Professional Documents

Culture Documents

Wrought Iron (Besi Tempa)

Wrought Iron (Besi Tempa)

Uploaded by

Wildan AmirullohOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wrought Iron (Besi Tempa)

Wrought Iron (Besi Tempa)

Uploaded by

Wildan AmirullohCopyright:

Available Formats

Wrought Iron

(Besi Tempa)

Wrought iron is essentially a two-component metal consisting of high-

purity iron and slag. The slag is composed mainly of iron silicate. The small and

uniformly distributed particles of slag exist physically separate in the iron.

There is no fusion or chemical relationship between the slag and the iron.

Wrought iron is used for standard pipe, nails, barbed wire, rivets, and

welding fittings. It is available in plates, sheets, tubular forms, and structural

shapes. Wrought iron has many applications in the railroad, shipbuilding, and

oil industries, as well as for architectural purposes and for farm implements.

Wrought iron was originally produced by the hand-puddling process, later

by mechanical puddling, and since 19! by the "yers or #ston process. There

are three essential steps in the manufacture of wrought iron$ first to melt and

refine the base metal$ second, to produce and %eep molten a proper slag& and

third, to granulate, or disintegrate, the base metal and mechanically incorporate

with it the desired amount of slag.

W'()*+T I'(, -urya .arma 1

Kesimpulan:

Besi tempa mempunyai fasa besi dan terak silikat yang bentuknya

menyerupai serat sehingga menambah kekuatannya.

Terak yang bentuknya butiran (granulate) atau bentuk remukan/hancur

(disintegrate )secara mekanik disatukan dengan logam dasar (besi).

Penggunaannya:

Pipa standar, paku, kaat berduri, paku keling, fittingyang dilas,

bangunan kapal, industri perminyakan,, arsitektur, dan peralatan

pertanian.

Besi tempa tersedia dalam bentuk plat, lembaran, bentuk bulat dan

bentuk profil struktur.

Bentuk patahan adalah fibrous (seperti berserat)

W'()*+T I'(, -urya .arma /

W'()*+T I'(, -urya .arma

You might also like

- Wrought Iron UGMDocument2 pagesWrought Iron UGMRizki Khikmawanto PamungkasNo ratings yet

- Chapter ThreeDocument38 pagesChapter ThreeAbi DemNo ratings yet

- MetalsDocument39 pagesMetalsVipin Kumar SharmaNo ratings yet

- 2.steels and AlloyDocument40 pages2.steels and AlloyMohanmed Rizwan shaikNo ratings yet

- 150 Sample-Chapter PDFDocument25 pages150 Sample-Chapter PDFMochammad Waris SNo ratings yet

- Engineering Materials NotesDocument25 pagesEngineering Materials NotesRoobanesh ManoharanNo ratings yet

- Types of MetalsDocument14 pagesTypes of MetalsThabiso MmesoNo ratings yet

- Module 4 Add-Ons - Types of MetalsDocument14 pagesModule 4 Add-Ons - Types of MetalsWerdNaNo ratings yet

- Cast Iron PropertiesDocument8 pagesCast Iron PropertiesGerardo JM Palacios100% (1)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- METALSDocument48 pagesMETALSMian Afzaal 72No ratings yet

- Bgtech 1 Research Paper Ferrous and Non Ferrous Metals: Far Eastern University Institute of Architecture and Fine ArtsDocument23 pagesBgtech 1 Research Paper Ferrous and Non Ferrous Metals: Far Eastern University Institute of Architecture and Fine ArtsRousseau Pierre LouisNo ratings yet

- Note 4Document9 pagesNote 4Dr. Aung Ko LattNo ratings yet

- Enginering Material 3chapterDocument9 pagesEnginering Material 3chapterTayyeb AliNo ratings yet

- MicroprojectDocument13 pagesMicroprojectomkar digamabar sonone0% (1)

- Group 7: Steel and Steel Alloy What Is Metal?Document4 pagesGroup 7: Steel and Steel Alloy What Is Metal?Kent Clark VillaNo ratings yet

- Ferrous MaterialsDocument151 pagesFerrous MaterialsAli RayyaNo ratings yet

- Technical Manual - The Blacksmith and the Welder - June 16, 1941From EverandTechnical Manual - The Blacksmith and the Welder - June 16, 1941No ratings yet

- Mechanical MaterialDocument19 pagesMechanical MaterialcacaNo ratings yet

- Ferrous and Non Ferrous Materials - Dr. ChalimbaDocument61 pagesFerrous and Non Ferrous Materials - Dr. ChalimbaTadala Angella GomondaNo ratings yet

- Cast IronDocument12 pagesCast IronMANOJ MNo ratings yet

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingFrom EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingNo ratings yet

- Steel in ConstructionDocument69 pagesSteel in ConstructionLibs matttNo ratings yet

- IRON - Module - 02Document27 pagesIRON - Module - 02Asna AbbasNo ratings yet

- Cast Iron MicrostructuresDocument41 pagesCast Iron MicrostructuresNeo TarunNo ratings yet

- Cast Iron MicrostructuresDocument41 pagesCast Iron MicrostructuresZeeshan KhanNo ratings yet

- Hand-Forging and Wrought-Iron Ornamental WorkFrom EverandHand-Forging and Wrought-Iron Ornamental WorkRating: 5 out of 5 stars5/5 (1)

- Grey Cast IronDocument43 pagesGrey Cast IronVasanth PrasadNo ratings yet

- Cast Iron: Gray Iron Ferrous Alloys Eutectic CarbideDocument12 pagesCast Iron: Gray Iron Ferrous Alloys Eutectic CarbideMANOJ MNo ratings yet

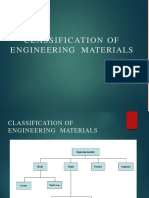

- Classification of MetalsDocument26 pagesClassification of MetalsNomi Wahla100% (1)

- CH 7 MetalsDocument16 pagesCH 7 MetalsNirose ChhukanNo ratings yet

- Building Construction & Material V: Simran Kaur - 1818242 - Batch 2k18Document22 pagesBuilding Construction & Material V: Simran Kaur - 1818242 - Batch 2k18Kaur SimranNo ratings yet

- Unit IiDocument80 pagesUnit Iikiran raajNo ratings yet

- Unit 6-Metals & Non-MetalsDocument8 pagesUnit 6-Metals & Non-MetalsRahul KumarNo ratings yet

- Iron and SteelDocument3 pagesIron and SteelSatriaSunuNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Brass Is AnyDocument7 pagesBrass Is AnyDiljith DineshNo ratings yet

- The Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenFrom EverandThe Blacksmith's Craft - An Introduction To Smithing For Apprentices And CraftsmenNo ratings yet

- Types of Cast IronDocument7 pagesTypes of Cast IronEddy VëraNo ratings yet

- 2 Metal PDFDocument40 pages2 Metal PDFNORIO GAMING YTNo ratings yet

- BMC MergedDocument93 pagesBMC Mergedkevin tomNo ratings yet

- Module 5Document45 pagesModule 5loading 123No ratings yet

- Module - 5Document45 pagesModule - 5Rakesh LodhiNo ratings yet

- Fracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanDocument33 pagesFracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanNarasimha Murthy InampudiNo ratings yet

- Material Technology IInd SemDocument262 pagesMaterial Technology IInd SemvinayakNo ratings yet

- Metal and AlloysDocument20 pagesMetal and AlloysShifat RashidNo ratings yet

- Alloys of Zinc and Their ApplicationsDocument4 pagesAlloys of Zinc and Their ApplicationsBookMaggotNo ratings yet

- Week 9Document60 pagesWeek 9Belmonte, Jhon Romel C.No ratings yet

- Esc 36 Quiz 3 Notes CompilationDocument98 pagesEsc 36 Quiz 3 Notes CompilationkbgainsanNo ratings yet

- ReportDocument3 pagesReportShamRock CasasNo ratings yet

- Cast Iron - WikipediaDocument11 pagesCast Iron - WikipediaBhumikNo ratings yet

- Engineering Materials I Notes 2022 METALSDocument15 pagesEngineering Materials I Notes 2022 METALSAliciaNo ratings yet

- Presentation On: Non-Ferrous MetalsDocument56 pagesPresentation On: Non-Ferrous MetalsMohd AnasNo ratings yet

- Fittting OperationDocument16 pagesFittting OperationsaniNo ratings yet

- Fittting OperationDocument16 pagesFittting OperationsaniNo ratings yet

- Cast IronDocument12 pagesCast IronCarlos EsparzaNo ratings yet

- Metal and Metal Alloys NotesDocument18 pagesMetal and Metal Alloys NotesKshitij SaojiNo ratings yet

- Wrought IronDocument32 pagesWrought IronHicham KorichiNo ratings yet

- Ironwork - Part III - A Complete Survey of the Artistic Working of Iron in Great Britain from the Earliest TimesFrom EverandIronwork - Part III - A Complete Survey of the Artistic Working of Iron in Great Britain from the Earliest TimesNo ratings yet

- Cast Iron: A Widely Used MaterialDocument19 pagesCast Iron: A Widely Used MaterialHarshaDesuNo ratings yet