Professional Documents

Culture Documents

Mathematical Manipulation of Pure Sine Wave Inverter Using Atmel 89S2051

Mathematical Manipulation of Pure Sine Wave Inverter Using Atmel 89S2051

Uploaded by

usamaelkomy0 ratings0% found this document useful (0 votes)

10 views6 pagesOriginal Title

Sine Inverter

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views6 pagesMathematical Manipulation of Pure Sine Wave Inverter Using Atmel 89S2051

Mathematical Manipulation of Pure Sine Wave Inverter Using Atmel 89S2051

Uploaded by

usamaelkomyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

Mathematical Manipulation of Pure Sine Wave Inverter

Using Atmel 89S2051

Didik Rostyono (rostyono@webmail.bppt.go.id) & Harsono Hadi (harsono50@yahoo.com)

Introduction

Approach used for creating the pure sine wave described in this paper is done

through manipulation of mathematical representation of the original sine wave. It is

done by dividing half the sine wave into m (even number) segmentations, where

area under a quarter of the sine wave from 0 to /2 resembles series of the form

[2n-1] where n=1,, m/2, while areas of the next quarter from /2 to will

resemble series of the form [2n-1] where n=m/2,.., 1.

Figure 1. Dividing the sine wave into small segments

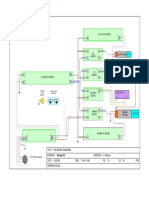

Block Diagram & Schematic

The inverter will converts 12 Volt dc from battery into 110 Volt ac, 50 Hz, sine

wave. Figure 2 and 3 show the block dagram and schemnatic circuit of the inverter.

B

A

Micro

Controller

89S2051

Driver

Switching

MOSFET

Start/ Stop Button

Battery Sensing

Reset Button

FI LTER

LPF

TRAFO

Clock

Power

Supply

Figure 2. Block diagram of pure sine wave inverter

Pulse train as shown in figures 5 is produced interchangeably from port (A)

and port (B) by microcontroller 89S2051 during the positive half and negative half of

the sine wave. The pulse train is then inputted to the MOSFET power switching

circuit, which is next directed to the primary side of the transformer. Output of the

secondary side is shown in Figure 6, which then be filtered resulting in the sine wave

as seen in figure 7, where amplitude attenuation can reach up to 50%. Measured

inverter output THD reaches 5-8%, where the largest harmonics appeared to be the

second and third harmonics as shown in figure 8.

0

PURE SINE INVERTER

A

1 1 Monday, J uly 16, 2007

Title

Size Document Number Rev

Date: Sheet of

< AC OUTLET >

AC LOAD

*) Low Vol t age

Reset

S

t

a

r

t

/

S

t

o

p

12 VDC

33 pf

1 uF

1

0

K

B

C

5

4

7

1

2

K

1K5

1

2

K

2

N

3

9

0

6

I

R

F

Z

4

4

N

1

0

0

1

0

K

1

2

K

1

2

K

2

N

3

9

0

6

1

2

K

1

0

K

B

C

5

4

7

1

2

V

-

2

2

0

V

2 uF

1

0

K

12 MHz

AT89S2051

RST

P3.0

P3.1

XT1

XT2

P3.2

P3.3

P3.4

P3.5

GND

VCC

P1.7

P1.6

P1.5

P1.4

P1.3

P1.2

P1.1

P1.0

P3.7

1

,

2

m

H

7805

1

2

3

1

0

K

1

0

0

I

R

F

Z

4

4

N

B

C

5

4

7

*

)

1 K

BUZER

1K5

Figure 3. Schematic of Pure Sine Inverter

Figure 4. PCB of Pure Sine Inverter

Testing

Figure 5. Pulse train (m=10) of Atmel 89s2051

Figure 6. Secondary Side Transformer Output

Figure 7. Filter Output

Figure 8. Harmonic measurement result (Hioki)

Listing Software

; ===========================================

; PROGRAM I NVERTER OLEH: DI DI K ROSTYONO 2006

; ===========================================

; P1=I NPUT P3=OUTPUT

; P1. 2=TOMBOL START P1. 3=BATERE CEK

; P3. 0=DRI VER1 P3. 1=DRI VER2

; P3. 4=BUZZER P3. 5=LED

; I NI SI ALI SASI ( BEEP PENDEK + BEEP PANJ ANG)

ORG 00H

ON: MOV P3, #20H; DRI VER OFF, BUZZER OFF, LED OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

SETB P3. 4; BEEP ON

CLR P3. 5; LED BI RU ON

ACALL DELAI ; TUNGGU 1/ 4 DETI K

CLR P3. 4; BEEP OFF

SETB P3. 5; LED BI RU OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

SETB P3. 4; BEEP ON

CLR P3. 5; LED BI RU ON

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

CLR P3. 4; BEEP OFF

SETB P3. 5; LED BI RU OFF

; CEK KONDI SI BATERE ( LOWVOLTAGE = 2 X BEEP PENDEK)

CEK: J NB P1. 3, MULAI ; CEK KONDI SI BATERE

CLR P3. 5; LED BI RU ON

SETB P3. 4; BEEP ON

ACALL DELAI ; TUNGGU 1/ 4 DETI K

SETB P3. 5; LED BI RU OFF

CLR P3. 4; BEEP OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

CLR P3. 5; LED BI RU ON

SETB P3. 4; BEEP ON

ACALL DELAI ; TUNGGU 1/ 4 DETI K

SETB P3. 5; LED BI RU OFF

CLR P3. 4; BEEP OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

SJ MP CEK

; I NVERTER MENUNGGU PENEKANAN TOMBOL ON

MULAI : SETB P3. 5; LED BI RU OFF

CLR P3. 4; BEEP OFF

MULAI 1: J NB P1. 2, START; BACA TOMBOL START

CLR P3. 5; LED BI RU ON

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

J NB P1. 2, START; BACA TOMBOL START

SETB P3. 5; LED BI RU OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

AJ MP CEK

; I NVERTER ON

START: SETB P3. 5; LED BI RU OFF

CLR P3. 4; BEEP OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

ACALL DELAI ; TUNGGU 1/ 4 DETI K

SETB P3. 4; BEEP ON

CLR P3. 5; LED BI RU ON

ACALL DELAI ; TUNGGU 1/ 4 DETI K

CLR P3. 4; BEEP OFF

ACALL DELAI ; TUNGGU 1/ 4 DETI K

; PWM GENERATOR

PULSE: J NB P1. 2, ON; J I KA STOP DI TEKAN KEMBALI KE AWAL

J B P1. 3, ON; CEK KONDI SI BATERE

PWM: CLR P3. 0;

CLR P3. 1;

SETB P3. 0;

ACALL PULSE_TRAI N;

CLR P3. 0;

CLR P3. 1;

ACALL PULSE_TRAI N;

CLR P3. 0;

CLR P3. 1;

AJ MP PULSE

; RUTI N DELAI 1

DELAI : MOV R1, #2

L1: MOV R2, #250

L2: MOV R3, #250

L3: DJ NZ R3, L3

DJ NZ R2, L2

DJ NZ R1, L1

RET

You might also like

- A320 Schematics PDFDocument4 pagesA320 Schematics PDFAlina Costica100% (2)

- T09849 - CTR Fire Systems Rev.2Document30 pagesT09849 - CTR Fire Systems Rev.2Rudra Dash89% (9)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Doosan Eschemtic PDFDocument318 pagesDoosan Eschemtic PDFThomas Hansen100% (3)

- NIKE - Failure in Demand ForecastingDocument10 pagesNIKE - Failure in Demand ForecastingVeer Gupte100% (1)

- Building The MPP Beach (Rev-E)Document19 pagesBuilding The MPP Beach (Rev-E)Mhuhammad KhanNo ratings yet

- 29ltd-st 29wx-st SM pg12 pg34Document23 pages29ltd-st 29wx-st SM pg12 pg34Jesus Antonio Gonzalez QuinteroNo ratings yet

- Route To Market StrategyDocument31 pagesRoute To Market StrategyVeer Gupte100% (2)

- Building The MPP Beach (Rev-E)Document19 pagesBuilding The MPP Beach (Rev-E)dzuglicNo ratings yet

- Mini Pulse ReveDocument19 pagesMini Pulse Revejackomino100% (1)

- Com 069 Agk 2030 EdDocument14 pagesCom 069 Agk 2030 EdSimamora Samuel HansenNo ratings yet

- NavNet Service Manual B 7 19 2002 PDFDocument296 pagesNavNet Service Manual B 7 19 2002 PDFErvin Luka TodiNo ratings yet

- Pm1 HT Motor & Panel: ECM Check List Doc No: ECM-02 Checking List No: 5 Genting Sanyen Rev.2 Electrical DepartmentDocument3 pagesPm1 HT Motor & Panel: ECM Check List Doc No: ECM-02 Checking List No: 5 Genting Sanyen Rev.2 Electrical DepartmentMohd A IshakNo ratings yet

- Renr2477renr2477-02 SisDocument4 pagesRenr2477renr2477-02 SisNanda PutriNo ratings yet

- Cat - Dcs.sis - Controller 3412 XDocument2 pagesCat - Dcs.sis - Controller 3412 XKariem R Noweer67% (3)

- Panasonic Inverter ManualDocument8 pagesPanasonic Inverter Manualsamernet2100% (1)

- Salon Tipi 3 Faz ServisDocument79 pagesSalon Tipi 3 Faz ServisaydintarakNo ratings yet

- Schedule 22-09-2014 Final Without Spare LoadDocument42 pagesSchedule 22-09-2014 Final Without Spare LoadhafizrahimmitNo ratings yet

- Set Point Table 3-1iDocument17 pagesSet Point Table 3-1iRyo NugrohoNo ratings yet

- Bom For ZCL MCCDocument21 pagesBom For ZCL MCCsaleemNo ratings yet

- Trace Elliot Velocette 12r Schematic DiagramDocument9 pagesTrace Elliot Velocette 12r Schematic DiagramjonnycoolNo ratings yet

- Akai GX-C730DDocument57 pagesAkai GX-C730Dlpy21No ratings yet

- FTM 181 Manual Rev 3Document3 pagesFTM 181 Manual Rev 3Brandi ChandlerNo ratings yet

- DC Motor Control ReportDocument21 pagesDC Motor Control ReportNishant SinghNo ratings yet

- Ac Transformer P.C.B. (Repx0203G... E/Eg)Document1 pageAc Transformer P.C.B. (Repx0203G... E/Eg)DjrichardMixNo ratings yet

- Datasheet 74hct40103Document17 pagesDatasheet 74hct40103Yettie OgunduboyeNo ratings yet

- FDG Wiring DetailDocument13 pagesFDG Wiring DetailHerman_MLNo ratings yet

- CA12000202-A Pump Starter With ProfibusDocument1 pageCA12000202-A Pump Starter With Profibusnickname12345No ratings yet

- TCL Series Solid State Tesla CoilDocument20 pagesTCL Series Solid State Tesla CoilNayanka SpringerNo ratings yet

- ILMS Approved Drawing_29.03.2011Document10 pagesILMS Approved Drawing_29.03.2011PankajNo ratings yet

- BOP - DCS IO List Rev 2.5 (08.04.2014)Document535 pagesBOP - DCS IO List Rev 2.5 (08.04.2014)prateek0291No ratings yet

- Product Profile: 1.1 General DescriptionDocument12 pagesProduct Profile: 1.1 General DescriptionRakesh Kumar DNo ratings yet

- How To Configure A 555 Timer ICDocument9 pagesHow To Configure A 555 Timer ICHebert Danilo Auccapure CusiNo ratings yet

- RE7ML11BU TelemecaniqueDocument22 pagesRE7ML11BU TelemecaniqueHugo FermartiNo ratings yet

- Precision Waveform Generator/Voltage Controlled Oscillator FeaturesDocument12 pagesPrecision Waveform Generator/Voltage Controlled Oscillator FeaturesCharles Tineo0% (1)

- HT9170B/HT9170D DTMF Receiver: FeaturesDocument14 pagesHT9170B/HT9170D DTMF Receiver: FeaturesjanepriceNo ratings yet

- BOP - DCS IO List Rev 2.4 (27.01.2014)Document566 pagesBOP - DCS IO List Rev 2.4 (27.01.2014)vinospaceshuttleNo ratings yet

- 3kW Water Spare Parts 62Document6 pages3kW Water Spare Parts 62ccarneroNo ratings yet

- Solution For 150 W Half Bridge Resonant DC-DC ConverterDocument13 pagesSolution For 150 W Half Bridge Resonant DC-DC ConverterFabrício AngieneNo ratings yet

- 38tdb 3wiring DiagramDocument4 pages38tdb 3wiring DiagramMakWilliamsNo ratings yet

- Amos - Commandline Interface: 1. Getting Started 1.1 Launching Amos From Oss Front Page GuiDocument20 pagesAmos - Commandline Interface: 1. Getting Started 1.1 Launching Amos From Oss Front Page GuiSefyuNo ratings yet

- Memorex Mt1130c TV Service ManualDocument13 pagesMemorex Mt1130c TV Service Manualricardo_MassisNo ratings yet

- PAK Martono Laporan FixDocument29 pagesPAK Martono Laporan FixBudiSetiawanNo ratings yet

- Ikc2-Service Tips PDFDocument18 pagesIkc2-Service Tips PDFzoltan esteban Hrotko gonzalez100% (1)

- Nad 705 Receiver Integrated Amplifier Service ManualDocument50 pagesNad 705 Receiver Integrated Amplifier Service ManualpapirojedecNo ratings yet

- Electronics Soalan Measurement MySkills Akhir 2011Document14 pagesElectronics Soalan Measurement MySkills Akhir 2011Afdzam AzuraNo ratings yet

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- The Mediterranean Sea: Temporal Variability and Spatial PatternsFrom EverandThe Mediterranean Sea: Temporal Variability and Spatial PatternsNo ratings yet

- Organic Light-Emitting Transistors: Towards the Next Generation Display TechnologyFrom EverandOrganic Light-Emitting Transistors: Towards the Next Generation Display TechnologyNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- CRM TajDocument36 pagesCRM Tajanup_58100% (15)

- Valuation of BondsDocument46 pagesValuation of BondsRajesh K. PedhaviNo ratings yet

- Passage To India Selling To Indias Consumer MarketDocument12 pagesPassage To India Selling To Indias Consumer MarketVeer GupteNo ratings yet

- A Report On Brand Bulding of VolkswagenDocument44 pagesA Report On Brand Bulding of VolkswagenVeer GupteNo ratings yet

- Getting Routes To Market RightDocument16 pagesGetting Routes To Market RightVeer Gupte100% (3)

- CRM Hotel IndustryDocument17 pagesCRM Hotel IndustryVeer GupteNo ratings yet

- Role of IT & Operations in FMCG IndustryDocument5 pagesRole of IT & Operations in FMCG IndustryVeer GupteNo ratings yet

- Final Report - Nike & Its International Labor PracticesDocument38 pagesFinal Report - Nike & Its International Labor PracticesVeer GupteNo ratings yet

- Low Voltage Transmission Circuit With Dialler Interface: ILA1062ADocument9 pagesLow Voltage Transmission Circuit With Dialler Interface: ILA1062AVeer GupteNo ratings yet