Professional Documents

Culture Documents

1542 - Sand For Plastering

1542 - Sand For Plastering

Uploaded by

Deepak Balasubramanian0 ratings0% found this document useful (0 votes)

18 views5 pagesSand IS code

Original Title

1542- Sand for Plastering

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSand IS code

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views5 pages1542 - Sand For Plastering

1542 - Sand For Plastering

Uploaded by

Deepak BalasubramanianSand IS code

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

I ndian Standard

SAND FOR PLASTER - SECIFICATION

/ Second Revision J

Second Reprint FEBRUARY 1999

UDC 691.223:691.55

@ BIS 1992

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARC3

NEW DELHI 110002

J&J 1992

Wcibql

( Reaffirmed 1999 )

Flooring, Wall Finishing and Roofing Sectional Committee, CED 5

FOREWORD

This Indian Standard ( Second Revision ) was adopted by the Bureau of Indian Standards, after the

draft finalized by the Flooring, Wall Finishing and Roofing Sectional Committee had been approved

by the Civil Engineering Division Council.

This standard was first published in 1960 and subsequently revised in 1977. In this second revision

following major modifications are made :

a) Crushed gravel sand and ALPM have been added in the scope and pit sand has been included

under naturally occurring sands;

b) As per the grading given in Table 1, the fineness modulus of sand could vary from I.2 to 2.2.

However, it is preferable to have minimum fineness modulus of l-4 in case of crushed stone

sands and crushed gravel sands and a F. M of 1 5 in case of naturally occurring sands. Hence,

this new clause, namely 5.2 has been added;

c) Amendment No. 1 giving O-15 percent passing for 150 micron IS Sieve in Table 1 has been

incorporated;

d) A new clause, namely 7.1 (a) has been added so that when requested by the purchaser, the

supplier shall supply particle size grading of sand.

For the purpose of deciding whether a particular requirement of this standard is complied with, the

final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in

accordance with IS 2 : 1960 Rules for rounding off numerical values ( revised ). The number of

significant places retained in the rounded off value should be the same as that of the specified value in

this standard.

IS x42:1992

I ndian Standard

SAND FOR PLASTER - SPECIFICATION

( Second Revision J

1 SCOPE

1.1 This standard covers the requirements of

naturally occurring sands, crushed stone sands

and crushed gravel sands used in mortars for

internal wall and ceiling plastering, and external

plastering using mixes of lime, cement, compo-

site lime-cement, activated lime pozzolana

mixture ( ALMP ) or gypsum with or without

admixtures and sand.

2 REFERENCES

2.1 The following Indian Standards are neces-

sary adjuncts to this standard.

IS No. Title

383 : 1970 Specification for coarse and

fine aggregates from natural

sources for concrete ( second

revision )

1727 : 1967 Method of test for pozzolanic

materials (first revision )

2250 : 1981 Code of practice for prepara-

tion and use of masonry

mortars (jirst revision )

2386 Methods of test for aggrega-

tes for concrete :

( Part 1 ) : 1963 Part 1 Particle size and shape

( Part 2 ) : 1963 Part 2 Estimation of deleteri-

ous materials and organic

impurities

( Part 3 ) : 1963 Part 3 Specific gravity, den-

sity, voids, absorption and

bulking

2430 : 1986 Methods for sampling of

aggregates for concrete

3 TERMINOLOGY

3.1 For the purpose of this standard, the follow-

ing definitions shall apply.

3.2 Sand

A fine aggregate which is either a natural sand,

crushed stone sand or crushed gravel sand.

3.3 Natural Sand

A fine aggregate produced by the natural disin-

tegration of rock which has been deposited by

streams or glacial agencies or obtained from

pits.

3.4 Crushed Stone Sand and Crashed Gravel Sand

A fine aggregate produced by crushing hard

stone or natural gravel.

4 QUALITY OF SAND

4.1 General

The sand shall consist of natural sand, crushed

stone sand or crushed gravel sand or a combina-

tion of any of these. The sand shall be hard,

durable, clean and free from adherent coatings

and organic matter and shall not contain clay,

silt and dust more than specified under 4.3 (a).

4.2 Deterious Materials

The sand shall not contain any harmful impurr-

ties, such as, iron pyrites, alkalis, salts, coal,

mica, shale or similar laminated materials, soft

fragments, sea shells and organic impurities in

such quantities as to affect adversely the

hardening, the strength, the durability of the

appearance of the plaster or applies decoration,

or to cause corrosion of metal lathing or other

metal in contact with the plaster.

4.3 Limits of Deleterious Materials

Unless found satisfactory as a result of further

tests as may be specified by the engineer or

architect, or unless evidence of such perfor-

mance is offered which is satisfactory to him,

the maximum quantities of clay, fine silt, fine

dust and organic impurities in the sand shall not

exceed the following limits:

a) Clay, silt and dust Not more than 5

[ determined in percent by weight

accordance with

IS 2386 ( Part 2 ) :

1963 ]

b) Organic impuriries Colour

[ determined

of liquid

in below that indicated

accordance with by comparison with

IS 2386 ( Part 2 ) : the standard solution

1963 ] specified in 6.2.2 of

IS 2336 ( Part 2 ) :

1963

NOTE - In particular cases crushed stone sand with

even higher proportions of fine dust than specified

above, may be satisfactory and the limit so permitted

may be subject to the agreement between the suppliel

anti the purchaser.

1

X31542:1992

4.4 The average compressive strength, determi-

ned by the standard procedure detailed in

Appendix A of IS 2250 : 1981, of mortar cubes

composed of one part of cement and six parts

of sand conforming to gradation in Table 1

shall be not less than 3 N/mm2 at 28 days.

4.4.1 The amount of water for gauging shall be

that required to give a flow between 110 to 115

with 25 drops in 15 seconds, as determined in

9.5.3 of IS 1727 : 1967.

5 GRADING OF SAND

5.1 The particle size grading of sand for plaster

work for internal as well as external walls and

ceiling as analyzed by the method described in

IS 2386 ( Part 1 ) : 1973 shall be as specified in

Table 1. Where the grading falls outside the

limits of the grading zones of sieves other than

150, 300 and 600 micron IS Sieve by a total

amount not exceeding 5 percent, it shall be

regarded as falling within the grading.

Table 1 Grading of Saod for Internal Wall or

External Wall or Ceiling Plaster

( C/awe 5.1 )

16 Sieve Designation

( See IS 460 : 1985 )

1Omm

475 mm

236 mm

118 mm

600 micron

300 micron

150 micron

Percentage Passiog

100

95-100

95-100

90-100

80-100

20-65

o-15

NOTE - For crushed stone sands and crushed gravel

sands, the permissible limit on 150 micron IS Sieve is

increased to 20 percent. This does not affect the

5 percent allowance permitted in 5.1.

5.2 The fineness modulus of sand shall be not

less than I.4 in case of crushed stone sands and

crushed gravel sands and not less than I.5 in

case of naturally occurring sands.

5.3 The various sizes of particles of which the

sand is composed shall be uniformly distributed

throughout the mass.

5.4 The required grading may often be obtained

by screening and/or by blending together either

natutal sands or crushed stone screenings, which

are by themselves of unsuitable grading.

6 SAMPLING AND TESTING

6.1 Sampling

The method of sampling shall be in accordance

with IS 2430 : 1986. The amount of material

required for each test shall be as specified in

relevant parts of IS 2386 and as per the require-

ments of 4.4.

6.2 Testing

Any test which the purchaser or his representa-

tive may require in connection with this

standard shall be carried out in accordance with

the provisions of various clauses in the standard.

Unless otherwise stated in the enquiry or order,

duplicate tests shall be made to al1 cases and

the results of both tests reported.

7 ADDITIONAL INFORMATION TO BE

FURNISHED BY THE SUPPLIER

7.1 When requested by the purchaser or his

representative, the supplier shall provide the

following additional particulars:

4

b)

4

Source of supply - Precise locality from

where the materials were obtained, with

the name of the quarry or pit;

Trade group of principal rock type in case

of manufactured sand ( see Appendix C

of IS 383 : 1970 ); and

Particle size of grading when determined

ip96;ccordance with IS 2386 ( Part I ) :

.

7.2 Subject to prior agreement, the supplier

shall furnish the following additional informa-

tion, when required by the purchaser or his

representative:

a) Specific gravity of sand [ determined with

IS 2386 ( Part 3 ) : 1963); and

b) Bulk density [ determined in accordance

with IS 2386 ( Part 3 ) : 1963 1.

7.3 If possible, information on the bulking of

the sand with varying moisture content may be

furnished in the form of a graph.

2

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of I ndi an Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quaIity_certification of goods and

attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sixes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the hasis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments,or edition by referring to the latest issue

of BIS Handbook and Standards Monthly Additions.

This Indian Standard has been developed from Dot: No. CED 5 ( 4875 )

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah &far Marg, New Delhi 110002

Telephones: 323 0131,323 33 75,323 94 02

Regional Offices:

Telegrams: Manaksanstha

(Common to all offices)

Telephone

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern :

Northern :

l/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCUTTA 700054

SC0 335336, Sector 34-A CHANDIGARH 160022

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI.

HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

PATNA. PUNE. THIRUVANANTHAPURAM.

323 76 17,323 38 41

337 84 99,337 85 61

337 86 26,337 9120

{

60 38 43

602025

{

235 02 16,235 04 42

235 15 19,235 23 15

832 92 95,832 78 58

832 78 91,832 78 92

Printed by Reprography Unit, BIS, New Delhi

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aashto M294Document19 pagesAashto M294asdrecv100% (1)

- Hydrostatic Strength of HDPE Pipes - Test ProcedureDocument5 pagesHydrostatic Strength of HDPE Pipes - Test ProceduremuhamedzNo ratings yet

- Hilti 2008 Product Technical Guide r021 1Document452 pagesHilti 2008 Product Technical Guide r021 1shasta963No ratings yet

- Dmg-Area2-Refresher-Ans-Part 1Document8 pagesDmg-Area2-Refresher-Ans-Part 1DessNo ratings yet

- Welding Technology Unit 6008Document10 pagesWelding Technology Unit 6008loganathanNo ratings yet

- API575 Closed Book Q For 653 StudyDocument26 pagesAPI575 Closed Book Q For 653 StudyTasneemAhmad100% (1)

- MAI R32N&S 9851 2230 01cDocument2 pagesMAI R32N&S 9851 2230 01cesteban muñozNo ratings yet

- Equipment & Material List: Sinoma International Engineering Co.,LtdDocument1 pageEquipment & Material List: Sinoma International Engineering Co.,LtdSadiq TurkiNo ratings yet

- Labour Productivity ChartDocument1 pageLabour Productivity ChartGlenn Mark Dagohoy0% (1)

- Fire-Rated Glazing ProductsDocument3 pagesFire-Rated Glazing ProductsKristoffer Jose AlcantaraNo ratings yet

- SG Insert SpecificationDocument16 pagesSG Insert SpecificationRaamkriss Raja100% (2)

- Material Selection For Designing The AirfoilDocument1 pageMaterial Selection For Designing The AirfoilJoséLuisPillajoNo ratings yet

- IKEA Fixa-Skruv-Och-Pluggset-Delar - AA-2097280-1 - Pub PDFDocument64 pagesIKEA Fixa-Skruv-Och-Pluggset-Delar - AA-2097280-1 - Pub PDFyavuz danisNo ratings yet

- Facade Presentattions FinalDocument34 pagesFacade Presentattions FinalSyed Mohammed ZakariaNo ratings yet

- Product Catalogue.27214653 PDFDocument28 pagesProduct Catalogue.27214653 PDFvishnutryNo ratings yet

- Md-216-3110-Eg-Cv-Cal-1003-A01 Calculation 3110 Primary Crushing Rom Retaining Wall Design Calculation PDFDocument417 pagesMd-216-3110-Eg-Cv-Cal-1003-A01 Calculation 3110 Primary Crushing Rom Retaining Wall Design Calculation PDFSuperkineticNo ratings yet

- Simplified Construction Estimate: ConcreteDocument11 pagesSimplified Construction Estimate: ConcreteGreta Andrea TalipNo ratings yet

- Sika PDS E Sika CrackstopDocument2 pagesSika PDS E Sika Crackstoplwin_oo2435No ratings yet

- BOQ of Puddle PipeDocument4 pagesBOQ of Puddle PipeSmit BhivgadeNo ratings yet

- Data Sheet For BRASS SPECIFICATIONS PDFDocument5 pagesData Sheet For BRASS SPECIFICATIONS PDFvkmsNo ratings yet

- Water Tank SpecificationDocument28 pagesWater Tank Specificationdan20000No ratings yet

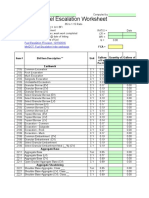

- Fuel Escalation WorksheetDocument3 pagesFuel Escalation WorksheetDilhara WickramaarachchiNo ratings yet

- Leo Pump Stainlesssteel Horizontal AMS CatalogueDocument12 pagesLeo Pump Stainlesssteel Horizontal AMS CataloguemantenimientonautilusNo ratings yet

- Auto Sequential Control Panel - Blue VoltDocument4 pagesAuto Sequential Control Panel - Blue VoltdesignNo ratings yet

- PP PP4-0R Polypropylene: Technical Data Sheet (TDS)Document1 pagePP PP4-0R Polypropylene: Technical Data Sheet (TDS)Jorge MedinaNo ratings yet

- Wear Reducing Technology in Severe Pumping ServicesDocument29 pagesWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNo ratings yet

- Astm A709 A709m-09Document8 pagesAstm A709 A709m-09Tran Tien DungNo ratings yet

- Bulk Water Meter Installation in Chamber LDPE Connection Guidelines Rev3 27042022.ashxDocument7 pagesBulk Water Meter Installation in Chamber LDPE Connection Guidelines Rev3 27042022.ashxsyed ahamed spacemakerNo ratings yet

- Heat Treatment PPTDocument70 pagesHeat Treatment PPTJhonrey QuejadaNo ratings yet

- 4 MMCsDocument33 pages4 MMCsGunasekaran JagadeesanNo ratings yet