Professional Documents

Culture Documents

Argus 2: Cutout Details Features Description Ordering Information

Argus 2: Cutout Details Features Description Ordering Information

Uploaded by

smcraftCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Steam Engine PlansDocument20 pagesSteam Engine Planstszabi26100% (2)

- 31 AHUsDocument46 pages31 AHUsZen LohNo ratings yet

- Omnicone 937 Parts List-OMNIDocument2 pagesOmnicone 937 Parts List-OMNIgusjav2014c12No ratings yet

- Operations & Maintenance Manual For CraneDocument18 pagesOperations & Maintenance Manual For Craneparvezblog100% (1)

- Voltage Regulation GeneratorsDocument29 pagesVoltage Regulation Generatorsprabhakaran_hdecNo ratings yet

- Electrical Engineer VocabularyDocument13 pagesElectrical Engineer Vocabularyprabhakaran_hdecNo ratings yet

- Tapcon Avr-Ba1801003 - 05 - en - TC260 - Iec61850Document222 pagesTapcon Avr-Ba1801003 - 05 - en - TC260 - Iec61850prabhakaran_hdecNo ratings yet

- Micom P122 RelayDocument2 pagesMicom P122 Relayprabhakaran_hdec100% (1)

- Argus 7Document4 pagesArgus 7prabhakaran_hdecNo ratings yet

- Reg DA RelayDocument16 pagesReg DA Relayprabhakaran_hdecNo ratings yet

- 7SG114 - Argus Technical ManualDocument4 pages7SG114 - Argus Technical Manualprabhakaran_hdecNo ratings yet

- Fuse 10 - A01Document2 pagesFuse 10 - A01prabhakaran_hdecNo ratings yet

- Resistor WikipediaDocument18 pagesResistor Wikipediaprabhakaran_hdecNo ratings yet

- Argus 8: Cutout Details DescriptionDocument4 pagesArgus 8: Cutout Details Descriptionprabhakaran_hdecNo ratings yet

- Cyme GridDocument6 pagesCyme Gridprabhakaran_hdec100% (1)

- Pilot Wire ProtectionDocument5 pagesPilot Wire Protectionprabhakaran_hdec100% (1)

- ABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHADocument5 pagesABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHAjavedsmg1No ratings yet

- Digital Control ValveDocument8 pagesDigital Control Valvecnrk777100% (1)

- WA450-3 S/N 53001-UP (For Malaysia)Document2 pagesWA450-3 S/N 53001-UP (For Malaysia)Anonymous cS9UMvhBqNo ratings yet

- Axle CounterDocument15 pagesAxle CounterSourav MahatoNo ratings yet

- AN5004Document5 pagesAN5004rdc02271No ratings yet

- Distributor Price Details (1672312436.309) (410 IsqDocument8 pagesDistributor Price Details (1672312436.309) (410 IsqRohit ShrivastavaNo ratings yet

- AC Drive Theory and Application: Benefits of Using AC DrivesDocument8 pagesAC Drive Theory and Application: Benefits of Using AC DrivesRaghu KodiNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- 2000-2001 CR250 Ignition Service ManualDocument13 pages2000-2001 CR250 Ignition Service ManualHeidi Hanson0% (1)

- GearDocument1 pageGearAndy SefayanNo ratings yet

- TSB 20230830 - New Launch Lifelong Air Cooler - Technical DetailsDocument4 pagesTSB 20230830 - New Launch Lifelong Air Cooler - Technical DetailsNavjot KaurNo ratings yet

- Computer Architecture - Teachers NotesDocument11 pagesComputer Architecture - Teachers NotesHAMMAD UR REHMANNo ratings yet

- 03 LexusDocument7 pages03 Lexuswalson glen CrastaNo ratings yet

- Sindoh N500 N510 MF Series SMDocument1,131 pagesSindoh N500 N510 MF Series SMsgrNo ratings yet

- Ske Series: Installation & Instruction ManualDocument40 pagesSke Series: Installation & Instruction ManualRoger FoisyNo ratings yet

- LUISA Product Data SheetDocument4 pagesLUISA Product Data SheetSaad ALANAZINo ratings yet

- Fuller-Kinyon Type M Pump W/3 PC Screw Parts IdentificationDocument2 pagesFuller-Kinyon Type M Pump W/3 PC Screw Parts IdentificationJhon Jairo Arango MarquezNo ratings yet

- Piping Painting Colour CodeDocument1 pagePiping Painting Colour CodeBalaraman SNo ratings yet

- Data LoggerDocument86 pagesData LoggerYoshiro Chicmana Toralva100% (1)

- HSD Spindle Manual ES789 ES799 EnglishDocument62 pagesHSD Spindle Manual ES789 ES799 EnglishCamilo Andrés Lara castilloNo ratings yet

- Bme (22214)Document2 pagesBme (22214)SHUBHAM KADAMNo ratings yet

- PI-200, PI-400, PI-750, XI41B: Models / ModelosDocument31 pagesPI-200, PI-400, PI-750, XI41B: Models / ModelosRolando MaasNo ratings yet

- Digital Signal Processors and Architectures (DSPA) Unit-2Document92 pagesDigital Signal Processors and Architectures (DSPA) Unit-2Chaitanya DuggineniNo ratings yet

- Product CatalogueDocument44 pagesProduct CatalogueTo Van TinhNo ratings yet

- Wiring SubsDocument8 pagesWiring Subsjun8888No ratings yet

- 2023-02-01 T3 IndiaDocument84 pages2023-02-01 T3 IndiaJ. C.No ratings yet

Argus 2: Cutout Details Features Description Ordering Information

Argus 2: Cutout Details Features Description Ordering Information

Uploaded by

smcraftOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Argus 2: Cutout Details Features Description Ordering Information

Argus 2: Cutout Details Features Description Ordering Information

Uploaded by

smcraftCopyright:

Available Formats

Numerical

Directional Overcurrent

Protection Relay

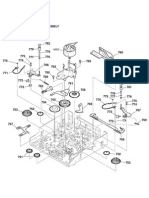

Cutout Details Features

The Argus range of numerical overcurrent protection devices

combine the power and flexibility of microprocessor technology

with decades of experience in the field of overcurrent protection.

Thus a wide range of protection elements and characteristics

are supplemented by advanced features such as metering,

data storage and communications.

The directional members of the family provide the ability to

apply bi-directional control to each protection stage

independently.

Different settings can be applied for operation in the forward

and reverse zones. The advantage of this capability is that a

single Argus 2 relay can perform the function of two traditional

directional relays.

Phase-fault directional elements are polarised by the quadrature

phase-phase connection, and earth fault elements are polarised

by the system residual voltage obtained from the open delta

tertiary winding of a voltage transformer or alternatively the

relay will itself calculate the residual voltage internally from the

three applied phase to neutral voltges. Alternatively, current

polarised earth fault elements are available. Characteristic

angles (or MTA) are selectable.

A two-out-of-three gating feature is available in 3 variants.

When this feature is enabled, a protection algorithm will only

be permitted to operate if 2 out of 3 poles measure fault current

in the operate zone. This provides absolute discrimination

between two directional overcurrent protections in systems

where - 1:+2:-1 current distributions may be encountered.

The Argus range includes single pole, three pole and four pole

directional overcurrent relays. These compact units are housed

in withdrawable size E4, E6 and E8 cases. A single pole

directional sensitive earth fault relay is also available.

Argus 2 100 series - 1 pole directional

Argus 2 300 series - 3 pole directional

Argus 2 400 series - 4 pole directional

Argus 2 500 series - 4 pole directional + power metering

Applications

Parallel feeders

Ring feeders

Distribution feeders

Transformers

Protection requirement

3P(D)+E(D), 3P(D)+SE, 2P(D)+E(D)+SE

Auxiliary and digital (status) input voltages

Voltage or current polarisation

Fibre-optic or RS485 communication port

Description

Digital Directional Overcurrent Protection Relay - Argus 2

ARGUS 2

Ordering Information

Qualification

ISO 9001 - 2000

F

A

C

T

/

A

R

G

U

S

2

/

1

2

-

0

5

/

R

E

V

0

Protection

IDMTL phase fault directional OC stage (51/67)

Three DTL phase fault directional OC stages (50/67)

IDMTL directional earth-fault (51N/67N)

Three DTL directional earth-fault (50N/67N)

Two stage circuit breaker failure (50BF)

Two instantaneous and DTL SEF/REF stages with harmonic

rejection (50N/64R)

Over/under voltage (59/27)*

* Available only in Argus 500 Model

Control

The basic Argus 2 relay contains 11 programmable output

relays, 3 of which have 1CO contact and 8 have 1NO contact

The basic Argus 2 relay contains 5 programmable

digital (status) input, with an additional 4 provided in

expanded relays

Single pole directional Argus 2 relay contains 7 programmable

output relays, 3 of which have 1 CO contact and 4 have

1 NO contact 3 pole and 4 pole variants can provide 4 extra

output relays, each having 1 NO contact

Single pole directional Argus 2 relay contains 1 programmable

digital (status) input, with an additional 4 or 8 provided in

3 pole or 4 pole relays

Case Weight

Argus 2-E4 3.3kg

Argus 2-E6 4.8kg

Argus 2-E8 6.6kg

MODULAR CASES:SIZES 4-8

SIZE 4 CASE SIZE 6 CASE SIZE 8 CASE

A B C A B C A B C

103 99.5 52 155 151 103.5 206 203 155.5

The policy of Easun Reyrolle is one of continuous improvement and development. The company therefore reserves the right to supply equipment, which

may differ slightly from that described and illustrated in this publication.

AUTOMATION DIVISION

Ashirwad, #25, 29

th

Main,

4

th

B Cross, BTM Layout 2

nd

Stage,

Bangalore-560 076, India.

Tel: +91 80 26685496/51311405

Fax: +91 80 26685446

Email: smabp@easunreyrolle.net

HOSUR WORKS

#98, Sipcot Industrial Complex,

Hosur 635 126, India.

Tel: +91 4344 401600/01/02

Fax: +91 4344 276397

SWITCHGEAR WORKS

Ernavur,

Chennai-600 057, India.

Tel: +91 44 25733715/358

Fax: +91 44 25733468

Email: switchgear@easunreyrolle.net

BANGALORE WORKS

#17/3 Arakere,

Bannerghatta Road,

Bangalore-560 076, India.

Tel: +91 80 26581023 / 3268

Fax: +91 80 26580642

Email: blrworks@easunreyrolle.net

EXPORTS DIVISION

#17/3 Arakere,

Bannerghatta Road,

Bangalore-560 076, India.

Tel: +91 80 26581023 / 3268

Fax: +91 80 26580642

Email: exports@easunreyrolle.net

Sales Offices

Mumbai

Tel: +91 22 22022270/22855415

Fax: +91 22 22825703

Email: mumbai@easunreyrolle.net

Bangalore

Tel: +91 80 26685496/51311405

Fax: +91 22 26685446

Email: blroffice@easunreyrolle.net

Bhopal

Telefax: +91 755 2684221

Email: bhopal@easunreyrolle.net

Delhi

Tel: +91 11 25747321/25747322

Fax: +91 11 25747320

Email: delhi@easunreyrolle.net

Chennai

Tel: +91 44 24346425/24347608

Fax: +91 44 24346435

Email: chennai@easunreyrolle.net

Secunderabad

Telefax: +91 40 27817847

Email: hyderabad@easunreyrolle.net

Kolkata

Tel: +91 33 22848320

Fax: +91 33 22848326

Email: kolkata@easunreyrolle.net

Corporate Office

Easun Reyrolle Limited. 98 Sipcot Industrial Complex

Hosur 635 126 India. Tel: +91 4344 401600/01/02

Fax: +91 4344 276397

www.easunreyrolle.com

Technical Information

Monitoring

Trip circuit supervision (95)

Current Transformer (CT) supervision

Circuit breaker maintenance

Storage of 500 time-tagged event records

Storage of 5 wave form records

Records for upto last 5 faults

Self-monitoring capability

Metering

Primary/secondary current Ia, Ib, Ic, Ise

Primary/secondary phase to phase voltages*

Primary/secondary phase voltages*

Apparent power, real and reactive power*

Power factor*

Forward/reverse WHr, VARHr*

Rolling and maximum demand for Ia, Ib, Ic

Rolling & maximum demand for W & VAR*

Direction

* Applicable only for Argus 500 Model

User Interface

User-friendly settings and indications

Backlit liquid crystal alpha-numeric display with

16-characters, 2 lines

LEDs for trip, starter and protection healthy status

indications

Push buttons for programming and resetting

Communication

RS485 or fibre-optic communication port at rear

Data communication using IEC 60870-5-103 or MODBUS

RTU Protocol

Wiring Diagram

CT input rating

AC current 1A/5A, 50/60Hz

AC voltage 110V line-line or

63.5V line-neutral

Settings

Phase fault 0.05 x In to 2.5 x In 0.05 x In

Earth fault 0.05 x In to 2.5 x In 0.05 x In

Highsets1&2 0.05 x In to 2.5 x In 0.05 x In

2.5 x In to 52.5 x In 0.5 x In

Lowset 0.05 x In to 2.5 x In 0.05 x In

2.5 x In to 52.5 x In 0.5 x In

SEF/REF 0.005 x In to 0.96 x In 0.005 x In

Definite time 0sec to 300sec

Time multiplier 0.025 to 1.6 0.025

Reset delay 0sec to 60sec 1sec

Phase Fault MTA -90 to + 90 1

Earth Fault MTA -90 to + 90 1

Over/under voltage 5-200 V*

NB. External resistors and metrosils can be calculated and

supplied to complete REF schemes.

* In Argus 500 Model only

Directional Characteristics

Operating angle 87.5 about MTA

Operate time <20ms at MTA

DC Auxiliary supply

Nominal Operating range

24, 30, 48V 18-60V

110, 220V 88-280V

Output relays

The basic Argus 2 relay contains 11 programmable output

relays, 3 of which have 1 CO contact and 8 have 1 NO

contact

Single pole directional Argus 2 relay contains

7 programmable output relays, 3 of which have 1 CO contact

and 4 have 1 NO contact 3 pole and 4 pole variants can

provide 4 extra output relays, each having 1 NO contact

Contact ratings

Carry continuously - 5A AC or DC

Make and carry - 30A AC or DC for 0.2sec

Resistive break - 75W DC, 1250VA AC

DC digital (status) input

The basic Argus 2 relay contains 5 programmable numerical

input, with an additional 4 provided in expanded relays.

The digital (status) inputs have programmable pick-up and

drop-off timers.

Auxiliary voltage Operating range

30V DC 18-37.5V DC

48V DC 37.5- 60V DC

110/125V DC 87.5-137.5V DC

220/250V DC 175 - 280V DC

For relay with 110/125V DC or 220/225V DC auxiliary a

48 voltage input is supplied for use with external dropper

resistors: 110/125V resistor 2K7 5% 2.5W 220/250V

resistor 8K2 5% 6.0W

Burdens

AC current

1 A Phase/Earth 0.05 VA

5 A Phase/Earth 0.2 VA

1 A SEF/REF 0.2 VA

5 A SEF/REF 0.4 VA

AC voltage 0.2 VA

DC voltage

Quiescent (Typical) 3 W

Maximum 10 W

Indications

LEDs for trip, starter and protection healthy status indications

LCD - Alphanumeric display for setting, instruments and fault

data

Environmental

Temperature IEC 68- 2-1/2

Operating range -10C to + 55C

Storage range -25C to + 70C

Humidity IEC 68-2-3

Vibration IEC 255 -21-1 class I

Shock and bump IEC 255 -21-2 class I

Seismic IEC 255 -21-3 class I

Insulation IEC 255-5

2kVrms for 1 min between all terminals and earth.

2kVrms for 1 min between independent circuits.

1kVrms for 1 minute across NO contacts.

Transient overvoltage IEC 255-5 class III

5kV 1.2/50s between

all terminals and earth

without damage or

flashover.

High frequency IEC 255-22-1 class III

disturbance

2.5kV common mode <3% deviation

1.0kV series mode <3% deviation

Electrostatic discharge IEC255- 22-2 class III

8kV direct without

maloperation or

damage

Radio frequency IEC 255-22-3

disturbance

20MHz to 1GHz at 10V/m <5% deviation

Fast transient IEC 255-22-4 class IV

4kV 5/50ns <3% deviation

Mechanical Classification

Durability 10

6

operations

Tri-state directional element

Independent direction control for each protection

characteristic

Different settings for forward and reverse operation

Voltage or current polarized directional earth fault

Open delta tertiary winding not necessary for directional

earth fault*

Voltage controlled change of setting groups*

Separate outputs for forward & reverse direction*

* Available only in Argus 500 Model

Notes

1 Diagram shows 3PF+SEF model using a ring core CT.

See diagram below for alternative connection other CT mixes

also available.

2 Diagram shows 3 and earth voltage inputs.

3 Optional expansion card, fitted onlyon models with 5 digital

(status) inputs and 11output relays.

4 Optional expansion card, fitted only on models with 9 digital

(status) inputs and 7output relays.

5 Diagram shows 3PF+EF using residual connection other CT

mixes also available.

6 Voltage card shown can be fitted only on Argus 2 relays, type

AG2-5xx.

Technical Information

Monitoring

Trip circuit supervision (95)

Current Transformer (CT) supervision

Circuit breaker maintenance

Storage of 500 time-tagged event records

Storage of 5 wave form records

Records for upto last 5 faults

Self-monitoring capability

Metering

Primary/secondary current Ia, Ib, Ic, Ise

Primary/secondary phase to phase voltages*

Primary/secondary phase voltages*

Apparent power, real and reactive power*

Power factor*

Forward/reverse WHr, VARHr*

Rolling and maximum demand for Ia, Ib, Ic

Rolling & maximum demand for W & VAR*

Direction

* Applicable only for Argus 500 Model

User Interface

User-friendly settings and indications

Backlit liquid crystal alpha-numeric display with

16-characters, 2 lines

LEDs for trip, starter and protection healthy status

indications

Push buttons for programming and resetting

Communication

RS485 or fibre-optic communication port at rear

Data communication using IEC 60870-5-103 or MODBUS

RTU Protocol

Wiring Diagram

CT input rating

AC current 1A/5A, 50/60Hz

AC voltage 110V line-line or

63.5V line-neutral

Settings

Phase fault 0.05 x In to 2.5 x In 0.05 x In

Earth fault 0.05 x In to 2.5 x In 0.05 x In

Highsets1&2 0.05 x In to 2.5 x In 0.05 x In

2.5 x In to 52.5 x In 0.5 x In

Lowset 0.05 x In to 2.5 x In 0.05 x In

2.5 x In to 52.5 x In 0.5 x In

SEF/REF 0.005 x In to 0.96 x In 0.005 x In

Definite time 0sec to 300sec

Time multiplier 0.025 to 1.6 0.025

Reset delay 0sec to 60sec 1sec

Phase Fault MTA -90 to + 90 1

Earth Fault MTA -90 to + 90 1

Over/under voltage 5-200 V*

NB. External resistors and metrosils can be calculated and

supplied to complete REF schemes.

* In Argus 500 Model only

Directional Characteristics

Operating angle 87.5 about MTA

Operate time <20ms at MTA

DC Auxiliary supply

Nominal Operating range

24, 30, 48V 18-60V

110, 220V 88-280V

Output relays

The basic Argus 2 relay contains 11 programmable output

relays, 3 of which have 1 CO contact and 8 have 1 NO

contact

Single pole directional Argus 2 relay contains

7 programmable output relays, 3 of which have 1 CO contact

and 4 have 1 NO contact 3 pole and 4 pole variants can

provide 4 extra output relays, each having 1 NO contact

Contact ratings

Carry continuously - 5A AC or DC

Make and carry - 30A AC or DC for 0.2sec

Resistive break - 75W DC, 1250VA AC

DC digital (status) input

The basic Argus 2 relay contains 5 programmable numerical

input, with an additional 4 provided in expanded relays.

The digital (status) inputs have programmable pick-up and

drop-off timers.

Auxiliary voltage Operating range

30V DC 18-37.5V DC

48V DC 37.5- 60V DC

110/125V DC 87.5-137.5V DC

220/250V DC 175 - 280V DC

For relay with 110/125V DC or 220/225V DC auxiliary a

48 voltage input is supplied for use with external dropper

resistors: 110/125V resistor 2K7 5% 2.5W 220/250V

resistor 8K2 5% 6.0W

Burdens

AC current

1 A Phase/Earth 0.05 VA

5 A Phase/Earth 0.2 VA

1 A SEF/REF 0.2 VA

5 A SEF/REF 0.4 VA

AC voltage 0.2 VA

DC voltage

Quiescent (Typical) 3 W

Maximum 10 W

Indications

LEDs for trip, starter and protection healthy status indications

LCD - Alphanumeric display for setting, instruments and fault

data

Environmental

Temperature IEC 68- 2-1/2

Operating range -10C to + 55C

Storage range -25C to + 70C

Humidity IEC 68-2-3

Vibration IEC 255 -21-1 class I

Shock and bump IEC 255 -21-2 class I

Seismic IEC 255 -21-3 class I

Insulation IEC 255-5

2kVrms for 1 min between all terminals and earth.

2kVrms for 1 min between independent circuits.

1kVrms for 1 minute across NO contacts.

Transient overvoltage IEC 255-5 class III

5kV 1.2/50s between

all terminals and earth

without damage or

flashover.

High frequency IEC 255-22-1 class III

disturbance

2.5kV common mode <3% deviation

1.0kV series mode <3% deviation

Electrostatic discharge IEC255- 22-2 class III

8kV direct without

maloperation or

damage

Radio frequency IEC 255-22-3

disturbance

20MHz to 1GHz at 10V/m <5% deviation

Fast transient IEC 255-22-4 class IV

4kV 5/50ns <3% deviation

Mechanical Classification

Durability 10

6

operations

Tri-state directional element

Independent direction control for each protection

characteristic

Different settings for forward and reverse operation

Voltage or current polarized directional earth fault

Open delta tertiary winding not necessary for directional

earth fault*

Voltage controlled change of setting groups*

Separate outputs for forward & reverse direction*

* Available only in Argus 500 Model

Notes

1 Diagram shows 3PF+SEF model using a ring core CT.

See diagram below for alternative connection other CT mixes

also available.

2 Diagram shows 3 and earth voltage inputs.

3 Optional expansion card, fitted onlyon models with 5 digital

(status) inputs and 11output relays.

4 Optional expansion card, fitted only on models with 9 digital

(status) inputs and 7output relays.

5 Diagram shows 3PF+EF using residual connection other CT

mixes also available.

6 Voltage card shown can be fitted only on Argus 2 relays, type

AG2-5xx.

Numerical

Directional Overcurrent

Protection Relay

Cutout Details Features

The Argus range of numerical overcurrent protection devices

combine the power and flexibility of microprocessor technology

with decades of experience in the field of overcurrent protection.

Thus a wide range of protection elements and characteristics

are supplemented by advanced features such as metering,

data storage and communications.

The directional members of the family provide the ability to

apply bi-directional control to each protection stage

independently.

Different settings can be applied for operation in the forward

and reverse zones. The advantage of this capability is that a

single Argus 2 relay can perform the function of two traditional

directional relays.

Phase-fault directional elements are polarised by the quadrature

phase-phase connection, and earth fault elements are polarised

by the system residual voltage obtained from the open delta

tertiary winding of a voltage transformer or alternatively the

relay will itself calculate the residual voltage internally from the

three applied phase to neutral voltges. Alternatively, current

polarised earth fault elements are available. Characteristic

angles (or MTA) are selectable.

A two-out-of-three gating feature is available in 3 variants.

When this feature is enabled, a protection algorithm will only

be permitted to operate if 2 out of 3 poles measure fault current

in the operate zone. This provides absolute discrimination

between two directional overcurrent protections in systems

where - 1:+2:-1 current distributions may be encountered.

The Argus range includes single pole, three pole and four pole

directional overcurrent relays. These compact units are housed

in withdrawable size E4, E6 and E8 cases. A single pole

directional sensitive earth fault relay is also available.

Argus 2 100 series - 1 pole directional

Argus 2 300 series - 3 pole directional

Argus 2 400 series - 4 pole directional

Argus 2 500 series - 4 pole directional + power metering

Applications

Parallel feeders

Ring feeders

Distribution feeders

Transformers

Protection requirement

3P(D)+E(D), 3P(D)+SE, 2P(D)+E(D)+SE

Auxiliary and digital (status) input voltages

Voltage or current polarisation

Fibre-optic or RS485 communication port

Description

Digital Directional Overcurrent Protection Relay - Argus 2

ARGUS 2

Ordering Information

Qualification

ISO 9001 - 2000

F

A

C

T

/

A

R

G

U

S

2

/

1

2

-

0

5

/

R

E

V

0

Protection

IDMTL phase fault directional OC stage (51/67)

Three DTL phase fault directional OC stages (50/67)

IDMTL directional earth-fault (51N/67N)

Three DTL directional earth-fault (50N/67N)

Two stage circuit breaker failure (50BF)

Two instantaneous and DTL SEF/REF stages with harmonic

rejection (50N/64R)

Over/under voltage (59/27)*

* Available only in Argus 500 Model

Control

The basic Argus 2 relay contains 11 programmable output

relays, 3 of which have 1CO contact and 8 have 1NO contact

The basic Argus 2 relay contains 5 programmable

digital (status) input, with an additional 4 provided in

expanded relays

Single pole directional Argus 2 relay contains 7 programmable

output relays, 3 of which have 1 CO contact and 4 have

1 NO contact 3 pole and 4 pole variants can provide 4 extra

output relays, each having 1 NO contact

Single pole directional Argus 2 relay contains 1 programmable

digital (status) input, with an additional 4 or 8 provided in

3 pole or 4 pole relays

Case Weight

Argus 2-E4 3.3kg

Argus 2-E6 4.8kg

Argus 2-E8 6.6kg

MODULAR CASES:SIZES 4-8

SIZE 4 CASE SIZE 6 CASE SIZE 8 CASE

A B C A B C A B C

103 99.5 52 155 151 103.5 206 203 155.5

The policy of Easun Reyrolle is one of continuous improvement and development. The company therefore reserves the right to supply equipment, which

may differ slightly from that described and illustrated in this publication.

AUTOMATION DIVISION

Ashirwad, #25, 29

th

Main,

4

th

B Cross, BTM Layout 2

nd

Stage,

Bangalore-560 076, India.

Tel: +91 80 26685496/51311405

Fax: +91 80 26685446

Email: smabp@easunreyrolle.net

HOSUR WORKS

#98, Sipcot Industrial Complex,

Hosur 635 126, India.

Tel: +91 4344 401600/01/02

Fax: +91 4344 276397

SWITCHGEAR WORKS

Ernavur,

Chennai-600 057, India.

Tel: +91 44 25733715/358

Fax: +91 44 25733468

Email: switchgear@easunreyrolle.net

BANGALORE WORKS

#17/3 Arakere,

Bannerghatta Road,

Bangalore-560 076, India.

Tel: +91 80 26581023 / 3268

Fax: +91 80 26580642

Email: blrworks@easunreyrolle.net

EXPORTS DIVISION

#17/3 Arakere,

Bannerghatta Road,

Bangalore-560 076, India.

Tel: +91 80 26581023 / 3268

Fax: +91 80 26580642

Email: exports@easunreyrolle.net

Sales Offices

Mumbai

Tel: +91 22 22022270/22855415

Fax: +91 22 22825703

Email: mumbai@easunreyrolle.net

Bangalore

Tel: +91 80 26685496/51311405

Fax: +91 22 26685446

Email: blroffice@easunreyrolle.net

Bhopal

Telefax: +91 755 2684221

Email: bhopal@easunreyrolle.net

Delhi

Tel: +91 11 25747321/25747322

Fax: +91 11 25747320

Email: delhi@easunreyrolle.net

Chennai

Tel: +91 44 24346425/24347608

Fax: +91 44 24346435

Email: chennai@easunreyrolle.net

Secunderabad

Telefax: +91 40 27817847

Email: hyderabad@easunreyrolle.net

Kolkata

Tel: +91 33 22848320

Fax: +91 33 22848326

Email: kolkata@easunreyrolle.net

Corporate Office

Easun Reyrolle Limited. 98 Sipcot Industrial Complex

Hosur 635 126 India. Tel: +91 4344 401600/01/02

Fax: +91 4344 276397

www.easunreyrolle.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Steam Engine PlansDocument20 pagesSteam Engine Planstszabi26100% (2)

- 31 AHUsDocument46 pages31 AHUsZen LohNo ratings yet

- Omnicone 937 Parts List-OMNIDocument2 pagesOmnicone 937 Parts List-OMNIgusjav2014c12No ratings yet

- Operations & Maintenance Manual For CraneDocument18 pagesOperations & Maintenance Manual For Craneparvezblog100% (1)

- Voltage Regulation GeneratorsDocument29 pagesVoltage Regulation Generatorsprabhakaran_hdecNo ratings yet

- Electrical Engineer VocabularyDocument13 pagesElectrical Engineer Vocabularyprabhakaran_hdecNo ratings yet

- Tapcon Avr-Ba1801003 - 05 - en - TC260 - Iec61850Document222 pagesTapcon Avr-Ba1801003 - 05 - en - TC260 - Iec61850prabhakaran_hdecNo ratings yet

- Micom P122 RelayDocument2 pagesMicom P122 Relayprabhakaran_hdec100% (1)

- Argus 7Document4 pagesArgus 7prabhakaran_hdecNo ratings yet

- Reg DA RelayDocument16 pagesReg DA Relayprabhakaran_hdecNo ratings yet

- 7SG114 - Argus Technical ManualDocument4 pages7SG114 - Argus Technical Manualprabhakaran_hdecNo ratings yet

- Fuse 10 - A01Document2 pagesFuse 10 - A01prabhakaran_hdecNo ratings yet

- Resistor WikipediaDocument18 pagesResistor Wikipediaprabhakaran_hdecNo ratings yet

- Argus 8: Cutout Details DescriptionDocument4 pagesArgus 8: Cutout Details Descriptionprabhakaran_hdecNo ratings yet

- Cyme GridDocument6 pagesCyme Gridprabhakaran_hdec100% (1)

- Pilot Wire ProtectionDocument5 pagesPilot Wire Protectionprabhakaran_hdec100% (1)

- ABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHADocument5 pagesABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHAjavedsmg1No ratings yet

- Digital Control ValveDocument8 pagesDigital Control Valvecnrk777100% (1)

- WA450-3 S/N 53001-UP (For Malaysia)Document2 pagesWA450-3 S/N 53001-UP (For Malaysia)Anonymous cS9UMvhBqNo ratings yet

- Axle CounterDocument15 pagesAxle CounterSourav MahatoNo ratings yet

- AN5004Document5 pagesAN5004rdc02271No ratings yet

- Distributor Price Details (1672312436.309) (410 IsqDocument8 pagesDistributor Price Details (1672312436.309) (410 IsqRohit ShrivastavaNo ratings yet

- AC Drive Theory and Application: Benefits of Using AC DrivesDocument8 pagesAC Drive Theory and Application: Benefits of Using AC DrivesRaghu KodiNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- 2000-2001 CR250 Ignition Service ManualDocument13 pages2000-2001 CR250 Ignition Service ManualHeidi Hanson0% (1)

- GearDocument1 pageGearAndy SefayanNo ratings yet

- TSB 20230830 - New Launch Lifelong Air Cooler - Technical DetailsDocument4 pagesTSB 20230830 - New Launch Lifelong Air Cooler - Technical DetailsNavjot KaurNo ratings yet

- Computer Architecture - Teachers NotesDocument11 pagesComputer Architecture - Teachers NotesHAMMAD UR REHMANNo ratings yet

- 03 LexusDocument7 pages03 Lexuswalson glen CrastaNo ratings yet

- Sindoh N500 N510 MF Series SMDocument1,131 pagesSindoh N500 N510 MF Series SMsgrNo ratings yet

- Ske Series: Installation & Instruction ManualDocument40 pagesSke Series: Installation & Instruction ManualRoger FoisyNo ratings yet

- LUISA Product Data SheetDocument4 pagesLUISA Product Data SheetSaad ALANAZINo ratings yet

- Fuller-Kinyon Type M Pump W/3 PC Screw Parts IdentificationDocument2 pagesFuller-Kinyon Type M Pump W/3 PC Screw Parts IdentificationJhon Jairo Arango MarquezNo ratings yet

- Piping Painting Colour CodeDocument1 pagePiping Painting Colour CodeBalaraman SNo ratings yet

- Data LoggerDocument86 pagesData LoggerYoshiro Chicmana Toralva100% (1)

- HSD Spindle Manual ES789 ES799 EnglishDocument62 pagesHSD Spindle Manual ES789 ES799 EnglishCamilo Andrés Lara castilloNo ratings yet

- Bme (22214)Document2 pagesBme (22214)SHUBHAM KADAMNo ratings yet

- PI-200, PI-400, PI-750, XI41B: Models / ModelosDocument31 pagesPI-200, PI-400, PI-750, XI41B: Models / ModelosRolando MaasNo ratings yet

- Digital Signal Processors and Architectures (DSPA) Unit-2Document92 pagesDigital Signal Processors and Architectures (DSPA) Unit-2Chaitanya DuggineniNo ratings yet

- Product CatalogueDocument44 pagesProduct CatalogueTo Van TinhNo ratings yet

- Wiring SubsDocument8 pagesWiring Subsjun8888No ratings yet

- 2023-02-01 T3 IndiaDocument84 pages2023-02-01 T3 IndiaJ. C.No ratings yet