Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsBasic Fabrication Steps in VLSI

Basic Fabrication Steps in VLSI

Uploaded by

Thomas Jamesh

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design Methodologies and ToolsDocument95 pagesDesign Methodologies and ToolsThomas JamesNo ratings yet

- FPGA-Based Feature DetectionDocument9 pagesFPGA-Based Feature DetectionThomas JamesNo ratings yet

- High Performance 8-Bit Display Interface AD9980: Features Functional Block DiagramDocument44 pagesHigh Performance 8-Bit Display Interface AD9980: Features Functional Block DiagramThomas JamesNo ratings yet

- Experiment 11: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 11: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- B - Tech - B - Arch Degree Exam November, December 2015 NTFNDocument2 pagesB - Tech - B - Arch Degree Exam November, December 2015 NTFNThomas JamesNo ratings yet

- DSP 2 LowpassfilterDocument20 pagesDSP 2 LowpassfilterDr-Atul Kumar DwivediNo ratings yet

- Experiment 13: Aim: Eda Tool Used: MethodologyDocument2 pagesExperiment 13: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 5: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 5: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 12: Aim: Eda Tool Used: MethodologyDocument2 pagesExperiment 12: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Program 9Document4 pagesProgram 9Thomas JamesNo ratings yet

- Experiment 13: Aim: Eda Tool Used: MethodologyDocument2 pagesExperiment 13: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Digital Signal Processing Lab (EC2156) : Thomas James Thomas REG NO: 2014TMPGI01 M.Tech (Digital Systems)Document4 pagesDigital Signal Processing Lab (EC2156) : Thomas James Thomas REG NO: 2014TMPGI01 M.Tech (Digital Systems)Thomas JamesNo ratings yet

- Experiment 5: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 5: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 6: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 6: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 2 (B) : Aim: To Write A MATLAB Program To Receive An Input Sequence From The User and ToDocument4 pagesExperiment 2 (B) : Aim: To Write A MATLAB Program To Receive An Input Sequence From The User and ToThomas JamesNo ratings yet

- Program 15Document4 pagesProgram 15Thomas JamesNo ratings yet

- Digital Signal Processing LabDocument4 pagesDigital Signal Processing LabThomas JamesNo ratings yet

- Program 15Document4 pagesProgram 15Thomas JamesNo ratings yet

- Program 14Document3 pagesProgram 14Thomas JamesNo ratings yet

Basic Fabrication Steps in VLSI

Basic Fabrication Steps in VLSI

Uploaded by

Thomas James0 ratings0% found this document useful (0 votes)

2 views1 pageh

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenth

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views1 pageBasic Fabrication Steps in VLSI

Basic Fabrication Steps in VLSI

Uploaded by

Thomas Jamesh

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

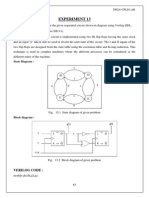

Basic fabrication steps in VLSI

The basic fabrication steps in VLSI are:

1.oxidation

2.photolithography and etching

3.diffussion and implantation

4.mettallization

1. oxidation

The oxidation process is one of the most important processes in VLSI fabrication. The

development of high quality silicon dioxide has helped to establish the dominance of

si in the production of commercial ICs. generally Sio2 functions as an insulator in a

number of device structures or as a barrier to diffussion or implantation during device

fabrication.

There are two types of Sio2 growth methods:

1. dry oxidation

2.wet oxidation

dry oxidation is generally used to form thin oxides in a device structures because of its

si-sio2 interface characteristics. It is implemented in processes such as the gate

dielectric growth, the quality of which is extremely important for the scaling and

performance of today's integrated circuit technology. An oxidation concentration

versus oxidation layer thickness figure is plotted almost instantaneously after the users

specify the necessary parameters and conditions. The slope of the curve depicts the

oxidation flux. The oxidation process is simulated after one click on the web interface,

while all the complicated details and equation-solving procedures are hidden behind

the scene. The interactive interface of the module and its simplicity of usage

demonstrates the module's educational value in that it helps students and engineers

build intuition into the oxidation process with minimum learning curve. Insightful

comparison, such as one between thin and thick oxide growth, can be done easily.

Moreover, the module can be used as a handy and efficient "oxidation flux

calculator".

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design Methodologies and ToolsDocument95 pagesDesign Methodologies and ToolsThomas JamesNo ratings yet

- FPGA-Based Feature DetectionDocument9 pagesFPGA-Based Feature DetectionThomas JamesNo ratings yet

- High Performance 8-Bit Display Interface AD9980: Features Functional Block DiagramDocument44 pagesHigh Performance 8-Bit Display Interface AD9980: Features Functional Block DiagramThomas JamesNo ratings yet

- Experiment 11: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 11: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- B - Tech - B - Arch Degree Exam November, December 2015 NTFNDocument2 pagesB - Tech - B - Arch Degree Exam November, December 2015 NTFNThomas JamesNo ratings yet

- DSP 2 LowpassfilterDocument20 pagesDSP 2 LowpassfilterDr-Atul Kumar DwivediNo ratings yet

- Experiment 13: Aim: Eda Tool Used: MethodologyDocument2 pagesExperiment 13: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 5: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 5: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 12: Aim: Eda Tool Used: MethodologyDocument2 pagesExperiment 12: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Program 9Document4 pagesProgram 9Thomas JamesNo ratings yet

- Experiment 13: Aim: Eda Tool Used: MethodologyDocument2 pagesExperiment 13: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Digital Signal Processing Lab (EC2156) : Thomas James Thomas REG NO: 2014TMPGI01 M.Tech (Digital Systems)Document4 pagesDigital Signal Processing Lab (EC2156) : Thomas James Thomas REG NO: 2014TMPGI01 M.Tech (Digital Systems)Thomas JamesNo ratings yet

- Experiment 5: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 5: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 6: Aim: Eda Tool Used: MethodologyDocument4 pagesExperiment 6: Aim: Eda Tool Used: MethodologyThomas JamesNo ratings yet

- Experiment 2 (B) : Aim: To Write A MATLAB Program To Receive An Input Sequence From The User and ToDocument4 pagesExperiment 2 (B) : Aim: To Write A MATLAB Program To Receive An Input Sequence From The User and ToThomas JamesNo ratings yet

- Program 15Document4 pagesProgram 15Thomas JamesNo ratings yet

- Digital Signal Processing LabDocument4 pagesDigital Signal Processing LabThomas JamesNo ratings yet

- Program 15Document4 pagesProgram 15Thomas JamesNo ratings yet

- Program 14Document3 pagesProgram 14Thomas JamesNo ratings yet