Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

30 viewsAMS 5659 (15-5PH) : Min Max

AMS 5659 (15-5PH) : Min Max

Uploaded by

silpawdmThis document summarizes the properties and applications of 15-5PH precipitation hardening stainless steel. It is a chromium-nickel alloy that develops medium to high strengths through heat treatment. It offers corrosion resistance and excellent transverse properties. The steel is supplied as solution treated bar or can be aged to specific hardness conditions ranging from H900 to H1150. It is well-suited for aircraft structural parts and engine components.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Steel SpecificationsDocument4 pagesSteel Specificationsgaurav tiwariNo ratings yet

- MaterialDocument4 pagesMaterialAmit PandeyNo ratings yet

- Cast Materials: Sulzer PumpsDocument6 pagesCast Materials: Sulzer PumpsElmey Bin JulkeplyNo ratings yet

- 7147 7149 20MnCr5 20MnCrS5Document1 page7147 7149 20MnCr5 20MnCrS5Suhas KararNo ratings yet

- ASTM A514 GR H Data Sheet 2012 04 02 PDFDocument2 pagesASTM A514 GR H Data Sheet 2012 04 02 PDFRodolfoMarínNo ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazNo ratings yet

- Metalshield MC - 110: Conformances Key FeaturesDocument1 pageMetalshield MC - 110: Conformances Key FeaturesH_DEBIANENo ratings yet

- AMS6265 Gear Material PropertiesDocument2 pagesAMS6265 Gear Material PropertiesSinan YıldızNo ratings yet

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocument3 pagesDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNo ratings yet

- Dental Base Metals and PFM AlloysDocument25 pagesDental Base Metals and PFM AlloysH. Ralph RawlsNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- Alloy Steels: Dr. Indika de SilvaDocument25 pagesAlloy Steels: Dr. Indika de SilvaChandima K Priyamal100% (1)

- WeldabilityDocument26 pagesWeldabilityvivek bhangaleNo ratings yet

- Materials For Engineering 12 - Ferritic Stainless SteelDocument14 pagesMaterials For Engineering 12 - Ferritic Stainless SteelKris WilochNo ratings yet

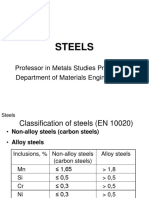

- SteelsDocument28 pagesSteelsMalik Ansar HayatNo ratings yet

- SteelsDocument28 pagesSteelsPAUL PRAVEEN A 15PHD0053No ratings yet

- SteelsDocument28 pagesSteelssaba AnasNo ratings yet

- 0.3C-Crmov (Esr) Ultrahigh Strength Steel: by Chidanand Magadum, Resident Engineer, MWCDocument49 pages0.3C-Crmov (Esr) Ultrahigh Strength Steel: by Chidanand Magadum, Resident Engineer, MWCRahul JaitpalNo ratings yet

- Weldability of Structural SteelsDocument48 pagesWeldability of Structural SteelsAytuğ KarameşeNo ratings yet

- Lecture 03 - Introduction To Steel Structures (Demarits of Steel Construction)Document23 pagesLecture 03 - Introduction To Steel Structures (Demarits of Steel Construction)Vai re Vai100% (1)

- Basic MetallurgyDocument55 pagesBasic MetallurgyTina Miller100% (2)

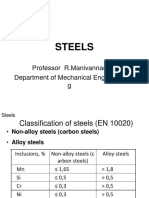

- Steels: Professor R.Manivannan Department of Mechanical Engineerin GDocument28 pagesSteels: Professor R.Manivannan Department of Mechanical Engineerin GManivannan JeevaNo ratings yet

- 11-14%Cr IIW Document - Part 2 PDFDocument21 pages11-14%Cr IIW Document - Part 2 PDFManuel CarreñoNo ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- Heat Treatment and The Effect of Welding: Week 2Document44 pagesHeat Treatment and The Effect of Welding: Week 2Arun SundarNo ratings yet

- S6900QLDocument4 pagesS6900QLmechkashanNo ratings yet

- Classification of Steel & Alloy SteelsDocument39 pagesClassification of Steel & Alloy SteelsNetaa sachinNo ratings yet

- XAR 450 (WB 710) EnglischDocument3 pagesXAR 450 (WB 710) EnglischMario MoranNo ratings yet

- MR2006 Wed 64JCostaDocument68 pagesMR2006 Wed 64JCostaseagull70No ratings yet

- Preheat Ions For A 514 Grade B MaterialDocument2 pagesPreheat Ions For A 514 Grade B Materialjrod64No ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- 2005 Stainless SteelsDocument76 pages2005 Stainless SteelsAnonymous 98vSKYTaDgNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- CR Mo Temper EmbrittlementDocument26 pagesCR Mo Temper EmbrittlementAsad Bin Ala QatariNo ratings yet

- Manufactory Profile: Characteristics For Grade 12050Document3 pagesManufactory Profile: Characteristics For Grade 12050kifle abelNo ratings yet

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Document3 pagesMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNo ratings yet

- D-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldDocument42 pagesD-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldTrepend Simplifying BusinessNo ratings yet

- MINEX Metallurgical CoDocument41 pagesMINEX Metallurgical CoPriyank SamagraNo ratings yet

- CH 14 CarbonandAlloySteelsDocument43 pagesCH 14 CarbonandAlloySteelsMohmmad ShaikhNo ratings yet

- S 960 QDocument2 pagesS 960 Qmohsen_267No ratings yet

- Boiler MaterialsDocument47 pagesBoiler MaterialsSaptarshi SenguptaNo ratings yet

- Corporate Induction Training Programme On Reactor Engineering (NE-04)Document34 pagesCorporate Induction Training Programme On Reactor Engineering (NE-04)Sourav BasakNo ratings yet

- CHH517Document1 pageCHH517KureiNo ratings yet

- Steels For Oil - Gas - ExplorationDocument16 pagesSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNo ratings yet

- Report On Civil EngineeringDocument48 pagesReport On Civil EngineeringArmaan GuptaNo ratings yet

- Iron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiDocument41 pagesIron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiAmrit MallickNo ratings yet

- Alloy Steel Astm A217 Grade Wc6 1Document1 pageAlloy Steel Astm A217 Grade Wc6 1didi sudiNo ratings yet

- 6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsDocument1 page6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsMadhu KumarNo ratings yet

- Classification of SteelDocument39 pagesClassification of SteelSudarshan GNo ratings yet

- 13 - Q+T Steels & Welding Q+T SteelsDocument22 pages13 - Q+T Steels & Welding Q+T SteelsbbqarNo ratings yet

- CH 14 CarbonandAlloySteelsDocument42 pagesCH 14 CarbonandAlloySteelsdarwin_hua100% (1)

- Material Specification Sheet Saarstahl - 16Mncr5 - 16Mncrs5Document1 pageMaterial Specification Sheet Saarstahl - 16Mncr5 - 16Mncrs5manjuNo ratings yet

- Alloy & Special SteelsDocument33 pagesAlloy & Special Steelstanishka narayan100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

AMS 5659 (15-5PH) : Min Max

AMS 5659 (15-5PH) : Min Max

Uploaded by

silpawdm0 ratings0% found this document useful (0 votes)

30 views2 pagesThis document summarizes the properties and applications of 15-5PH precipitation hardening stainless steel. It is a chromium-nickel alloy that develops medium to high strengths through heat treatment. It offers corrosion resistance and excellent transverse properties. The steel is supplied as solution treated bar or can be aged to specific hardness conditions ranging from H900 to H1150. It is well-suited for aircraft structural parts and engine components.

Original Description:

15-5

Original Title

15-5PH

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the properties and applications of 15-5PH precipitation hardening stainless steel. It is a chromium-nickel alloy that develops medium to high strengths through heat treatment. It offers corrosion resistance and excellent transverse properties. The steel is supplied as solution treated bar or can be aged to specific hardness conditions ranging from H900 to H1150. It is well-suited for aircraft structural parts and engine components.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

30 views2 pagesAMS 5659 (15-5PH) : Min Max

AMS 5659 (15-5PH) : Min Max

Uploaded by

silpawdmThis document summarizes the properties and applications of 15-5PH precipitation hardening stainless steel. It is a chromium-nickel alloy that develops medium to high strengths through heat treatment. It offers corrosion resistance and excellent transverse properties. The steel is supplied as solution treated bar or can be aged to specific hardness conditions ranging from H900 to H1150. It is well-suited for aircraft structural parts and engine components.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

06/2003

The future in metal

Corus Engineering Steels

AMS 5659 (15-5PH)

15%Cr 5%Ni Precipitation Hardening Stainless Steel

Consumable Electrode Melted (ESR or VAR)

Features & Benefits

Medium to high strengths developed by

appropriate ageing treatment

Corrosion resistant

Excellent transverse properties

Min Max

C - 0.07

Si - 1.00

Mn - 1.00

P - 0.030

S - 0.015

Cr 14.00 15.00

Mo - 0.50

Ni 3.50 5.50

Nb (Cb) 5xC 0.45

Cu 2.50 4.50

Ta - 0.05

Chemical Composition (Wt %)

Supply Condition & Availability

Supplied as solution treated bright

machining quality bar

Also available on request aged to specific

H conditions

Stock sizes range 12.7 mm - 250 mm dia.

Other sections on request

Final Heat Treatment

Solution treat @ 1038C. Age @ appropriate

temperature for relevant H condition.

(Hxxx condition aged at xxxF).

Related specs

1.4545

Z7 CNU15.05

Applications

Aircraft structural parts

Flap Tracks

Engine pylons

Condition 0.2% Tensile Elongation Reduction Hardness

Proof Stress Strength of area

MPa MPa % % HB

Min Min Min Min Min Max

Long. Trans. Long. Trans.

H900 1172 1310 10 6 35 20 388 444

H1000 1069 1172 10 7 38 25 375 429

H1025 1000 1069 12 8 45 32 331 401

H1050 862 1000 13 9 45 33 311 375

H1100 793 965 14 10 45 34 302 363

H1150 724 931 16 11 50 35 277 352

N.B. 1Mpa = 1 N/mm

2

Specified strength levels refer to both Transverse and Longitudinal directions.

Mechanical Properties

www.corusgroup.com

Corus Engineering Steels

PO Box 50

Aldwarke Lane

Rotherham

S60 1DW

United Kingdom

Telephone +44 (0) 1709 371234

Facsimile +44 (0) 1709 826233

Care has been taken to

ensure that the information

herein is accurate, but

Corus Engineering Steels

Limited does not accept

responsibility for errors or

for information which is

found to be misleading.

CES02:6000:UK:03/2000

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Steel SpecificationsDocument4 pagesSteel Specificationsgaurav tiwariNo ratings yet

- MaterialDocument4 pagesMaterialAmit PandeyNo ratings yet

- Cast Materials: Sulzer PumpsDocument6 pagesCast Materials: Sulzer PumpsElmey Bin JulkeplyNo ratings yet

- 7147 7149 20MnCr5 20MnCrS5Document1 page7147 7149 20MnCr5 20MnCrS5Suhas KararNo ratings yet

- ASTM A514 GR H Data Sheet 2012 04 02 PDFDocument2 pagesASTM A514 GR H Data Sheet 2012 04 02 PDFRodolfoMarínNo ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- Datenblatt 4105 UKDocument2 pagesDatenblatt 4105 UKVahid SarfarazNo ratings yet

- Metalshield MC - 110: Conformances Key FeaturesDocument1 pageMetalshield MC - 110: Conformances Key FeaturesH_DEBIANENo ratings yet

- AMS6265 Gear Material PropertiesDocument2 pagesAMS6265 Gear Material PropertiesSinan YıldızNo ratings yet

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocument3 pagesDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNo ratings yet

- Dental Base Metals and PFM AlloysDocument25 pagesDental Base Metals and PFM AlloysH. Ralph RawlsNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- Alloy Steels: Dr. Indika de SilvaDocument25 pagesAlloy Steels: Dr. Indika de SilvaChandima K Priyamal100% (1)

- WeldabilityDocument26 pagesWeldabilityvivek bhangaleNo ratings yet

- Materials For Engineering 12 - Ferritic Stainless SteelDocument14 pagesMaterials For Engineering 12 - Ferritic Stainless SteelKris WilochNo ratings yet

- SteelsDocument28 pagesSteelsMalik Ansar HayatNo ratings yet

- SteelsDocument28 pagesSteelsPAUL PRAVEEN A 15PHD0053No ratings yet

- SteelsDocument28 pagesSteelssaba AnasNo ratings yet

- 0.3C-Crmov (Esr) Ultrahigh Strength Steel: by Chidanand Magadum, Resident Engineer, MWCDocument49 pages0.3C-Crmov (Esr) Ultrahigh Strength Steel: by Chidanand Magadum, Resident Engineer, MWCRahul JaitpalNo ratings yet

- Weldability of Structural SteelsDocument48 pagesWeldability of Structural SteelsAytuğ KarameşeNo ratings yet

- Lecture 03 - Introduction To Steel Structures (Demarits of Steel Construction)Document23 pagesLecture 03 - Introduction To Steel Structures (Demarits of Steel Construction)Vai re Vai100% (1)

- Basic MetallurgyDocument55 pagesBasic MetallurgyTina Miller100% (2)

- Steels: Professor R.Manivannan Department of Mechanical Engineerin GDocument28 pagesSteels: Professor R.Manivannan Department of Mechanical Engineerin GManivannan JeevaNo ratings yet

- 11-14%Cr IIW Document - Part 2 PDFDocument21 pages11-14%Cr IIW Document - Part 2 PDFManuel CarreñoNo ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- Heat Treatment and The Effect of Welding: Week 2Document44 pagesHeat Treatment and The Effect of Welding: Week 2Arun SundarNo ratings yet

- S6900QLDocument4 pagesS6900QLmechkashanNo ratings yet

- Classification of Steel & Alloy SteelsDocument39 pagesClassification of Steel & Alloy SteelsNetaa sachinNo ratings yet

- XAR 450 (WB 710) EnglischDocument3 pagesXAR 450 (WB 710) EnglischMario MoranNo ratings yet

- MR2006 Wed 64JCostaDocument68 pagesMR2006 Wed 64JCostaseagull70No ratings yet

- Preheat Ions For A 514 Grade B MaterialDocument2 pagesPreheat Ions For A 514 Grade B Materialjrod64No ratings yet

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanNo ratings yet

- 2005 Stainless SteelsDocument76 pages2005 Stainless SteelsAnonymous 98vSKYTaDgNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- CR Mo Temper EmbrittlementDocument26 pagesCR Mo Temper EmbrittlementAsad Bin Ala QatariNo ratings yet

- Manufactory Profile: Characteristics For Grade 12050Document3 pagesManufactory Profile: Characteristics For Grade 12050kifle abelNo ratings yet

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Document3 pagesMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNo ratings yet

- D-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldDocument42 pagesD-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldTrepend Simplifying BusinessNo ratings yet

- MINEX Metallurgical CoDocument41 pagesMINEX Metallurgical CoPriyank SamagraNo ratings yet

- CH 14 CarbonandAlloySteelsDocument43 pagesCH 14 CarbonandAlloySteelsMohmmad ShaikhNo ratings yet

- S 960 QDocument2 pagesS 960 Qmohsen_267No ratings yet

- Boiler MaterialsDocument47 pagesBoiler MaterialsSaptarshi SenguptaNo ratings yet

- Corporate Induction Training Programme On Reactor Engineering (NE-04)Document34 pagesCorporate Induction Training Programme On Reactor Engineering (NE-04)Sourav BasakNo ratings yet

- CHH517Document1 pageCHH517KureiNo ratings yet

- Steels For Oil - Gas - ExplorationDocument16 pagesSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNo ratings yet

- Report On Civil EngineeringDocument48 pagesReport On Civil EngineeringArmaan GuptaNo ratings yet

- Iron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiDocument41 pagesIron (Fe) - Cementite (Fe C) Phase Diagram: Asst. Prof. Sandeep Parida Dept. of Mechanical Engineering CUTM, ParlakhemundiAmrit MallickNo ratings yet

- Alloy Steel Astm A217 Grade Wc6 1Document1 pageAlloy Steel Astm A217 Grade Wc6 1didi sudiNo ratings yet

- 6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsDocument1 page6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsMadhu KumarNo ratings yet

- Classification of SteelDocument39 pagesClassification of SteelSudarshan GNo ratings yet

- 13 - Q+T Steels & Welding Q+T SteelsDocument22 pages13 - Q+T Steels & Welding Q+T SteelsbbqarNo ratings yet

- CH 14 CarbonandAlloySteelsDocument42 pagesCH 14 CarbonandAlloySteelsdarwin_hua100% (1)

- Material Specification Sheet Saarstahl - 16Mncr5 - 16Mncrs5Document1 pageMaterial Specification Sheet Saarstahl - 16Mncr5 - 16Mncrs5manjuNo ratings yet

- Alloy & Special SteelsDocument33 pagesAlloy & Special Steelstanishka narayan100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet