Professional Documents

Culture Documents

LG Catlog

LG Catlog

Uploaded by

raghuragooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LG Catlog

LG Catlog

Uploaded by

raghuragooCopyright:

Available Formats

LG AIR CONDITIONING

We always pursue highly advanced technologies to improve the quality of your life.

Enjoy a clean, quiet & comfortable life with LG Air Conditioners.

w

w

w

.

l

g

e

a

i

r

c

o

n

.

c

o

m

LG Electronics Air Conditioning Marketing

20 Yeouido-dong, Yeongdeungpo-gu, Seoul 150-721, Korea

Phone: 82-2-3777-1114 E-Mail : kambo@lge.com

http://www.lge.com

F

o

r

c

o

n

t

i

n

u

a

l

p

r

o

d

u

c

t

d

e

v

e

l

o

p

m

e

n

t

,

L

G

r

e

s

e

r

v

e

s

t

h

e

r

i

g

h

t

t

o

c

h

a

n

g

e

s

p

e

c

i

f

i

c

a

t

i

o

n

s

w

i

t

h

o

u

t

n

o

t

i

c

e

.

L

G

E

l

e

c

t

r

o

n

i

c

s

I

n

c

.

P

r

i

n

t

e

d

i

n

K

o

r

e

a

2

0

0

9

ME-CA091

Contents

LG Electronics,

The Worlds Best Seller

06

Single Packaged Type

14

Ducted Split Type

20

Fan Coil Unit

24

MULTI M & M DX

36

Ceiling Concealed Duct

Type

Models Line up

The Worlds Number 1 Choice in Air Conditioners!

Single Packaged Type Ducted Split Type

Btu/h

3~6tons 3~6tons 7.5~30tons 3~5tons 7.5~12.5tons 15~20tons

7,000 9,000 12,000 18,000 22,000 24,000 26,000 30,000 36,000 42,000 48,000 60,000 80,000 100,000 72,000 150,000

Ceiling Concealed Duct Type

Fan Coil Unit Type

* The exact appearance of products may vary from the images shown here.

Single Split Wall Mounted Type

Ceiling Cassette Type

Floor Standing Type

Ceiling and Floor Type

Ceiling Suspended Type

18,000 7,000 Btu/h 9,000 12,000 18,000 22,000 24,000 26,000 30,000 36,000 42,000 48,000 60,000 80,000 100,000 72,000 150,000

C

e

i

l

i

n

g

C

o

n

c

e

a

l

e

d

D

u

c

t

T

y

p

e

06

07

Ceiling Concealed Duct Type

LG AI R CONDI TI ONERS 2009

Ceiling Concealed Duct Type

Hidden in the ceiling, this model is designed for buildings that require floor

level air conditioning for many individual rooms or large areas, like

restaurants, concert halls and hotels. Installation is not restricted by lighting

fixtures or the building layout, and interior renovation is made easy by

installing ventilation diffusers.

The air volume and sound level is kept constant as designed

regardless of changes in E.S.P.(External Static Pressure)

E.S.P. technology

- Optimizes Duct Installation

- Keeps Capacity & Sound Levels within desired ranges

- Reduces the number of models

Phase control motor technology reduces installation costs. The

desired air flow is obtained by adjusting the phase motor during

installation of the product, giving you more flexibility when

setting up your duct system. The E.S.P can be adjusted linearly

from 0 to 10mmAq.

*E.S.P: External Static Pressure

The i ntegrated PLASMA Ai r Puri fyi ng System removes

microscopic contaminants and dust, eliminates offensive odors

and prevents allergic reactions. It can also be used as an air-

purifying unit only, without running the air conditioner.

Evaluated by CSIRO Australia (DBCE Doc 98/204)

Tested by Korean Food Research Institute and Japanese Environmental

Centre and Yonsei Univ. College of Medicine. (Allergy Research Lab.)

PLASMA Air Purifying System (Accessory)

Respirable particles from 5 cigarettes in a sealed

room removed by the LG Plasma Air Purifying

System.

LG's Plasma Air Purifying unit effectively removes

high concentrations of tobacco odors (Confirmed

in sensory tests carried out in Korea and Japan.)

In clinical tests, the LG Plasma Air Purifying System

reached a satisfaction level of 82% .

Dust Reduction

Deodorization

Anti-Allergy

C

e

i

l

i

n

g

C

o

n

c

e

a

l

e

d

D

u

c

t

T

y

p

e

08

09

1) Basic Operation

- With a temperature sensor controlling every diffuser, the

temperature for each zone can be monitored and adjusted

automatically.

2) Control Features

- If every damper is closed, the compressor and outer fan are

turned off, to protect the compressor.

1) Basic Operation

- Linking several units, one Central Control Unit can manage

and turn off several units individually or as a group.

2) Control Features

- Each indoor unit is connected to a Central Control Unit via a

data communication cable and can be operated or turned off

individually or together with a group of units with the central

controller.

- The Central Control Unit can manage up to 8 * 16 indoor

units.

Ceiling Concealed Duct Type

LG AI R CONDI TI ONERS 2009

Zone Controller (Accessory)

- Eliminates waste of electricity in standby mode.

- Electricity is wasted when an appliance is connected to an

outlet, even though the appliance is turned off.

- Development of a super power-saving SMPS

(Swiching Mode Power Supply)

- Minimal standby power consumption

(90% reduction of standby power).

- No need to pull the main power plug when the appliance is not

in use.

Zero standby power consumption

Central Controller (Accessory)

LG Air Conditioners (Cassette and Duct-type models) can be

i nstalled at long di stances (max 50m) and hi gh hei ght

differences (30m) from the outdoor unit.

Plz refer to the picture below.

Ceiling Concealed Duct Type

LG AI R CONDI TI ONERS 2009

Long Distance Piping High Elevation

Need not control on each times at big diurnal range areas.

Auto Changeover

The dual thermistor control regulates the difference between

the indoor temperature and the temperature of the conditioned

air by monitoring both temperatures, to ensure a uniform room

temperature. The sensor readings are adjusted for optimum

room temperature.

Two Thermistor Control

If desired, you can set operation times for up to one week in

advance.

Timer-controlled Operation

The High Head Drain Pump pumps water up to 700mm high for

smooth drainage.

High Head Drain Pump (Accessory)

50m 30m

Heating

Dehumidifying

Cooling

Micro Processor

Analyze 3 Temperature

Measure Periodically

Target Temperature

Outdoor Temperature

Indoor Temperature

LCD Wired Remote Controller

24-Hour ON/ OFF Timer with 1 hour intervals

TEST RUN Mode

Self-Diagnosis feature

3-Step Fan Speed selection

Operation Indicator

Room Temperature Display

Only 20mm thick

Option

Wireless Remote controller

Pipe fixture

Flexible

Drain Hose

Drain pump

Wall

Drain pipe

700mm

Zone A

Zone C

Zone D

Zone B

On Off

1 2 3 4

5 6 7 8

9 10 11 12

13 14 15 16

1 2 16

Controller

#1

Controller

#2

On Off

1 2 3 4

5 6 7 8

9 10 11 12

13 14 15 16 Controller

#8

On Off

1 2 3 4

5 6 7 8

9 10 11 12

13 14 15 16

1 2 16

1) Basic Operation

- Linking several units, one Group Control Unit can manage a

number of indoor units.

2) Control Features

- Through a data cable connected to each indoor unit, a group

of units can be managed from the group controller.

- The Group Control function is enabled by cutting an optional

jump wire in the wired remote control, which prevents data

collision.

- One Group Control Unit can control up to 16 indoor units.

Ceiling Concealed Duct Type

LG AI R CONDI TI ONERS 2009

Group Control

LGs Outdoor Heat Exchanger is coated with a gold-colored

anti-corrosive epoxy treatment on the aluminum coil, to

prevent corrosion. This maintainsexcellent heat transfer

properties of the coil for an extended time, whereas non-Gold

Fin coils progressively lose efficiency due to surface

corrosion. Gold Fin fin is perfect for areas with high pollution

or locations exposed to saltwater spray from the sea.

Gold Fin Anti Corrosion

Long Distance, High Elevation Weekly Program Standby Power Zero Two Thermistor Control Group Control

Child Lock Function Auto Restart EZ Tuning Zone Control(Accessory) High Head Drain Pump(Accessory)

Wireless Remote Controller(Accessory) Gold Fin Anti Corrosion(Optional) PLASMA Air Purifying system(Accessory)

Central ControllerI(Accessory)

Features

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TB-H246HSS0

24,000

24,000

1, 220~240,50

2,700 / 2,700

12.0 / 12.0

8.89

2.61

18/16.5/14

2.7

37/35/33

55

6

3*2.5

5*0.75*220

880*260*450

870*800*320

35/60

44/85

6.35/15.88

LB-C246HSS1

24,000

-

1, 220~240,50

2,750 / -

12 / -

8.73

-

18/16.5/14

2.7

37/35/33

55

6

3*2.5

4*0.75*220

880*260*450

870*800*320

35/60

44/85

6.35/15.88

TB-H186HSS0

18,000

18,000

1, 220~240,50

2,020 / 2,020

9.5 / 9.5

8.91

2.90

16/14.5/13

1.5

36/34/32

55

6

3*2.5

5*0.75*220

880*260*450

870*655*320

35/55

52/107

6.35/15.88

LB-C186HSS1

18,000

-

1, 220~240,50

2,020 / -

9.5 / -

8.91

-

16/14.5/13

1.5

36/34/32

55

6

3*2.5

4*0.75*220

880*260*450

870*655*320

35/55

52/107

6.35/15.88

Ceiling Concealed Duct Type

LB-C186HSS1 TB-H186HSS0

LB-C246HSS1 TB-H246HSS0

10 11

2 16 ........

........

Gold Coated Aluminum Uncoated Aluminum

LG Gold Fin

Corrosion Free

Conventional

Starting to corrode

After 15 Days After 15 Days

Salt Spray Test for 15 Days

Long Distance, High Elevation Weekly Program Standby Power Zero Two Thermistor Control Group Control

Child Lock Function Auto Restart EZ Tuning Zone Control(Accessory) High Head Drain Pump(Accessory)

Wireless Remote Controller(Accessory) Gold Fin Anti Corrosion(Optional) PLASMA Air Purifying system(Accessory)

Central ControllerI(Accessory)

Features

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TB-H366GSS0

36,000

36,000

1, 220~240,50

4,100 / 4,100

18.8 / 18.8

8.78

2.57

32/29/26.5

3.5

43/42/40

58

8

3*5.5

5*0.75*220

1,180x298x450

870x1,038x320

38/78

30/63

6.35/15.88

LB-C366GSS1

36,000

-

1, 220~240,50

4,100 / -

18.8 / -

8.78

-

32/29/26.5

3.5

43/42/40

58

8

3*5.5

4*0.75*220

1,180x298x450

870x800x320

38/70

31/69

9.52/15.88

TB-H306GSS0

30,000

30,000

1, 220~240,50

3,400 / 3,400

15 / 15

8.82

2.59

28/26/24

3

43/42/40

56

8

3*3.5

5*0.75*220

1,180x298x450

870x800x320

38/65

31/69

6.35/15.88

LB-C306GSS1

30,000

-

1, 220~240,50

3,600 / -

17.0 / -

8.33

-

28/26/24

3

43/42/40

56

8

3*3.5

4*0.75*220

1,180x298x450

870x800x320

38/65

31/69

6.35/15.88

Long Distance, High Elevation Weekly Program Standby Power Zero Two Thermistor Control Group Control

Child Lock Function Auto Restart EZ Tuning Zone Control(Accessory) High Head Drain Pump(Accessory)

Wireless Remote Controller(Accessory) Gold Fin Anti Corrosion(Optional) PLASMA Air Purifying system(Accessory)

Central ControllerI(Accessory)

Features

12 13

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TB-H428GSS0

42,000

42,000

3, 380~415, 50

5,100 / 5,400

8 / 8.5

8.24

2.41

32/29/26.5

4.5

43/42/40

59

8

5*2.5

5*0.75*220

1,180x298x450

900x1,165x370

38/95

27/55

9.52/19.05

LB-C428GSS1

42,000

-

3, 380~415, 50

5,000 / -

7.8 / -

8.40

-

32/29/26.5

4.5

43/42/40

59

8

5*2.5

4*0.75*220

1,180x298x450

870x1,038x320

38/78

30/63

9.52/19.05

TB-H368GSS0

36,000

36,000

3, 380~415, 50

4,100 / 4,100

6.3 / 6.3

8.78

2.57

32/29/26.5

3.5

43/42/40

58

8

5*2.5

5*0.75*220

1,180x298x450

870x1,038x320

38/78

30/63

6.35/15.88

LB-C368GSS1

36,000

-

3, 380~415, 50

4,100 / -

6.3 / -

8.78

-

32/29/26.5

3.5

43/42/40

58

8

5*2.5

4*0.75*220

1,180x298x450

870x1,038x320

38/78

30/63

6.35/15.88

Ceiling Concealed Duct Type

LB-C306GSS1 TB-H306GSS0

LB-C366GSS1 TB-H366GSS0

Ceiling Concealed Duct Type

LB-C368GSS1 TB-H368GSS0

LB-C428GSS1 TB-H428GSS0

Long Distance, High Elevation Weekly Program Standby Power Zero Two Thermistor Control Group Control

Child Lock Function Auto Restart EZ Tuning Zone Control(Accessory) High Head Drain Pump(Accessory)

Wireless Remote Controller(Accessory) Gold Fin Anti Corrosion(Optional) PLASMA Air Purifying system(Accessory)

Central ControllerI(Accessory)

Features

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TB-H608RSS0

56,000

58,000

3, 380~415, 50

6,800 / 6,250

10.5 / 9.8

8.24

2.72

50/45/40

5.5

49/47/45

60

10

5*3.5

5*1.25*220

1,230x380x590

900x1,165x370

52/105

24/48

12.7/19.05

LB-C608RSS1

56,000

-

3, 380~415, 50

6,800 / -

10.5 / -

8.24

-

50/45/40

5.5

49/47/45

60

10

5*3.5

4*1.25*220

1,230x380x590

900x1,165x370

52/105

24/48

12.7/19.05

TB-H488RSS0

48,000

48,000

3, 380~415, 50

5,600 / 5,000

8.7 / 7.7

8.57

2.81

40/35/30

5

46/44/42

59

10

5*3.5

5*1.25*220

1,230x380x590

900x1,165x370

52/95

24/48

9.52/19.05

LB-C488RSS1

48,000

-

3, 380~415, 50

5,750 / -

9 / -

8.35

-

40/35/30

5

46/44/42

59

10

5*3.5

4*1.25*220

1,230x380x590

900x1,165x370

52/95

24/48

9.52/19.05

Long Distance, High Elevation Weekly Program Standby Power Zero Two Thermistor Control Group Control

Child Lock Function Auto Restart EZ Tuning Zone Control(Accessory) High Head Drain Pump(Accessory)

Wireless Remote Controller(Accessory) Gold Fin Anti Corrosion(Optional) PLASMA Air Purifying system(Accessory)

Central ControllerI(Accessory)

Features

14 15

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

LB-C246HSA4

24,000

-

1, 220~240, 50

2,880 / -

13 / -

8.6

-

18/16.5/14

2.50

37/35/33

57

6

3*3.5

4*0.75

880x260x450

870x655x320

35/55

52/106

6.35/15.88

LB-C186HSA4

18,000

-

1, 220~240, 50

2,000 / -

9.2 / -

9.0

-

16/14.5/13

2.0

36/34/32

55

6

3*3.5

4*0.75

880x260x450

801x555x262

35/50

63/134

6.35/15.88

Ceiling Concealed Duct Type

LB-C488RSS1 TB-H488RSS0

LB-C608RSS1 TB-H608RSS0

Ceiling Concealed Duct Type

LB-C186HSA4 LB-C246HSA4

Long Distance, High Elevation Weekly Program Standby Power Zero Two Thermistor Control Group Control

Child Lock Function Auto Restart EZ Tuning Zone Control(Accessory) High Head Drain Pump(Accessory)

Wireless Remote Controller(Accessory) Gold Fin Anti Corrosion(Optional) PLASMA Air Purifying system(Accessory)

Central ControllerI(Accessory)

Features

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

LB-C428GSA0

42,000

-

3, 380~415, 50

5,000 / -

7.8 / -

8.4

-

32/29/26

4.5

42/40/38

60

8

4*2.5

4*0.25

1,180x298x450

870x1,038x320

38/78

34/73

9.52/15.88

LB-C366GSA0

36,000

-

1, 220~240, 50

4,500 / -

20.0 / -

8

-

32/29/26

3.50

42/40//38

59

8

3*5.5

4*0.75

1,180x298x450

870x800x320

38/70

34/73

9.52/15.88

LB-C306GSA0

30,000

-

1, 220~240, 50

3,500 / -

16.0 / -

8.6

-

28/26/24

3.00

42/40/38

60

8

3*3.5

4*0.75

1,180x298x450

870x800x320

38/60

34/73

6.35/15.88

Gold Fin Anti Corrosion et CoolTM Auto Cleaning Auto Restart Natural Wind By CHAOS Swing

Wireless Remote Controller Quiet Operation Sleep Mode Auto Operation One-Touch Air Filter(Anti-Bacteria)

Healthy Dehumidification 24-Hour ON/OFF Setting Timer

Features

16 17

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

Power Input Cooling / Heating W

Running Current Cooling / Heating A

Performance

EER Cooling Btu/hr.W

COP Heating W/W

Air Circulation Indoor(H/M/L) CMM

Moisture Removal l /hr

Noise Level Indoor(H/M/L) dB(A)3

Outdoor Max dB(A)3

External Static Pressure mmAq

Cable Main No.*(mm2)*Max L.(m)

Conneting No.*(mm2)*Max L.(m)

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD) Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40ft

Service Valve Liquid/Gas (mm)

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

LB-C608RSA0

60,000

-

3, 380~415, 50

6,500 / -

10.2 / -

9.2

-

50/45/40

5.50

46/44/42

61

10

4*3.5

4*1.25

1,230x380x590

900x1,165x370

52/105

24/49

12.7/19.05

LB-C488RSA0

48,000

-

3, 380~415, 50

5,100 / -

8.0 / -

9.4

-

40/35/30

5.00

44/42/40

62

10

4*3.5

4*1.25

1,230x380x590

900x1,165x370

52/95

24/49

9.52/15.88

Ceiling Concealed Duct Type

LB-C306GSA0 LB-C366GSA0

LB-C428GSA0

Ceiling Concealed Duct Type

LB-C488RSA0 LB-C608RSA0

S

i

n

g

l

e

P

a

c

k

a

g

e

d

T

y

p

e

18

19

Single Packaged Type

LG AI R CONDI TI ONERS 2009

Single Packaged Type

Economical and user-friendly model, designed for medium-sized houses

and shops. Features include a number of operation modes, auto restart and

a washable anti-bacterial filter.

The unit can be installed outdoors to save valuable indoor

space, or in locations where no ceiling space is available.

Ground or roof installation options provide total flexibility

according to your requirements.

Easy Installation

The all-in-one design, with all access panels located on one

side of the unit and color-coded wiring, greatly facilitates

maintenance and service.

Easy Maintenance & Service

All units are designed for reverse-cycle operation, which means

electric heating functions can be added by specialized dealers.

This model also allows complete control over fresh air intake,

ratio of air purification, as well as monitoring and automatic

zone control (additional features available from specialized

dealers), through the powerful LG control system.

Additional functions available with duct

system

Selecting an air conditioner with the right capacity is very

important. A unit that is too small or too big will not only affect

your comfort, but may also unnecessarily increase your initial

purchasing cost and operational expenses. The LG cooling load

calculation program helps you choose the right system for your

specific needs.

LGs Cooling Load Calculation Program

A duct system allows you to freely control air-circulation.

Free & Easy Air-Circulation

Roof Jack Installation

Roof C urb Installation

Slab-on-G round Installation

Typical Installation

Compact & Lightweight Design U-shape Air Flow Safety Condenser Fin Guard Forklift Base rail Easy access Panel

Time Delay Relay is Standard Component Low Pressure Switch is Standard Component Durable Painted Steel Cabinet

Scroll Compressor with internal high-pressure & Over-current Protector Factory Charged Refrigerant

Direct-drive multi-speed PSC Blower Motor Direct-drive PSC Condenser Fan Motor Phase reversal Protection

Features

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions (WxHxD) mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TK-C0608HA0

59,900

-

3, 380~415,50

21.6

6,400

56.7

8.0

1,111x824x734

140

30/64/96

TK-C0488HA0

48,400

-

3, 380~415,50

17

4,900

45.3

7.9

1,111x824x734

120

30/64/96

TK-C0368HA0

35,700

-

3, 380~415,50

13.2

4,000

34

7.7

1,111x824x734

110

30/64/96

Wired LCD Remote Controller Easy Installation Auto Restart Low Noise Level

Easy Maintenance & Service Additional Functions Available with Duct System

Features

20 21

Model

Capacity

Cooling Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions (WxHxD) mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TK-C0908H00

96,000

-

3, 380~415,50

24.7

9,500

81.3

8.5

1,784x1,147x1,202

310

8/18/18

TK-C0728H00

72,000

-

3, 380~415,50

22.8

8,600

73.1

7.6

1,784x1,147x1,202

260

8/18/18

Single Packaged Type

TK-C0368HA0 TK-C0488HA0

TK-C0608HA0

Single Packaged Type

TK-C0728H00 TK-C0908H00

* Theexact appearanceof productsmay vary fromtheimagesshown here. * Theexact appearanceof productsmay vary fromtheimagesshown here.

Washable Anti-bacteria Filter Wired LCD Remote Controller Easy Installation

Oversized moter (Accessory) Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System Auto Restart

Features

Model

Capacity

Cooling (Gross) Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions (WxHxD) mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TK-C1508H00

129,600

-

3, 380~415,50

33

15,600

155

8.6

2,110x1,250x1,280

400

4/9/18

TK-C1208H00

112,600

-

3, 380~415,50

24.9

13,500

104

8.5

2,110x1,250x1,280

400

4/9/18

Washable Anti-bacteria Filter Wired LCD Remote Controller Easy Installation

Oversized moter (Accessory) Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System Auto Restart

Features

22 23

Model

Capacity

Cooling (Gross) Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions (WxHxD) mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

GK-C3608H00

360,000

-

3, 380~415,50

86.4

33,000

311

10

2,688x1,720x2,220

1,070

2/4/4

GK-C1808C00

175,000

-

3, 380~415,50

52.7

18,000

165

9.2

2,230x1,244x1,540

550

3/7/14

GK-C2108C00

197,000

-

3, 380~415,50

57

20,500

198

9.2

2,230x1,244x1,540

600

3/7/14

GK-C2408C00

238,900

-

3, 380~415,50

68.4

25,000

226

9.2

2,893x1,250x2,200

870

1/4/8

GK-C3008C00

280,400

-

3, 380~415,50

80.1

28,500

280.0283

9.2

2,893x1,250x2,200

870

1/4/8

Single Packaged Type

TK-C1208H00 TK-C1508H00

Single Packaged Type

GK-C1808C00 GK-C2108C00

GK-C2408C00 GK-C3008C00

GK-C3608H00

* Theexact appearanceof productsmay vary fromtheimagesshown here. * Theexact appearanceof productsmay vary fromtheimagesshown here.

Ducted Split Type

Economical and user-friendly model, designed for medium-sized houses

and shops. Features include a number of operation modes, auto restart and

a washable anti-bacterial filter.

4way Convertibility-horizontal(Left & right), up-flow, down-flow Plastic drain Pan High efficient Evaporator Coil

Galvanized Steel with painting Washable and Anti-fungus Filter Multi-speed blower Time delay PCB

220V primary & 24V secondary transformer Defrost sensor Hi-Reliability Compressor Factory supplied charge of R-22

Compressor internal overload protection Internal pressure relief valve provides high pressure protection for compressor

Outside pressure taps for refrigerant system check.

Features

Model

Capacity

Cooling (Gross) Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD)

Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TN-C0368SA0

37,000

-

3, 380~415,50

9.7

4,100

21.6

6

470x1,014x480

870x800x320

59/65

32/66/66

TN-C0488SA0

49,500

-

3, 380~415,50

13.9

5,000

50.9

6.2

600x1,135x500

900x1,135x370

63/100

12/26/26

TN-C0608SA0

60,000

-

3, 380~415,50

16.5

5,800

53.8

6.2

600x1,135x500

900x1,135x370

65/115

12/26/26

Ducted Split Type

TN-C0368SA0 TN-C0488SA0

TN-C0608SA0

25

LED Wired Remote Controller

Air Filter Guide

Blower Housing Assembly

A Type Indoor Coil

Plastic Drain Pan

Compact Size Quick and Easy Service Panels Anti-fungus, Hygienic and Easy-to-Clean filter

Convertible lnstallation Safety Condenser Fin Guard High/Low Static Driver Kit, Over Sized Motor(Accessory)

LCD Wired Remote Control

Features

Model

Capacity

Cooling (Gross) Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD)

Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TN-C1208T00

111,200

-

3, 380~415,50

30

11,800

102

6.3

1,760x890x840

1,330x1,570x740

190/300

6/15/19

TN-C0908T00

80,900

-

3, 380~415,50

20

8,100

76.4

6.0

1,760x890x840

855x1,570x740

190/175

6/15/22

Compact Size Quick and Easy Service Panels Anti-fungus, Hygienic and Easy-to-Clean filter

Convertible lnstallation Safety Condenser Fin Guard High/Low Static Driver Kit, Over Sized Motor(Accessory)

LCD Wired Remote Control

Features

26 27

Model

Capacity

Cooling (Gross) Btu/hr

Heating Btu/hr

Electrical Data

Power Supply ,V,Hz

M.C.A(with standard motor) Cooling / Heating Amps

Power Input Cooling / Heating W

Performance

Air Circulation Indoor CMM

Sound Rating bell

Installation & Stuffing

Net Dimensions Indoor mm

(WxHxD)

Outdoor mm

Net Weight Indoor/Outdoor Kg

Stuffing Quantity Without S/Parts 20/40/40ft Hi

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

TN-C1508T00

135,200

-

3, 380~415,50

35

13,200

125

8.0

1,760x890x840

1,130x1,180x1,100

190/250

7/14/19

TN-C1808T00

179,700

-

3, 380~415,50

57.2

20,400

150

8.0

2,065x680x1,160

1,640x1,130x880

200/280

7/14/19

TN-C2408T00

240,000

-

3, 380~415,50

76.2

27,200

200

8.0

1,870x980x1,230

1,840x1,130x970

230/340

7/14/19

Ducted Split Type

TN-C0908T00 TN-C1208T00

Ducted Split Type

TN-C1508T00 TN-C1808T00

TN-C2408T00

F

a

n

C

o

i

l

U

n

i

t

28

29

Fan Coil Unit

LG AI R CONDI TI ONERS 2009

Fan Coil Unit

The FCU (Fan Coil Unit) is supplied with cold or hot water by the control

center and circulates indoor air through the cooling and heating coils.

The structures using CAD & CAE technology helps users reduce

installation spaces.

Slim and compact design based on CAD/CAE systems enables

user to reduce installation space.

Slim & Compact Size

PCM Fin coated with anti corrosive & hydrophilic layers

prevents corrosion and make itself remains as like initial

condition, therefore it saves power & maintenance cost.

Heat Exchanger fins are coated with anticorrosive & hydrophilic

layers. It prevents the corrosion of heat exchanger. Fins remain

as new even after long time of operation and maintains

efficiency of heat exchanger constant.

Durable & Energy Saving PCM Fin

Easily removable motor & blower and removable panels help

users maintain units more conveniently.

Each unit is designed to occupy a minimum space. This feature,

along with convenient

wiring and piping connections, means reduces costs on

renovations or new construction sites.

Easy Maintenance

230

260

LG (WxHxD):

1,090x230x524

The other companies (WxHxD):

1,020x260x515

LG PCM FIN The other companies UNCOATED AL

Washable Anti-bacteria Filter Easy Installation

Free Easy Air-Circulation Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System District Cooling / Low Static

Features

Model

Performance

Nominial Air Flow H / M/ L CFM

Nominial Total Capacity H / M/ L Btu/h

Water Flow Rate GPM(US)

Water Pressure Drop kPa / ft.wg.

Indoor Noise Level

Noise Level L / M/H dB(A)

Coil

Tube Size inch(mm)

No. of Rows, Columns & FPI

Face Area sq.m

Face Velocity m/s

Motor

Type

No. of motor #

Class

Power Supply Ph/Hz/V

Total Rating Input watt

Fan

Material

Type

No. of Fans #

Water Content

3 Rows Liter

Drain Pan

Drain Pan (Material / Thickness)

Insulator (Meterial / Thickness)

Filter

Material

No. of Filter

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

YBNC146GCA0

1,422/1,195/948

38,150/35,280/28,217

4,840

30,330 / 9,948

38 / 43 / 48

3 / 8 (9.52)

4R 8C 11FPI

0.345

1.95

3

B

1 / 50 / 220~240

280

5

3.352

1

YBNC036ACA0

416/354/283

10,130/9,144/6,960

1,320

3,740 / 1,227

32 / 35 / 40

3 / 8 (9.52)

4R 8C 11FPI

0.122

1.61

1

B

1 / 50 / 220~240

67

2

1.183

1

YBNC046BCA0

508/424/341

14,252/11,874/9,519

1,850

7,590 / 2,490

28 / 34 / 40

3 / 8 (9.52)

4R 8C 11FPI

0.142

1.69

1

B

1 / 50 / 220~240

75

2

1.381

1

YBNC066CCA0

640/512/430

17,783/15,968/12,590

2,270

11,540 / 3,785

35 / 40 / 43

3 / 8 (9.52)

4R 8C 11FPI

0.189

1.60

1

B

1 / 50 / 220~240

102

2

1.834

1

YBNC086DCA0

869/736/577

24,921/22,656/17,640

3,190

12,050 / 3,952

35 / 40 / 44

3 / 8 (9.52)

4R 8C 11FPI

0.244

1.68

2

B

1 / 50 / 220~240

152

3

2.366

1

YBNC106ECA0

1,100/924/742

28,893/25,999/21,530

3,650

13,920 / 4,566

35 / 40 / 44

3 / 8 (9.52)

4R 8C 11FPI

0.284

1.83

2

B

1 / 50 / 220~240

188

4

2.761

1

YBNC126FCA0

1,242/1,048/848

35,089/31,970/25,624

4,460

17,550 / 5,756

37 / 41 / 45

3 / 8 (9.52)

4R 8C 11FPI

0.325

1.80

2

B

1 / 50 / 220~240

198

4

3.155

1

Washable Anti-bacteria Filter Easy Installation

Free Easy Air-Circulation Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System District Cooling / HighStatic

Features

30 31

Fan Coil Unit

YBNC036ACA0 YBNC046BCA0

YBNC066CCA0 YBNC086DCA0

YBNC106ECA0 YBNC126FCA0

YBNC146GCA0

Fan Coil Unit

YBNC126HDA0 YBNC146JDA0

YBNC166KDA0 YBNC186KDA0

YBNC206DLA0

4 Rows Coil

3 - Speed Permanent Split Capacitor Motor

Galvanized Steel

Centrifugal Fan (Forward Curve)

Galvanized Steel / T0.8

PE/ T5.0

Synthetic Nylon (optional Aluminum)

Model

Performance

Nominial Air Flow H / M/ L CFM

Nominial Total Capacity H / M/ L Btu/h

Water Flow Rate (Middle) GPM(US)

Water Pressure Drop (Middle) kPa / ft.wg.

Indoor Noise Level

Noise Level L / M/H dB(A)

Coil

Tube Size inch(mm)

No. of Rows, Columns & FPI

Face Area sq.m

Face Velocity m/s

Motor

Type

No. of motor #

Class

Power Supply Ph/Hz/V

Total Rating Input (Middle) watt

Fan

Material

Type

No. of Fans #

Water Content

3 Rows Liter

Drain Pan

Drain Pan (Material / Thickness)

Insulator (Meterial / Thickness)

Filter

Material

No. of Filter

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

YBNC126HDA0

1,348 / 1,115 / 1,051

37,028 / 31,455 / 28,123

3,800

7,200 / 2,361

50 / 53 / 59

3 / 8 (9.52)

4R 12C 13FPI

0.237

2.39

2

B

1 / 50 / 220~240

330

2

2.66

1

YBNC146JDA0

1,513 / 1,338 / 1,196

43,099 / 36,650 / 32,745

4,520

9,400 / 3,082

51 / 55 / 60

3 / 8 (9.52)

4R 12C 13FPI

0.274

2.41

2

B

1 / 50 / 220~240

440

2

3.01

1

YBNC166KDA0

1,702 / 1,562 / 1,296

47,219 / 41,558 / 37,474

5,120

11,000 / 3,607

49 / 55 / 59

3 / 8 (9.52)

4R 12C 13FPI

0.329

2.29

2

B

1 / 50 / 220~240

480

2

3.07

1

YBNC186KDA0

1,901 / 1,674 / 1,428

51,088 / 45,105 / 39,659

5,560

12,900 / 4,230

51 / 57 / 59

3 / 8 (9.52)

4R 12C 13FPI

0.329

2.59

2

B

1 / 50 / 220~240

550

2

3.07

1

YBNC206DLA0

2,089 / 1,928 / 1,638

55,530 / 47,889 / 41,737

5,900

14,400 / 4,623

53 / 58 / 62

3 / 8 (9.52)

4R 12C 13FPI

0.411

2.30

2

B

1 / 50 / 220~240

650

2

3.80

1

4 Rows Coil

3 - Speed Permanent Split Capacitor Motor

Galvanized Steel

Centrifugal Fan (Forward Curve)

Galvanized Steel / T0.8

PE/ T5.0

Synthetic Nylon (optional Aluminum)

Washable Anti-bacteria Filter Easy Installation

Free Easy Air-Circulation Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System Standard / Low Static

Features

Model

Performance

Nominial Air Flow H / M/ L CFM

Nominial Total Capacity H / M/ L Btu/h

Water Flow Rate GPM(US)

Water Pressure Drop kPa / ft.wg.

Indoor Noise Level

Noise Level L / M/H dB(A)

Coil

Tube Size inch(mm)

No. of Rows, Columns & FPI

Face Area sq.m

Face Velocity m/s

Motor

Type

No. of motor #

Class

Power Supply Ph/Hz/V

Total Rating Input watt

Fan

Material

Type

No. of Fans #

Water Content

3 Rows Liter

Drain Pan

Drain Pan (Material / Thickness)

Insulator (Meterial / Thickness)

Filter

Material

No. of Filter

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

YBNB146GAA0

1,728/1,270/1,082

48,621/43,947/37,020

10,990

31,070 / 10,191

37 / 43 / 48

3 / 8 (9.52)

3R 8C 11FPI

0.345

1.97

3

B

1 / 50 / 220~240

250

5

2.514

1

YBNB036AAA0

306/253/200

12,249/11,294/8,803

2,780

4,950 / 1,624

32 / 35 / 40

3 / 8 (9.52)

3R 8C 11FPI

0.122

1.18

1

B

1 / 50 / 220~240

60

2

0.887

1

YBNB046BAA0

432/379/329

14,876/13,898/10,884

3,400

6,070 / 1,991

28 / 33 / 40

3 / 8 (9.52)

3R 8C 11FPI

0.142

1.47

1

B

1 / 50 / 220~240

70

2

1.036

1

YBNB066CAA0

686/570/484

21,905/19,790/15,968

5,000

16,300 / 5,346

35 / 39 / 42

3 / 8 (9.52)

3R 8C 11FPI

0.189

1.70

1

B

1 / 50 / 220~240

97

2

1.376

1

YBNB086DAA0

859/765/647

27,637/24,839/21,018

6,210

20,510 / 6,727

35 / 39 / 42

3 / 8 (9.52)

3R 8C 11FPI

0.244

1.69

2

B

1 / 50 / 220~240

148

3

1.775

1

YBNB106EAA0

1,059/946/812

31,049/28,490/24,566

7,040

26,630 / 8,735

35 / 40 / 44

3 / 8 (9.52)

3R 8C 11FPI

0.284

1.69

2

B

1 / 50 / 220~240

178

4

2.071

1

YBNB126FAA0

1,182/1,053/929

37,805/34,188/28,081

8,510

28,840 / 9,460

37 / 41 / 45

3 / 8 (9.52)

3R 8C 11FPI

0.325

1.80

2

B

1 / 50 / 220~240

182

4

2.366

1

Washable Anti-bacteria Filter Easy Installation

Free Easy Air-Circulation Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System Standard / High Static

Features

32 33

Fan Coil Unit

YBNB036AAA0 YBNB046BAA0

YBNB066CAA0 YBNB086DAA0

YBNB106EAA0 YBNB126FAA0

YBNB146GAA0

Fan Coil Unit

YBNB126HBA0 YBNB146JBA0

YBNB166KBA0 YBNB186KBA0

YBNB206LBA0

3 Rows Coil

3 - Speed Permanent Split Capacitor Motor

Galvanized Steel

Centrifugal Fan (Forward Curve)

Galvanized Steel / T0.8

PE / T5.0

Synthetic Nylon (optional Aluminum)

Model

Performance

Nominial Air Flow H / M/ L CFM

Nominial Total Capacity H / M/ L Btu/h

Water Flow Rate GPM(US)

Water Pressure Drop kPa / ft.wg.

Indoor Noise Level

Noise Level L / M/H dB(A)

Coil

Tube Size inch(mm)

No. of Rows, Columns & FPI

Face Area sq.m

Face Velocity m/s

Motor

Type

No. of motor #

Class

Power Supply Ph/Hz/V

Total Rating Input watt

Fan

Material

Type

No. of Fans #

Water Content

3 Rows Liter

Drain Pan

Drain Pan (Material / Thickness)

Insulator (Meterial / Thickness)

Filter

Material

No. of Filter

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

YBNB126HBA0

1,238 / 1,052 / 941

38,385 / 33,642 / 29,173

8,640

21,920 / 7,190

44 / 48 / 52

3 / 8 (9.52)

3R 12C 13FPI

0.237

2.47

2

B

1 / 50 / 220~240

334

2

1.99

1

YBNB146JBA0

1,441 / 1,225 / 1,095

43,844 / 37,123 / 33,608

9,890

24,810 / 8,138

46 / 49 / 54

3 / 8 (9.52)

3R 12C 13FPI

0.274

2.48

2

B

1 / 50 / 220~240

396

2

2.18

1

YBNB166KBA0

1,594 / 1,403 / 1,265

47,086 / 41,285 / 37,941

10,700

28,040 / 9,197

47 / 52 / 56

3 / 8 (9.52)

3R 12C 13FPI

0.329

2.29

2

B

1 / 50 / 220~240

428

2

2.30

1

YBNB186KBA0

1,803 /1,591/ 1,400

49,815 / 43,674 / 38,556

11,400

34,040 / 11,165

49 / 54 / 57

3 / 8 (9.52)

3R 12C 13FPI

0.329

2.59

2

B

1 / 50 / 220~240

517

2

2.30

1

YBNB206LBA0

2,006 / 1,759 / 1,548

56,639 / 49,815 / 42,991

12,990

38,300 / 12,562

51 / 55 / 59

3 / 8 (9.52)

3R 12C 13FPI

0.411

2.30

2

B

1 / 50 / 220~240

710

2

2.85

1

4 Rows Coil

3 - Speed Permanent Split Capacitor Motor

Galvanized Steel

Centrifugal Fan (Forward Curve)

Galvanized Steel / T0.8

PE / T5.0

Synthetic Nylon (optional Aluminum)

Washable Anti-bacteria Filter Easy Installation

Free Easy Air-Circulation Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System Standard / High Static

Features

Model

Performance

Nominial Air Flow H / M/ L CFM

Nominial Total Capacity H / M/ L Btu/h

Water Flow Rate (Middle) GPM(US)

Water Pressure Drop (Middle) kPa / ft.wg.

Indoor Noise Level

Noise Level L / M/H dB(A)

Coil

Tube Size inch(mm)

No. of Rows, Columns & FPI

Face Area sq.m

Face Velocity m/s

Motor

Type

No. of motor #

Class

Power Supply Ph/Hz/V

Total Rating Input (Middle) watt

Fan

Material

Type

No. of Fans #

Water Content

3 Rows Liter

Drain Pan

Drain Pan (Material / Thickness)

Insulator (Meterial / Thickness)

Filter

Material

No. of Filter

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

YBNC126HBA0

1,348 / 1,115 / 1,051

44,066 / 38,764 / 33,927

8,600

28,300 / 9,279

50 / 53 / 59

3/8 (9.52)

4R 12C 13FPI

0.237

2.39

2

B

1/50/220~240

330

2

2.66

1

YBNC146JBA0

1,513 / 1,338 / 1,196

53,022 / 46,645 / 40,842

10,340

30,000 / 9,836

51 / 55 / 60

3/8 (9.52)

4R 12C 13FPI

0.274

2.41

2

B

1/50/220~240

440

2

3.01

1

YBNC166KBA0

1,702 / 1,562 / 1,296

56,713 / 50,873 / 46,072

11,280

31,800 / 10,426

49 / 55 / 59

3/8 (9.52)

4R 12C 13FPI

0.274

2.41

2

B

1/50/220~240

480

2

3.01

1

Washable Anti-bacteria Filter Easy Installation

Free Easy Air-Circulation Low Noise Level Easy Maintenance & Service

Additional Functions Available with Duct System Standard / High Static

Features

34 35

Fan Coil Unit

YBNC126HBA0 YBNC146JBA0

YBNC166KBA0

Fan Coil Unit

YBNC186KBA0 YBNC206LBA0

4 Rows Coil

3 - Speed Permanent Split Capacitor Motor

Galvanized Steel

Centrifugal Fan (Forward Curve)

Galvanized Steel / T0.8

PE / T5.0

Synthetic Nylon (optional Aluminum)

Model

Performance

Nominial Air Flow H / M/ L CFM

Nominial Total Capacity H / M/ L Btu/h

Water Flow Rate (Middle) GPM(US)

Water Pressure Drop (Middle) kPa / ft.wg.

Indoor Noise Level

Noise Level L / M/H dB(A)

Coil

Tube Size inch(mm)

No. of Rows, Columns & FPI

Face Area sq.m

Face Velocity m/s

Motor

Type

No. of motor #

Class

Power Supply Ph/Hz/V

Total Rating Input (Middle) watt

Fan

Material

Type

No. of Fans #

Water Content

3 Rows Liter

Drain Pan

Drain Pan (Material / Thickness)

Insulator (Meterial / Thickness)

Filter

Material

No. of Filter

Specification

Note :Due to our policy of innovation some specifications may be changed without notification.

YBNC186KBA0

1,901 / 1,674 / 1,428

63,412 / 54,814 / 47,326

12,160

36,500 / 11,967

51 / 57 / 59

3/8 (9.52)

4R 12C 13FPI

0.329

2.59

2

B

1/50/220~240

550

2

3.07

1

YBNC206LBA0

2,089 / 1,928 / 1,638

73,802 / 64,129 / 54,814

14,220

54,100 / 17,738

53 / 58 / 62

3/8 (9.52)

4R 12C 13FPI

0.411

2.30

2

B

1/50/220~240

650

2

3.80

1

4 Rows Coil

3 - Speed Permanent Split Capacitor Motor

Galvanized Steel

Centrifugal Fan (Forward Curve)

Galvanized Steel / T0.8

PE / T5.0

Synthetic Nylon (optional Aluminum)

M

U

L

T

I

M

D

X

36

37

LG AI R CONDI TI ONERS 2009

Multi Mdx are freely interchangeable multi systems with

MPS-controlled, constant speed compressors.

These systems are perfectly suited for tropical conditions.

Multi Mdx are freely interchangeable multi systems with MPS-controlled, constant speed

compressors. These systems are perfectly suited for tropical conditions.

M

U

L

T

I

M

D

X

38

39

LG AI R CONDI TI ONERS 2009

Tropical MPS Multi System Installation

Next Generation LG MPS Tropical Multi System

are freely interchangeable multi systems with MPS-controlled, constant speed

compressors. These systems are perfectly suited for tropical conditions.

Single Piping Type

MPS Variable Control is LGs unique, energy-saving control technology,

which is applied in both the Multi MDX series.

* Made in Thailand

Type

Btu/h

Wall-Mounted

12K 18K 24K 30K 36K 48K

ARTCOOL Mirror

High Staic Duct

Low Staic Duct

4-Way Cassette

Color variable

*Metal

*Blue

*White Wood

*Cherry

Outdoor Unit Line-up

Indoor Unit Line-up

L4UC608FA2 L5UC728FA3

L6UH728FA2

L8UC1008FA3

L8UC1008FA2

L8UC1508FA1

MPS Variable System

- High efficiency

- High reliability

- Long piping & high elevation flexibility

- Max.8 indoor units by simple piping

- Low noise

- Central control

M

U

L

T

I

M

D

X

40

41

LG AI R CONDI TI ONERS 2009

Tropical MPS Multi System Installation

Next Generation LG MPS Tropical Multi System

Tropical MPS Multi System Solutions

Small Office Building

Small Office Small Shop Restaurant

For Commercial Sites

Resort Apartment Villa

For Residential Sites

Residential Building

M

U

L

T

I

M

D

X

42

43

LG AI R CONDI TI ONERS 2009

Tropical MPS Multi System Installation

Next Generation LG MPS Tropical Multi System

Energy Saving with Tropical MPS Variable Control

Basic Principle of Tropical MPS Variable Control Long Distance & High Elevation Piping

Simple & Cutting Edge Control System

Tropical Compressor Technology

The Tropical MPS (multi power system) control two or more constant speed compressors, a hot gas bypass circuit and an linear

expansion valve (LEV). With multiple compressors operating according to increasing cooling requirements, considerable amounts of

energy can be saved. In case of a low cooling load, only one compressor will operate. When the cooling load increases, both

compressors will operate and balance the load.

100%

Conventional system (On/Off Operation)

50% 50%

MPS Variable Control

Power Consumption Comparison

MPS Variable Multi system opeates in one cycle with two compressors. Only one compressor or two compressors run together,

according to the load conditions.With small load. only one compressor completes the cycle. It saves power consumption at low

operation. This concept is explained in the picture below.

BLDC Fan

BLDC fan motor offers additional energy saving in operating mode. Compared with AC motors, BLDC fan motor can cut energy by

35%at full velocity. AC motor is operating at full velocity only, but BLDC Motor can change velocity according to load. Energy efficiency

levels at low velocities in particular have been improved by 65%.

The finely tuned refrigerant return ratio and special accumulator

allow piping lengths of up to 110m at a max. elevation of 45m. The

runback returns refrigerant to the compressor to maintain a safe

level of refrigerant at all times. It allows better flexibility for

installation under difficult structural conditions.

Long Distance &

High Elevation Piping:

Max. Pipe Length:

110m/cycle

- Please Refer to Page 64

The Tropical compressor is highly reliable, even under extreme

conditions (15~60C average), sandstorms and 24 hour

operation. At extreme temperatures over 54C only 1 large

compressor operates to protect the smaller compressors and to

prevent the indoor temperature from rising due to repeated OLP

triggering.

INCREASED RELIABILITY

- Overload Protector

- High Torque Motor

- Special Anti-Wear Coating

- High Rigidity Crank Shaft

28

110

10%

Standard

New Design -muffle -resonator

33

115

15%

Tropical

Max Press.(kgf/cm

2

)

Td(C)

Under voltage

Noise

M

U

L

T

I

M

D

X

44

45

LG AI R CONDI TI ONERS 2009

Tropical MPS Multi System Installation

Next Generation LG MPS Tropical Multi System

Flexible Design & Simple Piping

The MPS Variable multi system uses a simple refrigerant pipe to connect one outdoor unit with multiple indoor units.

It is easy to install and very economical.

Various distributors for flexible design

For 2 Room For 3 Room For 4 Room

Connecting distributor without brazing

Direct Connection Type

Various Combination

Piping length : 50m(A), 50m(B) Total system piping length : 100m(50+50)

(Please refer to PDB for detail piping spec.)

Installation of outdoor unit in an elevated position Installation of outdoor unit in a lower position

Outdoor Unit

(L8UC1008FA3)

Short Tube

Indoor Unit

Indoor Unit

45m

Outdoor Unit

(L8UC1008FA3)

Indoor Unit

Indoor Unit

45m

A

A B

B

Distributor Type

The Tropical MPS Multi allows simple piping for easy installation by using branch distributors.

Total main piping length : 50m(A), 50m(B) With L5UC728FA3, L8UC1008FA3, L8UC150FA1

Total branch piping length : 60m(L1+L2+L3+L4), 60m(L5+L6+L7+L8)

Maximum length of single branch piping: 15m(L1, L2, L3,L4, L5, L6, L7, L8)

Total system piping length: 220m = 110m(A+L1+L2+L3+L4)+110m(B+L5+L6+L7+L8)

Maximum elevation from outdoor unit to indoor unit : 45m with L5UC728FA3, L8UC1008FA3, L8UC150FA1

Installation of

outdoor unit

in lower position

Installation of

theoutdoor unit

in an upper

position

Outdoor Unit

(L8UC1008FA3)

Outdoor Unit

(L8UC1008FA3)

Indoor Unit

45m

45m

A

B

B

A

L1

L2

L3

L4

L1

L2

L3

L4

L5

L6

L7

L8

L5

L6

L7

L8

Branch Distributor

A,B: Main piping

L1,L2,L3,L4,L5,L6,L7,L8: Branch piping

Thespecificationsaboveareonly for two models,

L8UC1008FA3/L8UC1508FA1.

Pleaserefer to theProduct Data Book for other models.

Branch Distributor

Branch Distributor

Branch Distributor

Indoor Unit

Distributor

For

Connectable indoor Unit

Power Consumption (W)

Running Current Type (A)

Net Dimensions (WxHxD) (mm)

Net Weight (kg)

Piping Connection (Outdoor Unit) Liquid / Gas (mm)

Piping Connection (Indoor Unit) Liquid / Gas (mm)

2 indoors

1~2

10

0.05

300 x 150 x 250

4.8

9.52 / 19.05

6.35x2 / 12.7x2

3 indoors

1~3

10

0.05

300 x 150 x 250

4.9

9.52 / 19.05

6.35x3 / 12.7x3

4 indoors

1~4

10

0.05

300 x 150 x 250

5.0

9.52 / 19.05

6.35x4 / 12.7x4

PMBD5420L Unit PMBD5430L PMBD5440L

Notes: 1.BD unit BD unit, Indoor Unit Indoor Unit : Max. Height - 10mSet up the BD unit and Indoor Unit in 15m.

2. Piping connectors must fit the piping sizes of the indoor unit to be connected.(If required, use the connector which is included with the indoor unit.)

3. The BD unit should be installed inside the building.

Easy installation with various distributors

A variety of distributors makes installation on any site much easier.

4 Room Type 5~6 Room Type 8 Room Type

Use short tube in case of connecting 48K indoor unit to outdoor unit(direct piping)

For detailed usage of short tube and Y-branch, please refer to PDB

Short Tube Y Branch

46 47

L4UC608FA2 / L5UC728FA3 / L6UH728FA2

Specification

HP

Nomal Capacity Cooling kW

(Min~Rating) Btu/h

Heating kW

Btu/h

Nominal Input Cooling kW

(Min~Rating) Heating kW

Running Current Cooling A

Heating A

Starting Current Cooling/Heating A

Power Supply , V, Hz

Power Supply Cable (outdoor) No.*mm

2

Power and transmission cable(outdoor to BD) No.*mm

2

Power and transmission cable(BDto indoor) No.*mm

2

Dimensions W*H*D mm(inch)

Net Weight kg(Ibs)

Max. Number of Connectable indoor Units

Compressor Type

constant speed Qty x Model

(A+B) Motor Type

(MPS cycle 1) Oil Type

Oil Charge cc

Compressor Type

constant speed Qty x Model

(C or C+D) Motor Type

(Single or MPS cycle 2) Oil Type

Oil Charge cc

Refrigerant Charge (at 7.5m) g(oz)

Type

Control EEV

Short tube

Heat Exchanger (Row x Column x FPI)*No.

Defrosting Method

Fan motor Capacitor F/Vac

Drive

Discharge direction Side/Top

AirFlowRatexNo.of fan CMM(cfm)

Noise Level (H/L) Sound Pressure at 1m dB(A)+3

Piping connections Liquid()(Circuit 1) mm(inch)

Gas()(Circuit 1)

Liquid()(Circuit 2)

Gas()(Circuit 2)

Max.total Piping m

Max. OD~BD Piping m

Max. total sumof BD~IDPiping m

Max. OD~ID Piping m

Max. OD~ID Piping m

Max. Elevation Indoor Unit~Outdoor Unit m

Difference Indoor Unit~Indoor Unit m

Multi

MDx

MPS

BD

Piping

DirectPiping

Single

L6UH728FA2

3.5~21.1

12,000~72,000

3.5~21.1

12,000~72,000

2.2~7.3

2.8~7.2

4.9~14.7

4.8~14.5

24

3, 380~415, 50

5 * 5.0 (includes earth)

4 * 0.75 (includes earth)

4 * 0.75 (includes earth)

806*1,607*730(31.7*63.3*28.7)

190 (419)

6

Twin Rotary

2 x QPT425YAB

3 Phase Induction

ATMOS M60/SUNISO 4GSI

1,200

Twin Rotary

1 x QP425YAB

3 Phase Induction

ATMOS M60/SUNISO 4GSI

1,200

Cycle 1: 4000(141)/Cycle 2:2000(70.5)

R22

MPS cycle EEV In BD unit

Single cycle EEV in outdoor unit

(079 / - / 079), (085 / - / 096)

(2Rx17Cx18)*2+(2Rx36Cx18)*2

Reverse cycle

10/450

Direct drive

top

90 (3179) x 1

60

9.52 (3/8)

19.05 (3/4)

6.35 (1/4)

15.88 (5/8)

Cycle1:60 / Cycle2:45

Cycle1:30 / Cycle2:30

Cycle1:30 / Cycle2:15

Cycle1:50 / Cycle2: -

-

30

10

L4UC608FA2

5.3~17.6

18,000~60,000

-

-

2.9~5.7

-

5.3~10.2

-

24

3, 380~415, 50

5 * 50 (includes earth)

4 * 0.75 (includes earth)

4 * 0.75 (includes earth)

900*1,165*370 (35.4*45.8*14.5)

104 (230)

4

Twin Rotary

2 x QPT525YAB

3 Phase Induction

SUNISO NM56

1,200

-

-

-

-

-

3,400 (120)

R22

MPS cycle EEV In BD unit

Single cycle EEV in outdoor unit

-

(2R x 26C x 18) * 2

-

6/370~400

Direct drive

side

80 (2,824) x 1

60

9.52 (3/8)

19.05 (3/4)

-

-

60

30

30

-

-

30

10

Notes: 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27C(80.6F) DB /19C(66.2F) WB

- Outdoor Temperature 35C(95F) DB /24C(75.2F) WB

Heating: - Indoor Temperature 20C(68F) DB /15C(59F) WB

- Outdoor Temperature 7C(44.6F) DB /6C(42.8F) WB

Piping Length: - Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. At least two indoor units should be connected.

L5UC728FA3

3.5~21.1

12,000~72,000

-

-

1.9~6.8

-

3.8~12.3

-

24

3, 380~415, 50

5 * 5.0 (includes earth)

4 * 0.75 (includes earth)

4 * 0.75 (includes earth)

806*1,607*730(31.7*63.3*28.7)

205 (452)

5

Rotary

2 x QPT425Y

3 Phase Induction

ATMOS M60/SUNISO 4GSI

1,130

Rotary

1 x QP425Y

3 Phase Induction

ATMOS M60/SUNISO 4GSI

1,130

Cycle 1: 4600(162.21)/Cycle 2:2300(81.1)

R22

MPS cycle EEV In BD unit

Single cycle EEV in outdoor unit

(079 / - / 079)

(2Rx17Cx18)*2+(2Rx36Cx18)*2

-

10/370

Direct drive

top

90 (3,179) x 1

60

9.52 (3/8)

19.05 (3/4)

6.35 (1/4)

15.88 (5/8)

110

50

60

50

50

45

10

Specification

HP

Nomal Capacity Cooling kW

(Min~Rating) Btu/h

Heating kW

Btu/h

Nominal Input Cooling kW

(Min~Rating) Heating kW

Running Current Cooling A

Heating A

Starting Current Cooling/Heating A

Power Supply , V, Hz

Power Supply Cable (outdoor) No.*mm

2

Power and transmission cable(outdoor to BD) No.*mm

2

Power and transmission cable(BDto indoor) No.*mm

2

Dimensions W*H*D mm(inch)

Net Weight kg(Ibs)

Max. Number of Connectable indoor Units

Compressor Type

constant speed Qty x Model

(A+B) Motor Type

(MPS cycle 1) Oil Type

Oil Charge cc

Compressor Type

constant speed Qty x Model

(C or C+D) Motor Type

(Single or MPS cycle 2) Oil Type

Oil Charge cc

Refrigerant Charge (at 7.5m) g(oz)

Type

Control EEV

Short tube

Heat Exchanger (Row x Column x FPI)*No.

Defrosting Method

Fan motor Capacitor F/Vac

Drive

Discharge direction Side/Top

AirFlowRatexNo.of fan CMM(cfm)

Noise Level (H/L) Sound Pressure at 1m dB(A)+3

Piping connections Liquid()(Circuit 1) mm(inch)

Gas()(Circuit 1)

Liquid()(Circuit 2)

Gas()(Circuit 2)

Max.total Piping m

Max. OD~BD Piping m

Max. total sumof BD~IDPiping m

Max. OD~ID Piping m

Max. total Piping m

Max. OD~ID Piping m

Max. Elevation Indoor Unit~Outdoor Unit m

Difference Indoor Unit~Indoor Unit m

Piping

length

spec.

Multi

MDx

MPS

BD

Piping

DirectPiping

Multi M

L8UC1508FA1

5.3~44.0

18,000~150,000

--

--

3.5~16.3

--

6.39~29.1

--

--

3, 380~415, 50

5 * 8.4 (includes earth)

4 * 0.75 (includes earth)

4 * 0.75 (includes earth)

1,280*1,607*730(50.4*63.3*28.7)

320 (661)

8

Twin Rotary

3 x QPT525Y

3 Phase Induction

SUNISO NM56

1200

Twin Rotary

2 x QPT525Y

3 Phase Induction

SUNISO NM56

1200

Cycle1:7200(254)/Cycle2:4800(169)

R22

2 MPS cycles EEV in BD unit

-

(2Rx14Cx18)*2+(2Rx30C x18)*1

+(3Rx30Cx18)*1

--

10/370

Direct drive

top

180 (6357)

60

12.7 (1/2)

25.4 (1)

9.52 (3/8)

19.05 (3/4)

110

50

60

--

--

--

45

10

L8UC1008FA3

3.5~29.3

12,000~100,000

--

--

1.6~9.9

--

3.4~21.8

--

--

3, 380~415, 50

5 * 5.0 (includes earth)

4 * 0.75 (includes earth)

4 * 0.75 (includes earth)

1,280*1,607*730(50.4*63.3*28.7)

250 (551)

8

Rotary

2 x QP425Y

3 Phase Induction

ATMOS M60/SUNISO 4GSI

1130

Rotary

2 x QP425Y

3 Phase Induction

ATMOS M60/SUNISO 4GSI

1130

4000(141.1)

R22

2 MPS cycle EEV In BD unit

(079 / - / 079), (085 / - / 096)

(2R x 14C x 18)*2 +

(1R x 30C x 18)*2

--

10/370

Direct drive

top

90 (3179) x 2

60

9.52 (3/8)

19.05 (3/4)

9.52 (3/8)

19.05 (3/4)

110

50

60

50

--

--

45

10

Notes: 1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27C(80.6F) DB /19C(66.2F) WB

- Outdoor Temperature 35C(95F) DB /24C(75.2F) WB

Heating: - Indoor Temperature 20C(68F) DB /15C(59F) WB

- Outdoor Temperature 7C(44.6F) DB /6C(42.8F) WB

Piping Length: - Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. At least two indoor units should be connected.

3. Wiring cable size must comply with the applicable local and national code.

4. The specification may be subject to change without prior notice for purpose of improvement.

L8UH1008FA2

3.5~29.3

12,000~100,000

3.5~29.3

12,000~100,000

1.6~9.9

2.3~9.0

3.4~21.8

4.2~16.0

--

3, 380~415, 50

5 * 5.0 (includes earth)

4 * 0.75 (includes earth)

4 * 0.75 (includes earth)

1,280*1,607*730(50.4*63.3*28.7)

250 (551)

8

Rotary

2 x QP425Y

3 Phase Induction

ATMOS M60/SUNISO 4GSI

700

Rotary

2 x QP425Y

3 Phase Induction

ATMOS M60/SUNISO 4GSI

700

4000(141.1)

R22

2 MPS cycles EEV in BD unit

(079 / - / 079), (085 / - / 096)

(2R x 14C x 18)*2 +

(1R x 30C x 18)*2

Reverse cycle

10/370

Direct drive

top

90 (3179) x 2

60

9.52 (3/8)

19.05 (3/4)

9.52 (3/8)

19.05 (3/4)

60

30

30

50

--

--

30

10

L8UC1008FA3 / L8UH1008FA2 / L8UC1508FA1

48 49

Combination of Indoor and Outdoor Unit

Model Type

Capacity

Wall Mounted General

Mirror

4 Way

Hight Static

Low Static

ARTCOOL

Ceiling Cassette

Ceiling Concealed

Duct

Index

12

18

24

12

18

24

12

18

24

30

36

48

18

24

30

36

48

12

18

24

Btu/h

12,000

18,000

24,000

12,000

18,500

24,000

12,000

18,000

24,000

30,000

36,000

48,000

18,000

24,000

30,000

36,000

48,000

12,000

18,000

24,000

kW

3.52

5.28

7.03

3.52

5.42

7.03

3.2

5.28

7.03

8.79

10.55

14.07

5.28

7.03

8.79

10.55

14.07

3.52

5.28

7.03

up to 4

-

-

-

-

-

-

-

up to 5

up to 8

up to 6

up to 8

-

-

-

-

Indoor Units

Number of Connectible Indoor Units

L4UC608FA2 L5UC728FA3 L6UH728FA2 L8UC1008FA3

L8UH1008FA2

L8UC1508FA1

Outdoor Units

Notes:

1. The total capacity index of indoor units is the of capacity index of eachunits and shoul be within the maximumcapacity index of the outdoor unit.

Combination Table L4UC608FA2

L5UC728FA3

Current (A) Input (W)

Operation

Unit

1 unit

2 units

3 units

4 units

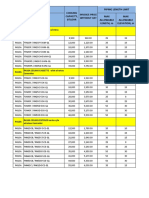

Unit-A

18000

24000

30000

36000

48000

18000

18000

18000

18000

16000

24000

24000

20000

30000

28000

18000

18000

16000

15000

20000

15000

Unit-B

-

-

-

-

-

18000

24000

30000

36000

44000

30000

36000

40000

30000

34000

18000

18000

16000

15000

20000

15000

Unit-C

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

18000

23000

28000

30000

20000

15000

Unit-D

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

15000

Total

18000

24000

30000

36000

48000

36000

42000

48000

54000

60000

54000

60000

60000

60000

62000

54000

59000

60000

60000

60000

60000

2850

2850

3000

5600

6050

5600

5600

6050

5800

6300

6300

6300

6300

6300

6300

5800

5700

6300

6300

5800

5900

5.3

5.3

5.5

9.0

9.2

9.0

9.2

9.6

9.6

9.8

9.6

9.6

10.2

9.6

9.6

10.2

10.2

9.6

9.6

10.2

10.6

Combination of Indoor unit(k Btu/h)

Capacity (Btu/h)

Cooling

Notes:

1. Cooling Capacity is based on : indoor temp.27C(80.6F) DB, 19C(66.2F) WB; outdoor temp. 35C(95F) DB

2. The total capacity of indoor unit of "Circuit 1" is up to 36000 Btu/h (10.6kW). The total capacity of indoor unit of "Circuit 2" is up to 24000 Btu/h (7.1kW).

3. The capacity is based on standard length of interconnecting refrigerant line. [Standard length : Direct Piping - 7.5m(25ft), Distributor Piping - Main 5m(16.4ft), Branch 7.5m(25ft)]

Unit-A

18

24

30

36

48

18

18

18

18

18

24

24

24

30

30

18