Professional Documents

Culture Documents

Sulfuric Acid

Sulfuric Acid

Uploaded by

chikukotwalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulfuric Acid

Sulfuric Acid

Uploaded by

chikukotwalCopyright:

Available Formats

R8.

4 Industrial Example of Nonadiabatic Reactor

Operation: Oxidation of Sulfur Dioxide

R8.4.1 Manufacture of Sulfuric Acid

In the manufacture of sulfuric acid from sulfur, the rst step is the burning of

sulfur in a furnace to form sulfur dioxide:

Following this step, the sulfur dioxide is converted to sulfur trioxide, using a

catalyst:

A owsheet of a typical sulfuric acid manufacturing plant is shown in Figure

A8-1. It is the converter that we shall be treating in this section.

Although platinum catalysts once were used in the manufacture of sulfu-

ric acid, the only catalysts presently in use employ supported vanadia.

12

For

our problem, we shall use a catalyst studied by Eklund, whose work was ech-

oed extensively by Donovan

13

in his description of the kinetics of oxida-

tion. The catalyst studied by Eklund was a Reymersholm catalyst

deposited on a pumice carrier. The cylindrical pellets had a diameter of 8 mm

and a length of 8 mm, with a bulk density of 33.8 lb/ . Between 818 and

1029

F, the rate law for oxidation over this particular catalyst was

(R8.4-1)

in which was the partial pressure of species

i.

This equation can be used

when the conversion is greater than 5%. At all conversions below 5%, the rate

is essentially that for 5% conversion.

Sulfuric acid manufacturing processes use different types of reactors.

Perhaps the most common type has the reactor divided into adiabatic sections

with cooling between the sections (recall Figure 8-8). One such layout is

shown in Figure R8.4-2. In the process in Figure R8.4-2, gas is brought out of

the converter to cool it between stages, using the hot converter reaction mix-

ture to preheat boiler feedwater, produce steam, superheat steam, and reheat

the cold gas, all to increase the energy efciency of the process. Another type

has cooling tubes embedded in the reacting mixture. The one illustrated in Fig-

ure A8-3 uses incoming gas to cool the reacting mixture.

A typical sulfuric acid plant built in the 1970s produces 1000 to 2400 tons

of acid/day.

14

Using the numbers of Kastens and Hutchinson,

15

a 1000-ton/day

12

G. M. Cameron,

Chem. Eng. Prog., 78

(2), 71 (1982).

13

R. B. Eklund, Dissertation, Royal Institute of Technology, Stockholm, 1956, as quoted

by J. R. Donovan, in

The Manufacture of Sulfuric Acid,

ACS Monograph Series 144,

W. W. Duecker and J. R. West, eds. (New York: Reinhold, 1959), pp. 166168.

14

L. F. Friedman,

Chem. Eng. Prog.,

78

(2), 51 (1982).

15

M. L. Kastens and J. C. Hutchinson,

Ind. Eng. Chem., 40,

1340 (1948).

S O

2

SO

2

SO

2

1

2

--- O

2

SO

3

V

2

O

5

SO

2

V

2

O

5

ft

3

SO

2

r

SO

2

k

P

SO

2

P

SO

3

---------- P

O

2

P

SO

3

K

p

P

SO

2

-----------------

( ,

, (

j \

2

P

i

An ow rate

of 0.241 mol /s over

132.158 lb of

catalyst can

produce 1000 tons

of acid per day.

SO

2

126

Chap.

F

i

g

u

r

e

R

8

.

4

-

1

F

l

o

w

s

h

e

e

t

o

f

a

s

u

l

f

u

r

i

c

a

c

i

d

m

a

n

u

f

a

c

t

u

r

i

n

g

p

r

o

c

e

s

s

.

[

R

e

p

r

i

n

t

e

d

w

i

t

h

p

e

r

m

i

s

s

i

o

n

o

f

t

h

e

A

I

C

h

E

a

n

d

L

.

J

.

F

r

i

e

d

m

a

n

.

C

o

p

y

r

i

g

h

t

1

9

8

2

A

I

C

h

E

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

]

Sec. R8.4 Industrial Example of Nonadiabatic Reactor Operation: Oxidation of Sulfur Diox-

sulfuric acid plant might have a feed to the converter of 7900 lb mol/h,

consisting of 11% , 10% , and 79% inerts (principally ). We shall use

these values.

For preliminary design purposes, we shall calculate the conversions for

two situations and compare the results. Only one of the situations will be pre-

sented in detail in this example.

1. The rst situation concerns two stages of a typical commercial adia-

batic reactor. The principles of calculating the conversion in an adia-

batic reactor were covered earlier and illustrated in Section 8.3, so

will not be presented here but as a problem at the end of the chapter.

2. The second case concerns a reactor with the catalyst in tubes, with the

walls cooled by a constant-temperature boiling liquid. Calculations

for this system are presented in detail next.

R8.4.2 Catalyst Quantities

Harrer

16

states that the volumetric ow rate in an adiabatic converter,

measured at normal temperature and pressure, customarily is about 75 to 100

16

T. S. Harrer, in

Kirk-Othmer Encyclopedia of Chemical Technology,

2nd ed., Vol. 19

(New York: Wiley-Interscience, 1969), p. 470.

Figure R8.4-2

Sulfur dioxide converter with internal cooling between catalyst

layers. [Reprinted with permission of Barnes & Noble Books.]

SO

2

SO

2

O

2

N

2

SO

2

128

Chap.

/ of converter area. He also states that the catalyst beds in the con-

verter may be from 20 to 50 in. deep.

It is desirable to have a low mass velocity through the bed to minimize

blower energy requirements, so the 75 / value will be used. Normal

conversions in adiabatic converters are 70% in the rst stage and an additional

18% in the second.

17

Using Eklunds Reymersholm catalyst, solution of the adi-

abatic reactor problem at the end of the chapter shows that these conversions

require 1550 (23 in. deep) in the rst stage and 2360 (35 in. deep) in the

second. As a result, in our cooled tubular reactor, we shall use a total catalyst

volume of 3910 .

R8.4.3 Reactor Conguration

The catalyst is packed in tubes, and the tubes are put in heat exchangers where

they will be cooled by a boiling liquid. The outside diameter of the tubes will

be 3 in. Severe radial temperature gradients have been observed in oxida-

tion systems,

18

although these systems had platinum catalysts and greatly dif-

ferent operating conditions than those being considered here. The 3-in.

diameter is chosen as a compromise between minimizing temperature gradi-

17

J. R. Donovan and J. M. Salamone, in

Kirk-Othmer Encyclopedia of Chemical Tech-

nology,

3rd ed., Vol. 22 (New York: Wiley-Interscience, 1978), p. 190.

18

For example, R. W. Olson, R. W. Schuler, and J. M. Smith,

Chem Eng. Prog., 46

, 614

(1950); and R. W. Schuler, V. P. Stallings, and J. M. Smith,

Chem. Eng. Prog. Symp.

Ser. 48

(4), 19 (1952).

Figure R8.4-3 Sulfur dioxide converter with catalyst cooled by incoming reaction

mixture. [Reprinted with permission of Barnes & Noble Books.]

ft

3

min ft

2

ft

3

min ft

2

ft

3

ft

3

ft

3

Optimizing capital

and operating costs

SO

2

Sec. R8.4 Industrial Example of Nonadiabatic Reactor Operation: Oxidation of Sulfur Diox-

ents and keeping the number of tubes low. For this service, 12-gauge thickness

is specied, which means a thickness of 0.109 in. and an inside diameter of

2.782 in. A 20-ft length will be used, as a compromise between decreasing

blower energy requirements (shorter tube length) and lowering capital costs

(fewer tubes from a longer tube length). For 3910 of catalyst, the number

of tubes that will be required is

The total cross-sectional area of the tubes is

The overall heat-transfer coefcient between the reacting gaseous mixture and

the boiling coolant is assumed to be 10 Btu/ . This coefcient is toward

the upper end of the range of heat-transfer coefcients for such situations as

reported by Colburn and Bergelin.

19

R8.4.4 Operating Conditions

Sulfur dioxide converters operate at pressures only slightly higher than atmo-

spheric. An absolute pressure of 2 atm will be used in our designs. The inlet

temperature to the reactor will be adjusted so as to give the maximum conver-

sion. Two constraints are present here. The reaction rate over catalyst is

negligible below , and the reactor temperature should not exceed

at any point.

20

A series of inlet temperatures should be tested, and the

one above 760 giving the maximum conversion, yet having no reactor tem-

perature exceeding 1120 , should be used.

The cooling substance should operate at a high temperature so as to

improve thermal efciency by reuse of heat. The most suitable substance

appears to be Dowtherm A, with a normal operating limit of but which

on occasion has been used as the coolant in this preliminary design.

21

Example R8.41 Oxidation of

SO

2

The feed to an converter is 7900 lb mol/h and consists of 11% , 10% ,

and 79% inerts (principally ). The converter consists of 4631 tubes packed with

catalyst, each 20 ft long. The tubes are 3 in. o.d. and 2.782 in. i.d. The tubes will be

19

Colburn and Bergelin, in

Chemical Engineers Handbook

; 3rd ed. (New York:

McGraw-Hill, 1950).

20

J. R. Donovan and J. M. Salamone, in

Kirk-Othmer Encyclopedia of Chemical Tech-

nology, 3rd ed. (New York: Wiley, 1984).

21

The vapor pressure of Dowtherm A at is very high, and this pressure would

have to be maintained in the shell side of the reactor for boiling Dowtherm A to be

used as a coolant at this temperature. This aspect will be included in the discussion of

the problem results.

ft

3

N

t

volume of catalyst

volume per tube

--------------------------------------------

3910

20 ( ) ( ) 2.782 12 ( )

2

/4

----------------------------------------------------- 4631 tubes

A

c

3910 ft

3

20 ft

------------------- 195.5 ft

2

h ft

2

F

V

2

O

5

~750F

~1125F

F

F

~750F

805F

SO

2

SO

2

O

2

N

2

130 Chap.

cooled by a boiling liquid at 805F, so the coolant temperature is constant over this

value. The entering pressure is 2 atm.

For inlet temperatures of 740 and 940F, plot the conversion, temperature, equi-

librium conversion, and reaction rate prole down the reactor.

Additional information:

Using recent JANAF

22

values of at 700 and 900 K, the equilibrium constant at

any temperature T is

(ER8.4-1)

at 1600R,

For rate constants, the data of Eklund

23

can be correlated very well by the equation

(ER8.4-2)

where k is in lb mol /lb and T is in R.

There are diffusional effects present in this catalyst at these temperatures, and

Equation (E8-10.2) should be regarded as an empirical equation that predicts the

effective reaction rate constant over the range of temperatures listed by Donovan (814

to 1138F). The JANAF tables were used to give the following:

where is in Btu/lb and T in R.

22

D. R. Stull and H. Prophet, Project Directors, JANAF Thermochemical Tables, 2nd

ed., NSRDS-NBS 37 (Washington, D.C.: U.S. Government Printing Ofce, 1971).

23

R. B. Eklund, as quoted by J. R. Donovan, in W. W. Duecker and J. R. West, The

Manufacture of Sulfuric Acid (New York: Reinhold, 1959).

0.45

0

0.054 lb/ft

3

P

0

2 atm

D

p

0.015 ft

0.090 lb/ft h at 1400 R

U 10 Btu/h ft

2

R

A

c

0.0422 ft

2

T

0

1400

R (also

T

0

1200 R)

g

c

4.17 10

8

lb

m

ft/ lb

f

h

2

b

33.8 lb/ft

3

(bulk density)

K

p

K

p

42,311

RT

---------------- 11.24

( ,

, (

j \

exp K

p

in atm

1 2

T in R , ( )

K

p

7.8 atm

1 2

k

176,008

T

------------------------ 110.1 T ln ( ) 912.8 exp

SO

2

cat. s atm

Kinetic and

thermodynamic

properties

H

Rx

800F ( ) 42,471 Btu/lb mol SO

2

C

p

SO

2

7.208 5.633 10

3

T 1.343 10

6

T

2

C

p

O

2

5.731 2.323 10

3

T 4.886 10

7

T

2

C

p

SO

3

8.511 9.517 10

3

T 2.325 10

6

T

2

C

p

N

2

6.248 8.778 10

4

T 2.13 10

8

T

2

C

p

mol R

Sec. R8.4 Industrial Example of Nonadiabatic Reactor Operation: Oxidation of Sulfur Diox-

Solution

1. General procedure:

a. Apply the plug-ow design equation relating catalyst weight to the rate of

reaction and conversion. Use stoichiometric relationships and feed speci-

cations to express the rate law as a function of conversion.

b. Apply the energy balance relating catalyst weight and temperature.

c. Using the Ergun equation for pressure drop, determine the pressure as a

function of catalyst weight.

d. State property values [e.g., k, , , ] and their respective

temperature dependences necessary to carry out the calculations.

e. Numerically integrate the design equation, energy balance, and Ergun equa-

tion simultaneously to determine the exit conversion and the temperature

and concentration proles.

2. Design equations. The general mole balance equations (design equations) based

on the weight of catalyst were given in their differential and integral forms by

3. Rate law:

4. Stoichiometric relationships and expressing as a function of X:

We let A represent and be the stoichiometric coefcient for species i:

(ER8.4-3)

Substituting for partial pressures in the rate law and combining yields

(ER8.4-4)

where , atm, , , , and

; lb mol/h, and lb mol/h.

Per tube:

Weight of catalyst in one lb cat. /tube

K

p

H

Rx

T

R

( ) C

P

i

F

A0

dX

dW

-------- r

A

r

SO

2

k

P

SO

2

P

SO

3

---------- P

O

2

P

SO

3

K

p

P

SO

2

-----------------

( ,

, (

j \

2

r

SO

2

SO

2

1

2

--- O

2

SO

3

A

1

2

---

B

C

SO

2

v

i

P

i

C

i

RT ( ) C

A0

i

v

i

X

( )

RT

( )

P

1

( )

T T

0

( ) P

0

-------------------------------------------- P

A0

i

v

i

X

( )

P

1

X

( ) P

0

------------------------------

dX

dW

--------

r

A

F

A0

----------

k

F

A0

--------

1 X

SO

3

X

----------------------

P

P

0

----- P

A0

O

2

1

2

---

X

1 X

----------------------

SO

3

X

1 X

----------------------

( ,

, (

j \

2

1

K

p

2

------

0.055 P

A0

0.22

SO

2

1.0

O

2

0.91

SO

3

0.0

N

2

7.17 F

T0

7900 F

A0

869

tube W

b

D

2

4 L 28.54

F

A0

869

4631

------------ 0.188 lb mol/h tube

132 Chap.

Substituting these values gives us

(ER8.4-5)

that is,

(ER8.4-6)

The limits of integration are from zero to the weight of catalyst in one tube,

28.54 lb.

5. Energy balance. For steady-state operation and no shaft work, Equation (8-56)

can be rewritten in terms of catalyst weight as the spatial variable, that is,

(ER8.4-7)

6. Evaluating the energy balance parameters:

Heat of reaction:

(ER8.4-8)

For the oxidation, ,

Similarly,

Substituting into Equation (ER8.4-8) with T

R

1260R, we have

Heat-transfer coefcient term:

(ER8.4-9)

The combined mole

balance, rate law,

and stoichiometry

dX

dW

--------

r

A

F

A0

---------- 5.32k

1 X

X

-------------

0.2 0.11X

1 0.055X

----------------------------

( ,

, (

j \

P

P

0

-----

X

1 X ( )K

p

------------------------

2

dX

dW

-------- f

1

X T P , , ( )

dT

dW

--------

4U/

b

D ( ) T

a

T ( ) r

A

( ) H

Rx

T ( ) [ ]

F

A0

i

C

P

i

X C

P

( )

--------------------------------------------------------------------------------------------------

H

Rx

T ( ) H

Rx

T

R

( ) T T

R

( )

2

------- T

2

T

R

2

( )

3

------- T

3

T

R

3

( )

SO

2

SO

2

1

2

--- O

2

SO

3

SO

3

1

2

---

O

2

SO

2

8.511 0.5 ( ) 5.731 ( ) 7.208 1.563

0.00262 and 0.738 10

6

H

Rx

T ( ) 42,471 1.563 ( ) T 1260 ( ) 1.36 10

3

( ) T

2

1260

2

( )

2.459 10

7

( ) T

3

1260

3

( )

i

C

P

i

57.23 0.014T 1.94 10

6

T

2

UD

b

A

c

-------------

4U

b

D

----------

4 10 Btu/ h ft

2

R ( )

33.8 lb/ft

3

( ) 2.78/12 ( ) ft [ ]

--------------------------------------------------------------

5.11 Btu/h lb cat R

Energy balance

dT

dW

--------

5.11 T

a

T ( ) r

A

( ) H

Rx

T ( ) [ ]

0.188

i

C

P

i

X C

P

( )

------------------------------------------------------------------------------------

Sec. R8.4 Industrial Example of Nonadiabatic Reactor Operation: Oxidation of Sulfur Diox-

that is,

(ER8.4-10)

7. Pressure drop: After rearranging Equation (4-23), the pressure drop is given by

where

Recalling that , we obtain

(ER8.4-11)

8. Evaluating the pressure-drop parameters:

Substituting in Equation (ER8.4-11), we get

(ER8.4-12)

We wish to obtain an order-of-magnitude estimate of the pressure drop. To

obtain this estimate, we consider the reaction to be carried out isothermally

with ,

Integrating with limits atm at and at lb of cat-

alyst yields

Because the gas-phase viscosity is a weakly varying function of temperature

(i.e., ), we shall consider viscosity to be independent of temperature:

dT

dW

-------- f

2

T P X , , ( )

Momentum balance

dP

dz

------

1 ( )G 1 X ( )

0

P P

0

( ) T

0

T ( ) g

c

D

p

3

------------------------------------------------------------

150

1

( )

D

p

------------------------------- 1.75G

G

F

i0

M

i

A

c

------------------- M

i

molecular weight of i ( )

1307.6 lb/ft

2

h

A

c

cross-sectional area D

2

4

W

b

A

c

z

dP

dW

--------

GTP

0

1 ( ) 1 X ( )

b

A

c

0

T

0

PD

P

g

c

3

------------------------------------------------------

150 1

( )

D

P

------------------------------- 1.75G

f

3

X T P , , ( )

GTP

0

1 ( ) 1 X ( )

b

A

c

0

T

0

3

D

P

g

c

P

------------------------------------------------------

150 1

( )

D

P

------------------------------- 1.75G

dP

dW

--------

1.12 10

8

1 0.55X ( )T

P

-------------------------------------------------------------------- 5500 2288 ( )

0

dP

dW

--------

0.0432

P

---------------------

Back-of-the-

envelope

calculation for P

P

0

2 W 0 P P W 28.54

P

2

4

2

--------------- 0.0432 0 28.54 ( )

P 1.239 atm

P 2 1.24 0.76 atm

T

134

Chap.

(ER8.4-13)

9.

Solution procedure

. There are three coupled differential equations that must

be solved simultaneously:

Mole balance: (ER8.4-14)

Energy balance: (ER8.4-15)

Momentum balance: (ER8.4-16)

10.

Numerical procedure

. The rate equation is independent of conversion

between

X

0.0 and

X

0.05, and the rate of disappearance of over this

range is equal to the rate of reaction at

X

0.05:

(ER8.4-17)

a. Set , , and .

b. Calculate

k

from Equation (ER8.4-2).

c. Calculate from Equation (ER8.4-1).

d. If , calculate from Equation (ER8.4-17). If , use

Equation (ER8.4-5).

e. Calculate

X

,

T

, and

P from a numerical solution to Equations (ER8.4-5),

(ER8.4-9) and (ER8.4-12).

The Polymath program is given in Table ER8.4-1.

11. Discussion of results. Figures ER8.4-1.1(a) and (b) show the proles for inlet

temperatures of 1200R and 1400R, respectively. Only 68.5% conversion is

achieved for 1200R, even though 0.99. For an entering tempera-

ture of 1400R, the major portion of the reaction takes place in the rst 6 ft of

the reactor. At this point, the conversion is 0.81, with only another 0.06 of the

conversion occurring in the remaining 14 ft, as shown in Figure ER8.4-1.1(b).

The cause of this low amount of conversion in the nal 14 ft is the steadily

dropping temperature in the reactor. Beyond the 6-ft point, the temperature is

too low for much reaction to take place, which means that the reactor is

cooled too much.

This detrimental situation indicates that the coolant temperature is too low

for obtaining maximum conversion. Thus even boiling Dowtherm A at its

highest possible operating temperature is not a suitable coolant. Perhaps a gas

would give a better performance as a coolant in this reaction system. Two

problems at the end of the chapter pursue this aspect. One of them seeks the

optimum coolant temperature for a constant-coolant-temperature system, and

the other uses inlet gas as a coolant.

dP

dW

-------- f

3

T P X , , ( )

dX

dW

-------- f

1

T P X , , ( )

The coupled

differential

equations to be

solved with an ODE

solver

dT

dW

-------- f

2

T P X , , ( )

dP

dW

-------- f

3

T P X , , ( )

SO

2

r

SO

2

k 0.848

0.012

K

p

2

-------------

( ,

, (

j \

X 0.00 T T

0

P P

0

K

p

X 0.05 r

SO

2

X 0.05

T

0

X

e

Sec. R8.4 Industrial Example of Nonadiabatic Reactor Operation: Oxidation of Sulfur Diox-

TABLE ER84-1 SO

3

OXIDATION POLYMATH PROGRAM

Equations:

Figure ER8.4-1.1(a) Conversion,

temperature, and equilibrium conversion

proles within the reactor: (a) inlet

temperature at 1200R; (b) inlet

temperature at 1400R.

Figure ER8.4-1.1(b) Conversion,

temperature, and equilibrium conversion

proles within the reactor: (a) inlet

temperature at 1200R; (b) inlet

temperature at 1400R.

136 Chap.

Another possible way to operate such a reactor is to use multiple-stage operation

with progressively higher coolant temperatures. Because pressure drop over the

reactor is small (0.7 atm), neglecting the pressure drop does not affect the exit

conversion signicantly (Figures ER8.4-1.1 or ER8.4-1.2)). The effect is more sig-

nicant at lower reactor inlet temperatures because the rate of reaction is apprecia-

ble over a longer portion of the reactor bed. At higher inlet temperatures, the

conversion is limited by the approach to equilibrium, and hence the pressure drop

has a negligible effect.

Figure ER84-1.2 Prole of molar ow rates F

A

, F

B

, and F

C

.

Analyzing the

effects of pressure

drop

Sec. R8.4 Industrial Example of Nonadiabatic Reactor Operation: Oxidation of Sulfur Diox-

You might also like

- HL740 9SDocument528 pagesHL740 9SAnonymous yjK3peI786% (7)

- Chbi502 Chapter 2Document24 pagesChbi502 Chapter 2Chau MaiNo ratings yet

- Lab With Index1Document35 pagesLab With Index1Labdhi ShahNo ratings yet

- Flue Gas Desulfurization TechnologiesDocument13 pagesFlue Gas Desulfurization Technologieshozipek5599No ratings yet

- HW Stoich1Document1 pageHW Stoich1Marie Angeline BautistaNo ratings yet

- Production of LABSADocument39 pagesProduction of LABSANaveen Kamat86% (7)

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsFrom EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengNo ratings yet

- 2000 Ifa Neworleans GobbitDocument14 pages2000 Ifa Neworleans GobbitFajar ZonaNo ratings yet

- Multiple Effect EvaporationDocument4 pagesMultiple Effect EvaporationDianne VillanuevaNo ratings yet

- Sulfuric Acid Manufacturing ProcessDocument5 pagesSulfuric Acid Manufacturing ProcessamirahabidinNo ratings yet

- Japan-Philippine Steel Manufacturing Corporation: Acid Fumes ScrubberDocument84 pagesJapan-Philippine Steel Manufacturing Corporation: Acid Fumes ScrubberLuis UrzoNo ratings yet

- 6 PDFDocument20 pages6 PDFMuhammadNo ratings yet

- Brauer 1981Document41 pagesBrauer 1981rodgerNo ratings yet

- Lecture 1 - Sulfur and Sulfuric AcidDocument9 pagesLecture 1 - Sulfur and Sulfuric AcidNayan HalderNo ratings yet

- Denox DesoxDocument20 pagesDenox DesoxArzu AkarNo ratings yet

- Sulphuric Acid Process Flow ChartDocument1 pageSulphuric Acid Process Flow ChartPoon CYNo ratings yet

- AlkyDocument37 pagesAlkyMỹ PhanNo ratings yet

- BTPDocument15 pagesBTPPARTH NAGARNo ratings yet

- Chemical Engineer: MATERIAL BALANCEDocument12 pagesChemical Engineer: MATERIAL BALANCEMuhammad AsifNo ratings yet

- Heat Transfer in Wiped Film EvaporatorsDocument4 pagesHeat Transfer in Wiped Film EvaporatorsAlexNo ratings yet

- Oxidation of Sulfur Dioxide Heterogeneous CatalystDocument13 pagesOxidation of Sulfur Dioxide Heterogeneous Catalysthafidz maNo ratings yet

- Sulfuric Acid - Wikipedia PDFDocument94 pagesSulfuric Acid - Wikipedia PDFrajesh indukuriNo ratings yet

- Briefs - Emergency Chlorine ScrubberDocument8 pagesBriefs - Emergency Chlorine ScrubberSher MuhammadNo ratings yet

- 3 Short Path DistillationDocument55 pages3 Short Path DistillationBhavin SolankiNo ratings yet

- Kinetic Studies of Ketazine Formation PDFDocument6 pagesKinetic Studies of Ketazine Formation PDFkamesh_che009100% (1)

- Phosphoric Acid PDFDocument24 pagesPhosphoric Acid PDFabderrahimnNo ratings yet

- Brochure 2021 Eka Chlorine Dioxide Generation SystemsDocument8 pagesBrochure 2021 Eka Chlorine Dioxide Generation SystemsirNo ratings yet

- Methanol - Material BalanceDocument3 pagesMethanol - Material BalanceAnonymous Ksq1dyPRhNo ratings yet

- Sulphur Line ExperiencesDocument17 pagesSulphur Line ExperiencesscaranoNo ratings yet

- REACTOR DESIGN - Docx Fyp MyDocument5 pagesREACTOR DESIGN - Docx Fyp Myabdul rehmanNo ratings yet

- FT&HXDocument55 pagesFT&HXKelvin TanNo ratings yet

- EvaporatorDocument21 pagesEvaporatormpromentilla100% (1)

- Lecture 3 - Chapter 2-Conversion - and Reactor SizingDocument42 pagesLecture 3 - Chapter 2-Conversion - and Reactor SizingNizam JumadiNo ratings yet

- Nitrogen Oxides Removal With Liquid SolutionsDocument10 pagesNitrogen Oxides Removal With Liquid SolutionsPravin PatilNo ratings yet

- Scrubber Design For Phosphoric Acid Production FacilityDocument57 pagesScrubber Design For Phosphoric Acid Production FacilityAndres Rodriguez Herrera100% (2)

- Adsorption Tower DesignDocument12 pagesAdsorption Tower DesignbabuyuvarajNo ratings yet

- Design of Gasifier System For Diesel Engine PPT FinaleDocument28 pagesDesign of Gasifier System For Diesel Engine PPT FinaleNitu ShresthaNo ratings yet

- Material and Energy BalanceDocument9 pagesMaterial and Energy BalanceSana100% (1)

- Cebu Institute of Technology: UniversityDocument10 pagesCebu Institute of Technology: UniversityArchie HisolerNo ratings yet

- Producción Del Ácido SulfúricoDocument102 pagesProducción Del Ácido SulfúricoLuis Diego Cardenas PadillaNo ratings yet

- Fouling in Phosphoric AcidDocument8 pagesFouling in Phosphoric AcidÖmer LaçinNo ratings yet

- Sulfuric Acid (H SO) IndustryDocument27 pagesSulfuric Acid (H SO) IndustryAqsa chNo ratings yet

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnDocument6 pagesKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnAshraf SeragNo ratings yet

- Types of GasifierDocument13 pagesTypes of GasifierMehul ZareNo ratings yet

- Developing and Using Stio Tables NotesDocument27 pagesDeveloping and Using Stio Tables NotesThabangNo ratings yet

- Sulphur VapoursDocument12 pagesSulphur VapoursAnvay Choudhary100% (1)

- Melt CrystallizationDocument10 pagesMelt Crystallizationarsh19706636No ratings yet

- Benitez Cap9Document44 pagesBenitez Cap9Srinivasa Rao VenkumahanthiNo ratings yet

- Reactor DesignDocument9 pagesReactor DesignKin Wai CheahNo ratings yet

- Appendix Flash DrumDocument2 pagesAppendix Flash DrumRodney Craft100% (1)

- Flash Tank PDFDocument19 pagesFlash Tank PDFMufita RamadhinaNo ratings yet

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- 7 - Sulfur & Sulfuric Acid TaughtDocument58 pages7 - Sulfur & Sulfuric Acid TaughtsahibjotNo ratings yet

- Ion Exchange For Dummies RHDocument9 pagesIon Exchange For Dummies RHDaverrrNo ratings yet

- Modern Spent-Caustic Wastewater Treatment Simulation by Aspen Plus in Electrolytic MediumDocument10 pagesModern Spent-Caustic Wastewater Treatment Simulation by Aspen Plus in Electrolytic MediumarmanNo ratings yet

- Tutorial SheetsDocument11 pagesTutorial SheetsKAMARAJU SAI VAMSHINo ratings yet

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Materials and Processes for CO2 Capture, Conversion, and SequestrationFrom EverandMaterials and Processes for CO2 Capture, Conversion, and SequestrationNo ratings yet

- Process Intensification Technologies for Green Chemistry: Engineering Solutions for Sustainable Chemical ProcessingFrom EverandProcess Intensification Technologies for Green Chemistry: Engineering Solutions for Sustainable Chemical ProcessingKamelia BoodhooNo ratings yet

- Beverage SCADADocument16 pagesBeverage SCADANaveen KamatNo ratings yet

- Lachrom Elite: Hitachi High-Performance Liquid ChromatographDocument10 pagesLachrom Elite: Hitachi High-Performance Liquid ChromatographNaveen KamatNo ratings yet

- hESC (Electronics)Document20 pageshESC (Electronics)Naveen KamatNo ratings yet

- Lactic Acid FermentationDocument13 pagesLactic Acid FermentationpreetibtNo ratings yet

- Alginate Coating of Xenopus Laevis Embryos: N. Kampf, C. Zohar, and A. NussinovitchDocument9 pagesAlginate Coating of Xenopus Laevis Embryos: N. Kampf, C. Zohar, and A. NussinovitchNaveen KamatNo ratings yet

- Air HeatersDocument34 pagesAir HeatersNaveen KamatNo ratings yet

- (A) Publication in OJ (B) To Chairmen and Members (C) (X) To Chairmen (D) No DistributionDocument20 pages(A) Publication in OJ (B) To Chairmen and Members (C) (X) To Chairmen (D) No DistributionNaveen KamatNo ratings yet

- Cadison P&id DesignerDocument4 pagesCadison P&id DesignerNaveen KamatNo ratings yet

- PDF Created With Pdffactory Trial VersionDocument2 pagesPDF Created With Pdffactory Trial VersionNaveen KamatNo ratings yet

- Lactic Acid FermentationDocument13 pagesLactic Acid FermentationpreetibtNo ratings yet

- Karnataka Global Agribusiness & Food Processing Summit'11: Sector Profile - SericultureDocument31 pagesKarnataka Global Agribusiness & Food Processing Summit'11: Sector Profile - SericultureNaveen KamatNo ratings yet

- Silk - Technology, Types, Market, Production, Processing, Projects, Machinery, Company ProfilesDocument3 pagesSilk - Technology, Types, Market, Production, Processing, Projects, Machinery, Company ProfilesNaveen KamatNo ratings yet

- Mid-Size EPC Reduces Cost Estimating Time Up To 90% To Meet Tighter Schedules and BudgetsDocument2 pagesMid-Size EPC Reduces Cost Estimating Time Up To 90% To Meet Tighter Schedules and BudgetsNaveen KamatNo ratings yet

- Sericulture ReportDocument47 pagesSericulture ReportNaveen Kamat100% (1)

- Sericulture Industry in India - A ReviewDocument27 pagesSericulture Industry in India - A ReviewNaveen Kamat100% (1)

- Bioconversion of Cinnamic Acid Pseudomonad: Microbial Production ofDocument5 pagesBioconversion of Cinnamic Acid Pseudomonad: Microbial Production ofNaveen KamatNo ratings yet

- Silk - Industry Technology Trade Project InformationDocument2 pagesSilk - Industry Technology Trade Project InformationNaveen KamatNo ratings yet

- Karnataka Global Agribusiness & Food Processing Summit'11: Sector Profile - SericultureDocument31 pagesKarnataka Global Agribusiness & Food Processing Summit'11: Sector Profile - SericultureNaveen KamatNo ratings yet

- PDF Created With Pdffactory Trial VersionDocument14 pagesPDF Created With Pdffactory Trial VersionNaveen KamatNo ratings yet

- Faq 4 Silkworm DiseasesDocument4 pagesFaq 4 Silkworm DiseasesNaveen KamatNo ratings yet

- Pilot PlantDocument7 pagesPilot PlantNaveen Kamat100% (1)

- Module Title: Bioreactor Design: CHEP 7001Document3 pagesModule Title: Bioreactor Design: CHEP 7001Naveen KamatNo ratings yet

- Biotechnology Handbook by Niir Board, IsBN - 8178330709 - NPCSDocument83 pagesBiotechnology Handbook by Niir Board, IsBN - 8178330709 - NPCSNaveen KamatNo ratings yet

- ACCET Mech Syllabus R-2015 PDFDocument201 pagesACCET Mech Syllabus R-2015 PDFajithNo ratings yet

- Rittal Climate Control Quick Reference 5 3082 PDFDocument2 pagesRittal Climate Control Quick Reference 5 3082 PDFpedro torresNo ratings yet

- Hvac QuestionsDocument4 pagesHvac Questionssyedkaleem55No ratings yet

- Heat Transfer in Finned Tubes Lab ReportDocument6 pagesHeat Transfer in Finned Tubes Lab ReportHarikrishnan Cb0% (1)

- ChE Objective Type Questions Compilation Dean Medina 8 27 10Document177 pagesChE Objective Type Questions Compilation Dean Medina 8 27 10BEA GEDELYN GARCIANo ratings yet

- 1078 Pool Heater SizingDocument1 page1078 Pool Heater SizingAnwar SyedNo ratings yet

- Pros Systec V Serie EDocument32 pagesPros Systec V Serie EkostrenarijekaNo ratings yet

- Manual Remote ControllerDocument106 pagesManual Remote ControllerMarian Nicolae HenzuleaNo ratings yet

- CALCULO DE CARGA TERMICA PARA AIRE ACONDICIONADO - PoligonoDocument8 pagesCALCULO DE CARGA TERMICA PARA AIRE ACONDICIONADO - PoligonoCarlos EduardoNo ratings yet

- Moisture ContentDocument3 pagesMoisture ContentAli RazuNo ratings yet

- Review of Literature On Steam AccumulatorDocument10 pagesReview of Literature On Steam Accumulatortamil vaananNo ratings yet

- Thermal Management of A High Performance Electric Motorcycle: Active Vs Passive CoolingDocument6 pagesThermal Management of A High Performance Electric Motorcycle: Active Vs Passive CoolingValentina Mejia GallonNo ratings yet

- Baking Rules Basic Rules of BakingDocument4 pagesBaking Rules Basic Rules of BakingGerry DayananNo ratings yet

- Carga Refrigerante R22Document1 pageCarga Refrigerante R22FernandoNo ratings yet

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

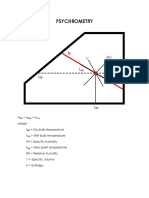

- Psychrometry: V RH T T SHDocument13 pagesPsychrometry: V RH T T SHKAL ELNo ratings yet

- GMV6 Outdoor Max Power Mentioned PDFDocument1 pageGMV6 Outdoor Max Power Mentioned PDFMaxhar AbbasNo ratings yet

- 2a Simple Therm Syst - PVT Syst Illustr ExamplesDocument4 pages2a Simple Therm Syst - PVT Syst Illustr ExamplesSamuel BoujeeNo ratings yet

- Derivacion de La Ley de Los Gases Ideales PDFDocument2 pagesDerivacion de La Ley de Los Gases Ideales PDFDomingo KarrascalNo ratings yet

- HT NotesDocument197 pagesHT NotesT.AnbukumarNo ratings yet

- Ropex Cirus A4 ENDocument6 pagesRopex Cirus A4 ENRainNo ratings yet

- BS 812 Part 2Document37 pagesBS 812 Part 2SANTU SIKDERNo ratings yet

- Unit 7Document3 pagesUnit 7Salwani ShafieNo ratings yet

- Mechanical Engineering Handbook - Air-Conditioning and RefrigerationDocument3 pagesMechanical Engineering Handbook - Air-Conditioning and RefrigerationCabra Volklingen0% (1)

- Air Distribution System Vav VRVDocument3 pagesAir Distribution System Vav VRVsiva ramanNo ratings yet

- Me2121-2 Performance Evaluation of Air-Conditioners (E1-03-01)Document11 pagesMe2121-2 Performance Evaluation of Air-Conditioners (E1-03-01)hybri8No ratings yet

- Hvac PDFDocument121 pagesHvac PDFPrajwal Komarla SwaminathNo ratings yet

- Commercial Unit Cooler:Cubic Type: E45HC 4922 E 9 N. Units: 1Document1 pageCommercial Unit Cooler:Cubic Type: E45HC 4922 E 9 N. Units: 1Mario UrsuNo ratings yet