Professional Documents

Culture Documents

Digital Distributing Frame (DDF) Installation Procedures For Panels and Modules General

Digital Distributing Frame (DDF) Installation Procedures For Panels and Modules General

Uploaded by

chi83940 ratings0% found this document useful (0 votes)

32 views16 pagesTECDC

Original Title

847_591_963

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTECDC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

32 views16 pagesDigital Distributing Frame (DDF) Installation Procedures For Panels and Modules General

Digital Distributing Frame (DDF) Installation Procedures For Panels and Modules General

Uploaded by

chi8394TECDC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 16

CommScope 365-301-136-1

Instruction Sheet Issue 10, February 2004

Material ID 847 591 963

2007 CommScope, Inc.

All Rights Reserved

Printed in U.S.A.

Page 1

16 Pages

DIGITAL DISTRIBUTING FRAME (DDF)

INSTALLATION PROCEDURES FOR

PANELS AND MODULES

General

The Digital Distributing Frame (DDF) is a 75-ohm frame system that serves as an equal level cross-connect

point for signals conforming to the DS3 (44.76 Mb/s), CEPT-1 (2.048 Mb/s), CEPT-2 (8.448 Mb/s), CEPT-3

(34.368 Mb/s), CEPT-4 (139.264 Mb/s), and STM-1 (155.52 Mb/s) signal formats. The modules allow access

to all equipment terminated at the frame and provide a flexible cross-connect between two Network Elements.

Equipment Description

The DDF system consists of individual DDF modules mounted in a panel. There are three types of DDF

modules: the Rear/Front DDF Dual Monitor (R/F-DDF-DM), the DDF Performance Module (DDF-PM), and the

Rear/Rear DDF Dual Monitor (R/R-DDF-DM). The DDF-DM modules have two protected monitor-level (20

dB) jacks to provide nonservice interrupt monitoring of all circuits. The DDF-PM modules have a single

protected monitor level jack.

The Rear/Front DDF Dual Monitor (R/F-DDF-DM) module, shown in Figure 1, is equipped with six BNC

connectors. Four BNC connectors are located on the front of the module: MON-O (Monitor Out), MON-I

(Monitor In), OUT, and IN. Two BNC connectors are located on the rear of the module: TX and RX (Out

transmit and In receive, respectively).

Figure 1. Digital Distribution Frame Dual Monitor (DDF-DM)

The Rear/Rear Dual Monitor (R/R-DDF-DM) module (shown in Figure 2) is equipped with six BNC

connectors. Four BNC connectors are included on the front of the module: OUT, IN, TX (Out transmit),

and RX (In receive). This module is snapped into panels from the rear for rear cross-connect

applications.

The DDF Performance Module (DDF-PM) is equipped with five BNC connectors. Three BNC

connectors are located on the front of the module: MON, OUT, and IN. Two BNC connectors are located

on the rear of the module: TX and RX (Out transmit and In receive, respectively).

MON-O

MON-I

OUT

IN

(16 mm)

0.75" (19 mm)

0.8" (21 mm)

0.75" (19 mm)

TX

RX

Out (transmit)

1" (25 mm)

3.6"

(92 mm)

0.62"

Front Side Rear

Fig01DDF-DM.wmf

Material ID 847 591 963

Instruction Sheet

Page 2

16 Pages

Figure 2. Rear/Rear Digital Distribution Frame Dual Monitor (R/R-DDF-DM) Module

The R/F panels are available in both 32-module and 24-module arrangements and mount horizontally in either

a 23-inch (600 mm) wide bay frame (32-module version) or a 19-inch (500 mm) wide bay frame (24 module

version). The 24-module Rear/Rear panel includes adapter brackets for mounting in a 23-inch (600 mm) wide

bay frame.

The 32-module R/F-DDF panel, shown in Figure 3, mounts horizontally in a 23-inch (600 mm) wide network

bay frame. A 7-foot (2.1 m) bay frame can accommodate up to 12 panels for a total of 384 circuits, or if the

optional horizontal trough is used, up to nine panels for a total of 288 circuits.

Figure 3. DDF 32-Module Panel With Optional Horizontal Trough

MON-O

MON-I

OUT

IN

TX

RX

Fig02RR-DDF-DM.wmf

22.2"

(566 mm)

6.8"

(175 mm)

Fig03DDF 32-Mod.wmf

Material ID 847 591 963

Issue 10, February 2004

Page 3

16 Pages

The 24-Module R/F DDF panel, shown in Figure 4, mounts horizontally in a 19-inch (500 mm) wide network

bay frame. A 7-foot (2.1 m) bay frame can accommodate up to 12 panels for a total of 288 circuits, or if the

optional horizontal trough is used, up to nine panels for a total of 216 circuits.

Figure 4. DDF 24-Module Panel With Optional Horizontal Trough

The 24-module R/R DDF panel shown in Figure 5 mounts horizontally in a 19-inch (500 mm) wide network bay

frame; or, if the supplied adapter brackets are used in a 23-inch (600 mm) wide network bay frame. A 7-foot

(2.1 mm) bay frame can accomodate up to 15 panels for a total of 360 circuits.

Figure 5. 24-Module R/R DDF Panel

The DDF system may be configured for front or rear cross-connect and interconnect applications.

A complete line of network bay frames, framework hardware, and patch and test cords are available to support

installation, cable management, and operations.

Fig04DDF 24-Mod.wmf

Fig05 24-Mod RR DDF.wmf

18.3"

(465 mm)

4.0"

(101.6 mm)

Material ID 847 591 963

Instruction Sheet

Page 4

16 Pages

Features of the DDF include the following:

Compatible with DS3, CEPT-1, CEPT-2, CEPT-3, CEPT-4, and STM-1 signal rates.

BNC connectors are equipped with a locking mechanism for both the patch cords (in cross-connect

arrangements).

Recommended front cross-connect arrangement allows easy access for patching around faulty

equipment.

Ground-isolated modules (no separate grounding required at the DDF).

Test cords are equipped with easy to use, push-on BNC connectors.

Patch cords are equipped with locking BNC connectors.

Standard BNC connectors are available from a variety of sources for any coaxial cable type.

Two standard panel sizes are available, while other panel sizes are available upon request.

R/F Panels include a heavy-duty hinge incorporated into the bottom, which allows it to swing forward for

easy access to the rear of the panel. This feature is especially useful when mounting in a cabinet.

How to Contact Us

To find out more about Carrier Apparatus products, visit us on the web at:

http://cw.commscope.com/

For technical assistance regarding Carrier Apparatus products: contact your local CommScope account

representative or CommScope technical support at 1-800-344-0223.

Report any missing or damaged parts to CommScope customer service in Omaha, Nebraska, at

1-866-539-2795.

References

860220078 Digital Distributing Frame (DDF) System Reference Guide

More product documentation for Digital Distributing Frames is available at the following CommScope web

address: http://cw.commscope.com/eng/index.html click Support & Documentation.

Tools Required

Flat-blade 0.2-inch (5 mm) wide, 6-inch (152 mm) long screwdriver

Material ID 847 591 963

Issue 10, February 2004

Page 5

16 Pages

Ordering Information

Table 1: DDF Panel and Module Ordering Information

Apparatus Code Material ID Description

Patch and Test Cords

DDF-WCA1-02-PBNC 107 200 545 Test Cord, single push-on BNC to BNC, 6 feet 6 inches (2 m) Long

DDF-WCA1-03-PBNC 107 200 552 Test Cord, single push-on BNC to BNC, 9 feet 10 inches (3 m) Long

DDF-PC1A-00-BNC 107 200 560 Locking U-link Cord, single BNC to BNC, 4 inches (100 mm) Long

DDF-PC1A-01-BNC 107 200 578 Patch Cord, single BNC to BNC, 3 feet 2 inches (1 m) Long

DDF-PC1A-02-BNC 107 200 586 Patch Cord, single BNC to BNC, 6 feet 6 inches (2 m) Long

DDF-PC1A-03-BNC 107 200 594 Patch Cord, single BNC to BNC, 9 feet 10 inches (3 m) Long

DDF-PC1A-04-BNC 107 200 602 Patch Cord, single BNC to BNC, 13 feet 1 inches (4 m) Long

DDF-PC1A-06-BNC 107 200 628 Patch Cord, single BNC to BNC, 19 feet 7 inches (6 m) Long

DDF-PC2A-01-BNC 107 200 651 Patch Cord, duplex BNC to BNC, 3 feet 2 inches (1 m) Long

DDF-PC2A-02-BNC 107 200 669 Patch Cord, duplex BNC to BNC, 6 feet 6 inches (2 m) Long

DDF-PC2A-03-BNC 107 200 677 Patch Cord, duplex BNC to BNC, 9 feet 10 inches (3 m) Long

DDF-PC2A-04-BNC 107 200 685 Patch Cord, duplex BNC to BNC, 13 feet 1 inches (4 m) Long

DDF-PC2A-06-BNC 107 200 701 Patch Cord, duplex BNC to BNC, 19 feet 7 inches (6 m) Long

Modules

DDF-1B-01 107 538 597 Single DDF-PM assembly

DDF-1B-24 107 538 605 Package of 24 DDF-PM modules

DDF-DM-1B-01 107 917 163 Single DDF-DM assembly. Rear/Front cabled

DDF-DM-1B-24 107 922 171 Package of 24 DDF-DM Rear/Front cabled modules

DDF-DM-1B-32 107 922 189 Package of 32 DDF-DM Rear/Front cabled modules

DDF-DM-NE-1B-01 107 922 197 Single DDF-DM assembly. Rear/Rear cabled.

DDF-DM-NE-1B-24 107 922 205 Package of 24 DDF-DM Rear/Rear cabled modules

Panels

DDF-1B500-24/4BNC 107 538 548 Hinged, cross-connect/interconnect panel equipped with 24 single

monitor modules for 19-inch (500 mm) bay and cabinets.

DDF-1B600-32/EMP 107 538 563 Hinged, empty panel that can accommodate up to 32 modules, for 23-

inch (600 mm) bay.

DDF-1B600-32/4BNC 107 538 571 Hinged, cross-connect/interconnect panel equipped with 32 single

monitor modules for 23-inch (600 mm) bay.

DDF-1B600-SHLF 107 665 440 Horizontal trough for use with 23-inch (600 mm) panel, includes circuit

identification label.

DDF-1B500-SHLF 107 665 432 Horizontal trough for use with 19-inch (500 mm) panel, includes circuit

identification label.

DDF-DM-1A600-32/6BNC 107 970 543 Hinged, cross-connect/interconnect panel equipped with 32 dual monitor

R/F modules for 23-inch (600 mm) bay.

DDF-DM-1A600-32/6EMP 107 991 358 Hinged, empty panel that can accomodate up to 32 modules, for 23-inch

(600 mm) bay.

DDF-DM-1A500-24/5BNC 108 387 192 Hinged cross-connect/interconnect panel equipped with 24 dual monitor

modules for 19 inch (500 mm) bay.

Material ID 847 591 963

Instruction Sheet

Page 6

16 Pages

DDF-DM-NE-1A500-24/

4EMP

760 012 054 Empty panel for rear/rear applications that can accomodate up to 24

modules for 19-inch (500 mm) or 23-inch (600 mm) bays.

DDF-DM-NE-1A500-24/

4BNC

760 011 064 Cross-connect/interconnect panel equipped with 24 dual monitor R/R

modules for 19-inch (500 mm) or 23-inch (600 mm) bays.

Panel Installation Configurations

AD-8C500-50 Group 5 AD8C50050G5 For Rear/Rear Applications: 7-foot (21 mm) high, 23-inch (600 mm)

wide, unequal flange, Network Bay Frame with 5-inch guard rail cover

on open duct side.

AD-8C501-50 Group 1 AD8C50150G1 For All Rear/Front Applications: 7-foot (2.1 m) high, 23-inch (600 mm)

wide, unequal flange, Network Bay Frame with 5-inch guard rail cover

on closed duct side.

ED-6C157-30 Group 12 ED6C15730G12 One 8x8 inch lower express trough and extension bracket

ED-6C157-30 Group 16 ED6C15730G16 One 8x10 inch upper horizontal express trough

ED-6C157-30 Group 36 ED6C15730G36 Single full vertical trough. Includes label set, label holder, cover, and

mounting hardware.

ED-6C157-30 Group 37 ED6C15730G37 Single half vertical trough. Includes label set, label holder, cover, and

mounting hardware.

ED-6C157-30 Group 51 ED6C15730G51 5-inch bay spacing hardware

ED-6C157-31 Group 5 ED6C15731G5 For Rear/Front Cross-Connect Application Only: Bay hardware.

Includes upper and lower express troughs, six rear cable brackets, bay

spacing hardware, guard rail extension kit, rear cable cover kit, two

jumper retainers, and mounting hardware.

ED-6C157-31 Group 6 ED6C15731G6 For Rear/Front Interconnect Application Only: Interconnect bay

hardware. Includes six rear cable brackets, rear cable cover kit, and

mounting hardware.

ED-6C157-31 Group 7 ED6C15731G7 For Cross-Connect Application Only: Full vertical troughs. Includes

12 full vertical troughs, 12 label sets, 24 label holders and covers, and

mounting hardware.

ED-6C157-31 Group 8 ED6C15731G8 For Cross-Connect Application Only: Half vertical troughs. Includes

12 half vertical troughs, 12 label sets, 24 label holders and covers, and

mounting hardware.

Apparatus Code Material ID Description

Material ID 847 591 963

Issue 10, February 2004

Page 7

16 Pages

PANEL INSTALLATION FOR R/F PANELS ON 5-INCH (127 mm) CENTERS

Rear/Front cabled panels should be installed on 5-inch (127 mm) centers if the optional horizontal troughs are

not used, as shown in Figure 6. Panels should be installed on 7-inch (178 mm) centers if the optional horizontal

troughs are used as shown in Figure 7 on page 8.

1. Mount the framework hardware and panels in the locations shown in Figure 6.

Note: Figure 6 shows an upper and lower express trough and vertical trough used in Front-Cross Con-

nect applications only. Disregard this information if using Interconnect application. Panels are

mounted on top of the vertical troughs and the upper and lower express troughs are used to route

and manage cross-connect cords running between adjacent bays.

2. Route Network Element cabling into the bay frame from either the top or bottom (depending upon site

requirements).

Figure 6. Panel Installation for Panels on 5-Inch (127 mm) Centers

7" (178 mm)

11" (279 mm)

4" (102 mm)

H #7 ole

Front view

Upper express trough

5" (127 mm)

Hole #67

Hole #62

Hole #57

Hole #52

Hole #47

Hole #42

Hole #37

H #32 ole

H #27 ole

H #22 ole

H #17 ole

H #12 ole

Lower express trough

Hole #73

12

11

10

9

8

7

6

5

4

3

2

1

Rear view

Rear cable cover

Rear cable enclosure

10" (254mm)

11" (279mm)

H #8 ole

Hole #19

Hole #29

Hole #39

Hole #49

Hole #59

Hole #69

H #6 ole

REAR CABLE BRACKET

14" (356mm)

5" (127mm)

5" (127mm)

5" (127 mm)

5" (127mm)

5" (127mm)

5" (127 mm)

5" (127 mm)

5" (127 mm)

5" (127 mm)

5" (127 mm)

10" (254mm)

10" (254mm)

10" (254 mm)

10" (254 mm)

10" (254mm)

Vertical

trough

Fig06 installation for 5-inch panels.wmf

Material ID 847 591 963

Instruction Sheet

Page 8

16 Pages

PANEL INSTALLATION FOR R/F PANELS ON 7-INCH (178 mm) CENTERS

Rear/Front cabled panels should be installed on 7-inch (178 mm) centers if optional horizontal troughs are

used as shown in Figure 7. Panels should be installed on 5-inch (127 mm) centers if optional horizontal troughs

are not used, as shown in Figure 6.

1. Mount the framework hardware and panels in the locations shown in Figure 7.

Note: Figure 7 shows an upper and lower express trough and vertical trough used in Front-Cross Con-

nect applications only. Disregard this information if using Interconnect application. Panels are

mounted on top of the vertical troughs and the upper and lower express troughs are used to route

and manage cross-connect cords running between adjacent bays.

2. Route Network Element cabling into the bay frame from either the top or bottom (depending upon site

requirements).

Figure 7. Panel Installation for Panels on 7-Inch (178 mm) Centers

7" (178 mm)

11" (279 mm)

4" (102 mm)

H #7 ole

Front view

Upper express trough

7" (178 mm)

Hole #69

H #62 ole

H #55 ole

H #48 ole

H #41 ole

H #34 ole

H #27 ole

HOLE #20

HOLE #13

Lower express trough

Hole #73

9

8

7

6

5

4

3

2

1

Rear view

Rear cable cover

Rear cable enclosure

10" (254 mm)

15" (381 mm)

14" (356 mm)

14" (356 mm)

H #8 ole

H #23 ole

H #37 ole

H #51 ole

H #65 ole

H #6 ole

Rear cable bracket

11" (279mm)

14" (356 mm)

7" (178 mm)

7" (178 mm)

7" (178 mm)

7" (178 mm)

7" (178 mm)

7" (178 mm)

7" (178 mm)

Fig07 installation for 7-inch panels.wmf

Material ID 847 591 963

Issue 10, February 2004

Page 9

16 Pages

WATERFALL CABLING FOR REAR/FRONT CABLED PANELS

Cabling for equipment terminated on Panels 1 through 12 uses the waterfall cabling method. A DDF system

comprised of 12 panels and using waterfall cabling is shown in Figure 8.

1. Cable the equipment terminated on Panel Position No. 1 in the left most slot (as viewed from rear of bay

frame) of the rear cable brackets. Cabling for other panels are routed in their respective bracket slots,

continuing from the left. As an example, cabling for Panel No. 2 is routed in the second slot from the left.

This cabling scheme continues until cabling for Panel No. 12 is routed in the right-most slot.

2. Secure cabling to the rear cabling brackets with cable ties or lacing material, depending on local practices.

3. Route cables to the bottom of the panel and spread across the rear of the panel.

4. Install BNC connectors and connect cables as follows:

Transmit from N.E. No. 1 to upper BNC port on rear of module.

Receive from N.E. No. 1 to lower BNC port on rear of module.

Figure 8. Waterfall Cabling for Rear/Front Cabled Panels

Rear view

Rear cable cover

Rear cable bracket

DDF Panel

Panel #12

Panel #11

Panel #10

Panel #9

Panel #8

Panel #7

Panel #6

Panel #5

Panel #4

Panel #3

Panel #2

Panel #1

Rear cable enclosure

Module

(Rear View)

N.E. #1-Transmit

N.E. #1- Receive

Equipment cabling

Fig08 waterfall cabling for rear-front panels.wmf

Material ID 847 591 963

Instruction Sheet

Page 10

16 Pages

PANEL INSTALLATION FOR R/R PANELS ON 4-INCH (102 mm) CENTERS

Panels should be installed on 4-inch (102 mm) centers as shown in Figure 9.

1. Mount the framework hardware and panels in the locations shown in Figure 9.

Note: The upper and lower express troughs are used to route and manage cross-connect cords run-

ning between adjacent bays.

2. Route Network Element cabling into the bay frame from either the top or bottom (depending upon site

requirements).

Figure 9. Panel Installation for R/R Panels on 4-Inch (102 mm) Centers

Rear View Front View

Lower

Express

Trough

Upper

Express

Trough

Label

Holder

Towel

Bracket

4.00"

(101.60 mm)

13.00"

(330.10 mm)

1

2

3

5

6

7

8

9

10

11

12

13

14

15

4.00"

(101.60 mm)

13.00"

(330.10 mm)

(15) 4-Inch

Panels (Typical)

Vertical

Trough

Fig09 insatallation for 4-inch RR panels.wmf

Material ID 847 591 963

Issue 10, February 2004

Page 11

16 Pages

CONNECTING R/F DDF MODULES FOR FRONT CROSS-CONNECT APPLICATION

The front cross-connect configuration requires two DDF modules to complete a circuit. The module allows

easy access to jumpers for circuit rearrangements during installation of new network elements and/or

restorations. The circuit may be monitored in both directions of transmission. The connections at the module

and a functional schematic of the application are shown in Figure 10.

Figure 10. Connecting R/F DDF Module for Front Cross-Connect Application

N.E. #1

N.E. #2

Transmit (N.E. #1)

Monitor

Monitor

J umpers

DDF-DM

DDF-DM

Monitor

N.E. #1 (Receive)

N.E. #1 (Transmit)

N.E. #2 (Receive)

N.E. #2 (Transmit)

Transmit (N.E. #2)

Receive (N.E. #1)

Receive (N.E. #2)

Fig10 connecting RF DDF module.wmf

Material ID 847 591 963

Instruction Sheet

Page 12

16 Pages

CONNECTING R/F DDF MODULE FOR INTERCONNECT APPLICATION

The interconnect application requires one Dual Monitor module to complete a circuit. This configuration is as

flexible as the cross-connect application. The circuit may be monitored in both directions of transmission. The

connections at the module and a functional schematic of the application are shown in Figure 11 for the Rear/

Front cabled module.

Figure 11. Connecting R/F DDF Module for Interconnect Application

N.E. #1

Monitor (Out)

DDF-DM

Monitor

Test cord (Push-on type)

N.E. #2 (Receive)

Monitor (In)

Dual monitor

N.E. #2 (Transmit)

N.E. #1 (Transmit)

N.E. #1 (Receive)

N.E. #2

Fig11 DDF module for interconnect.wmf

Material ID 847 591 963

Issue 10, February 2004

Page 13

16 Pages

CONNECTING R/F DDF MODULES FOR REAR CROSS-CONNECT APPLICATION

The rear cross-connect configuration requires two DDF modules to complete a circuit. The module allows easy

access to jumpers for circuit rearrangements during installation of new network elements and/or restorations.

The circuit may be monitored in both directions of transmission. The connections at the module and a

functional schematic of the application are shown in Figure 12.

Figure 12. Connecting R/F DDF Module for Rear Cross-Connect Application

N.E. #2

N.E. #2(Transmit)

J umpers

Rear/Rear DDF-DM

N.E. #1 (Receive)

N.E. #1 (Transmit)

N.E. #2 (Receive)

N.E. #2 (Transmit)

N.E. #2 (Receive)

N.E. #1 (Transmit)

N.E. #1

Rear/Rear DDF-DM

Monitor

Monitor

N.E. #1 (Receive)

Fig12 DDF module for rear cross-connect.wmf

Material ID 847 591 963

Instruction Sheet

Page 14

16 Pages

CONNECTING R/R DDF MODULE FOR INTERCONNECT APPLICATION

The interconnect application requires one Dual Monitor module to complete a circuit. This configuration is as

flexible as the cross-connect application. The circuit may be monitored in both directions of transmission. The

connections at the module and a functional schematic of the application are shown in Figure 13 for the Rear/

Front cabled module.

Figure 13. Connecting R/R DDF Module for Interconnect Application

Rear/Rear dual monitor

N.E. #1 (Transmit)

N.E. #2 (Receive)

N.E. #2 (Transmit)

N.E. #1 (Receive)

N.E. #2

N.E. #1

Rear/Rear

DDF-DM

Monitor

Fig13 RR DDF module for interconnect.wmf

Material ID 847 591 963

Issue 10, February 2004

Page 15

16 Pages

INSTALLING AND REMOVING THE DDF MODULE

Installing DDF Module in Panel

1. Position the module at an angle to the panel so that the bottom of the module is close to the tab molded

into panel. Place bottom of module onto tab, as shown in Figure 14.

2. With the bottom of the module on the tab, swing the module up until it contacts the panel and continue

pushing until it locks into place.

The module is now ready to attach patch cords.

Removing DDF Module From Panel

1. Swing the panel forward to allow access to the rear of module (Rear/Front panels only).

2. Using a flat screwdriver or other blunt tool, press the latch at the top of the module.

3. Swing the module down and lift it out of panel.

Figure 14. Installing and Removing the DDF Module

Installing DDF module Removing DDF module

Latch on module

Position module

at an angle on tab

Tab in panel

Push module forward

until it snaps in place

Swing panel forward to gain

access to rear of module

Swing module

down and lift out

Press latch

on module

Fig14 installing and removing DDF module.wmf

Material ID 847 591 963

Instruction Sheet

Page 16

16 Pages

PATCH AND TEST CORDS

There are four types of cords used with the DDF:

Single push-on BNCBNC test cord

Locking U-link BNCBNC patch cord

Single BNCBNC patch cord

Duplex BNCBNC patch cord

The duplex BNCBNC patch cords are constructed with one white coaxial cable and one blue coaxial cable

encased in a white outer jacket. The different colored coaxial cables allow easy identification of Transmit and

Receive and help to maintain circuit integrity from one panel to another. The patch cords and test cords are

shown in Figure 15.

Figure 15. Patch and Test Cords

Fig15 patch and test cords.wmf

Push-on BNC

Length

Strain relief

Single Push-On BNC-BNC Test Cord

100 mm

Locking BNC

Locking U-Link Cord

Length

Single BNC-BNC Patch Cord

Blue coaxial cable

White coaxial cable

White outer jacket

Strain relief

Length

Duple/BNC-BNC Patch Cord

Strain relief

Locking BNC

Strain relief

Locking BNC

You might also like

- Fujikura - Optical ComponentsDocument42 pagesFujikura - Optical ComponentsSeung-Min LeeNo ratings yet

- Network Materials February 2012Document84 pagesNetwork Materials February 2012Edward BeanNo ratings yet

- ED 2002 125NexgenieBaseUnitNG16DLNG14RLInstallationManualDocument2 pagesED 2002 125NexgenieBaseUnitNG16DLNG14RLInstallationManualAmit Chaturvedi100% (1)

- Ds BasicdDocument2 pagesDs Basicdjgrisi065757100% (1)

- Standard 1-95 FGS Cat 104892BEDocument95 pagesStandard 1-95 FGS Cat 104892BETunaru GabrielNo ratings yet

- I/A Series Hardware 50 Series Workstation Processor WP51, Styles B and B1Document4 pagesI/A Series Hardware 50 Series Workstation Processor WP51, Styles B and B1Harik RafiryNo ratings yet

- DDF E1Document8 pagesDDF E1Anjang PurnomoNo ratings yet

- LDDocument38 pagesLDfeliprolNo ratings yet

- Manual Xbee 900Document63 pagesManual Xbee 900Murilo Marin PechotoNo ratings yet

- KV-S3105CSERIES KV-S3085SERIES: High Speed Color ScannerDocument35 pagesKV-S3105CSERIES KV-S3085SERIES: High Speed Color ScannerMargelatu SemintarNo ratings yet

- 1.2 - Dac-NetDocument2 pages1.2 - Dac-NetGustavo VieiraNo ratings yet

- HP Parts Reference Guide™: 2500C ElectronicsDocument13 pagesHP Parts Reference Guide™: 2500C ElectronicsIulian_DNo ratings yet

- DCX-4S Rack Mount Kit: Installation ProcedureDocument10 pagesDCX-4S Rack Mount Kit: Installation ProcedureHam ZaNo ratings yet

- Corning Lanscape® Solutions: For Security / Surveillance ApplicationsDocument12 pagesCorning Lanscape® Solutions: For Security / Surveillance ApplicationsFabio CostaNo ratings yet

- Fire-Lite ACM-16ATF Data SheetDocument4 pagesFire-Lite ACM-16ATF Data SheetJMAC SupplyNo ratings yet

- MS 9200 (C) MS 9200E Fire Lite Alarms DF 51276Document4 pagesMS 9200 (C) MS 9200E Fire Lite Alarms DF 51276Miguel PerezNo ratings yet

- Fiber Optic Ieee c37.94 g.703 E1 Multiplexer Pdf2 133Document18 pagesFiber Optic Ieee c37.94 g.703 E1 Multiplexer Pdf2 133nnt236No ratings yet

- Optical Cross-Connect Family: DescriptionDocument8 pagesOptical Cross-Connect Family: DescriptionMohd Nazri Mohd WaripNo ratings yet

- Ap2600getstart PDFDocument38 pagesAp2600getstart PDFtranduongtinhNo ratings yet

- Ap2600getstart PDFDocument38 pagesAp2600getstart PDFtranduongtinhNo ratings yet

- Fl2000 FDPDocument10 pagesFl2000 FDPSeanSeymourNo ratings yet

- Concept of PDH MultiplexingDocument27 pagesConcept of PDH MultiplexingRohit SinghNo ratings yet

- HP Parts Reference Guide™Document33 pagesHP Parts Reference Guide™Iulian_DNo ratings yet

- Amp CatalogoDocument132 pagesAmp CatalogoLewixDarkNo ratings yet

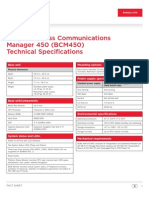

- Avaya Business Communications Manager 450 (BCM450) Technical SpecificationsDocument6 pagesAvaya Business Communications Manager 450 (BCM450) Technical Specificationsursus006No ratings yet

- For The West Somerset Amateur Radio Club VX-7/5R Computer Interfacing by Bas Helman G4TICDocument8 pagesFor The West Somerset Amateur Radio Club VX-7/5R Computer Interfacing by Bas Helman G4TICRenan ValenteNo ratings yet

- Connectrix DS-300B: Key FeaturesDocument13 pagesConnectrix DS-300B: Key FeaturesFelipe Gabriel Nieto ConchaNo ratings yet

- VIPA System 200V ManualDocument422 pagesVIPA System 200V Manualwww.otomasyonegitimi.comNo ratings yet

- Metasys® Intelligent Fire Controller: DescriptionDocument4 pagesMetasys® Intelligent Fire Controller: DescriptionekapridhiNo ratings yet

- Beckhoff Bus TerminalDocument154 pagesBeckhoff Bus TerminalJuan JimenezNo ratings yet

- 976 - DesignJet 1055CMDocument29 pages976 - DesignJet 1055CMIulian_DNo ratings yet

- Ap 2600 GetstartDocument38 pagesAp 2600 GetstartFrancisco DiazNo ratings yet

- Corning WIC Interconnect CenterDocument4 pagesCorning WIC Interconnect CentercolinyNo ratings yet

- CF2000 User ManualDocument93 pagesCF2000 User ManualDanijel DanicicNo ratings yet

- 7 CompSolutions 08rev1Document52 pages7 CompSolutions 08rev1Chris HazeldineNo ratings yet

- 1235832Document2 pages1235832Sofwan MuhamadNo ratings yet

- 7SS52xx Ordering SheetDocument20 pages7SS52xx Ordering SheetAhmed Bilal KhanNo ratings yet

- CMTS OverviewDocument54 pagesCMTS OverviewAmol AmollNo ratings yet

- Aironet 2602i Access Point AIRCAP2602IAK9Document38 pagesAironet 2602i Access Point AIRCAP2602IAK9Ignacio Ortega ClaudeNo ratings yet

- Installation 3G Network ElementsDocument108 pagesInstallation 3G Network ElementsChinmaya Samal100% (2)

- Xbee /Xbee-Pro Oem RF Modules: Product Manual - 802.15.4 ProtocolDocument69 pagesXbee /Xbee-Pro Oem RF Modules: Product Manual - 802.15.4 ProtocolhadiNo ratings yet

- CM2 User Manual 3 - 8Document62 pagesCM2 User Manual 3 - 8Hung VanTienNo ratings yet

- JPX321 BM2 96F User ManualDocument15 pagesJPX321 BM2 96F User ManualSamuelNo ratings yet

- FTTX Infrastructure SolutionsDocument39 pagesFTTX Infrastructure SolutionsMuhammad Adil AdilNo ratings yet

- Manual Phenix BaseDocument34 pagesManual Phenix BaseEmerson De Andrade LimaNo ratings yet

- HP Parts Reference Guide™: 2500C ElectronicsDocument12 pagesHP Parts Reference Guide™: 2500C ElectronicsIulian_DNo ratings yet

- BT PB - en - 1.3 - 08.09Document97 pagesBT PB - en - 1.3 - 08.09euqehtbNo ratings yet

- Sony HCD Xb4kDocument97 pagesSony HCD Xb4kFrancisco OrozcoNo ratings yet

- NCR 333Document6 pagesNCR 333Ufuk AkgülNo ratings yet

- DN 60548Document2 pagesDN 60548Victor Keiji MuraokaNo ratings yet

- AMAG-5013 Data Sheet Rebranding - Symmetry Multinode M2150 Intelligent Controller US - V2 - May2023Document7 pagesAMAG-5013 Data Sheet Rebranding - Symmetry Multinode M2150 Intelligent Controller US - V2 - May2023Teodor DanNo ratings yet

- SeriesDocument4 pagesSeriesNgoãn Nguyễn ĐứcNo ratings yet

- ComNet CWGE26FX2TX24MSPOE Instruction ManualDocument138 pagesComNet CWGE26FX2TX24MSPOE Instruction ManualJMAC SupplyNo ratings yet

- Cisco ONS 15216 SeriesDocument38 pagesCisco ONS 15216 SeriesPavleObradovicNo ratings yet

- 852 PDFDocument30 pages852 PDFcarlosvicunavNo ratings yet

- FO Catalogue SpecSheet Collection en Chap5Document30 pagesFO Catalogue SpecSheet Collection en Chap5damianson69No ratings yet

- Surpass 7300Document206 pagesSurpass 7300Maxim KuzmenkoNo ratings yet

- EMEA Gesamt 2006 (E) PDFDocument132 pagesEMEA Gesamt 2006 (E) PDFjoe_anesNo ratings yet

- VLSI Design for Video Coding: H.264/AVC Encoding from Standard Specification to ChipFrom EverandVLSI Design for Video Coding: H.264/AVC Encoding from Standard Specification to ChipNo ratings yet