChandrajeet ShelkeNo ratings yet

- DT50U PartsDocument74 pagesDT50U PartshuckinnzNo ratings yet

- Front End Tipping SolutionsDocument16 pagesFront End Tipping SolutionsramabhplNo ratings yet

- Cushioning CalculationDocument2 pagesCushioning CalculationramabhplNo ratings yet

- Leroy Somer Electrical MotorDocument132 pagesLeroy Somer Electrical Motorramabhpl100% (1)

- METRIC THREADS - CHART For Higher SizesDocument2 pagesMETRIC THREADS - CHART For Higher SizesramabhplNo ratings yet

- 2016 Hydraulic Cylinders Industry ReportDocument35 pages2016 Hydraulic Cylinders Industry Reportramabhpl100% (1)

- A005 AtosDocument4 pagesA005 AtosramabhplNo ratings yet

- PV SeriesDocument43 pagesPV SeriesramabhplNo ratings yet

- BreatherDocument4 pagesBreatherramabhplNo ratings yet

- Sweet Spot Front Axle Assembly: Boundary/Block DiagramDocument1 pageSweet Spot Front Axle Assembly: Boundary/Block DiagramramabhplNo ratings yet

- Trelleborg DAS SealDocument3 pagesTrelleborg DAS SealramabhplNo ratings yet

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Ressia at Elmina Gardens - City of Elmina - Way of LivingDocument15 pagesRessia at Elmina Gardens - City of Elmina - Way of LivingSime Darby PropertyNo ratings yet

- ElectricalDocument18 pagesElectricalLimuel Espiritu100% (1)

- Welding Washers For Steel DeckDocument2 pagesWelding Washers For Steel DecktylerlhsmithNo ratings yet

- PCB Designing and Fabrication P.C.B. (Printed Circuit Board)Document2 pagesPCB Designing and Fabrication P.C.B. (Printed Circuit Board)Ashwani DhimanNo ratings yet

- 3M Work Gloves BrochureDocument4 pages3M Work Gloves BrochureherminNo ratings yet

- Cathodic Protection System For Offshore StructureDocument13 pagesCathodic Protection System For Offshore StructureheikelNo ratings yet

- Flowfit CylindersDocument4 pagesFlowfit CylinderspvssrhNo ratings yet

- 1 - Skills and Knowledge of Cost EngineeringDocument17 pages1 - Skills and Knowledge of Cost EngineeringSherazNo ratings yet

- Total Balance ConcreteDocument2 pagesTotal Balance ConcreteNICMAILNo ratings yet

- Super Heavy AerbDocument42 pagesSuper Heavy Aerbarpitmehta85051No ratings yet

- Manual Masina de Spalat Rufe Incorporabila BekoDocument72 pagesManual Masina de Spalat Rufe Incorporabila BekoPerfectreviewNo ratings yet

- GB 50011-2010-EnDocument240 pagesGB 50011-2010-Enrahman fatah0% (1)

- TE-6070V Sampler Calibration Worksheet: Site and Calibration Information (Using G-Factor)Document3 pagesTE-6070V Sampler Calibration Worksheet: Site and Calibration Information (Using G-Factor)EDWARDNo ratings yet

- Motor Diesel F5L912Document35 pagesMotor Diesel F5L912Anonymous iu95trpxN100% (1)

- America's Secret Space Program and The Super ValkyrieDocument9 pagesAmerica's Secret Space Program and The Super ValkyrieVen Geancia0% (1)

- N2XH IEC 60502-1 XLPE FRNC 0.6/1kV CableDocument4 pagesN2XH IEC 60502-1 XLPE FRNC 0.6/1kV Cableesilva2021No ratings yet

- This PDF Document Is A Partial Sample Chapter From The Book..Document9 pagesThis PDF Document Is A Partial Sample Chapter From The Book..Anonymous VRspXsmNo ratings yet

- WeishauptDocument24 pagesWeishauptpatitay036817No ratings yet

- Datasheet 5451 and 5452 QSIIDocument6 pagesDatasheet 5451 and 5452 QSIIvictornoesgrunfeldNo ratings yet

- Development of Hybrid BT Cotton in China A Successful Integration of Transgenic Technology and Conventional TechniquesDocument5 pagesDevelopment of Hybrid BT Cotton in China A Successful Integration of Transgenic Technology and Conventional Techniqueszhongshunmao1541No ratings yet

- Security Survey of SITEDocument4 pagesSecurity Survey of SITEbcsharma_2009100% (1)

- 2020 ProposalDocument14 pages2020 Proposalapi-338285899No ratings yet

- Ehouse MCC Switchgear BuildingDocument15 pagesEhouse MCC Switchgear BuildingSARAVANA100% (1)

- Technical Manual 50UB-2014Document41 pagesTechnical Manual 50UB-2014SHNODANo ratings yet

- Bulb Flat, Steel Bulb Flats, hp100x8 Bulb Bar PDFDocument4 pagesBulb Flat, Steel Bulb Flats, hp100x8 Bulb Bar PDF9245126694No ratings yet

- Hollow Structural Section NSMPDocument16 pagesHollow Structural Section NSMPAngelo MoralNo ratings yet