Professional Documents

Culture Documents

Fordson Major Tractor Manual

Fordson Major Tractor Manual

Uploaded by

feral86088%(24)88% found this document useful (24 votes)

29K views98 pagesfordson major tractor manual

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

TIF, PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfordson major tractor manual

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TIF, PDF or read online from Scribd

Download as tif or pdf

88%(24)88% found this document useful (24 votes)

29K views98 pagesFordson Major Tractor Manual

Fordson Major Tractor Manual

Uploaded by

feral860fordson major tractor manual

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TIF, PDF or read online from Scribd

Download as tif or pdf

You are on page 1of 98

ordson

mMagor

TRACTOR

AGRICULTURAL - ROW CROP

LAND UTILITY - INDUSTRIAL

INSTRUCTION

MANUAL

PRICE 2/- POST FREE

FORD MOTOR COMPANY LID

DAGENHAM

FORDSON MAJOR INSTRUCTION MANUAL 3

Specification

AGRICULTURAL TRACTOR

Row Crop, Indl or Land Uy Tractors similar except whee

soted).

Engine.—Four cylinder, four-stroke, cylinders cast on bloc. Cylinder

bore 4} in. (1048 mm). Piston stroke 5 in. (127.0 mm.)

Cubic capacity 267 cu. in, (4380 cc). Firing order 1 2, 4, 3

Special cast alloy crankshaft, statically and dynamically balanced,

carried on 3 main bearings, 2 in. (50.8 mm.) diam. by 3} in.

(62.55 mm, long. Big end bearings, 2 in. (0.8 mm.) diam. by

24: (57.15 mm, long. Cast-iron pistons, with 3 compression and

{ol contrel piston rings fed above the piston pin. Side by side

valves of special steel alloy. Industrial Tractor has high com-

pression cylinder head for running on petrol. Low compression

Sjlinder head for running on vapourizing oil

Lubrication by splash system with oil csculation main-

tained by oil thrown off flywheel by centrifugal action. Ducts

Head oi to main bearings and timing gears. Oil capacity 2

Sopra pills (959 tre)

‘Use a good quality oil of S.A.E. 30 viscosity in Winter and

SALE. qo viscosity in Simmer.” For climates baving a ten

perature above gorF. use an oil of SALE. 50 viscosity, for

climates with a Severe Winter temperature below 20°F. use an

oil of S.AE. 20 or 20W viscosity.

operating exclusively on petrol can use an engine oil

fone grade lighter in each case

Cooling System.—Thermo-syphon, impeller assisted, Efficient

cooling ensured by vertical tube type radiator with very large

reinforced tanks, in conjunction with ample water jackets sound

ojlinder block and cylinder head, and four-bladed fan (6 blade

optional) which draws 1,700 cu. ft. (48.14 cu. m.) of ait per

minute through the radiator. Water capacity, 10_ gallons

(4s4 litres). A radiator blind is fitted at the bottom of the core

50 that a greater or lesser area is exposed. This permits a

satisfactory operating temperature beitg attained and should

be suitably adjusted to compensate for varying load conditions

‘which may be encountered

Water temperature gauge, mounted on the’ radiator is

visible to the operator and indicates the cooling water tempera-

ture, This is not fitted when a pressure cap is supplied as

special equipment.

Ignition System.—High tension magneto with impulse coupling

for easy starting, driven by a helical gear from camshaft gear.

‘Manual advance and retard controlled by lever on dash.

ee

4 # FORDSON MAJOR 5

Governor —Centrifugal type, adjustable to maintain any desired

ELQESSELHEDES engine speed from 4o0-1,450 pm. Controlled from dash.

cyepectee tld Optional on Industrial Tractor, which normally has. throttle

gbetaeiepeetdy lever beneath steering wheel, ditecly connected to carburettor,

Hil i

Fuel System.—Gravity feed from 17} imperial gallon (79.55 litres)

overhead tank, through a sediment bulb which filters all fuel be-

fore it reaches the vapourizer or carburettor. Tractors equipped

to run on vapourizing oil have a one gallon (4.55 litres) awaliary

petrol tank inside the main one

Vapourizer.—Tractor fitted with low compression cylinder

hhead for running on vapourizing oil has a special vapourizer

with an adjustable mixture control and an exhaust heated plate to

ensure economy and proper vapourization of fuel.

Carburettor—Tractor fitted with high compression cylinder

head for running on petrol has special down draught carburettor.

‘air inlet pipe, and an oil bath air cleaner ensure that all air used

by the engine is thoroughly clean, thus minimising wear on all

gin pars A gauze typeof filter may be used when operting

on petrol only.

# i Air Intake System. —A primary air lane at he tp ofthe vera

Figure

Section of Tractor

Steering System.—Worm and nut (steel sector and worm on early

tractor). Ratio 17 to 1 All steering arms and rods are of

A hheavy construction. Easily replaceable bushes are fitted to

steering shaft and spindle bodies.

Letina wes}

Front Axle—Heavy cast steel axle, heat treated to provide maximum

strength. It is mounted at the centre of the front of the engine

ff on a trunnion. Heavy radius rods are fitted to take up thrust.

le ‘ends which can be altered to give track widths from 48 ins to

i ‘72 ins, (121,92 om. to 182.88 cm.) for cast-iron wheels, 49% ins.

i 10 738 ins, (126.36 cm. to 187.32 cm.) when pneumatic tyres are

fitted, without affecting the radius rods or drag link.

. .\ : Front Axle, Row Crop.—Adjustable for width by means of extensible

forward and reverse. All shafts run on ball or roller beatings.

Single plate lurch mounted on fywheel and operating ini.

il capacity approximately 23 imperial gallons (12.5 litres). "Use

4 good grade of get ol of SALE. 90 viscosity for both Winter

and Summer. For hot climates with temperatures above 90°F.

Use a gear ol of SALE. 140 viscosity, for climates having Winter

‘temperatures below 10°F. use a gear oil of S.A.E, 80 viscosity.

i Gearbox.—Constant mesh sliding selective type with three speeds

i

i

i

ce

:

E

5

INSTRUCTION MANUAL

a3

ie

ag

&

Figure 2

Vapourizer Side of Tractor

- aA eee

z=.

FORDSON MAJOR

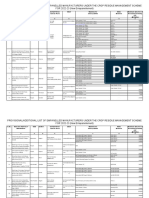

Gear Ratios chased on an engine speed of 200 RPM)

Type 4.3 (Low Speed Top Gear)

Standard Ratio (Intermediate Gears)

Gear Final Ratio Mp Kp.

: rane

Fist 73.6: 248 254 3.51 4.09

Second 48.6: 3.31385 $33. 6.20

Top 3484: 4.61537 7-42 8.64

Reverse 8591 188218 3.03 3.51

‘Special Ratio (Intermediate Gears)

Gear Final Ratio Mph, = Kph,

i

Fist 92972 2022.77 3.24

Second G6r32:1 262 306 3.32 4.92

Top 3484 4.61 5.37 742 8.64

Reverse 08.21 148172 238 2.77

Type 7.7 (High Speed Top Gear)

Standard Ratio (Intermediate Gears)

Gear Final Ratio M.p.h, Kph,

ves eae

Fist 6851 235273 378 439

Second 486: 331385 3.33 6.20

Top 1944-830 9.65 13,36 15:53

Reverse 506: 318 404 5.12 6.50

Special Ratio (Intermediate Gears)

Gear Final Ratio Mph. = Kph,

eo eed

Fit 86.51 186216 2.99 3.48

Second 614 ix 2.62 3.06 3,32 4.92

Top 1941-830 8.65 13.36 15.53

Reverse 63.91 248203 3.99 472

| Tdentification

STD. 43

(Green Spot)

| fdentification

SR. 43

(Red Spot)

| Tdentification

STD. 77

(Green Spot)

|| Tdentification

SR. 77

(Red Spot)

INDUSTRIAL TRACTOR, WITH PNEUMATIC TYRES

‘Type 7.7 (High Speed Top Gear)

Standard Ratio (Intermediate Gears)

t With Stee! Wheels,

+ With Paeumatic Tyres.

| Stamped on RH. flange of gearbox housing towards the top where this mates

‘With the Hywheel housing,

INSTRUCTION MANUAL

FORDSON MAJOR : 9

Handbrake.—Multi-plate disc, running in oil, operated by hand brake

lever, acting on transmission.

Foot Brake (optional equipment).—External brake drums fitted t0

:

i

i

‘countershaft at each side with internal expanding self energising

‘dual shoes, Foot pedals in duplicate, side by side on left hand

of tractor, enabling brake on either side, or both, to be operated.

Foot Brake.—Industrial Tractor. Brake drums fitted to rear wheels,

brake’ back plates carried on axle housings. Brake shoes of

internal expanding type, non-servo, with simple adjustment for

lining wear.

Rear Axle.—Semi-floating, four-pinion differential, running on roller

Figure 3

‘earings.

Crown and pinion spiral bevel reduction of 3.5 : 1 10

countershaft. Spur gear reduction from countershaft to rear

axle shafts 5.308 : 1. Oil capacity, 10 imperial gallons

(45.46 lites) approximately. Usea good grade of gear oil of S.A-E.

90 viscosity for both Summer and Winter. For hot climates

‘with temperatures above 90°F. use a gear oil of S.A. 140

viscosity, for climates having Winter temperatures below

10°F, use a gear oil of S.A-E. 80 viscosity.

Wheels—Front.—Heavy cast-iron, mounted on adjustable roller

Rear View of Row Crop Tractor

‘earings.

Rear.—Have spokes welded to the rim, which is punched to

allow spade lugs to be fitted. Wheels adjustable to vary width

‘of track on Row Crop from 48 ins, to 72 ins. (121.92 cm. t0

182,88 cm.) minimum width with pneumatics 52 ins. (132.08 cm).

Wheels—Front—Land Utility and Industrial. Heavy cast-iron,

similar to agricultural, mounting pneumatic tyres, 6.00-19 in.

Tyre pressure 25 Ibs. per sq. in. (1.758 kg, per sq. cm.)

Rear—Land Utility. Steel wheel, with welded spokes,

mounting pneumatic tyres, 11.00-36 in, ‘Tyre pressures?

Land work—min. 11 Ibs. per sq. in. (0.773 kg. per sq. cm.) 5

Road use—r4 Ibs. per sq. in. (0.984 kg. per sq. cm.)

Adjustable Drawbar.—A drawbar, adjustable for height and hinged

to provide lateral movement if required, is mounted accessibly

beind the rear axle housing at the centre.

Rear Towing Attachment.—Industrial Tractor. Automatic coupling

‘mounted on laminated transverse leaf spring, carried on channel

iron frame.

INSTRUCTION MANUAL

aos

Figure 4

Industrial Tractor

ere

seeteyeoaiee ——

FORDSON Major _ a

Relt Pulley Drive, having either a fixed drive or @ control lever,

Permitting the drive to the pulley to be disconnected at will,

may be fited. Diameter of pulley 94 in (24.13 om.) fabric type,

oF 9f in, (24.76 em.) castiron type, operating at engine speed,

giving belt speed of 2,984 ft (604.7 m,) per minute for each type,

Power Take-off Shaft above draw-bar at rear centre of axle operates,

at $74 p.m. for 1,200 rpm. of engine, clockwise rotation,

6 splines, x} in, (34.92 mm.) dia. (optional equipment : not

avaiable for Industrial “Tractor.

Hydraulic Power Lift.—Power take-off from top of gearbox, driving

self-contained pump unit and lift, hand lever contrel (extra

equipment. Not fitted to Industrial Tractors).

Wiectrical System (Extra equipment: standard on Industrial

Tractor)—12, volt, two-brush generator, belt-driven from

crankshaft pulley, with automatic current control by regulator

unit. Battery mounted on dash panel above gearbox, starter

fitted on left-hand side of engine wich solenoid switch controlled

from dash or starter, lamps and horn,

Weight.—Agricultural Tractor, with spade lugs, 4340 Ibs. (1968 ke.)

ADPrOX.

Land Utility Tractor, 4214 Ibs. (2911 kg.) approx,

‘Row Crop Tractor, with spade lugs, 4368 Ibs. (2981 kg.)

approx.

Above weights are less driver, but with water and oil,

Welght.— Industrial Tractor, less driver, water, oil and fuel, but including

tools, wheel weights and ballast, 2 tons, 13 eWwts. 3 qts. (2730 kg)

approx.

Weight for Taxation.—Over 2 tons. (2032 kg.)

Dimensions.—Wheelbase, 77 ins. (195.58 em.); diameter of front wheel,

30 ins. (762.em.); width of rear rims, 9 ins. (22.86 cm.) (Row Crop.

44 ins.) (11.43 cm.) width of extension rim 4} ins. (11.43 om.)3

diameter of rear rim 45 ins. (114.3 om) (spade lugs additional).

Overall length of tractor 133 ins. (337.8 cin.) overall width 65 ins,

(165.1 em.) 774 ins. (196.85 cm.) with extension rims less spade

lugs, overall height, 82 ins. (208.28 cm). Ground clearance at

front axle, 17} ins. (44.45 cm.), pneumatics, 163 ins. (41.59 em.)

steel wheels. “Ground clearance at engine, 19 ins. (48.26 em.)

steel wheels, or 22} ins. (57.63 cm.) on pneumatics. "Height of

drawbar from ground, stel wheels 114 ins. (29.21 cm.) minimum,

14h ins. (37.78 cm.) maximum ; pneumatic tyres, 16). ins

(1.38 cm) minimum, 19% in. (49.8 cm.) maximum. Taming

rele 26 ft. (7.92 m.) ar ft. (6.4 m.)—with brakes in operation,

4 With Pneumatics 4062 Ibs. (1842 ke).

2 INSTRUCTION MANUAL

.—Industrial Tractor —Overall length, 10 ft. 8} ins,

(G364 em.); overall width, 5 ft.6 ins, (167.6 cm,); overall

Height, 7 &.'4 ins. (223.5 cm). Ground clearance at silencer,

2 ins. Go.4 cm.) approx. Height at coupling, 184 ins. (47 cm.)

approx. Turning circle, 26 ft. (7.92 m.)

‘Tootbox.—Beneath seat with full equipment of tools. On left side of

‘engine when Hydraulic Power Lift is fitted and on Industrial

Tractor.

Location of Engine Number.—Front end of cylinder block on

right-hand side between No. 1 cylinder exhaust port and inlet

port.

Important Instructions for

Operators

1. The importance of adequate and correct lubrication cannot be

too strongly impressed on tractor drivers. ‘The correct grades of oil

‘must be used in the engine and transmission. The oil should be main-

tained at the proper level at all times and changed frequently. Keep

the strainers in the oil filler and bottom of the crankcase clean and in

good condition. Clean oil will protect the engine bearings, minimise

‘Wear on all engine parts, and cut down sparking plug trouble

2, The worst abuse shat can be given the tractor is racing the

‘engine. Drivers must avoid this at all times. The proper speed to

Fun the engine is 1,200 revolutions per minute. ‘The tractor is equipped

With a governor which can be set to give the correct speed to suit

‘operating conditions. The manual control permits the speed to be

adjusted by the operator to the desired figure immediately. A throtle

control is fitted beneath the steering wheel on Industral ‘Tractors and

acts directly on the carburettor, without any governor device. “When

the engine is idling cut the speed down as low as possible and retard

{ignition (ignition lever up). When starting do not race the engine to

heat up the manifold quickly. This is destructive to the tractor and

will not sccomplish your purpose,

3, Do not allow the engine to labour, but change to a lower gear

immediately it shows signs of doing so.

4- It is very important that the correct oil level is maintained in

the air cleaner of the oil bath type. If it is not kept cleaned and filled

to the oil level mark with engine oil, dire and grit will be drawn into the

cylinders, resulting in premature wear of pistons, rings and cylinders

and loss of power. Never operate this type of air cleaner with the oil

‘container empty.

FORDSON MAJOR _ _3

‘The dry, gauze type air filter should be cleaned approximately

every three months, see page 69.

5. The Drawbar or coupling is provided for your convenience in

hitching. Always hitch to this and do not hitch a chain or rope round

the rear axle housing under any circumstances. When pulling a heavy

load, or when the tractor is travelling on very soft ground where there

may be a tendency for the wheels to sink and dig in, be sure to Keep

your foot adjacent to the clutch pedal. If the tractor should become

‘bogged, always pull out in first gear. Do not attempt to pull tree stumps

‘out of the ground or do any similar work which may bring the tractor

to a sudden stop.

6. Do not race the engine and let the clutch in suddenly, this

‘may lift the front end of the tractor off the ground. Should this happen,

release the clutch immediately—this will bring the front wheels back

to the ground at once.

‘The clutch pedal should always be depressed when using. the

starter motor. Not only does this reduce the oil drag from the gearbox,

‘but it also isolates any of the various drives such as the pulley drive,

‘power take-off shaft or hydraulic lift drive should these not have been

returned to the neutral position.

7. Do not atterapt 10 engage or disengage gears until the clutch

pedal has been pushed down far enough to release the clutch fully.

‘Alvways allow the clutch pedal to engage gradually, so taking up the

drive smoothly. Do not, however, slip” the clutch when the tractor

is in motion, as this damages the clutch disc and clutch as a whole.

‘When changing gear, ifthe clutch is not properly disengaged, the teeth

‘on the gears will not mesh readily, and there is danger of breaking off the

‘edges of the teeth so that in time they will not remain in mesh. Always

reduce the speed of the engine when changing gear.

8. Do not run the tractor downhill with the gears in neutral or

with the clutch released. Engage either first or second gear and use

the governor or throttle lever to control the speed of the engine. To

bring the tractor to complete stop, declutch and apply the hand brake,

tis good practice to lift the paw! from the ratchet when pulling “ on”

the handbrake as this saves wear on these parts. When the footbrake

pedals are fitted the tractor wheels may be locked by frst engaging the

Jatch which locks both pedals together and then pressing down the pedals

to apply the brakes. When firmly applied, engage the pawl which will

then enter one of the serrations of the sector (see also page 20 and Fig. 8).

9. Remember that a new tractor requires more careful attention

during the first few days it is being driven, than after the parts have

become thoroughly “ run in.” The tractor which is driven carefully

‘when new gives the most satisfactory service in the end. See that the

4 INSTRUCTION MANUAL

tractor has plenty of oil and water before starting work, If the tractor

is left in the open overnight, see that itis properly covered and drain the

radiator if there is any likelihood of frost. ‘The radiator drain tap is

beneath the radiator, 10 the left-hand side, See Fig. 9. When the tap

is opened to drain the radiator, itis good practice to probe the passage

‘when the flow of water ceases as sediment or some foreign matter may

cause a blockage, thus it may appear that the system is empty when in

fact water may be trapped. "Nothing will shorten the life of the tractor

‘more than being left exposed to the weather. INSPECT THE TRAC-

TOR DAILY AND SEE THAT ALL BOLTS AND NUTS ARE

TIGHT AND THAT THERE ARE NO OIL LEAKS, Make a

practice of taking care of each repair and adjustment as soon as its

necessity is discovered ; this attention requires but lite time and

may avoid delay or accident. When the tractor is delivered it is in

pproper mechanical adjustment. After it has been worked it is plainly

the duty of the owner to see that it is kept in that condition.

to. If a noise develops in the engine or transmission, it is im-

portant that the cause be investigated at once and corrected. If not

Corrected it may become more pronounced, thereby causing lack of

power and tending to shorten the life of the tractor. Do not continue

fo operate the tractor when the engine fires only on two or three

cylinders, ‘This, besides causing loss of power and wasting fuel, will

allow unburnt fuel to get into the crankcase, thinning the lubricating.

oil, and accelerating wear.

11. Full use should be made of the radiator blind. When starting

the tractor pull the blind up to the fullest extent and on no account

should vapourizing oil be admitted until the engine is hot enough to

vvapourize the fuel completely,

12, The blind should be adjusted during work so that the cooling.

‘water is at least 80°C. or 176°F., preferably just below boiling point.

‘The calormeter fitted to the radiator indicates the temperature

of the cooling water by means of an indicator needle. For efficent

operation, Keep the blind so adjusted that the needle of the circular-

type calormeter is within the white-coloured sector, and with the pillar-

type calormeter the red and white sections must be centrally positioned

in the aperture.

13, Do not run with the mixture richer than necessary. A ri

mixture wastes fuel, forms carbon, dilutes the lubricating oil and gives

inferior results.

14. When electrical equipment is fitted there is the possibility

that the battery may freeze in extremely severe conditions of frost,

v7

FORDSON MAJOR 15

particularly if it is not fully charged or the electrolyte specific gravity

{snot correct. Suitable precautions must be taken to obviate damage

bby such freezing which can resultina cracked container and ifthe Tractor

has to be out of use under conditions of severe frost for some time,

the battery should be removed for proper storage.

15. Do restrict the speed of the tractor when implements

are in the fully raised position, with hydraulic equipment. Severe

shock loading can be imposed on the hydraulic pump and lift mechanism,

possibly causing damage, if implements, when raised, are subjected 10

bumps caused by driving too fast over uneven surfaces.

IN CASE OF DIFFICULTY CONSULT YOUR

FORDSON DEALER.

Controls

‘The Choke Control is located on the extreme right of the dash,

Ic is pulled out to enrich the mixture when starting.

‘The Governor Control is placed immediately above the choke

‘control and controls the speed of the engine, It may be set in any

desired position by means of a ratchet, To increase the engine speed,

ppull the control out.

‘The Throttle Lever on Industrial Tractors is on the right-hand

side underneath the steering wheel. To open the throttle, move the

lever downwards, ie., towards the driver.

‘The Ignition Control Lever which is located to the left of the

governor control serves two purposes :—

3. To advance and retard the timing of the spark which ignites

the combustible mixture in the cylinders.

2. To stop the engine by earthing the primary current of the

‘magneto.

When the tractor is running, the ignition control lever should be

moved down to the stop, which is the fully advanced position. When-

cever heavy pulling causes the engine to pink” the ignition should be

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lister LDDocument39 pagesLister LDferal860100% (3)

- Dellorto ManualDocument34 pagesDellorto Manualmarkintosh44100% (16)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Clayton Dewandre HSR1/950Document1 pageClayton Dewandre HSR1/950feral860No ratings yet

- Royal EnfieldDocument19 pagesRoyal Enfieldferal860No ratings yet

- Loc NPB Europe 11-2010Document12 pagesLoc NPB Europe 11-2010Tung Nguyen XuanNo ratings yet

- Directory of Agricultural Machinery ManufacturersDocument55 pagesDirectory of Agricultural Machinery ManufacturersadhinayakgoharNo ratings yet

- Project C ProposalDocument14 pagesProject C ProposalRobertson MeroNo ratings yet

- Agro-Based Industries PDFDocument4 pagesAgro-Based Industries PDFKaran PatelNo ratings yet

- Land Preparation Machineries Used in AgricultureDocument47 pagesLand Preparation Machineries Used in Agriculturejanurtpat0% (1)

- Defects of Farm Tool and RemediesDocument5 pagesDefects of Farm Tool and RemediesAbela Jazen Jacob100% (1)

- Unit 7 Agriculture NotesDocument18 pagesUnit 7 Agriculture Notesm.furqanullahNo ratings yet

- SDF Quick Reference Product Spec Positioning - 04 - 10Document20 pagesSDF Quick Reference Product Spec Positioning - 04 - 10Lacatusu MirceaNo ratings yet

- Country Presentation Paper - India: Dr. Surendra SinghDocument25 pagesCountry Presentation Paper - India: Dr. Surendra SinghArpit KastureNo ratings yet

- Fendt 900 Vario Edition Electrical DiagramDocument4 pagesFendt 900 Vario Edition Electrical Diagramjennifer100% (56)

- Buhler Quick HitchDocument4 pagesBuhler Quick Hitchsunilbhol0% (1)

- Pulses PDFDocument219 pagesPulses PDFVara Prasad Raju PNo ratings yet

- HE Transmissions PDFDocument13 pagesHE Transmissions PDFlahcen boudaoud100% (1)

- DONALDSON Caterpillar Vehicle CardDocument151 pagesDONALDSON Caterpillar Vehicle CardAgus Yulfizar100% (1)

- Zetor 4712Document81 pagesZetor 4712SalisburNo ratings yet

- MechanizationBaselineResearchReportfinalElsa 2021 PDFDocument81 pagesMechanizationBaselineResearchReportfinalElsa 2021 PDFLeulNo ratings yet

- List of Empanelled 2022 23Document26 pagesList of Empanelled 2022 23Alok Singh DangiNo ratings yet

- Pib - Gov.in-Schemes For Welfare of FarmersDocument12 pagesPib - Gov.in-Schemes For Welfare of Farmersvinit bhartiNo ratings yet

- Experiences of Farmers in Using Modern Agricultural Types of Machines in The PhilippinesDocument44 pagesExperiences of Farmers in Using Modern Agricultural Types of Machines in The PhilippinesAngela Stacey Talens100% (1)

- K To 12 Crop Production Learning ModulesDocument124 pagesK To 12 Crop Production Learning Modulesjazzy mallariNo ratings yet

- Eoi Information On Iihr Horticultural Macinery May 2019 - 1575864134 - 0Document13 pagesEoi Information On Iihr Horticultural Macinery May 2019 - 1575864134 - 0Viji ShreeNo ratings yet

- Design & Construction of A Soil Cultivation Tractor For Small Scale Farming1Document10 pagesDesign & Construction of A Soil Cultivation Tractor For Small Scale Farming1Kibrom MenasboNo ratings yet

- Blu BerryDocument9 pagesBlu BerryDarshan BhalaniNo ratings yet

- Primena Application: Belarus DeutzDocument6 pagesPrimena Application: Belarus DeutzDragan LazicNo ratings yet

- The Evolution of Farming MachineryDocument3 pagesThe Evolution of Farming MachinerySujan ChapagainNo ratings yet

- Organizational Study at Kamco-RaheesDocument59 pagesOrganizational Study at Kamco-RaheesRAHEES100% (3)

- Economic History of Kerala From 1800 To 1947 Ad: Part I: MalabarDocument68 pagesEconomic History of Kerala From 1800 To 1947 Ad: Part I: Malabarvishnu.hNo ratings yet

- Agricultural Building and StructureDocument5 pagesAgricultural Building and StructureNick ivan Alvares100% (1)

- Assignment 1 Slide - Nur Alia Najwa Binti Mohd Sakri (2020462342)Document30 pagesAssignment 1 Slide - Nur Alia Najwa Binti Mohd Sakri (2020462342)Alia najwaNo ratings yet

- Agro DataDocument52 pagesAgro DataPreeti Jaiswal0% (1)