Professional Documents

Culture Documents

Engine 5442 Drive Shaft AI

Engine 5442 Drive Shaft AI

Uploaded by

khanto0 ratings0% found this document useful (0 votes)

12 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views10 pagesEngine 5442 Drive Shaft AI

Engine 5442 Drive Shaft AI

Uploaded by

khantoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 10

BLM Non-Serious Accident Investigation

Drive Shaft Failure on BLM Southern Nevada District Engine 5442

Date of Accident: July 10, 2011

Date of Report: August 13, 2011

Chief Investigator: Brent Higbee, BLM FA Division of Fire Operations

Executive Summary

At approximately 1100 hours on J uly 10, 2011, the front drive shaft on Bureau of Land

Management Southern Nevada District Fire Engine 5442 broke and separated from the vehicle.

The vehicle was travelling at approximately 60 miles per hour on US 95 near Las Vegas,

Nevada. This failure caused severe damage to the engine, totaled one and moderately damaged

three other privately owned vehicles that were travelling in the vicinity of the accident. No

injuries occurred. Engine 5442 is a 2002 class 667 (Type 4) International 4800 4X4 with 76,928

miles and approximately 3200 hours of use at the time of the accident.

Narrative

On J uly 10, 2011 at approximately 1100 hours BLM engine 5442 was driving on highway US 95

to Logandale Fire Station. The crew felt a strong vibration followed by a pop, and then witnessed

an array of parts exiting from under the vehicle. The driver pulled the vehicle over to the left

shoulder, and the crew inspected the engine for damage. The crew then noticed a blue POV with

apparent damage had pulled over in front of them on the right shoulder, and later another POV

(gold) parked behind the blue car. Upon inspection of the Engine 5442 the crew, noted

transmission leaks, large dents in the fuel tank, and the majority of the front drive shaft was

missing and/or broken (See figure 3 thru 7). After surveying the area, the driver saw several

pieces of the drive shaft approximately 100 yards behind them in the highway. Due to the speed

and volume of traffic, it was deemed unsafe to retrieve the pieces of broken drive shaft. The

driver tried to move the engine further off the road but it would not move under its own power.

Approximately ten minutes later a Nevada State Police officer arrived on scene and talked to the

driver of the engine and POV owners. Ten minutes later a second Nevada State Police officer

arrived on scene with a broken piece of drive shaft retreived from the road (See figure 2). The

second officer gathered the engine drivers license and insurance information and proceeded up

to the firsts officers location. Later, the first Police officer returned and stated that there were

possibly four vehicles damaged in the accident. A tow truck from Quality Towing arrived and

towed the damaged engine to McCandless International Truck, 3780 Losee Road N., Las Vegas,

NV, 89030. There were no injuries so no medical actions were taken.

Investigation Methodology

BLM FA Division of Fire Operations Equipment Specialist Brent Higbee was assigned to

investigate this accident according to established non-serious accident investigation standards.

He arrived in Las Vegas at 1600 J uly 14

th

, 2011. This investigation included the following:

Visually inspected BLM engine 5442

Interviewed engine 5442 captain and crewmembers

Collected and reviewed written statements from the captain and crewmembers

Reviewed engine 5442 maintenance records

Considered environmental, equipment, material, procedural, and human factors as they

related to the incident

Collected information not specific to this incident, but pertaining to similar failures from

other entities in support of the development of findings and recommendations for this

report

Findings, Discussion, Recommendations

Finding 1: The drive shaft on E-5442 failed during operation of the vehicle. This caused the

accident.

Discussion: BLM engine 5442 had the original drive shaft replaced in a safety recall issued by

International in the May 2005 Safety Recall G-05501-R2 (See attachment #1). The drive shaft

installed has a non-serviceable part. The centering ball and seat assembly section inside the

coupling yoke of the drive shaft is non-serviceable at the field level (Figure 1). This was

identified as the major contributing factor to the failure.

When the joint wears out due to lack of grease (Figures 2a and 3) it will limit the normal

flexibility of the joint on the drive shaft, which causes wear and heat until one of the parts fails.

The McCandless International Truck service manager and his lead technician stated that the

centering ball and seat assembly had failed due to lack of grease. They stated that the multiple

cardan joint design on this style of drive shaft will allow for service of the u-joints but not the

centering ball and seat assembly in between the u-joints.

Recommendation 1: The BLM National Fire Equipment Program Manager should identify all

BLM engines affected by Internationals May 2005 Safety Recall G-05501-R2 and issue

guidance requiring the following actions:

All identified engines must be taken to International or Dana/Spicer dealers for removal

and thorough inspection of the drive shaft/joints.

Substandard drive shafts must be ordered and replaced.

On an interim basis, engines awaiting replacement drive shaft may remove the existing

substandard drive shafts and operate in two wheel drive mode. Firefighting tactics and

safety considerations must be adjusted accordingly.

International will be providing front hubs manufactured by Fabco as they become

available (see attachment #3).

Until replacement hubs are installed, remove the front drive shaft for any long distance

travel over 40 MPH (Follow International drive shaft installation recommendations).

Finding 2: Recommended service interval and estimated 50,000 mile life cycle information

(See attachment #2) for the drive shaft was not available to the field. This contributed to the

accident.

Discussion: The Engine Captain was aware of drive shaft issues on this model of BLM trucks

and the previous recall issued from International. The crew performed a thorough inspection on

the morning of the incident.

The Southern Nevada District had a similar drive shaft failure on 8/22/10 on Engine 5441, which

was the same year, make, and model as engine 5442. Due to the previous failure, the Engine

Captain and crew of 5442 were diligent in daily inspections and did thorough weekly inspections

every Friday. The Engine Captain and investigator were unaware of the recommended service

interval and estimated 50,000 mile life cycle that Dana/Spicer had established after the recall had

taken place. This was provided to the investigator on J uly 15

th

2011 from the Navistar regional

service manager. To the investigators knowledge, no information ever made it to the field; this

information remained at International and their service centers. Cal Fire had experienced two

similar failures with less damage. Cal Fire has been working with Navistar for a long term

repair.

Recommendation 2: The BLM National Fire Equipment Program Manager should continue to

work with Navistar and subcomponent manufacturers to ensure that maintenance requirements

are effectively communicated to BLM fire personnel through established channels.

Finding 3: The engine crew did not utilize the Fire Equipment Maintenance and Procedure

Record (FEMPR). This may have contributed to the accident.

Discussion: The engine crew performed daily Preventive Maintenance (PM) Checks that were

documented. The investigator did not find any records of greasing the drive shaft as described

and recommended in the vehicle owners manual. Last recorded service was on 10/01/2010

when BLM engine 5442 had its yearly preventive maintenance done at Silver State Truck and

Trailer, 3701 Freightliner drive, N Las Vegas, NV, 89081. When needed repairs were identified,

there was no tracking as to when the repairs were completed and who performed the repairs

(6/29/2010 daily checklist identified small Transfer Case leak but no record of any corrective

actions taken or the repair had been performed). International had performed the 2005 safety

recall number G-05501-R2 (see attachment #1) on the front drive shaft. This was verified by the

style of drive shaft that failed on the engine, which was different than the original drive shaft.

However, no records were found to support this. The engines FEMPR could have documented

this had it been utilized.

Recommendation 3: The Southern Nevada District Fire Management Officer should ensure

that the BLM Fire Equipment Maintenance and Procedure Record (FEMPR) are used as required

by the Interagency Standards for Fire and Fire Aviation Operations (chapter 2, page 37).

Finding 4: Operational and environmental conditions may have decreased the service life of the

drive shaft. This may have contributed to the accident.

Discussion: Prolonged periods of high drive shaft speeds associated with highway travel, high

ambient temperatures and dusty conditions contributed to the equipment failure by causing the

drive shaft to overheat and wear out. To date, Navistar International has not developed a

replacement part for these drive shafts; therefore, the potential for the same failure still exists.

Recommendation 4: The BLM National Fire Equipment Program Manager should continue to

work with Navistar International and sub-manufacturers to formulate a long term solution. One

possible remedy is installation of Fabco front hubs for the front axle (See attachment #3).

Maps/Photos/Illustrations

Figure 1 Typical Double Cardan Joint Exploded View

Non-Serviceable parts

Figure 2 Driveshaft recovered at scene

Figure 2a (Note close up of bluing of ball due to lack of grease)

Figure 3 Front Axle Yoke (Note rust color and signs of lack of grease in the seat)

Figure 4 Transfer Case Section of driveshaft. (Note big dent next to splines that part of the drive shaft hit

the frame of the truck)

Figure 5 Fuel tank dented and leaking.

figure 6 Transmission Cracked and Leaking from driveline hitting the case of the transmission.

Figure 7 View from transfer case (note damage to transmission, exhaust, and fuel tank)

You might also like

- How to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsFrom EverandHow to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsRating: 3.5 out of 5 stars3.5/5 (4)

- Ford Y-Block Engines: How to Rebuild & ModifyFrom EverandFord Y-Block Engines: How to Rebuild & ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- The GM Documents, Part 1Document184 pagesThe GM Documents, Part 1ballaban8685No ratings yet

- Glenwood Caverns Adventure Park Haunted Mine Drop Accident ReportDocument9 pagesGlenwood Caverns Adventure Park Haunted Mine Drop Accident ReportMichael_Roberts2019No ratings yet

- NTSB Report On July 4 Plane Crash in KilleenDocument9 pagesNTSB Report On July 4 Plane Crash in KilleenKCEN-TV 6 NewsNo ratings yet

- NTSB Report On B-17 Crash at Bradley International AirportDocument24 pagesNTSB Report On B-17 Crash at Bradley International AirportPatrick JohnsonNo ratings yet

- TM 9-765 BOMB SERVICE TRUCK M6Document281 pagesTM 9-765 BOMB SERVICE TRUCK M6Advocate100% (1)

- 737 Incident ReportDocument61 pages737 Incident ReportAbdul Qadeer Khan100% (1)

- Freightliner Coronado 122SD and 132SD Driver's Manual PDFDocument183 pagesFreightliner Coronado 122SD and 132SD Driver's Manual PDFAram MorenoNo ratings yet

- Vehicle Information: Vin: Engine Size/Type: Transmission Type: Drive Type: MileageDocument30 pagesVehicle Information: Vin: Engine Size/Type: Transmission Type: Drive Type: MileageJeffrey ValeoNo ratings yet

- Fast & Furious Car SpecsDocument7 pagesFast & Furious Car SpecsfauziNo ratings yet

- List of IMO Model CourseDocument2 pagesList of IMO Model CourseSachin SikkaNo ratings yet

- Recall Tipm RCDNN 14v530 4400Document3 pagesRecall Tipm RCDNN 14v530 4400Yargen GonzalezNo ratings yet

- Around The Time of The Launch of The 2005 Chevrolet Cobalt, GM Learned of at Least OneDocument5 pagesAround The Time of The Launch of The 2005 Chevrolet Cobalt, GM Learned of at Least OnepatrickegeorgeNo ratings yet

- Rcrit 16V418 9858 PDFDocument14 pagesRcrit 16V418 9858 PDFHesti NiaNo ratings yet

- GM Document 1Document12 pagesGM Document 1ballaban8685No ratings yet

- FL576 DLRDocument7 pagesFL576 DLRRyan BishNo ratings yet

- 16 Recent Trouble IncidentsDocument18 pages16 Recent Trouble IncidentsGauravNo ratings yet

- Dodge Recalls Charger and Durango Pursuit Due To Improperly Heat Treated Shifter Pawls 205796Document4 pagesDodge Recalls Charger and Durango Pursuit Due To Improperly Heat Treated Shifter Pawls 205796arstjunkNo ratings yet

- Easa Ad Us-2006-01-05 1Document10 pagesEasa Ad Us-2006-01-05 1Mahdi abanNo ratings yet

- Oil Bypass Final ReportDocument60 pagesOil Bypass Final ReportScribd.comNo ratings yet

- NTSB Report MagnetoDocument5 pagesNTSB Report MagnetoNiko ArdianNo ratings yet

- Perform-Underchasis-Preventive-MaintenanceDocument39 pagesPerform-Underchasis-Preventive-MaintenanceUlog WorksNo ratings yet

- E Townhall 1108 MaitDocument43 pagesE Townhall 1108 MaitThe Press-Enterprise / pressenterprise.comNo ratings yet

- RCLRPT 23V338 2913Document3 pagesRCLRPT 23V338 2913WDIV/ClickOnDetroitNo ratings yet

- Inot Ea13002 59206Document26 pagesInot Ea13002 59206naufalsandro96No ratings yet

- Ford Recalls VehiclesDocument3 pagesFord Recalls VehiclesNational Content DeskNo ratings yet

- PM Emergency Diesel GeneratorDocument27 pagesPM Emergency Diesel GeneratorAchmad DanielNo ratings yet

- 2022-04-04Document7 pages2022-04-04Jhon Felipe Barragan ReyesNo ratings yet

- Ad 2005-13-16Document10 pagesAd 2005-13-16Lu SaNo ratings yet

- Florida Forensic Eng ReportDocument19 pagesFlorida Forensic Eng ReportThomas MatesNo ratings yet

- QC Story (Engine PU) - MahindraDocument6 pagesQC Story (Engine PU) - MahindraTruong ChiNo ratings yet

- Ad 2015-19-07Document8 pagesAd 2015-19-07Gilberto Alan Treviño CuevasNo ratings yet

- Handcontrol PDFDocument241 pagesHandcontrol PDFpaoadamsNo ratings yet

- National Transportation Safety Board: Spool Bearing Failures in Rolls-Royce 250-Series EnginesDocument3 pagesNational Transportation Safety Board: Spool Bearing Failures in Rolls-Royce 250-Series EnginesBahadorNo ratings yet

- 8D Root Cause Analysis and CA ImplementationDocument27 pages8D Root Cause Analysis and CA ImplementationJaiveer YadavNo ratings yet

- Mogas Use KNKTDocument38 pagesMogas Use KNKTrayaduqsNo ratings yet

- Airworthiness Directive Learjet 100823Document11 pagesAirworthiness Directive Learjet 100823bombardierwatchNo ratings yet

- RCLRPT 18V278 6812Document3 pagesRCLRPT 18V278 6812Mido FawzyNo ratings yet

- Cascadia Driver's ManualDocument260 pagesCascadia Driver's ManualJuanNo ratings yet

- Manual JD English C13960.Sflb - AshxDocument41 pagesManual JD English C13960.Sflb - AshxPete Okonski100% (1)

- MS-CC - QG212036 (1) - 133Document1 pageMS-CC - QG212036 (1) - 133Zain buttNo ratings yet

- Ecascadia Driver's ManualDocument236 pagesEcascadia Driver's Manualfernando100% (2)

- Freightliner 108SD and 114SD Driver's ManualDocument212 pagesFreightliner 108SD and 114SD Driver's ManualMiguel MottaNo ratings yet

- NHTSA LetterDocument4 pagesNHTSA LetterDetroit Free PressNo ratings yet

- Neas Miss Report (Blank Format)Document1 pageNeas Miss Report (Blank Format)kkalvi100% (1)

- Action Plan: Department of Facilities ManagementDocument3 pagesAction Plan: Department of Facilities ManagementticoNo ratings yet

- Freightliner 108SD 114SD Truck Driver's Manual PDFDocument192 pagesFreightliner 108SD 114SD Truck Driver's Manual PDFmucusseteNo ratings yet

- 122SD and Coronado 132 Driver's ManualDocument194 pages122SD and Coronado 132 Driver's ManualfernandoNo ratings yet

- Safe Driving GI1226Document7 pagesSafe Driving GI1226tuvrheinland40No ratings yet

- RCLRPT 24V276 7026Document3 pagesRCLRPT 24V276 7026Simon AlvarezNo ratings yet

- Seat Belt Recall FAQsDocument2 pagesSeat Belt Recall FAQsNational Content DeskNo ratings yet

- Fmvss No. 202aDocument54 pagesFmvss No. 202afacu1984No ratings yet

- Freightliner BC M2 Driver Manual PDFDocument197 pagesFreightliner BC M2 Driver Manual PDFRubén GonzàlezNo ratings yet

- FedEx - DOE Funded Study of Workhorse EGEN Truck With FedexDocument10 pagesFedEx - DOE Funded Study of Workhorse EGEN Truck With FedexFuzzy PandaNo ratings yet

- Recreational Vehicle Chassis Operator's ManualDocument204 pagesRecreational Vehicle Chassis Operator's ManualmarkNo ratings yet

- Epri 501a-DDocument154 pagesEpri 501a-DEKKACHAI PRABNAKORN100% (2)

- TSB 11-03-07-144538Document2 pagesTSB 11-03-07-144538corydynacongmail.comNo ratings yet

- Freightliner M2 100 - 112V OmDocument210 pagesFreightliner M2 100 - 112V OmRoberto RodríguezNo ratings yet

- High Temp FuelDocument2 pagesHigh Temp Fuelamin chaabenNo ratings yet

- Air Crash Investigations - Uncontained Engine Failure - The Accident of Delta Air Flight 1288From EverandAir Crash Investigations - Uncontained Engine Failure - The Accident of Delta Air Flight 1288No ratings yet

- DC-10 Briefing Paper and VLAT Example 5-1-2014Document2 pagesDC-10 Briefing Paper and VLAT Example 5-1-2014wildfiretodayNo ratings yet

- Deer Park Firefighter Injury & Helicopter Incident Facilitated Learning AnalysisDocument16 pagesDeer Park Firefighter Injury & Helicopter Incident Facilitated Learning AnalysisRamblingChiefNo ratings yet

- Wildland Fire Season Themes For 2011Document1 pageWildland Fire Season Themes For 2011wildfiretodayNo ratings yet

- Ventajas de Los Sistemas DistribuidosDocument8 pagesVentajas de Los Sistemas DistribuidosDavid RobledoNo ratings yet

- Daven Place Burnover, 24-hr ReportDocument1 pageDaven Place Burnover, 24-hr ReportwildfiretodayNo ratings yet

- NWCG#033-2010 Memorandum Wildland Fire Institute 2010-07-19Document2 pagesNWCG#033-2010 Memorandum Wildland Fire Institute 2010-07-19wildfiretodayNo ratings yet

- MAFFS II Press Release 07-20-2010Document2 pagesMAFFS II Press Release 07-20-2010wildfiretodayNo ratings yet

- Wildland Fire Initial Attack Efficiency For 2009Document4 pagesWildland Fire Initial Attack Efficiency For 2009wildfiretodayNo ratings yet

- Manage My Trips Delta Air LinesDocument1 pageManage My Trips Delta Air LinesAlonso GalindoNo ratings yet

- MSG97AL 722 Product Data BrochureDocument2 pagesMSG97AL 722 Product Data BrochureYAKOVNo ratings yet

- Fuel Consumption CalculationDocument27 pagesFuel Consumption CalculationVishal ManojNo ratings yet

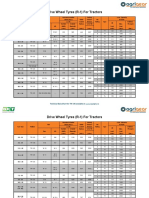

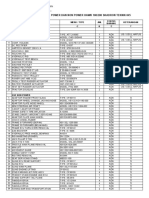

- Tyre Size CatalogueDocument4 pagesTyre Size CatalogueRahul RanaNo ratings yet

- Car ParkingDocument8 pagesCar ParkingArhit's Game ZoneNo ratings yet

- Chapter 3 - Car 145 Approved Maintenance OrganisationsDocument139 pagesChapter 3 - Car 145 Approved Maintenance OrganisationsPOLNo ratings yet

- 6H2 WBM 75 L SI Full Rev10 0 Edocs94793 PDFDocument102 pages6H2 WBM 75 L SI Full Rev10 0 Edocs94793 PDFStephen CollantesNo ratings yet

- Interim Survey Report: Sachin KumarDocument2 pagesInterim Survey Report: Sachin Kumarauto scannerNo ratings yet

- Front Coil Spring WarrantyDocument2 pagesFront Coil Spring WarrantyS PNo ratings yet

- Bill of Lading Not Negotiable: Shipper Provided Short Form OriginalDocument1 pageBill of Lading Not Negotiable: Shipper Provided Short Form OriginalGora PribadiNo ratings yet

- Essay Rough Draft 2 Post Peer ReviewDocument7 pagesEssay Rough Draft 2 Post Peer Reviewapi-288614500No ratings yet

- Fault Codes: STO U AndriivDocument23 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- Especificacion Chasis DieselDocument108 pagesEspecificacion Chasis Dieselluisvelandia1975No ratings yet

- Opel Vectra: Technical Data OverviewDocument4 pagesOpel Vectra: Technical Data OverviewkiltecutzaNo ratings yet

- Mazda Guidelines For Factory Scheduled MaintenanceDocument3 pagesMazda Guidelines For Factory Scheduled MaintenancebeyondteckNo ratings yet

- Cargoconnect August 2022Document92 pagesCargoconnect August 2022abhirajNo ratings yet

- Aoci Volume 2Document393 pagesAoci Volume 2hemkumar DahalNo ratings yet

- Business Class m2 Driver's Manual PDFDocument190 pagesBusiness Class m2 Driver's Manual PDFTeo DeustchNo ratings yet

- Driver Behavior On Speed-Change Lanes at Freeway Ramp TerminalsDocument9 pagesDriver Behavior On Speed-Change Lanes at Freeway Ramp TerminalsPothukuchi SarikaNo ratings yet

- 2 - Preparing To Drive You The DriverDocument4 pages2 - Preparing To Drive You The DriverJorge LuizNo ratings yet

- Manual Jeep Grand Cherokee 2015Document697 pagesManual Jeep Grand Cherokee 2015taringa2011No ratings yet

- Documents To Be Carried On Board by Indian Registered Aircraft.Document2 pagesDocuments To Be Carried On Board by Indian Registered Aircraft.hemalmod67% (3)

- Status Daftar Inventaris Gse Skatek 045 (Usul Hapus)Document3 pagesStatus Daftar Inventaris Gse Skatek 045 (Usul Hapus)Norma Nur AnnisaNo ratings yet

- Al115c Mio Sporty StarterDocument1 pageAl115c Mio Sporty StarterDidi IswantoNo ratings yet

- Ticket Azka Abirahman - CGKDocument1 pageTicket Azka Abirahman - CGKAzka AbirahmanNo ratings yet

- Analysis of Odd EvenDocument7 pagesAnalysis of Odd EvenMuhammad Edo FadhliNo ratings yet

- 4 For RoadDocument12 pages4 For RoadFraidon SarwaryNo ratings yet

- DLCA 4.11NigeriaAdditionalServicesContactList 221222 0546 10918Document19 pagesDLCA 4.11NigeriaAdditionalServicesContactList 221222 0546 10918Ekene OnyeagusiNo ratings yet