Professional Documents

Culture Documents

Outside Stairs

Outside Stairs

Uploaded by

Lory Dena HeathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Outside Stairs

Outside Stairs

Uploaded by

Lory Dena HeathCopyright:

Available Formats

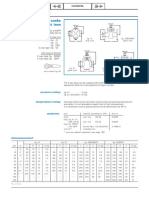

FIG.

1 - How a stairway is

built depends primarily on

the total risethe vertical

dimension from the upper

floor to the lower floor. The

total runthe horizontal

length of the stair assembly

depends on the slope of the

stairway, which is

determined by building

codes. From the Sunset

book, Basic Carpentry

Illustrated, Sunset

Publishing Corporation.

FIG. 2 - The components of a

stairway, with basic stair-

building terms. From the

Sunset book, Decks,

Sunset Publishing

Corporation

FIG. 3 - The components of a

railing. From the Sunset

book, Decks, Sunset

Publishing Corporation

STAIR-BUILDING TERMS

There are five basic design elements you'll

need to consider when planning outdoor

stairs:

The Total Run (Fig. 1) is the total

horizontal distance covered by the staircase,

from the edge of the upper floor (porch or

deck) to the edge of the staircase where it

rests on the landing.

The Total Rise (Fig. 1) is the total vertical

distance from the surface of the landing to a

point level with the surface of the upper

floor (Note: You can't find the rise simply by

measuring straight down from the upper

floor because the ground directly below may

not be level with the landing).

Run (Fig. 2) is the horizontal distance from

the leading edge of one tread to the leading

edge of the next tread.

Rise (Fig. 2) is the vertical distance from

the surface of one tread to the surface of the

next tread.

Passage Width (Fig. 2) is the width of the

stairway.

The ratio of the total rise to total run (or rise

to run) determines the slope of the stairway.

As a rule, that slope should be between 30

degrees and 35 degrees; an outdoor

stairway may be slightly shallower but

should not be steeper. The ideal riser height

is 7" with an 11" runwhich also works out

well with standard lumber widthsbut you

may have to vary the proportions somewhat

to make the height of each step work out

evenly between the landing and the upper

floor.

The passage width can also vary, depending

on how heavily you expect the stairs to be

used. As a rule, 36" is the minimum; 48" is

better for a single person, and you may

want to go to 60" to allow room for two

people to pass comfortably.

A stairway consists of four basic

components:

Stringers (Fig. 2) are the sloped members

that support the stairway. 2x10s are

generally allowed for stairs with four treads

or fewer, but 2x12s are sturdier.

In most cases, you'll need good quality

material with no large knots, either pressure

treated or cut from heart redwood or cedar,

to resist decay. Stringers should be placed

no more than 24" apart if the treads will be

5/4 material or 36" apart for 2"-thick

lumber.

Treads (Fig. 2) are the horizontal members

that you walk on. When building an outdoor

stairway, they are typically cut from the

same material as the upper floor deck or

porch5/4" pressure-treated pine or 2"-thick

lumber.

Risers (Fig. 2) are the vertical members at

the back of each tread. 1" surfaced boards

(3/4" net thickness) are the most common

material used.

The Railing Assembly (Fig. 3) consists of

posts, a cap rail and vertical balusters

between each post. 4x4 is the most common

post material with a 2x4 handrail. Codes

regulate the overall height of the railing

assembly (usually 30" to 34") and may

specify a maximum width for the handrail.

DESIGNING YOURS STAIRS

To design the stairway, first find the total

rise. Divide that number by 7 (the ideal riser

height) to find the number of steps. You'll

probably have a fractional remainder, so

round your result up or down to the nearest

whole number.

Then divide the total rise by that number to

find the exact height of each riser. For

example:

FIG. 4 - Common tread-to-

riser ratios. From the Sunset

book, Decks, Sunset

Publishing Corporation.

1) Total rise = 40-1/2"

2) 40-1/2" divided by 7" per riser = 5.78

risers

3) Round 5.78 up to 6 risers, then 40-1/2"

divided by 6 = 6.75" or 6-3/4" per riser

This document assumes that the total run is

not limited, so you can make the assembly

as long as you want. Use the following table

to determine the width of the treads,

depending on your riser height.

Riser Height Run Width

6" 14"

6-1/4" 13-1/2"

6-1/2" 13"

6-3/4" 12-1/2"

7" 12"

7-1/4" 11-1/2"

7-1/2" 11"

To find the amount of material needed for

risers, simply multiply the number of risers

by the passage width. To find the amount of

tread material, subtract 1 from the number

of risers (you'll need one fewer tread than

risers) and multiply by the passage width.

Remember to double up if you'll be using

two boards for each tread.

To find the length of the stringers, you'll

need a calculator with a square root

function. First, find the total run (number of

treads multiplied by the width of each

tread).

Then find the square of the total run (total

run multiplied by itself) and the square of

the total rise and add them together.

The square root of the result gives you the

exact stringer length; round up to the

nearest standard lumber length, then

multiply by the number of stringers you'll

need.

FIG. 6 - Stringers may be

hung from the rim joist

with a joist hanger so the

first step is flush with the

deck surface. In this

configuration, a piece of

pressure-treated lumber is

bolted to the landing pad

and the stringer is nailed

to it with 16d galvanized

nails. From the Sunset

book, Decks, Sunset

Publishing Corporation.

FIG. 7 - The stringer can

be bolted to the end of the

joist so the first step is

one step below the surface

of the deck. At the landing

pad, the stringer may be

fastened to an angle iron

(the angle should be

galvanized) bolted to the

concrete. From the Sunset

book, Decks, Sunset

Publishing Corporation.

BUILDING YOUR STAIRS

To build the staircase, first notch the stringers

for the treads and risers. Fasten two stair

gauges to a carpenter's square at the

dimensions of the rise and run (for example, at

6-1/2" on one leg and 13" on the other). Set

the square on the stringer so the gauges are

flush against the edge and trace the notch

along the edge of the square (Fig. 5).

FIG. 5 - Set the carpenter's square on the

stringer so the riser and tread dimensions are

at the edge, then trace along the square. Move

the square to the previous mark and repeat

the process. Subtract one tread thickness from

the layout at the bottom so the last step is

equal in height to the rest. From the Sunset

book, Decks, Sunset Publishing Corporation.

"Step" your way down the stringer, repeating

the process until you have laid out the correct

number of notches. Use the carpenter's square

to lay out the top cut on the stringer. The

height of the last riser should be less than the

others by an amount equal to the thickness of

the tread. That way, when you nail the last

tread in place, the step down to the lower floor

will be equal to the others.

You can set the stringer directly on the lower

floor (typically a landing pad) and bolt it in

place with a piece of angle iron, or bolt a

length of pressure-treated 2x6 to the floor and

nail the stringer to it.

If you plan to set the stringer on a 2x6, you

may have to notch the bottom of the stringer

to allow for that piece.

Once the stringer is laid out, cut the notches

partway only, using a circular saw. Take care

not to cut beyond the layout lines. Finish the

cuts with a handsaw.

Once you have one stringer finished, set it in

place to make sure it is cut correctly, then use

it as a template to lay out your cuts on the

other stringers.

You can hang the stringers to the rim joist with

joist hangers (Fig. 6), or bolt them in place to

a joist (Fig. 7). If you need to pour a concrete

landing pad at the bottom of the stairway, set

the stringers in place temporarily and lay out

the location of the pad. Pour the pad and set

anchor bolts for the angle iron or 2x6 base.

Instructions for pouring concrete are in

another brochure in this series.

Once the landing pad is cured, secure the

stringers at the top and bottom. Rip the risers

to the same width as the height of the riser cut

in the stringers. Then cut them to length and

nail them to the stringers with 8d galvanized

nails.

Measure the distance from the face of the riser

to the edge of the notch cut, then rip the

treads to width so they extend 1" to 1-1/8"

beyond the edge of the notch. If you're using

two boards side by side as treads, rip half the

dimension from each board so both will be the

same width. Cut the treads to length and nail

them to the stringer with 16d galvanized nails.

To build the railing, first secure 4x4 posts at

the top and bottom of the stringer. Notch the

posts 1-1/2" deep and bolt them to the sides

of the stringers with 1/2x4-1/2 hex bolts,

using a level to keep them plumb. Use d

resistant lumber for the posts. They should be

at least long enough to extend 36" above the

surface of the treads. Leave them a few inches

too long at the top so you can cut them after

they are in place.

ecay-

Measure from the bottom of the stringer up the

posts to the location of the top and bottom

rails. The top surface of the upper rail should

be 30" to 34" above the tread; the rail should

be about 6" above the tread. Lay the railing

material against the posts and lay out angled

cuts for any rails that will be fastened between

the posts.

Cut the railings to length and toenail them with

four 8d galvanized nails. If you'll be using

balusters, cut them to length and nail them to

the rails. Check local codes for spacing

requirements on balusters.

TOOL AND MATERIAL CHECKLIST

2x10 Stringers

1x8 Risers

5/4" or 2" Tread

Material

2x6 Pressure-Treated

Cleat

Angle Iron Anchor Bolts

Hex Bolts 16d Galvanized Nails

8d Galvanized Nails 4x4 Posts

2" Railing Material Baluster Material

Hammer Carpenter's Square

Measuring Tape Adjustable Wrench

Joist Hangers

Check your state and local codes before starting any project. Follow all safety

precautions. Information in this document has been furnished by the National

Retail Hardware Association (NRHA) and associated contributors. Every effort has

been made to ensure accuracy and safety. Neither NRHA, any contributor nor the

retailer can be held responsible for damages or injuries resulting from the use of

the information in this document.

You might also like

- Dokumen - Tips - Outdoor Woodworking PlansDocument5 pagesDokumen - Tips - Outdoor Woodworking Plansypy.dnm6No ratings yet

- A3CF - WB - 213 - 01Document39 pagesA3CF - WB - 213 - 01Ricardo Cruz100% (2)

- Pallet Wood WorkbenchesDocument10 pagesPallet Wood WorkbenchesRicardo Fernandes GalliNo ratings yet

- Self-Install: User ManualDocument20 pagesSelf-Install: User Manual15101980No ratings yet

- 00 Folding Picnic Table DIY Out of 2x4 LumberDocument48 pages00 Folding Picnic Table DIY Out of 2x4 Lumberbf100% (2)

- Fin Jig InstructionsDocument4 pagesFin Jig InstructionsJohn AndersonNo ratings yet

- Housed-Stringer Exterior StairsDocument7 pagesHoused-Stringer Exterior StairsLen S100% (3)

- Stairs InfoDocument60 pagesStairs Infoshamrin62No ratings yet

- Deck Construction GuideDocument39 pagesDeck Construction GuideJoão Paulo FerreiraNo ratings yet

- DIY 3D Printed Dremel CNC PDFDocument38 pagesDIY 3D Printed Dremel CNC PDFStephen OHaraNo ratings yet

- DIY Tutorial Pallet Teenager Cabin 1001palletsDocument10 pagesDIY Tutorial Pallet Teenager Cabin 1001palletscristian fulgencioNo ratings yet

- Basic Scribing TechniquesDocument6 pagesBasic Scribing TechniquesLen S100% (1)

- DITRA Installation HandbookDocument32 pagesDITRA Installation HandbookJoannaPappasNo ratings yet

- Using An Airless Paint Sprayer - tcm96-1128824Document6 pagesUsing An Airless Paint Sprayer - tcm96-1128824ravi00098No ratings yet

- Winter 2019 Cordless CatalogDocument47 pagesWinter 2019 Cordless CatalogDownloaderNo ratings yet

- Operator'S Manual: 5-1/2 In. 18 Volt Circular Saw P501Document40 pagesOperator'S Manual: 5-1/2 In. 18 Volt Circular Saw P501jahemscbdNo ratings yet

- Sliding Barn Door Media Center: AdvancedDocument36 pagesSliding Barn Door Media Center: AdvancedMaricruz Valdivieso de PalaciosNo ratings yet

- How To Build A Barristers BookcaseDocument5 pagesHow To Build A Barristers BookcaseAnonymous QJ5j94luLmNo ratings yet

- American Lock Service ManualDocument36 pagesAmerican Lock Service ManualMaxwell SmartNo ratings yet

- Refinishing Guide 2013 PDFDocument16 pagesRefinishing Guide 2013 PDFCarlos LimaNo ratings yet

- House Plans For Joshs HouseDocument6 pagesHouse Plans For Joshs HouseDiego DiazNo ratings yet

- Popular Mechanics Simple Shed SimpleDocument2 pagesPopular Mechanics Simple Shed Simpletimgarvey00100% (2)

- 2012 Logosol CatalogDocument60 pages2012 Logosol Catalogbogdanb1No ratings yet

- Reclaimed Pallet Wood Herringbone Outdoor Bench: InstructablesDocument19 pagesReclaimed Pallet Wood Herringbone Outdoor Bench: InstructablesMarin TurkovićNo ratings yet

- Pyrography: CharacteristicsDocument4 pagesPyrography: CharacteristicsJack SageNo ratings yet

- CRIMSON TRACE-Catalog - LSC PDFDocument27 pagesCRIMSON TRACE-Catalog - LSC PDFTacticas de Seguridad100% (1)

- Youngsters T Bucket Frame Plans V1 0Document24 pagesYoungsters T Bucket Frame Plans V1 0weirdbennyNo ratings yet

- Led LightingDocument10 pagesLed LightingDurai Raj Kumar100% (1)

- FREE 10x20 Shed PlanDocument9 pagesFREE 10x20 Shed PlanrimshaNo ratings yet

- Floating Shelf Drawer: An Out of The Woodwork Project PlanDocument23 pagesFloating Shelf Drawer: An Out of The Woodwork Project Planthanush_thampanNo ratings yet

- Recommended Standards For The Installation of Woodburning StovesDocument13 pagesRecommended Standards For The Installation of Woodburning StovesJohnny LibitzNo ratings yet

- Arborist Letter FormatDocument3 pagesArborist Letter FormatAndrew Stillman100% (1)

- Plan 1Document24 pagesPlan 1ParZiVal100% (1)

- Shimano Hub Type Maintenance-Manual PDFDocument5 pagesShimano Hub Type Maintenance-Manual PDFArmandSorianoNo ratings yet

- Delta Model 31-080 1" Belt Sander ManualDocument12 pagesDelta Model 31-080 1" Belt Sander ManualRobert Steven Ciaccio0% (1)

- Nitto Kohki Power Tools PDFDocument28 pagesNitto Kohki Power Tools PDFAnonymous E8YIWa4i6yNo ratings yet

- Circular Saw BenchesDocument86 pagesCircular Saw BenchesRJagatdeep Singh Rana0% (2)

- Make BiodieselDocument15 pagesMake BiodieselKhasvin100% (1)

- The Perfect LawnDocument2 pagesThe Perfect LawnDave CocciaNo ratings yet

- Rainwater Goods 18-09-2008Document22 pagesRainwater Goods 18-09-2008Sha Mas ShaNo ratings yet

- Craftsman Lathe 113.228162 Owners ManualDocument35 pagesCraftsman Lathe 113.228162 Owners ManualChrisNo ratings yet

- Express Police Supply Catalog #161Document89 pagesExpress Police Supply Catalog #161Robert RalphNo ratings yet

- Storage Shed Blueprints and DesignsDocument25 pagesStorage Shed Blueprints and Designsapi-236974610100% (1)

- Woodworking MachineryDocument511 pagesWoodworking MachineryCristiano RochaNo ratings yet

- Rust Repair Patches Made EasyDocument8 pagesRust Repair Patches Made EasyeduardowilkNo ratings yet

- Diyhuntress Igbc Desk PlansDocument23 pagesDiyhuntress Igbc Desk PlansEdwin Espinoza obandoNo ratings yet

- CNC in The Workshop Series Part 1Document13 pagesCNC in The Workshop Series Part 1ScotClockNo ratings yet

- Very Good TablesDocument44 pagesVery Good TablesMelendres BenitoNo ratings yet

- RouterTable Bob PlansDocument24 pagesRouterTable Bob Plansiacob_gilberto6473100% (2)

- Kerdi Shower HandbookDocument40 pagesKerdi Shower Handbookexothermal360No ratings yet

- Andrew Harris Woodwork Patio TableDocument16 pagesAndrew Harris Woodwork Patio TableYamil Paladino100% (1)

- DIY Concrete Dining Table Plans: Tools NeededDocument10 pagesDIY Concrete Dining Table Plans: Tools NeededLiban M XujaleNo ratings yet

- Wood Shed ConstructionDocument6 pagesWood Shed Constructionrfjm28rxgdNo ratings yet

- DIY Rustic X Bench With ShelfDocument8 pagesDIY Rustic X Bench With ShelfJoe RowingNo ratings yet

- By Guido Henn: (Translation by Brian Anderson)Document102 pagesBy Guido Henn: (Translation by Brian Anderson)jose cuauhtemoc mendoza torresNo ratings yet

- Workshop Pull Out StorageDocument7 pagesWorkshop Pull Out StorageDominguitoNo ratings yet

- Wooden Bench-Vise 6 InchDocument12 pagesWooden Bench-Vise 6 InchKates SimaduNo ratings yet

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Chest of Drawers 2Document6 pagesChest of Drawers 2khunchaiyai100% (3)

- Children's Bunkhouse LoftDocument7 pagesChildren's Bunkhouse Loft- yAy3e -100% (3)

- Crotch-Grained Chess Table: Walnut, PoplarDocument5 pagesCrotch-Grained Chess Table: Walnut, Poplarkhunchaiyai100% (2)

- Cherry End TableDocument5 pagesCherry End TablekhunchaiyaiNo ratings yet

- Carved Fruit BowlDocument5 pagesCarved Fruit Bowlkhunchaiyai100% (1)

- Chairside BookcaseDocument3 pagesChairside Bookcasekhunchaiyai100% (2)

- Candle BoxDocument4 pagesCandle Box- yAy3e -No ratings yet

- Bunk BedsDocument5 pagesBunk Bedskhunchaiyai100% (4)

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- Classic Bow SawDocument6 pagesClassic Bow Saw- yAy3e -No ratings yet

- Bread BoxDocument3 pagesBread Box- yAy3e -No ratings yet

- Book Case 2Document5 pagesBook Case 2khunchaiyai100% (1)

- Adjustable Plant ShelvesDocument3 pagesAdjustable Plant Shelves- yAy3e -No ratings yet

- Risk Assesment 1Document1 pageRisk Assesment 1Leon MonsalveNo ratings yet

- W201 Wiring Diagram PDFDocument290 pagesW201 Wiring Diagram PDFNadeem Mohd100% (2)

- PABCO Gypsum 2014 Product CatalogDocument60 pagesPABCO Gypsum 2014 Product CatalogabudabeejajaNo ratings yet

- Free Floating Lever Dual Gravity Drain TrapsDocument2 pagesFree Floating Lever Dual Gravity Drain Trapsandy131078No ratings yet

- Energy Conversion, SyllabusDocument2 pagesEnergy Conversion, SyllabusNathan Lee Marcos Binay-anNo ratings yet

- Problem 14Document3 pagesProblem 14monsinNo ratings yet

- F-MB-02-04 Kartu Service Diesel GeneratorDocument12 pagesF-MB-02-04 Kartu Service Diesel GeneratorDannyNo ratings yet

- Hih 4000 - Sensor de Humedad PDFDocument8 pagesHih 4000 - Sensor de Humedad PDFElias ChavezNo ratings yet

- Soal Bahasa Inggris MaritimDocument2 pagesSoal Bahasa Inggris Maritimmal tazar100% (1)

- S16 16 Updates AMDocument141 pagesS16 16 Updates AMMG Xie0% (1)

- Prof. Vijay Kumar Jain Mechanical Engineering Department Indian Institute of Technology Kanpur KANPUR-208016 (India)Document35 pagesProf. Vijay Kumar Jain Mechanical Engineering Department Indian Institute of Technology Kanpur KANPUR-208016 (India)Kartik ModiNo ratings yet

- Gear Pump ParkerDocument28 pagesGear Pump Parkerorlandolanchipa100% (1)

- Schedule 1819Document14 pagesSchedule 1819Jayamani KrishnanNo ratings yet

- T.Cook 6.17 ResumeDocument1 pageT.Cook 6.17 ResumeTyler Ann CookNo ratings yet

- Properties of AlluminiumDocument3 pagesProperties of Alluminiumtapan456No ratings yet

- North Eastern Electric Power Corporation LTD.: Notice Inviting Bid (E-Tender)Document1 pageNorth Eastern Electric Power Corporation LTD.: Notice Inviting Bid (E-Tender)Pransankar MajumdarNo ratings yet

- Maytag MSD2757AEW Refrigerator Owners ManualDocument24 pagesMaytag MSD2757AEW Refrigerator Owners Manualpaulfin1No ratings yet

- InverterDocument23 pagesInverterBittu Kumar SinhaNo ratings yet

- Sa 476Document6 pagesSa 476Widya widyaNo ratings yet

- Drilling and BlastingDocument5 pagesDrilling and BlastingPramodNo ratings yet

- Senior SAP MM PP-PI MES PMX/PASX PharmaDocument4 pagesSenior SAP MM PP-PI MES PMX/PASX Pharmaapi-79114108No ratings yet

- Asnt CatalogDocument51 pagesAsnt CatalogMohamed100% (1)

- Unit12chipcarving PDFDocument22 pagesUnit12chipcarving PDFMartinNo ratings yet

- (2011/5) Table 1 Value of Exports and Imports by Area andDocument8 pages(2011/5) Table 1 Value of Exports and Imports by Area andJosé Santos Cartes PalaciosNo ratings yet

- Hot, Arid and Semi-Arid Climate: Presented ByDocument36 pagesHot, Arid and Semi-Arid Climate: Presented ByMandeep DalalNo ratings yet

- Unit I CAD CAMDocument19 pagesUnit I CAD CAMpraveenNo ratings yet

- High-Precision Chilled Mirror HygrometerDocument4 pagesHigh-Precision Chilled Mirror HygrometerAldrin HernandezNo ratings yet

- Hotline TechniqueDocument20 pagesHotline Techniquesaravan1891No ratings yet

- Econ Gland and Plug Cocks Cast Iron: Valves & FittingsDocument1 pageEcon Gland and Plug Cocks Cast Iron: Valves & FittingsChristianGuerreroNo ratings yet