Professional Documents

Culture Documents

Dewatering Pumps For Raw Water Pumping: Grundfos DW Range

Dewatering Pumps For Raw Water Pumping: Grundfos DW Range

Uploaded by

Junior Felix0 ratings0% found this document useful (0 votes)

5 views12 pagesOriginal Title

Grundfosliterature-146014

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

5 views12 pagesDewatering Pumps For Raw Water Pumping: Grundfos DW Range

Dewatering Pumps For Raw Water Pumping: Grundfos DW Range

Uploaded by

Junior FelixCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 12

GRUNDFOS DW RANGE

Dewatering pump 0.7 - 20 kW

DEWATERING PUMPS

FOR RAW WATER PUMPING

EFFICIENT STATE-OF-ART DEWATERING PUMPS

Unique user benets

The Grundfos DW pumps form part of a complete range of wastewater and sewage

handling products. Like all Grundfos products the DW pump series offer unique cus-

tomer benefits, making them the natural choice for any job where raw water needs to

be pumped - whether from construction sites, mining pits, excavations, or flooded base-

ments, etc.

Grundfos offers a complete range of highly efficient dewatering pumps incorporating

state-of-the-art technology. The range comprises a series of pumps from 0.7kW to 20

kW with a flow rate of 82.7 l/sec.

Performance range

ADVANCED TECHNOLOGY INCORPORATED INTO

AN EXCEPTIONAL RANGE OF PUMPS

The Grundfos DW range is built to last longer than conven-

tional dewatering pumps. This is achieved through exten-

sive use of high-grade materials such as chromium steel,

nitril rubber, silicon carbide (SiC/SiC) and aluminium alloy.

Various protection devices minimise potential system

damage caused by overheating, whilst an integrated level

switch (optional) monitors water level and automatic ally

starts and stops the pump.

Can do more

The Grundfos DW pumps are capable of pumping water

containing abrasive materials such as sand and clay parti-

cles, drill cuttings, and other potenti ally damaging objects

that could be found on rock faces, at construction sites or

in mine shafts.

The Grundfos DW pumps are suitable for all kinds of drain-

age and dewatering jobs:

> Tunnels

> Mines

> Quarries

> Gravel pits

> Steel works

> Fish ponds

> Construction sites

ATTENTION TO DETAIL ENABLES THE DW RANGE

TO LEAD THE FIELD

The Grundfos DW range is designed with attention to every detail to ensure optimum

performance and years of trouble-free operation.

Performance range

Air valve for water level

compartment.

Integrated on/off switch for

automatic start and stop

(A), or for continuous pump

operation (C).

Electrodes for monitoring

the water level in the water

level compartment and

automatic opera tion of the

pump. 24 V con trol voltage.

No moving parts for start

and stop signal.

Replaceable,

wear-resistant nitrile

rubber lining where

water velocity is at its

highest.

Tight-fitting, wear resistant

nitrile rubber impeller back

plate.

Electrical control functions

are integrated in both di-

rect-on-line and star-delta

pump starting. This means

only one cable is required to

oper ate the pump.

Rubber covered

handle

Special low-weight,

shock-resistant

aluminium alloy

stator housing,

pump sleeve and

top cover.

Heavy-duty,

greased-for-life ball bearings.

Double shaft seal system

with intermediate oil cham-

ber. SiC/SiC primary seal.

Stator is insulation class F (155

C). Built-in thermal switch for

protection of the motor. The

motor will stop before over-

heating can cause any damage

to the system.

High alloyed cast iron (600

HV) semi-open impeller.

Tough, wear-resistant nitrile

rubber diffuser. Easily re-

placeable and adjustable to

ensure that optimum

performance is maintained

throughout the pumps life.

DW.65.39 three-phase

Motor: 3.9 kW, 2800 rpm

Max. power input: 5.7 kW

Discharge: R 2 1/2 or 2 1/2 hose

Weight: 38 kg (without cable)

DW.100.39 three-phase

Motor: 3.9 kW, 2800 rpm

Max. power input: 4.8 kW

Discharge: R 4 or 4 hose

Weight: 38 kg (without cable)

THE DW RANGE

The Grundfos DW pumps are portable submersible pumps

with vertical discharge port. They are designed to meet the

operating conditions typical of construction sites, excavations,

and in the mining industry where the pumped liquid often

contains sand, drill cuttings, and similar abrasive particles.

These demands are met by using only high-grade materi-

als. All pumps are available with or without automatic

level control.

(Performance overview according to ISO 9906 annex A).

DW.50.08.1 single-phase

Motor: 0.8 kW, 2800 rpm

Max. power input: 1.3 kW

Discharge: R 2 or 2 hose

Weight: 13 kg (without cable)

(With polypropylene pump sleeve)

DW.50.08.3 three-phase

Motor: 0.8 kW, 2800 rpm

Max. power input: 1.3 kW

Discharge: R 2 or 2 hose

Weight: 13 kg (without cable)

(With polypropylene pump sleeve)

DW.65.27 three-phase

Motor: 2.7 kW, 2800 rpm

Max. power input: 3.4 kW

Discharge: R 2 1/2 or 2 1/2 hose

or 3 hose connection

Weight: 33 kg (without cable)

DW.100.66.H three-phase

Motor: 6.6 kW, 2800 rpm

Max. power input: 6.5 kW

Discharge: R 4 or 4 hose

Weight: 51 kg (without cable)

DW.100.66 three-phase

Motor: 6.6 kW, 2800 rpm

Max. power input: 7.8 kW

Discharge: R 4 or 4 hose

Weight: 51 kg (without cable)

DW.50.07.1 single-phase

Motor: 0.7 kW, 2800 rpm

Max. power input: 0.9 kW

Discharge: R 2 or 2 hose

Weight: 18 kg (without cable)

DW.50.09.3 three-phase

Motor: 0.9 kW, 2800 rpm

Max. power input: 1.3 kW

Discharge: R 2 or 2 hose

Weight: 18 kg (without cable)

The Grundfos DW pumps incorporate a highly de pend able and very efcient automatic level

control system, which auto matic ally controls pump op eration as the water level varies.

STAND-BY/START

The pump with automatic level control will be in a stand-by position when power is

switched on and the water level is low. When the water level rises, the air will escape and

the water level compartment will be filled with water.

When water comes into contact with both lower and upper electrode

in the water level compartment, an electric circuit will switch on the pump.

PUMPING WATER

The water level decreases when the pump operates, but due to the water pressure inside

the pump, the rubber in the air valve will expand and close the valve. This maintains a high

water level in the water level compartment and the pump continues to operate.

STOP

When the outside water level is below the suction strainer, the pump

will start sucking air. Air will be sucked into the water level compartment through the

rubber air valve, but as long as the lower electrode is in contact with water the pump will

continue to operate.

When the water level in the electrode chamber falls to below the lower electrode, the elec-

tric circuit is broken and the pump stops.

FLAT SUCTION

AN ADDITIONAL BENEFIT

The model DW.50.08 offers an ad ditional benefit. A special flat suction valve that

enables the pump to suck down to floor level is available as an accessory.

AUTOMATIC LEVEL CONTROL

DW.100.200.H three-phase

Motor: 20 kW, 2800 rpm

Max. power input: 23.0 kW

Discharge: R 4 or 4 hose

Weight: 148 kg (without cable)

DW.150.200 three-phase

Motor: 20 kW, 2800 rpm

Max. power input: 25.5 kW

Discharge: R 6 or 6 hose

Weight: 148 kg (without cable)

DW.100.110.H three-phase

Motor: 11 kW, 2800 rpm

Max. power input: 12.8 kW

Discharge: R 4 or 4 hose

Weight: 110 kg (without cable)

DW.150.110 three-phase

Motor: 11 kW, 2800 rpm

Max. power input: 15.0 kW

Discharge: R 6 or 6 hose

Weight: 110 kg (without cable)

TECHNICAL DATA AND DIMENSIONS

Pump type

H

[mm]

D

[mm]

M

[mm]

S

[mm]/

[inch]

Max.

instalation

depth

[m]

Max. Q

[l/sec]

Max.

head

[m]

P

1

Max.

[kW]

I

N

[A]

I

start

I

N

Oil

[l]

Weight

[kg]

Single-phase pumps

DW.50.07.1 395 210 212 50/2 25 6.1 13 0.9 4 6 0.25 17

DW.50.09.A3 365 210 212 50/2 25 6.1 13 1.0 4 6 0.25 18

Three-phase pumps

DW.50.09.3 365 210 212 50/2 25 9.4 13.5 1.3 2.6 6 0.25 17

DW.65.27.3 365 210 212 50/2 25 9.4 13.5 1.3 2.6 6 0.25 18

DW.65.27.3 540 246 250 65/2* 25 17 17.3 3.4 6.2 6 0.3 33

DW.65.27.A3 540 246 250 65/2* 25 17 17.3 3.4 6.2 6 0.3 33

DW.65.39.3.H 605 246 275 65/2* 25 22.2 22.8 5.7 8.6 6 0.3 38

DW.65.39.A3.H 605 246 275 65/2* 25 22.2 22.8 5.7 8.6 6 0.3 38

DW.100.66.3.H 725 246 275 100/4 25 16.6 42 6.6 12.5 6 0.3 51

DW.100.66.A3.H 725 246 275 100/4 25 16.6 42 6.6 12.5 6 0.3 51

DW.100.39.3 605 246 275 100/4 25 31.9 18.1 5.6 8.6 6 0.3 38

DW.100.39.A3 605 246 275 100/4 25 31.9 18.1 5.6 8.6 6 0.3 38

DW.100.66.3 725 246 275 100/4 25 41.6 32 7.8 12.5 6 0.3 51

DW.100.66.A3 725 246 275 100/4 25 41.6 32 7.8 12.5 6 0.3 51

DW.100.110.3.H 850 360 410 100/4 20 21.9 77 12.8 21 6 2.3 110

DW.100.110.A3.H 850 360 410 100/4 20 21.9 77 12.8 21 6 2.3 110

DW.150.110.3 850 360 410 150/6 20 68.9 28.5 15 23 6 2.3 110

DW.150.110.A3 850 360 410 100/4 20 68.9 28.5 15 23 6 2.3 110

DW.100.200.3.H 1000 360 410 100/4 20 28.6 98.2 23 40 6 2.3 148

DW.100.200.A3.H 1000 360 410 100/4 20 28.6 98.2 23 40 6 2.3 148

DW.150.200.3 1000 360 410 150/6 20 82.7 42.1 25.2 41 6 2.3 148

DW.150.200.A3 1000 360 410 150/6 20 82.7 42.1 25.5 41 6 2.3 148

Pump type

H

[mm]

D

[mm]

M

[mm]

S

[mm]/

[inch]

Max.

instalation

depth

[m]

Max. Q

[l/sec]

Max.

head

[m]

P

1

Max.

[kW]

I

N

[A]

I

start

I

N

Oil

[l]

Weight

[kg]

DW.50.08.1 432 200 200 50/2 5 8.8 14.3 1.3 6 6 x 13

DW.50.08.A1 432 200 200 50/2 5 8.8 14.3 1.3 6 6 x 13

DW.50.08.3 432 200 200 50/2 5 8.8 15.1 1.3 2.5 6 x 13

DW.50.08.A.3 432 200 200 50/2 5 8.8 15.1 1.3 2.5 6 x 13

* With hose connection 3

PUMPS WITH POLYPROPYLENE PUMP SLEEVE

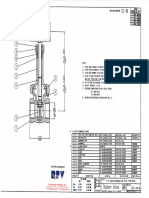

DIMENSIONAL SKETCH TYPE KEY

Example DW .50 .09 .A 3 .H

DW .50.09.A3.H

Type range

Nominal diameter of discharge port

Power output P2/100 (W)

Operation:A = With automatic level control

= For manual operation

Version:

1 = Single-phase

3 = Three-phase

H = High-head

M

S

H

D

MATERIAL SPECIFICATION

Description Material DIN W.-Nr. ASTM/AISI

Stator housing

Pump sleeve

Discharge

Top cover

All models*: Aluminium castings.

*DW.50.08 has a polypropylene pump sleeve + extruded alu-

minium stator housing.

1712:GA15:10Mg ASTM B265G 100A

Motor cable 20 metres, H07RN-F

Impeller High alloyed cast iron impeller 600HV JN3049

Shaft

DW.65.27 to DW.100.66:

Steel shaft (1.0533) with welded stainless steel (1.4301) shaft end

All other models: Stainless steel (1.4021)

Bearings

DW.50.07 to DW.100.66:

Two single-row heavy duty prelubricated ball bearings

DW.100.110 to DW.150.200 (11 and 20 kW):

Heavy-duty prelubricated ball bearings.

The lower ball bearing is a double-row ball bearing, the

upper a single-row ball bearing.

Shaft seals

DW.50.08 with polypropylene pump sleeve:

Seal bushing containing grease and a lip seal in both ends.

DW.50.07 to DW.100.66 with aluminium pump sleeve:

Combination of a mechanical seal and a lip seal.

Primary seal: Mechanical seal, silicon carbide/silicon carbide.

Secondary seal: Lip seal.

DW.100.110 to DW.150.200 (11 and 20 kW)

Primary seal: Silicon carbide/silicon carbide.

Secondary seal: Carbon/aluminium oxide.

Bottom plate and

strainer

DW.50.08: Polypropylene. All other models: Stainless steel 1.4301 AISI 304

Wear parts Nitrile rubber

Screws Stainless steel 1.4301 AISI 304

PUMPED LIQUIDS

The Grundfos DW pumps are specically designed

for pumping dirty water with a high content of abra-

sives, such as sand, drill cuttings and similar abra-

sive materials.

Ph-value: 5 to 8.

Temperature: 0 C to +40 C.

Max. density: 1100 kg/m

3

.

MOTOR

Two-pole motors for 50 Hz with voltage toler-

ances of 10%. As a protection against overload

all Grundfos DW pumps have thermal overload

switches in the stator windings. They break the cir-

cuit at 130 C or 150 C depends on the pump type.

Enclosure class: IP X8.

Insulation class: F (155 C).

PUMP TYPES AND PRODUCT NUMBERS

Pump type Voltage [V] Starting

Electrical connection Discharge connection

Product

number

N

o

p

l

u

g

S

c

h

u

k

o

p

l

u

g

M

o

t

o

r

s

t

a

r

t

e

r

*

P

r

e

p

a

r

e

d

f

o

r

e

x

t

r

e

n

a

l

c

o

n

t

r

o

l

H

o

s

e

c

o

n

n

e

c

t

i

o

n

T

h

r

e

a

d

e

d

S

t

o

r

z

c

o

u

p

l

i

n

g

h

a

l

f

Single-phase pumps

DW.50.07.1 1 x 230 DOL x x 96 09 02 04

DW.50.07.1 1 x 230 DOL x x 96 09 02 05

DW.50.07.1 1 x 230 DOL x x 96 09 02 38

DW.50.07.A1 3 x 230 DOL x x 96 09 02 39

DW.50.07.1 1 x 230 DOL x x 96 09 02 99

Three-phase pumps

DW.50.09.3 3 x 400 DOL x x 96 09 02 06

DW.50.09.A3 3 x 400 DOL x x 96 09 02 07

DW.50.09.3 3 x 400 DOL x x 96 09 02 53

DW.50.09.A3 3 x 400 DOL x x 96 09 02 54

DW.50.09.3 3 x 400 DOL x x 96 09 03 00

DW.50.09.3 3 x 230 DOL x x 96 09 02 76

DW.50.09.A3 3 x 230 DOL x x 96 09 02 77

DW.65.27.3 3 x 400 DOL x x 96 09 02 08

DW.65.27.A3 3 x 400 DOL x x 96 09 02 09

DW.65.27.3 3 x 400 DOL x x 96 09 02 40

DW.65.27.A3 3 x 400 DOL x x 96 09 02 55

DW.65.27.3 3 x 400 DOL x x 96 09 03 01

DW.65.27.3 3 x 230 DOL x x 96 09 02 78

DW.65.27.A3 3 x 230 DOL x x 96 09 02 79

DW.65.39.3.H 3 x 400 DOL x x 96 09 02 10

DW.65.39.A3.H 3 x 400 DOL x x 96 09 02 11

DW.65.39.3.H 3 x 400 DOL x x 96 09 02 41

DW.65.39.A3.H 3 x 400 DOL x x 96 09 02 56

DW.65.39.3.H 3 x 400 DOL x x 96 09 03 02

DW.65.39.3.H 3 x230 DOL x x 96 09 02 80

DW.65.39.A3.H 3 x 230 DOL x x 96 09 02 81

DW.100.39.3 3 x 400 DOL x x 96 09 02 12

DW.100.39.A3 3 x 400 DOL x x 96 09 02 13

DW.100.39.3 3 x 400 DOL x x 96 09 02 42

DW.100.39.3 3 x 400 DOL x x 96 09 02 98

DW.100.39.A3 3 x 400 DOL x x 96 09 02 57

Dw.100.66.3 3 x 230 DOL x x 96 09 02 82

DW.100.66.A3 3 x 230 DOL x x 96 09 02 83

DW.100.66.3 3 x 400 DOL x x 96 09 02 14

DW.100.66.A3 3 x 400 DOL x x 96 09 02 15

DW.100.66.H 3 x 400 DOL x x 96 09 02 32

DW.100.66.3A.H 3 x 400 DOL x x 96 09 02 33

DW.100.66.3.H 3 x 400 DOL x x 96 09 02 43

DW.100.66.3 3 x 400 DOL x x 96 09 02 44

DW.100.66.A3 3 x 400 DOL x x 96 09 02 59

DW.100.66.3.H 3 x 400 DOL x x 96 09 03 03

DW.100.66.3 3 x 400 DOL x x 96 09 03 04

DW.100.66.A3.H 3 x 400 DOL x x 96 09 02 58

All pumps are supplied with 20 metres of cable as stand-

ard. Other lengths are available on request.

Note: Pumps without integrated motor starter for direct

on-line or star-delta starting must be connected to an

external control box to protect the motor against overcur-

rent and overload.

Pumps with aluminium sleeve

TECHNICAL DATA

Pump type Voltage [V] Starting

Electrical connection Discharge connection

Product

number

N

o

p

l

u

g

S

c

h

u

k

o

p

l

u

g

M

o

t

o

r

s

t

a

r

t

e

r

*

P

r

e

p

a

r

e

d

f

o

r

e

x

t

r

e

n

a

l

c

o

n

t

r

o

l

H

o

s

e

c

o

n

n

e

c

t

i

o

n

T

h

r

e

a

d

e

d

S

t

o

r

z

c

o

u

p

l

i

n

g

h

a

l

f

DW.100.66.3 3 x 230 DOL x x 96 09 02 84

DW.100.66.A3 3 x 230 DOL x x 96 09 02 85

DW.100.66.3.H 3 x 230 DOL x x 96 09 02 86

DW.100.66.3A.H 3 x 230 DOL x x 96 09 02 87

DW.100.110.3.H 3 x 400 DOL x x 96 09 02 16

DW.100.110.A3.H 3 x 400 DOL x x 96 09 02 17

DW.100.110.3.H 3 x 400 Y/D x x 96 09 02 20

DW.100.110.A3.H 3 x 400 Y/D x x 96 09 02 21

DW.100.110.3.H 3 x 400 DOL x x 96 09 02 45

DW.100.110.3.H 3 x 400 Y/D x x x 96 09 02 47

DW.100.110.A3.H 3 x 400 DOL x x 96 09 02 60

DW.100.110.3.H 3 x 400 DOL x x 96 09 03 05

DW.100.110.3.H 3 x 400 DOL x x x 96 09 03 24

DW.100.110.3.H 3 x 230 DOL x x 96 09 02 88

DW.100.110.A3.H 3 x 230 DOL x x 96 09 02 89

DW.100.200.3.H 3 x 400 DOL x x 96 09 02 24

DW.100.200.A3.H 3 x 400 DOL x x 96 09 02 25

DW.100.200.3.H 3 x 400 Y/D x x 96 09 02 28

DW.100.200.A3.H 3 x 400 Y/D x x 96 09 02 29

DW.100.200.3.H 3 x 400 DOL x x x 96 09 02 49

DW.100.200.3.H 3 x 400 Y/D x x x 96 09 02 51

DW.100.200.3.H 3 x 400 DOL x x 96 09 02 68

DW.100.200.3.H 3 x 400 DOL x x x 96 09 03 06

DW.100.200.3.H 3 x 400 Y/D x x 96 09 02 70

DW.150.110.3 3 x 400 DOL x x 96 09 02 18

DW.150.110.A3 3 x 400 DOL x x 96 09 02 19

DW.150.110.3 3 x 400 Y/D x x 96 09 02 22

DW.150.110.A3 3 x 400 Y/D x x 96 09 02 23

DW.150.110.3 3 x 400 DOL x x 96 09 02 46

DW.150.110.3 3 x 400 Y/D x x x 96 09 02 48

DW.150110.A3 3 x 400 DOL x x 96 09 02 61

DW.150.110.3 3 x 400 DOL x x x 96 09 02 73

DW.150.110.3 3 x 400 DOL x x 96 09 03 07

DW.150.110.3 3 x 230 DOL x x 96 09 02 92

DW.150.110.A3 3 x 230 DOL x x 96 09 02 93

DW.150.200.3 3 x 400 DOL x x 96 09 02 26

DW.150.200.A3 3 x 400 DOL x x 96 09 02 27

DW.150.200.3 3 x 400 Y/D x x 96 09 02 30

DW.150.200.A3 3 x 400 Y/D x x 96 09 02 31

DW.150.200.3 3 x 400 DOL x x x 96 09 02 50

DW.150.200.3 3 x 400 Y/D x x x 96 09 02 52

DW.150.200.3 3 x 400 DOL x x 96 09 02 69

DW.150.200.3 3 x 400 DOL x x 96 09 03 08

DW.150.200.3 3 x 400 Y/D x x 96 09 02 71

Pumps with polypropylene pump sleeve

Single-phase pumps

DW.50.08.1 1 x 230 DOL x x 96 09 02 00

DW.50.08.A1 1 x 230 DOL x x 96 09 02 01

DW.50.08.1 1 x 230 DOL x x 96 09 02 34

DW.50.08.A1 1 x 230 DOL x x 96 09 02 35

DW.50.08.1 1 x 230 DOL x x 96 09 02 96

DW.50.08.A1 1 x 230 DOL x x 96 09 02 97

Three-phase pumps

DW.50.08.3 3 x 400 DOL x x 96 09 02 02

DW.50.08.A3 3 x 400 DOL x x 96 09 02 02

DW.50.08.3 3 x 400 DOL x x 96 09 02 36

DW.50.08.A3 3 x 400 DOL x x 96 09 02 37

DW.50.08.3 3 x 230 DOL x x 96 09 02 74

DW.50.08.A3 3 x 230 DOL x x 96 09 02 75

Pump type Voltage [V] Starting

Electrical connection Discharge connection

Product

number

N

o

p

l

u

g

S

c

h

u

k

o

p

l

u

g

M

o

t

o

r

s

t

a

r

t

e

r

*

P

r

e

p

a

r

e

d

f

o

r

e

x

t

r

e

n

a

l

c

o

n

t

r

o

l

H

o

s

e

c

o

n

n

e

c

t

i

o

n

T

h

r

e

a

d

e

d

S

t

o

r

z

c

o

u

p

l

i

n

g

h

a

l

f

Single-phase pumps

DW.50.07.1 1 x 230 DOL x x 96 09 02 04

DW.50.07.1 1 x 230 DOL x x 96 09 02 05

DW.50.07.1 1 x 230 DOL x x 96 09 02 38

DW.50.07.A1 3 x 230 DOL x x 96 09 02 39

DW.50.07.1 1 x 230 DOL x x 96 09 02 99

Three-phase pumps

DW.50.09.3 3 x 400 DOL x x 96 09 02 06

DW.50.09.A3 3 x 400 DOL x x 96 09 02 07

DW.50.09.3 3 x 400 DOL x x 96 09 02 53

DW.50.09.A3 3 x 400 DOL x x 96 09 02 54

DW.50.09.3 3 x 400 DOL x x 96 09 03 00

DW.50.09.3 3 x 230 DOL x x 96 09 02 76

DW.50.09.A3 3 x 230 DOL x x 96 09 02 77

DW.65.27.3 3 x 400 DOL x x 96 09 02 08

DW.65.27.A3 3 x 400 DOL x x 96 09 02 09

DW.65.27.3 3 x 400 DOL x x 96 09 02 40

DW.65.27.A3 3 x 400 DOL x x 96 09 02 55

DW.65.27.3 3 x 400 DOL x x 96 09 03 01

DW.65.27.3 3 x 230 DOL x x 96 09 02 78

DW.65.27.A3 3 x 230 DOL x x 96 09 02 79

DW.65.39.3.H 3 x 400 DOL x x 96 09 02 10

DW.65.39.A3.H 3 x 400 DOL x x 96 09 02 11

DW.65.39.3.H 3 x 400 DOL x x 96 09 02 41

DW.65.39.A3.H 3 x 400 DOL x x 96 09 02 56

DW.65.39.3.H 3 x 400 DOL x x 96 09 03 02

DW.65.39.3.H 3 x230 DOL x x 96 09 02 80

DW.65.39.A3.H 3 x 230 DOL x x 96 09 02 81

DW.100.39.3 3 x 400 DOL x x 96 09 02 12

DW.100.39.A3 3 x 400 DOL x x 96 09 02 13

DW.100.39.3 3 x 400 DOL x x 96 09 02 42

DW.100.39.3 3 x 400 DOL x x 96 09 02 98

DW.100.39.A3 3 x 400 DOL x x 96 09 02 57

Dw.100.66.3 3 x 230 DOL x x 96 09 02 82

DW.100.66.A3 3 x 230 DOL x x 96 09 02 83

DW.100.66.3 3 x 400 DOL x x 96 09 02 14

DW.100.66.A3 3 x 400 DOL x x 96 09 02 15

DW.100.66.H 3 x 400 DOL x x 96 09 02 32

DW.100.66.3A.H 3 x 400 DOL x x 96 09 02 33

DW.100.66.3.H 3 x 400 DOL x x 96 09 02 43

DW.100.66.3 3 x 400 DOL x x 96 09 02 44

DW.100.66.A3 3 x 400 DOL x x 96 09 02 59

DW.100.66.3.H 3 x 400 DOL x x 96 09 03 03

DW.100.66.3 3 x 400 DOL x x 96 09 03 04

DW.100.66.A3.H 3 x 400 DOL x x 96 09 02 58

ACCESSORIES

Accessories Pump type Product

number Pos. Description Dimensions DW.50.08 DW.50, 07/09 DW.65 DW.100 DW.150

1

Chain with

shackle

- galvanized

10 m x x x x x 96 00 20 12

6 m x x x x x 96 00 36 33

3 m x x x x x 96 00 36 34

2

Coupling half,

Storz coupling

Rp 2-2 hose x x 96 0019 82

Rp 2-2 hose x 90 00 19 83

Rp 2-3 hose x 96 00 20 86

Rp 4-4 hose x 96 00 52 52

Rp 6-6 hose x 96 00 52 53

2a

Socket for hose

connection

2 x 96 00 52 18

2 x 96 00 60 95

3 x 96 00 60 96

4 x (DW.65.39) x (DW.100.39) 96 00 60 97

4 x (DW.100.66) 96 00 50 49

4

x (DW.100.100

& 200)

x 96 00 49 91

6

x (DW.100.110

& 200)

x 96 00 60 98

3

10 m at hose,

incl. Storz

couplings

2 x x 96 00 19 87

3 x 96 00 52 54

4 x 96 00 52 55

6 x 96 00 52 56

4

20 m at hose,

incl. Storz

couplings

2 x x 96 00 52 57

3 x 96 00 52 59

4 x 96 00 52 60

6 x 96 00 52 61

5

Bushing for pipe

connection

Rp 2-2 x x 96 00 52 62

Rp 2-2 x 96 00 52 63

Rp 2-3 x 96 00 52 64

Rp 4-4 x 96 00 52 65

6 Union

Rp 2 x x 96 00 52 66

Rp 2 x 96 00 52 67

Rp 3 x 96 00 52 68

7

Non-return valve,

cast iron, ball-

type valve

Rp/Rp 2 x x 96 00 20 02

Rp/Rp 2 x 96 00 20 03

Rp/Rp 3 x 96 00 20 04

8

Hexagon head

screw

R/R 2 x x 96 00 19 93

R/R 2 x 96 00 19 94

R/R 3 x 96 00 19 95

9

Isolating valve,

brass

Rp/Rp 2 x x 96 00 20 05

Rp/Rp 2 x 96 00 20 06

Rp/Rp 3 x 96 00 20 07

10 Threaded ange

Rp 2 x 96 00 19 96

Rp 3 x 96 00 19 97

Rp 4 x 96 00 33 36

11

Gasket, bolts and

nuts

4 of each M16

x 65 mm

DN 80

x 96 00 19 98

8 of each M16

x 65 mm

DN 80

x 96 00 19 99

8 of each M16

x 65 mm

DN 100

x 96 00 38 23

8 of each M20

x 75 mm

DN 150

x 96 00 36 05

ACCESSORIES

Accessories Pump type

Product

number

Pos. Description Dimensions DW.50.08 DW.50, 07/09 DW.65 DW.100 DW.150

12

Non-return

valve, cast iron,

ball-type valve

DN 65 x 96 00 20 08

DN 80 x 96 00 20 09

DN 100 x 96 00 20 85

DN 150 x 96 00 20 23

13

Isolating valve,

cast iron

DN 65 x 96 00 20 10

DN 80 x 96 00 20 11

DN 100 x 96 00 20 12

DN 150 x 96 00 34 27

14

Pump connector

kit. Connectors

for two or more

DW pumps oper-

ating in series

2 x 96 47 20 79

3 x x (DW.100.66) 96 47 21 00

6

x

(DW.100.100)

(DW.100.200)

x 96 47 21 01

Flat suction kit x 96 00 52 48

Schuko plug x x 96 00 52 49

CE plug with

phase exchanger

and on/of

switch

2.5-4 A x x 96 00 52 50

6.3-10 A x (DW.6.5.27) 96 00 63 12

10-16 A x (DW.6.5.39)

x

(DW.100.39)

(DW.100.66)

96 00 52 51

16-25A

x

(DW.100.110)

x

(DW.150.110)

96 00 52 36

Accessories Pump type Product

number Pos. Description Dimensions DW.50.08 DW.50, 07/09 DW.65 DW.100 DW.150

1

Chain with

shackle

- galvanized

10 m x x x x x 96 00 20 12

6 m x x x x x 96 00 36 33

3 m x x x x x 96 00 36 34

2

Coupling half,

Storz coupling

Rp 2-2 hose x x 96 0019 82

Rp 2-2 hose x 90 00 19 83

Rp 2-3 hose x 96 00 20 86

Rp 4-4 hose x 96 00 52 52

Rp 6-6 hose x 96 00 52 53

2a

Socket for hose

connection

2 x 96 00 52 18

2 x 96 00 60 95

3 x 96 00 60 96

4 x (DW.65.39) x (DW.100.39) 96 00 60 97

4 x (DW.100.66) 96 00 50 49

4

x (DW.100.100

& 200)

x 96 00 49 91

6

x (DW.100.110

& 200)

x 96 00 60 98

3

10 m at hose,

incl. Storz

couplings

2 x x 96 00 19 87

3 x 96 00 52 54

4 x 96 00 52 55

6 x 96 00 52 56

4

20 m at hose,

incl. Storz

couplings

2 x x 96 00 52 57

3 x 96 00 52 59

4 x 96 00 52 60

6 x 96 00 52 61

5

Bushing for pipe

connection

Rp 2-2 x x 96 00 52 62

Rp 2-2 x 96 00 52 63

Rp 2-3 x 96 00 52 64

Rp 4-4 x 96 00 52 65

6 Union

Rp 2 x x 96 00 52 66

Rp 2 x 96 00 52 67

Rp 3 x 96 00 52 68

7

Non-return valve,

cast iron, ball-

type valve

Rp/Rp 2 x x 96 00 20 02

Rp/Rp 2 x 96 00 20 03

Rp/Rp 3 x 96 00 20 04

8

Hexagon head

screw

R/R 2 x x 96 00 19 93

R/R 2 x 96 00 19 94

R/R 3 x 96 00 19 95

9

Isolating valve,

brass

Rp/Rp 2 x x 96 00 20 05

Rp/Rp 2 x 96 00 20 06

Rp/Rp 3 x 96 00 20 07

10 Threaded ange

Rp 2 x 96 00 19 96

Rp 3 x 96 00 19 97

Rp 4 x 96 00 33 36

11

Gasket, bolts and

nuts

4 of each M16

x 65 mm

DN 80

x 96 00 19 98

8 of each M16

x 65 mm

DN 80

x 96 00 19 99

8 of each M16

x 65 mm

DN 100

x 96 00 38 23

8 of each M20

x 75 mm

DN 150

x 96 00 36 05

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

GRUNDFOS HOLDING A/S

Poul Due Jensens Vej 7

DK-8850 Bjerringbro

Tel: +45 87 50 14 00

www.grundfos.com

The name Grundfos, the Grundfos logo, and the payof BeThinkInnovate are registrated trademarks

owned by Grundfos Management A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

Business with an attitude

Knowledge The sharing of knowledge, experience

and expertise across our global network will always

lead our business forward.

Innovation Combining the best technology with fresh

ways of thinking, we will continue to de vel op even bet-

ter pumps, systems, services and standards.

Solution With a complete product range, capable

of provid ing every conceivable water solution, we are

the most complete player on the market.

9

6

4

8

5

0

5

0

/

0

2

1

2

/

W

A

T

E

R

U

T

I

L

I

T

Y

/

1

0

5

2

2

-

D

&

I

You might also like

- Natural Gas and Propane Installation Code: CSA B149.1:20Document34 pagesNatural Gas and Propane Installation Code: CSA B149.1:20c t0% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Load Combination On Frame CDocument6 pagesLoad Combination On Frame Cjolmarie llantoNo ratings yet

- Chiller Koolman CgakDocument8 pagesChiller Koolman Cgakfabieduarte440No ratings yet

- DW PompaDocument32 pagesDW PompaluxorraNo ratings yet

- En Daten MS-MFDocument20 pagesEn Daten MS-MFcazan93No ratings yet

- Cryo Pump PDFDocument0 pagesCryo Pump PDFkanchanabalajiNo ratings yet

- SubmersibleDewateringPumps E10361Document20 pagesSubmersibleDewateringPumps E10361Rolando AlvaradoNo ratings yet

- E2902 4 03 13 - Pumpen Uebersicht - LQDocument20 pagesE2902 4 03 13 - Pumpen Uebersicht - LQDenis Jimenez0% (1)

- Pumpe Za Septičkudw-Dw-VoxDocument12 pagesPumpe Za Septičkudw-Dw-VoxMiha GlighaNo ratings yet

- DS DVS DML DLDocument4 pagesDS DVS DML DLGabi PNo ratings yet

- Hydrolink General Product CatalogueDocument17 pagesHydrolink General Product CatalogueMarcoAlbaNo ratings yet

- So Do Binh Tich ApDocument3 pagesSo Do Binh Tich ApLongTranThienNo ratings yet

- Bomba de Engranajes Catalogo JOYANGDocument8 pagesBomba de Engranajes Catalogo JOYANGlizbethdiosesNo ratings yet

- FlygtDocument4 pagesFlygtToby Hopkins-AllanNo ratings yet

- Gardner Denver Industrial Blowers TF 140L K202Document8 pagesGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićNo ratings yet

- PS 438919507en W5330S enDocument2 pagesPS 438919507en W5330S enFelix RamirezNo ratings yet

- Technical Specifications For Centrifugal Pumps PDFDocument12 pagesTechnical Specifications For Centrifugal Pumps PDFVicky GautamNo ratings yet

- Pumps Catalog enDocument36 pagesPumps Catalog enJoão Paulo FogarolliNo ratings yet

- Daba50 PDFDocument20 pagesDaba50 PDFCatalin StanNo ratings yet

- RW PDFDocument6 pagesRW PDFnbharath1988No ratings yet

- 001-232500-0 2.7 Filtration EquipmentDocument34 pages001-232500-0 2.7 Filtration Equipmentmolinach100% (1)

- Raje-Dia AODD PumpsDocument24 pagesRaje-Dia AODD PumpsZai QuêNo ratings yet

- Catalogo JUMBO InglesDocument8 pagesCatalogo JUMBO InglesDarko BogdanovicNo ratings yet

- Air Preparation Equimaents FilDocument80 pagesAir Preparation Equimaents Filloveselvan43No ratings yet

- York Tecnologia Inverter MS Inverter RVCC09-24DSAADR - LDocument2 pagesYork Tecnologia Inverter MS Inverter RVCC09-24DSAADR - LYorgos J. Ramirez PNo ratings yet

- Dwatering Oct 2012Document92 pagesDwatering Oct 2012sukiraj100% (1)

- Grundfos Axial Flow Pumps BrochureDocument7 pagesGrundfos Axial Flow Pumps Brochurefg_111307359No ratings yet

- 520L0940 - PVG 100 VLV - DS - Aug-2005 - REVDocument2 pages520L0940 - PVG 100 VLV - DS - Aug-2005 - REVSasko DimitrovNo ratings yet

- NS PDFDocument5 pagesNS PDFTarunPatraNo ratings yet

- Espec - Tec.bombas Lowara DL A 60HzDocument39 pagesEspec - Tec.bombas Lowara DL A 60HzpapashoNo ratings yet

- Lemb 251 e 0409Document10 pagesLemb 251 e 0409Panagiotis PapadimatosNo ratings yet

- Catalogos EBARADocument15 pagesCatalogos EBARAJorge Alejandro Verde VereauNo ratings yet

- Shack Mounted Drill Rig VD8000Document5 pagesShack Mounted Drill Rig VD8000Alfredo Pozos100% (1)

- TC Fls Sihi Lem Lel 91 To 161 THR enDocument13 pagesTC Fls Sihi Lem Lel 91 To 161 THR enIamandii RoxanaNo ratings yet

- 6" Submersible Pumps: Performance RangeDocument12 pages6" Submersible Pumps: Performance RangeGuillermo Renato Monroy RodriguezNo ratings yet

- Boomer 104-1432Document4 pagesBoomer 104-1432Aldo CarvajalNo ratings yet

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesNo ratings yet

- Ebara DW VoxDocument2 pagesEbara DW Voxmarckalhi100% (1)

- Wind Power Evolved: Knowledge Really Is PowerDocument2 pagesWind Power Evolved: Knowledge Really Is Powerstoke20No ratings yet

- Valvula WW-820Document4 pagesValvula WW-820Anonymous Iic1fi49uENo ratings yet

- FPZ Membrane BlowersDocument16 pagesFPZ Membrane BlowersadifoteaNo ratings yet

- Motor PDFDocument81 pagesMotor PDFmaungNo ratings yet

- LEM 91-161 Fla E 0612Document13 pagesLEM 91-161 Fla E 0612Julen IturriozNo ratings yet

- Product Overviews - 2012 - : Drying Buildings and Water Damages The Dehumidifying SpecialistsDocument7 pagesProduct Overviews - 2012 - : Drying Buildings and Water Damages The Dehumidifying SpecialistsOLiveira Adão FilhoNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- WaterWolf Data Sheet PDFDocument2 pagesWaterWolf Data Sheet PDFcarlosfariasfakeNo ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- 23.bladder AccumlatorDocument12 pages23.bladder AccumlatorM S GokulNo ratings yet

- Sihi Lema 325 MANUALDocument8 pagesSihi Lema 325 MANUALHector Maldonado0% (1)

- DML DMLVDocument49 pagesDML DMLVCristian Muñoz AlarcónNo ratings yet

- Yanmar Engine Type 6CXM-GTE2Document2 pagesYanmar Engine Type 6CXM-GTE2Yoga_DMNo ratings yet

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- AHU 20sep11Document36 pagesAHU 20sep11Tạ Tuấn CườngNo ratings yet

- VacPumpReq TSB007Document6 pagesVacPumpReq TSB007zosuryantoNo ratings yet

- Leh 2200 3000 eDocument9 pagesLeh 2200 3000 eFrancisco RenteriaNo ratings yet

- SHURflo Pump BrochureDocument1 pageSHURflo Pump BrochureCarlos Eduardo RibeiroNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Design of RCC Silo: Presented byDocument31 pagesDesign of RCC Silo: Presented byAlok ThakurNo ratings yet

- Cyclic Load Behavior of Reinforced Concrete Beam-Column Subassemblages of Modern StructuresDocument11 pagesCyclic Load Behavior of Reinforced Concrete Beam-Column Subassemblages of Modern StructuresM Hadianto WaruwuNo ratings yet

- Shipham Valves: Mesc No. 772701.005.1 and Secured To Valve With ST - St. WireDocument1 pageShipham Valves: Mesc No. 772701.005.1 and Secured To Valve With ST - St. Wirepritam sarkarNo ratings yet

- 2nd Year Plumber Jess Harris Apprentice ApplicationDocument2 pages2nd Year Plumber Jess Harris Apprentice ApplicationflawlessjessNo ratings yet

- DESIGN AND CONSTRUCTION OF LARGE DIAMETER BORED PILES IN HIGH SEISMIC AND SOFT SOIL CONDITIONS - PhilDocument1 pageDESIGN AND CONSTRUCTION OF LARGE DIAMETER BORED PILES IN HIGH SEISMIC AND SOFT SOIL CONDITIONS - Philphilip claytonNo ratings yet

- PN16 Cast Iron Globe Valve - SDNR: SKU: GV5198Document2 pagesPN16 Cast Iron Globe Valve - SDNR: SKU: GV5198HotnCrispy CrispyNo ratings yet

- Shape of A Pressure VesselDocument3 pagesShape of A Pressure Vesselarif99pakNo ratings yet

- Rain LoadDocument6 pagesRain LoadAristo Onan100% (1)

- Line Sizing LiqDocument12 pagesLine Sizing LiqDana GuerreroNo ratings yet

- Unit 11 Design and InnovationDocument6 pagesUnit 11 Design and InnovationtranzhangsNo ratings yet

- Boq 17012020 PDFDocument10 pagesBoq 17012020 PDFAvinashNo ratings yet

- The Provinical StyleDocument29 pagesThe Provinical StyleManish SinghNo ratings yet

- Design of Drip Irrigation SystemDocument38 pagesDesign of Drip Irrigation SystemSriram SekaranNo ratings yet

- Beam Design Excel SheetDocument1 pageBeam Design Excel SheetDinesh GowdaNo ratings yet

- Data Unit Di Cibaliung (CSD) : NO Jenis Tahun No Kantor S/N No Lambung UnitDocument6 pagesData Unit Di Cibaliung (CSD) : NO Jenis Tahun No Kantor S/N No Lambung UnitKukuh Suryo AtmojoNo ratings yet

- EVAPCO Fill Offerings 1Document4 pagesEVAPCO Fill Offerings 1Walter J Naspirán CastañedaNo ratings yet

- Zio Ciro Catalogue 2020Document21 pagesZio Ciro Catalogue 2020ronNo ratings yet

- Acpml Plant Fire Fighting PhilosophyDocument14 pagesAcpml Plant Fire Fighting PhilosophyOkeymanNo ratings yet

- Building SSR 2008 09Document148 pagesBuilding SSR 2008 09kartheekaryans100% (2)

- Paper Storage TankDocument12 pagesPaper Storage TankAryanto YogaNo ratings yet

- Introduction of E TabsDocument18 pagesIntroduction of E TabsneerajNo ratings yet

- Side Horizontal TrussDocument14 pagesSide Horizontal TrussSatyajeet BeheraNo ratings yet

- BPD QuestionsDocument6 pagesBPD QuestionsViswanadham KaruNo ratings yet

- Dictionary of Concrete TechnologyDocument12 pagesDictionary of Concrete TechnologyJoseRodrigoPastorNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- British Highway Specifications - 22!11!04Document101 pagesBritish Highway Specifications - 22!11!04soran azizNo ratings yet

- Unops Feeder Roads-Feasibility Study Report-V1-15 June 15Document247 pagesUnops Feeder Roads-Feasibility Study Report-V1-15 June 15prashantNo ratings yet

- Brazing Pipe: Apply Alloy Here Heat Draws Alloy UpwardDocument6 pagesBrazing Pipe: Apply Alloy Here Heat Draws Alloy UpwardWilly UioNo ratings yet