Professional Documents

Culture Documents

04 Feam Phụ Kiện Ống

04 Feam Phụ Kiện Ống

Uploaded by

thanhlangdaiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Feam Phụ Kiện Ống

04 Feam Phụ Kiện Ống

Uploaded by

thanhlangdaiCopyright:

Available Formats

YOUR PARTNER FOR SAFETY

Since 1961

Explosion Proof Electrical Equipment

L

B

H

-

L

B

H

F

-

L

B

H

S

-

E

K

C

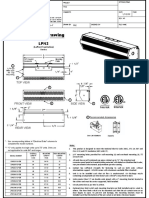

LBH-LBHF-LBHS-EKC

EKC

LBH LBHF

LBHS

Feam Catalogue 01 - 143

Ex Conduit fttings

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts)

Classifcation: Group II - Category 2G 2D

OPEN BENDS

AND PULLING BOXES

ON REQUEST ACCESSORIES:

Different thread from standard

Stainless steel screws

Painting

Mechanical characteristics

APPLICATIONS

Body / cover marine grade copper free aluminum light alloy

Screws galvanized steel

OPEN BENDS AND PULLING BOXES ARE USED FOR THE WIRING IN ELECTRICAL CONDUIT PLANTS.

PROVIDING FOR A GAP ON THE BACK IS MORE EASY INSPECTION AND THE INCLUSION OF ELECTRIC CABLES.

OPEN BENDS AND PULLING BOXES

ATEX 94/9/EC GOST-R (RTR / RTN) GOST-K

EXECUTION

II 2 G Ex d IIB / IIC

II 2 G Ex e II

II 2 D Ex tD A21

Ex d IIC U

DIP A21

Ex d IIC U

DIP A21

INSTALLATION ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22

PROTECTION DEGREE IP66 IP66 IP66

CERTIFICATE REF. LOM 06 ATEX 3079U POCC IT. 05.B02537 No. 07/43-269

RULES OF COMPLIANCE

EN 60079-0; EN 60079-14; EN 60079-7;

EN 61241-0; EN 61241-1

51330.9-99 ( 60079-10-95)

51330.13-99 ( 60079-14-96)

61241-3-99

51330.0 / 1 / 8 / 14-99

61241-1-1-2002

YOUR PARTNER FOR SAFETY

Since 1961

L

B

H

-

L

B

H

F

-

L

B

H

S

-

E

K

C

LBH2 LBHF2 LBHS2 EKC2 2 x 3/4"

LBH3 LBHF3 LBHS3 EKC3 2 x 1"

LBH4 - - EKC4 2 x 1-1/4"

LBH5 LBHF5 LBHS5 EKC5 2 x 1-1/2"

LBH6 LBHF6 LBHS6 EKC6 2 x 2"

LBH7 LBHF7 LBHS7 EKC7 2 x 2-1/2"

LBH8 LBHF8 LBHS8 EKC8 2 x 3"

LBH LBHF LBHS EKC

LBH LBHF LBHS EKC

LBH LBHF LBHS EKC

LBH LBHF LBHS EKC

9

0

90

D

D

D

D

9

0

A

C

B

D

144 - Feam Catalogue 01

Ex Conduit fttings

OPEN BENDS AND PULLING BOXES - Technical Features

REMARK:

Due to the development of the national and international specifcations and of the technology, the above technical characteristics showed

on this bulletin can be considered as binding on our confrmation only.

DETAIL "A" DETAIL "B" DETAIL "C" DETAIL "D"

D HUBS

(UNI6125 OR NPT)

TYPE TYPE TYPE TYPE

Reference Details

YOUR PARTNER FOR SAFETY

Since 1961

Explosion Proof Electrical Equipment

E

Y

S

E

Z

S

E

Z

D

/

B

M

F

-

R

M

F

B

F

F

-

R

F

F

EYS - EZS - EZD

BMF - RMF - BFF - RFF

EYS

EZS

Feam Catalogue 01 - 145

Ex Conduit fttings

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts)

Classifcation: Group II - Category 2G 2D

SEALING FITTINGS

AND THREE PIECE UNIONS

ON REQUEST ACCESSORIES:

Different threads from standard

Different materials from standard

THREE PIECE

UNIONS

Material marine grade copper free aluminium light alloy

Material galvanized steel

Gasket silicon rubber EPDM

SEALING FITTINGS - Mechanical characteristics

THREE PIECE UNIONS - Mechanical characteristics

SEALING FITTINGS

ATEX 94/9/EC GOST-R (RTR / RTN) GOST-K

EXECUTION

II 2 G Ex d IIC

II 2 D Ex tD A21

1 Ex d IIC U

DIP A21

Ex d IIC U

DIP A21

INSTALLATION ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22

PROTECTION DEGREE IP66 IP66 IP66

CERTIFICATE REF. CESI 05 ATEX 100 POCC IT. 05.B02537 No. 07/43-269

RULES OF COMPLIANCE

EN 60079-0; EN 60079-1;

EN 61241-1-1

51330.9-99 ( 60079-10-95)

51330.13-99 ( 60079-14-96)

61241-3-99

51330.0 / 1 / 8 / 14-99

61241-1-1-2002

THREE PIECE UNION

ATEX 94/9/EC GOST-R (RTR / RTN) GOST-K

EXECUTION

II 2 G Ex d IIB - II 2 G Ex d IIC

II 2 D Ex tD A21

Ex d IIB U - Ex d IIC U

DIP A21

Ex d IIB U - Ex d IIC U

DIP A22

AMBIENT TEMPERATURE -50C +130C -50C +130C -50C +130C

PROTECTION DEGREE IP66/67 IP66/67 IP66/67

CERTIFICATE REF. INERIS 07 ATEX 9002U POCC IT. 05.B02537 No. 07/43-269

RULES OF COMPLIANCE

EN 60079; EN 60079-1; EN 61241-0;

EN 61241-1

51330.9-99 ( 60079-10-95)

51330.13-99 ( 60079-14-96)

61241-3-99

51330.0 / 1 / 8 / 14-99

61241-1-1-2002

YOUR PARTNER FOR SAFETY

Since 1961

E

Y

S

E

Z

S

E

Z

D

/

B

M

F

-

R

M

F

B

F

F

-

R

F

F

EYS1 EZS1 EZD1 1/2"

EYS2 EZS2 EZD2 3/4"

EYS3 EZS3 EZD3 1"

- EZS5 EZD5 1-1/2"

- EZS6 EZD6 2"

- EZS7 EZD7 2-1/2"

- EZS8 EZD8 3"

BMF1 1/2" D

BMF2 3/4" D

BMF3 1" D

BMF4 1-1/4" D

BMF5 1-1/2" D

BMF6 2" D

BMF7 2-1/2" D

BMF8 3" D

BFF1 1/2" E

BFF2 3/4" E

BFF3 1" E

BFF4 1-1/4" E

BFF5 1-1/2" E

BFF6 2" E

BFF7 2-1/2" E

BFF8 3" E

RMF1 1/2" D

RMF2 3/4" D

RMF3 1" D

RMF4 1-1/4" D

RMF5 1-1/2" D

RMF6 2" D

RMF7 2-1/2" D

RMF8 3" D

RFF1 1/2" E

RFF2 3/4" E

RFF3 1" E

RFF4 1-1/4" E

RFF5 1-1/2" E

RFF6 2" E

RFF7 2-1/2" E

RFF8 3" E

1 35 140

2 50 140

3 100 140

5 - 390

6 - 570

7 - 1000

8 - 1000

EZS EZD EYS

D

FIGURA D FIGURA E

D D

EZS EZD EYS

D

F I G U R A D F I G U R A E

D D

EZS EZD EYS

D

EYS

D

EZS

A B

E

EZD C

BMF RFF

146 - Feam Catalogue 01

Ex Conduit fttings

SEALING FITTINGS - Technical Features

THREE PIECE UNIONS - Technical Features

REMARK: Due to the development of the national and international specifcations and of the technology, the above technical characteristics

showed on this bulletin can be considered as binding on our confrmation only.

DETAIL "A" DETAIL "B" DETAIL "C"

D HUBS

(UNI6125 OR NPT)

TYPE TYPE TYPE

THREE PIECE UNION MALE/FEMALE Ex d IIB

TYPE D DETAIL

THREE PIECE UNION FEMALE/FEMALE Ex d IIB

TYPE D DETAIL

THREE PIECE UNION MALE/FEMALE Ex d IIC

TYPE D DETAIL

THREE PIECE UNION FEMALE/FEMALE Ex d IIC

TYPE D DETAIL

SIZE

QUANTITY [gr] QUANTITY [gr]

EYS EZS - EZD

SEALING FITTINGS TO BE SEALED BY MEANS OF CRV-420 BI-COMPONENT SEALING COMPOUND PLEASE REFER TO SEALING TABLE FOR QUANTITIES.

Sealing compound table

VALVE

YOUR PARTNER FOR SAFETY

Since 1961

Explosion Proof Electrical Equipment

R

E

-

R

E

B

-

R

E

M

-

R

E

N

RE - REB - REM - REN

RE

REM

REN

REB

Feam Catalogue 01 - 147

Ex Conduit fttings

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts)

Classifcation: Group II - Category 2G 2D

EXPLOSION PROOF

REDUCERS AND ADAPTORS

ON REQUEST ACCESSORIES:

Different threads from standard

Different materials from standard

Silicon Rubber Gaskets

Mechanical characteristics

APPLICATIONS

Reducers materials galvanized steel (AZ)

Adaptors materials OT-58 marine brass (OT) - nichel plated brass (ON) - - AISI-316L stainless steel (IX) - galvanized steel (AZ)

Finishes full nickel plating threatment (brass material only)

Gasket silicon rubber EPDM / NYLON

EXPLOSION PROOF REDUCER AND ADAPTORS ARE USED TO CONNECT VARIOUS EQUIPMENT: ENCLOSURES, LIGHTING FIXTURES,

JUNCTION AND PULLING BOXES ECT. OF DIFFERENT DIAMETERS AND THREADS

ADAPTORS:

RE S.S. - BRASS

ADAPTORS:

REB S.S. - BRASS

REDUCERS - ADAPTORS

ATEX 94/9/EC GOST-R (RTR / RTN) GOST-K

EXECUTION

II 2 G Ex d IIC

II 2 G Ex e II

II 2 D Ex tD A21

Ex d IIC U

DIP A21

Ex d IIC U

DIP A21

INSTALLATION ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22

PROTECTION DEGREE IP66 IP66 IP66

CERTIFICATE REF. LOM 06 ATEX 3079U POCC IT. 05.B02537 No. 07/43-269

RULES OF COMPLIANCE

EN 60079-0; EN 60079-1; EN 60079-7;

EN 61241-0; EN 61241-1

51330.9-99 ( 60079-10-95)

51330.13-99 ( 60079-14-96)

61241-3-99

51330.0 / 1 / 8 / 14-99

61241-1-1-2002

YOUR PARTNER FOR SAFETY

Since 1961

R

E

-

R

E

B

-

R

E

M

-

R

E

N

RE21 3/4" 1/2" A

RE31 1" 1/2" A

RE32 1" 3/4" A

RE41 1-1/4" 1/2" A

RE42 1-1/4" 3/4" A

RE43 1-1/4" 1" A

RE51 1-1/2" 1/2" A

RE52 1-1/2" 3/4" A

RE53 1-1/2" 1" A

RE54 1-1/2" 1-1/4" A

RE61 2" 1/2" A

RE62 2" 3/4" A

RE63 2" 1" A

RE64 2" 1-1/4" A

RE65 2" 1-1/2" A

RE71 2-1/2" 1/2" A

RE72 2-1/2" 3/4" A

RE73 2-1/2" 1" A

RE74 2-1/2" 1-1/4" A

RE75 2-1/2" 1-1/2" A

RE76 2-1/2" 2" A

RE81 3" 1/2" A

RE82 3" 3/4" A

RE83 3" 1" A

RE84 3" 1-1/4" A

RE85 3" 1-1/2" A

RE86 3" 2" A

RE87 3" 2-1/2" A

REB21 1/2" 3/4" B

REB31 1/2" 1" B

REB32 3/4" 1" B

REB41 1/2" 1-1/4" B

REB42 3/4" 1-1/4" B

REB43 1" 1-1/4" B

REB51 1/2" 1-1/2" B

REB52 3/4" 1-1/2" B

REB53 1" 1-1/2" B

REB54 1-1/4" 1-1/2" B

REB61 1/2" 2" B

REB62 3/4" 2" B

REB63 1" 2" B

REB64 1-1/4" 2" B

REB65 1-1/2" 2" B

REB71 1/2" 2-1/2" B

REB72 3/4" 2-1/2" B

REB73 1" 2-1/2" B

REB74 1-1/4" 2-1/2" B

REB75 1-1/2" 2-1/2" B

REB76 2" 2-1/2" B

REB81 1/2" 3" B

REB82 3/4" 3" B

REB83 1" 3" B

REB84 1-1/4" 3" B

REB85 1-1/2" 3" B

REB86 2" 3" B

REB87 2-1/2" 3" B

REM21 3/4" 1/2" C

REM31 1" 1/2" C

REM32 1" 3/4" C

REM41 1-1/4" 1/2" C

REM42 1-1/4" 3/4" C

REM43 1-1/4" 1" C

REM51 1-1/2" 1/2" C

REM52 1-1/2" 3/4" C

REM53 1-1/2" 1" C

REM54 1-1/2" 1-1/4" C

REM61 2" 1/2" C

REM62 2" 3/4" C

REM63 2" 1" C

REM64 2" 1-1/4" C

REM65 2" 1-1/2" C

REM71 2-1/2" 1/2" C

REM72 2-1/2" 3/4" C

REM73 2-1/2" 1" C

REM74 2-1/2" 1-1/4" C

REM75 2-1/2" 1-1/2" C

REM76 2-1/2" 2" C

REM81 3" 1/2" C

REM82 3" 3/4" C

REM83 3" 1" C

REM84 3" 1-1/4" C

REM85 3" 1-1/2" C

REM86 3" 2" C

REM87 3" 2-1/2" C

REN21 3/4" 1/2" D

REN31 1" 1/2" D

REN32 1" 3/4" D

REN41 1-1/4" 1/2" D

REN42 1-1/4" 3/4" D

REN43 1-1/4" 1" D

REN51 1-1/2" 1/2" D

REN52 1-1/2" 3/4" D

REN53 1-1/2" 1" D

REN54 1-1/2" 1-1/4" D

REN61 2" 1/2" D

REN62 2" 3/4" D

REN63 2" 1" D

REN64 2" 1-1/4" D

REN65 2" 1-1/2" D

REN71 2-1/2" 1/2" D

REN72 2-1/2" 3/4" D

REN73 2-1/2" 1" D

REN74 2-1/2" 1-1/4" D

REN75 2-1/2" 1-1/2" D

REN76 2-1/2" 2" D

REN81 3" 1/2" D

REN82 3" 3/4" D

REN83 3" 1" D

REN84 3" 1-1/4" D

REN85 3" 1-1/2" D

REN86 3" 2" D

REN87 3" 2-1/2" D

RE 02 K 01 G ON

REB 03 N - M40 IX

RE A REB REM REN B C D

148 - Feam Catalogue 01

Ex Conduit fttings

REDUCERS Technical Features

RING REDUCERS RE

TYPE

A

MALE

B

FEMALE

DET.

REDUCERS BUSHING REB

TYPE

A

MALE

B

FEMALE

DET.

REDUCERS COUPLING REM

TYPE

A

FEMALE

B

FEMALE

DET.

REDUCERS NIPPLE REN

TYPE

A

MALE

B

MALE

DET.

A male larger dia.

B female smaller dia.

A male larger dia.

B male smaller dia.

A female larger dia.

B female smaller dia.

A female larger dia.

B male smaller dia.

EXAMPLE 1: RE02K01GON= RUDUCER TYPE RE MALE 3/4 6125 - FEMALE 1/2 ISO228 NIKEL PLATED BRASS

EXAMPLE 2: REB03NM40IX=REDUCER TYPE REB MALE 1NPT - FEMALE M40 STAINLESS STEEL

SIZE LARGER DIAMETER

02 / 03 / 04 / 05 /06 / 06 / 07 / 08

LARGER DIA. TYPE OF THREAD

K (UNI 6125-74), P(PG), N (NPT), G (ISO 228), M (ISO-metric)

SIZE SMALLER DIAMETER

01/ 02 / 03 / 04 / 05 /06 / 06 / 07

SMALLER DIA. TYPE OF THREAD

K (UNI 6125-74), P(PG), N (NPT), G (ISO 228), M (ISO-metric)

MATERIALS

IX (stainless steel), ON (nikel plated brass), OT (marine brass)

Identifcation adaptors selection table

TYPE

SIZE LARGER

DIAMETER

THREAD

SIZE SMALLER

DIAMETER

THREAD MATERIAL

EXAMPLE 1

EXAMPLE 2

REMARK: Due to the development of the national and international specifcations and of the technology, the above technical characteristics

showed on this bulletin can be considered as binding on our confrmation only.

B

YOUR PARTNER FOR SAFETY

Since 1961

Explosion Proof Electrical Equipment

P

L

G

-

N

P

-

E

M

-

E

L

-

V

-

D

L

-

D

B

PLG - NP - EM

EL - V - DL - DB

PLG

NP

DL

DB

V

PLG

INOX-OTT

EM

EL

Feam Catalogue 01 - 149

Ex Conduit fttings

ON REQUEST ACCESSORIES:

Different threads from standard

Different metal materials from standard

Mechanical characteristics

PLUGS - LOCKNUTS

Material - plugs

marine grade copper free aluminum

light alloy - galvanized steel - stainless

steel - nichel plated brass

Material - locknuts

galvanized steel - stainless steel

nichel plated brass - aluminium

ELBOWS - BUSHINGS

Material

marine grade copper free aluminum

light alloy - galvanized steel

Screws stainless steel (DBT only)

NIPPLES - COUPLINGS

Material

galvanized steel - stainless steel

(nipples only)

DRAIN/BREATHER VALVES

Material stainless steel AISI 316L

Gasket silicon rubber

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts)

Classifcation: Group II - Category 2G 2D

CONDUIT FITTINGS,

LOCKNUTS, BUSHINGS,

DRAIN / BREATHER VALVES

CONDUIT FITTINGS - DRAIN / BREATHER VALVES

ATEX 94/9/EC GOST-R (RTR / RTN) GOST-K

EXECUTION

II 2 G Ex d IIB / IIC

II 2 G Ex e II

II 2 D Ex tD A21

Ex d IIC U

DIP A21

Ex d IIC U

DIP A21

INSTALLATION ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22 ZONE 1 / 2 - ZONE 21 / 22

PROTECTION DEGREE IP66 IP66 IP66

CERTIFICATE REF. (1) LOM 06 ATEX 3079U POCC IT. 05.B02537 No. 07/43-269

RULES OF COMPLIANCE

EN 60079-0; EN 60079-1; EN 60079-7;

EN 61241-0; EN 61241-1

51330.9-99 ( 60079-10-95)

51330.13-99 ( 60079-14-96)

61241-3-99

51330.0 / 1 / 8 / 14-99

61241-1-1-2002

(1) REMARK: LOCKNUTS DL TYPE AND BUSHINGS TB-DBT TYPE ARE NOT COVERED BY Ex CERTIFICATE

YOUR PARTNER FOR SAFETY

Since 1961

P

L

G

-

N

P

-

E

M

-

E

L

-

V

-

D

L

-

D

B

PLG1 1/2"

PLG2 3/4"

PLG3 1"

PLG4 1-1/4"

PLG5 1-1/2"

PLG6 2"

PLG7 2-1/2"

PLG8 3"

NP1 1/2"

NP2 3/4"

NP3 1"

NP4 1-1/4"

NP5 1-1/2"

NP6 2"

NP7 2-1/2"

NP8 3"

EM1 1/2"

EM2 3/4"

EM3 1"

EM4 1-1/4"

EM5 1-1/2"

EM6 2"

EM7 2-1/2"

EM8 3"

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

D

D

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

D

ELF1 1/2"

ELF2 3/4"

ELF3 1"

ELF4 1-1/4"

ELF5 1-1/2"

ELF6 2"

ELF7 2-1/2"

ELF8 3"

ELFM1 1/2"

ELFM2 3/4"

ELFM3 1"

ELFM4 1-1/4"

ELFM5 1-1/2"

ELFM6 2"

ELFM7 2-1/2"

ELFM8 3"

ELM1 1/2"

ELM2 3/4"

ELM3 1"

ELM4 1-1/4"

ELM5 1-1/2"

ELM6 2"

ELM7 2-1/2"

ELM8 3"

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

D

D

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

D

D

PLG NP

EM

ELF ELFM

ELM

150 - Feam Catalogue 01

Ex Conduit fttings

CONDUIT FITTINGS - Technical Features

DETAIL "A"

MALE PLUGS

TYPE D

DETAIL B

NIPPLES

TYPE D

DETAIL C

COUPLING

TYPE D

DETAIL "D"

90deg ELBOWS

FEMALE - FEMALE

TYPE D

DETAIL E

90deg ELBOWS

MALE - FEMALE

TYPE D

DETAIL F

90deg ELBOWS

MALE - MALE

TYPE D

Det.A Det.B

Det.C

Det.D Det.E

Det.F

YOUR PARTNER FOR SAFETY

Since 1961

DL1 1/2"

DL2 3/4"

DL3 1"

DL4 1-1/4"

DL5 1-1/2"

DL6 2"

DL7 2-1/2"

DL8 3"

DL10 4"

ECD 1/2 NPT ECDE M20 VEXE M20

DB1 1/2"

DB2 3/4"

DB3 1"

DB4 1-1/4"

DB5 1-1/2"

DB6 2"

DB7 2-1/2"

DB8 3"

DB10 4"

DBT1 1/2"

DBT2 3/4"

DBT3 1"

DBT4 1-1/4"

DBT5 1-1/2"

DBT6 2"

DBT7 2-1/2"

DBT8 3"

DBT10 4"

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

D

D

D

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D D

D

P

L

G

-

N

P

-

E

M

-

E

L

-

V

-

D

L

-

D

B

DL DB

DBT

ECD ECDE

VEXE

Feam Catalogue 01 - 151

CONDUIT FITTINGS - Technical Features

Ex Conduit fttings

DETAIL "G"

LOCKNUTS (1)

TYPE D

DETAIL "L"

DRAIN/BREATHER VALVE

TYPE V BOXES FOR Ex-d ENCLOSURES

TYPE D

DETAIL "M"

DRAIN/BREATHER VALVE

TYPE V BOXES FOR ESX ENCLOSURES

TYPE D

DETAIL "N"

DRAIN/BREATHER VALVE

TYPE V BOXES FOR ESA ENCLOSURES

TYPE D

DETAIL H

BUSHINGS (1)

TYPE D

DETAIL I

BUSHINGS

WITH EARTH SCREWS (1)

TYPE D

(1) REMARK: LOCKNUTS DL TYPE AND BUSHINGS TB-DBT TYPE ARE NOT COVERED BY Ex CERTIFICATE

Det.G Det.H

Det.I

Det.L Det.M

Det.N

YOUR PARTNER FOR SAFETY

Since 1961

FIG. A

FIG. B

FIG. C

FIG. D

FIG. G

FIG. H FIG. I

FIG. E FIG. F

FIG. N FIG. M

FIG. L

FIG. O

D

P

L

G

-

N

P

-

E

M

-

E

L

-

V

-

D

L

-

D

B

PLG

STOPPING PLUGS - Technical Features

Ex Conduit fttings

EXAMPLE 1: NICKEL PLATED BRASS STOPPING PLUG 2UNI-6125

EXAMPLE 2: STAINLESS STEEL AISI-316L STOPPING PLUG 1NPT

EXAMPLE 3: STAINLESS STEEL AISI-316L STOPPING PLUG 3/4ISO-228

EXAMPLE 4: STAINLESS STEEL AISI-316L STOPPING PLUG ISO-M25

EXAMPLE 5: STAINLESS STEEL AISI-316L STOPPING PLUG 1 1/2UNI-6125

TYPE (Det. O)

PLG

THREAD / DIAMETER

01/ 02 / 03 / 04 / 05 /06 / 06 / 07 / 08

TYPE OF THREAD

K (UNI 6125-74), P(PG), N (NPT), G (ISO 228), M (ISO-metrico)

MATERIALS

IX (stainless steel), ON (marine brass),

Identifcation stopping plugs selection table

TYPE

THREAD

DIAMETER

TYPE OF

THREAD

MATERIALS

EXAMPLE 1 PLG 6 K ON

EXAMPLE 2 PLG 3 N IX

EXAMPLE 3 PLG 2 G IX

EXAMPLE 4 PLG 2 M IX

EXAMPLE 5 PLG 5 K IX

152 - Feam Catalogue 01

REMARK:

Due to the development of the national and international specifcations and of the technology, the above technical characteristics showed

on this bulletin can be considered as binding on our confrmation only.

Det.O

YOUR PARTNER FOR SAFETY

Since 1961

Explosion Proof Electrical Equipment

T

F

I

I

TFII

Feam Catalogue 01 - 153

Ex Conduit fttings

EXPLOSION PROOF STAINLESS

STEEL FLEXIBLE CONDUIT

ON REQUEST ACCESSORIES:

Different lengths from standard

PVC coating

Female thread end terminal

Male or female thread revolving end terninal

Mechanical characteristics

APPLICATIONS

Internal fexible pipe stainless steel

External braid stainless steel

Terminals threaded terminals in stainless steel or cold galvanized steel

FLEXIBLE CONDUITS ARE INSTALLED WHERE CONNECTIONS MUST BE MADE TO EQUIPMENT SUBJECT TO VIBRATIONS: MOTORS, PUMPS, ETC.

ALSO FAVOURED FOR CONNECTION TO PEDANT LIGHTING FITTING AND AT BENDS WHERE RIGID CONDUITS IS DIFFICULT TO HANDLE.

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts)

Classifcation: Group II - Category 2G 2D

FLEXIBLE CONDUIT PIPE

ATEX 94/9/EC GOST-R (RTR / RTN) GOST-K

EXECUTION

II 2 G Ex d IIB o II 2 G Ex d IIC

II 2 D Ex tD A21

Ex d IIBU o Ex d IICU

A21

Ex d IIBU o Ex d IICU

A21

AMBIENT TEMPERATURE -50C +130C -50C +130C -50C +130C

PROTECTION DEGREE IP66 / IP67 IP66 / IP67 IP66 / IP67

CERTIFICATE REF. INERIS 07 ATEX 9001U POCC IT. 05.B02537 No. 07/43-269

RULES OF COMPLIANCE

EN 60079-0:2006; EN 60079-1:2004; EN

61241-0:2006; EN 61241-1:2004;

51330.9-99 ( 60079-10-95)

51330.13-99 ( 60079-14-96)

61241-3-99

51330.0 / 1 / 8 / 14-99

61241-1-1-2002

YOUR PARTNER FOR SAFETY

Since 1961

T

F

I

I

300 X X - - - - - -

400 X X X X X X X X

450 X X X X X X X X

500 X X X X X X X X

600 X X X X X X X X

700 X X X X X X X X

800 X X X X X X X X

900 X X X X X X X X

1000 X X X X X X X X

A

C

TFII# 500 02 IN

TFII# 1000 06 AC

TFII

154 - Feam Catalogue 01

Ex Conduit fttings

TFII - Technical Features

Reference Details

STANDARD LENGHTS [mm]

FLEXIBLE CONDUIT SIZE

1 2 3 4 5 6 7 8

TFII Standard lenghts

*FLEX. CONDUIT PIPES WITH LENGHS DIFFERENT THAN STANDARD, PLEASE CONTACT OUR SALES DEPT.

TERMINAL TERMINAL

REMARK:

Due to the development of the national and international specifcations and of the technology, the above technical characteristics showed

on this bulletin can be considered as binding on our confrmation only.

SIZE THREAD*

INTERNAL DIA.

[A] [mm]

EXTERNAL DIA.

[B] [mm]

C - LENGHT

[mm]

TERMINALS MATERIAL

01 (1/2") 16 24 300 IN (stainless steel)-AC (galvanized steel)

02 (3/4) 20 29 300 IN (stainless steel)-AC (galvanized steel)

03 (1") 25 35 400 IN (stainless steel)-AC (galvanized steel)

04 (1-1/4") 32 44 400 IN (stainless steel)-AC (galvanized steel)

05 (1-1/2") 40 54 400 IN (stainless steel)-AC (galvanized steel)

06 (2") 50 66 400 IN (stainless steel)-AC (galvanized steel)

07 (2-1/2") 65 82 400 IN (stainless steel)-AC (galvanized steel)

08 (3") 80 100 400 IN (stainless steel)-AC (galvanized steel)

010 (4") 100 122 400 IN (stainless steel)-AC (galvanized steel)

C - LENGHT [mm] SIZE TERMINALS MATERIAL

*REMARK: please add N sentence after code TFII

to identify the terminal ends thread NPT (ASA B2.1).

The only code TFII identifes UNI-6125

terminal ends thread

EXAMPLE 1: TFIIN#50002IN = Flexible Conduit 3/4 Dia. 500mm total lenght c/w stainless steel NPT thread fxed male terminal ends.

EXAMPLE 2: TFIIN#100006IN = Flexible Conduit 2 Dia. 1000mm total lenght c/w galvanized steel UNI-6125 thread fxed male terminal ends.

YOUR PARTNER FOR SAFETY

Since 1961

Explosion Proof Electrical Equipment

C

-

L

-

T

-

X

-

A

D

P

E

C - L - T - X - ADPE

Feam Catalogue 01 - 155

Ex Conduit fttings

VAPOUR TIGHT CONDULETS RIGID

STEEL CONDUIT AND UNI 7683

ON REQUEST ACCESSORIES:

Different threads than standard

* Complete with one coupling at one end and plastic protecting cap at the other end. Suppliable in bars 3mt. Or 6mt. Lenght, contact our sales

dept for the availability.

CONDULETS

Mechanical characteristics

VAPOUR TIGHT CONDULETS

Material marine grade copper free aluminum light alloy

Screws galvanized steel

Gasket neoprene

*RIGID STEEL CONDUIT UNI7683

Material hot dip galvanized steel

Finishes hot galvanized according to UNI 5745

R.S.C. PIPE

Installation: hazardous areas - Zone 1 / 2 (Gases) - Zone 21 / 22 (Dusts) - Safe Area

Classifcation: Group II - Category 2G 2D

VAPOUR TIGHT CONDULETS

CEI / EN

EXECUTION INDUSTRIAL WATERPROOF

AMBIENT TEMPERATURE -

PROTECTION DEGREE IP66

CERTIFICATE REF. -

RULES OF COMPLIANCE CEI / EN 60529

RIGID STEEL CONDUIT

ATEX 94/9/EC

II 2 GD Ex d IIB / IIC

-

IP65 - IP66

-

UNI7683

YOUR PARTNER FOR SAFETY

Since 1961

C

-

L

-

T

-

X

-

A

D

P

E

C17 2 x 1/2"

C27 2 x 3/4"

C37 2 x 1"

C47 2 x 1-1/4"

C57 2 x 1-1/2"

C67 2 x 2"

C77 2 x 2-1/2"

C87 2 x 3"

LL17 2 x 1/2"

LL27 2 x 3/4"

LL37 2 x 1"

LL47 2 x 1-1/4"

LL57 2 x 1-1/2"

LL67 2 x 2"

LL77 2 x 2-1/2"

LL87 2 x 3"

LR17 2 x 1/2"

LR27 2 x 3/4"

LR37 2 x 1"

LR47 2 x 1-1/4"

LR57 2 x 1-1/2"

LR67 2 x 2"

LR77 2 x 2-1/2"

LR87 2 x 3"

FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

LB17 2 x 1/2"

LB27 2 x 3/4"

LB37 2 x 1"

LB47 2 x 1-1/4"

LB57 2 x 1-1/2"

LB67 2 x 2"

LB77 2 x 2-1/2"

LB87 2 x 3"

X17 4 x 1/2"

X27 4 x 3/4"

X37 4 x 1"

X47 4 x 1-1/4"

X57 4 x 1-1/2"

X67 4 x 2"

X77 4 x 2-1/2"

X87 4 x 3"

T17 3 x 1/2"

T27 3 x 3/4"

T37 3 x 1"

T47 3 x 1-1/4"

T57 3 x 1-1/2"

T67 3 x 2"

T77 3 x 2-1/2"

T87 3 x 3"

TB17 3 x 1/2"

TB27 3 x 3/4"

TB37 3 x 1"

TB47 3 x 1-1/4"

TB57 3 x 1-1/2"

TB67 3 x 2"

TB77 3 x 2-1/2"

TB87 3 x 3" FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

ADPE1 1/2"

ADPE2 3/4"

ADPE3 1"

ADPE4 1-1/4"

ADPE5 1-1/2"

ADPE6 2"

ADPE7 2-1/2"

ADPE8 3"

ADPE10 4"

FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

D

FIG. G FIG. F FIG. E FIG. D

FIG. C FIG. B FIG. A

C LL

LB

X

T TB

LR

156 - Feam Catalogue 01

Ex Conduit fttings

VAPOUR TIGHT CONDULETS - Technical Features

DETAIL "A"

CONDULETS C

TYPE HUBS SIZE

DETAIL B

CONDULETS LL

TYPE HUBS SIZE

DETAIL C

CONDULETS LR

TYPE HUBS SIZE

DETAIL "D"

CONDULETS LB

TYPE HUBS SIZE

DETAIL "G"

CONDULETS X

TYPE HUBS SIZE

DETAIL E

CONDULETS T

TYPE HUBS SIZE

DETAIL F

CONDULETS TB

TYPE HUBS SIZE

REMARK: Due to the development of the national and international specifcations and of the technology, the above technical characteristics

showed on this bulletin can be considered as binding on our confrmation only.

TYPE THREADS - UNI 6125 OR NPT

RIGID STEEL CONDUIT UNI 7683

Technical Features

Complete with one coupling at one end and plastic protecting cap at the other end.

Available in bars 3mt. or 6mt. lenght. Please contact our sales dept for relevant availability.

Det.A Det.B

Det.D Det.E

Det.G

Det.F

Det.C

You might also like

- Diff Formula StudentDocument1 pageDiff Formula StudentNikola ČegecNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- 3 Phase SCR ManualDocument68 pages3 Phase SCR Manualfreddy067No ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- Parts Lists: Gas Fired Steamers MODELS: SX-34GCR, SX-55GCR, SX-34GCR-RH, SX-55GCR-RH Red LobsterDocument13 pagesParts Lists: Gas Fired Steamers MODELS: SX-34GCR, SX-55GCR, SX-34GCR-RH, SX-55GCR-RH Red LobsterJosé GarciaNo ratings yet

- Elektrode Jesenice Consumables CatalogueDocument384 pagesElektrode Jesenice Consumables CatalogueValvemakerNo ratings yet

- HAT Series Air Circuit Breaker Hyundai ElectricDocument67 pagesHAT Series Air Circuit Breaker Hyundai Electricthanhlangdai67% (6)

- Manufacturing of Phthalic AnhydrideDocument16 pagesManufacturing of Phthalic AnhydrideAnkit Mistry100% (2)

- Cable Glands For Armoured CablesDocument12 pagesCable Glands For Armoured CablesFlo MircaNo ratings yet

- Solenoid Valves 3/2 551 553Document12 pagesSolenoid Valves 3/2 551 553frghertyertyergfhdftyertyNo ratings yet

- Automated Ball Valves, 3-Way SS Flange: Electric and Pneumatic ActuatorsDocument1 pageAutomated Ball Valves, 3-Way SS Flange: Electric and Pneumatic ActuatorsGilberto Meneses NavarroNo ratings yet

- Elektrode Jesenice Katalog 2009Document367 pagesElektrode Jesenice Katalog 2009Željko Brlić0% (1)

- 5 3 Way Ss ValveDocument12 pages5 3 Way Ss ValveGopinath GunasekaranNo ratings yet

- Aerial Cable: Overhead Electric Distribution StandardsDocument0 pagesAerial Cable: Overhead Electric Distribution Standardsstuv_leNo ratings yet

- 01 Feam ĐènDocument94 pages01 Feam ĐènthanhlangdaiNo ratings yet

- United Insulation DocumentsDocument168 pagesUnited Insulation Documentsjsherrer1No ratings yet

- 160.69-AD4-Application Data-YD Mod C Refrigerant Relief Valve Vent SizingDocument8 pages160.69-AD4-Application Data-YD Mod C Refrigerant Relief Valve Vent SizingMohamed AskarNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Kennedy Valve c515 Gate ValveDocument21 pagesKennedy Valve c515 Gate ValveHani SaadeNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageFlorin IordacheNo ratings yet

- Cable Schedule DG4Document16 pagesCable Schedule DG4dhirendraNo ratings yet

- DNC enDocument60 pagesDNC enjromero_rpgNo ratings yet

- ASCONDocument6 pagesASCONNithyANo ratings yet

- Manual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)Document6 pagesManual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)dharmendrabholeNo ratings yet

- 05 - Feam - CS & SP - EngDocument14 pages05 - Feam - CS & SP - EngLucian AlexandruNo ratings yet

- Pig Launcher ReceiverDocument6 pagesPig Launcher ReceiverhellothisisallenNo ratings yet

- Elektrode Jesenice KatalogDocument380 pagesElektrode Jesenice KatalogIvan Femic100% (2)

- EG 16-4-1.1 Electrical Grounding: Eca / EusaDocument23 pagesEG 16-4-1.1 Electrical Grounding: Eca / Eusaamin100% (1)

- Fuse Link SizeDocument14 pagesFuse Link Sizebilly12379224No ratings yet

- Sharp LC 19d1erd+lc 19d1eDocument12 pagesSharp LC 19d1erd+lc 19d1erictronix5586No ratings yet

- KF Trunnion Ball Valve 1-8 900lbsDocument2 pagesKF Trunnion Ball Valve 1-8 900lbsalefleavNo ratings yet

- Singhania-CO2 INERTISATION SYSTEM DataDocument12 pagesSinghania-CO2 INERTISATION SYSTEM DataAnandharaj .KNo ratings yet

- ASTM A182 F22 Flanges and SA 182 GR F22 Blind - Slip On - SWRF MaterialDocument14 pagesASTM A182 F22 Flanges and SA 182 GR F22 Blind - Slip On - SWRF MaterialMohanasundaram KandasamyNo ratings yet

- Class 1CJ1S01 (Pip PN01CJ1S01 - 2007)Document4 pagesClass 1CJ1S01 (Pip PN01CJ1S01 - 2007)Zvonko BešlićNo ratings yet

- L2301 Field Sketch PackageDocument6 pagesL2301 Field Sketch PackageMuhsen KhanNo ratings yet

- Yokogawa Differential Pressure TransmitterDocument18 pagesYokogawa Differential Pressure Transmitterprasanna1990No ratings yet

- KF Trunnion Ball Valve 2-6 150-300lbsDocument2 pagesKF Trunnion Ball Valve 2-6 150-300lbsalefleavNo ratings yet

- Cooper Ceag Datasheet Linear Fluorescent Luminaire Ellk CG S 1Document12 pagesCooper Ceag Datasheet Linear Fluorescent Luminaire Ellk CG S 1duque_sadeNo ratings yet

- Gate Valve - Post IndicatorDocument20 pagesGate Valve - Post IndicatorLENINROMEROH4168No ratings yet

- Parcol Globe ValveDocument120 pagesParcol Globe ValveAnderson SiqueiraNo ratings yet

- LPN2 Unheated Sanitation SubmittalsDocument2 pagesLPN2 Unheated Sanitation SubmittalsGabriel Ortiz MNo ratings yet

- Lifting Insp StandardsDocument3 pagesLifting Insp StandardsChandrasekhar Sonar100% (2)

- Petrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321Document21 pagesPetrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321raj_hp2000No ratings yet

- EDS Factory Sealed Tumbler SwitchesDocument9 pagesEDS Factory Sealed Tumbler SwitchesLuis RamirezNo ratings yet

- ATEX Certificate CML 737 797Document6 pagesATEX Certificate CML 737 797Milan DusankinNo ratings yet

- Ebara Pumps Europe S.p.a.'s Data&CertificatesDocument7 pagesEbara Pumps Europe S.p.a.'s Data&CertificatesErdi AkkusNo ratings yet

- 43-7500401 (Versa) PDFDocument20 pages43-7500401 (Versa) PDFAnthony WilliamsNo ratings yet

- Libro 7 1Document38 pagesLibro 7 1romanNo ratings yet

- Pic 05 0033 GBDocument14 pagesPic 05 0033 GBLis LisNo ratings yet

- ClemeDocument72 pagesClemeBeautycare SrlNo ratings yet

- 33-Electrical Design Build Guide PDFDocument18 pages33-Electrical Design Build Guide PDFKhaled MegahedNo ratings yet

- Pressure Reducing: Model 129FcDocument6 pagesPressure Reducing: Model 129Fcjames alfarasNo ratings yet

- Material Faltante FPDocument9 pagesMaterial Faltante FPmatias vargas apablazaNo ratings yet

- Ferret Complete Equipment ScheduleDocument21 pagesFerret Complete Equipment ScheduleBobby Chipping100% (1)

- Spor LanDocument30 pagesSpor LanKumar sssssNo ratings yet

- HONEYWELL VBN2 VBN3 Control Ball Valves PDFDocument12 pagesHONEYWELL VBN2 VBN3 Control Ball Valves PDFMarcello PorrinoNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Ong Thep Chlu Ap LR - RC: Ong Bao Ddy Diqn, Cap QuaDocument4 pagesOng Thep Chlu Ap LR - RC: Ong Bao Ddy Diqn, Cap QuathanhlangdaiNo ratings yet

- Earthing Clamps: Installation: Hazardous Areas - Zone 1 / 2 (Gases) Classification: Group II - Category 2GDocument10 pagesEarthing Clamps: Installation: Hazardous Areas - Zone 1 / 2 (Gases) Classification: Group II - Category 2GthanhlangdaiNo ratings yet

- Feam Junction Box EnclosureDocument36 pagesFeam Junction Box EnclosureMiky MooseNo ratings yet

- 01 Feam ĐènDocument94 pages01 Feam ĐènthanhlangdaiNo ratings yet

- 00 Feam Gioi ThieuDocument12 pages00 Feam Gioi ThieuthanhlangdaiNo ratings yet

- Hoaïch Ñònh Nhu Caàu Vaät TöDocument10 pagesHoaïch Ñònh Nhu Caàu Vaät TöthanhlangdaiNo ratings yet

- Chương 3 (TT) : Phaân Loaïi Taøi Khoaûn Heä Thoáng Taøi Khoaûn Keá Toaùn Thoáng NhaátDocument31 pagesChương 3 (TT) : Phaân Loaïi Taøi Khoaûn Heä Thoáng Taøi Khoaûn Keá Toaùn Thoáng NhaátthanhlangdaiNo ratings yet

- Bom Nuoc 100m3Document5 pagesBom Nuoc 100m3thanhlangdaiNo ratings yet

- Bom Chìm 20m3Document5 pagesBom Chìm 20m3thanhlangdaiNo ratings yet

- Bom Nuoc 10m3Document5 pagesBom Nuoc 10m3thanhlangdaiNo ratings yet

- 7.power System Stability1Document20 pages7.power System Stability1Maneesha ManuNo ratings yet

- Basic EE PrelimDocument3 pagesBasic EE PrelimJohnCris B. FornilosNo ratings yet

- V80EX N Data SheetDocument1 pageV80EX N Data SheetAlen KušecNo ratings yet

- Pipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)Document6 pagesPipework Components - Definition and Selection of DN (Nominal Size) (ISO 6708:1995) Rörledningar - Nominell Storlek, DN (ISO 6708:1995)white9013No ratings yet

- GROHE Digital Planning Master 2016 DSDocument25 pagesGROHE Digital Planning Master 2016 DSEduard CollNo ratings yet

- AIGA 075 - 11 Cal Method For Prevention of Overpress - Cryogenic Tanks - Reformated Jan 12 PDFDocument57 pagesAIGA 075 - 11 Cal Method For Prevention of Overpress - Cryogenic Tanks - Reformated Jan 12 PDFdaimon_pNo ratings yet

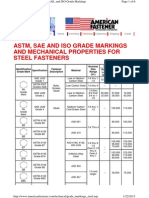

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- Sectoral ApproachDocument44 pagesSectoral ApproachDSGNo ratings yet

- HRE Prelim FinalsDocument163 pagesHRE Prelim FinalsPatrick PunzalanNo ratings yet

- Solar Water PumpingDocument4 pagesSolar Water PumpingVaibhav Vithoba NaikNo ratings yet

- Tdj-609017Deh-65F: Xpol 698 960Mhz 65° 16.5dbi 0° 10° Manual or by Optional Rcu (Remote Control Unit) AntennaDocument1 pageTdj-609017Deh-65F: Xpol 698 960Mhz 65° 16.5dbi 0° 10° Manual or by Optional Rcu (Remote Control Unit) AntennaАлександр100% (1)

- Project Scheduling: Precedence Diagram MethodDocument61 pagesProject Scheduling: Precedence Diagram MethodJacob LusterioNo ratings yet

- 1 EES Fatigue Testing Machine Is Used For Studying The Effects of Fatigue Using ADocument7 pages1 EES Fatigue Testing Machine Is Used For Studying The Effects of Fatigue Using AFrank.JNo ratings yet

- ML C 650 c65mm716Document8 pagesML C 650 c65mm716operacionesNo ratings yet

- Dymablanc DM-2907: Basic Properties Typical RecipesDocument1 pageDymablanc DM-2907: Basic Properties Typical RecipesAshfaq KoomarNo ratings yet

- Full Scale Load Test For BridgeDocument9 pagesFull Scale Load Test For BridgeAlsonChin0% (1)

- Allstyle Coil Company, L.P. Evaporator Coil Installation InstructionsDocument2 pagesAllstyle Coil Company, L.P. Evaporator Coil Installation Instructionsjhon manuel de jesusNo ratings yet

- STD - C37.2 - 1991 - IEEE Standard Electrical Power System Device Function NumbersDocument22 pagesSTD - C37.2 - 1991 - IEEE Standard Electrical Power System Device Function Numberslisused100% (2)

- Types of Air Conditioning SystemsDocument19 pagesTypes of Air Conditioning Systemsa_mohid17No ratings yet

- SADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)Document3 pagesSADCAS F 61e - Proficiency Testing Requirements ISO-IEC 17025-2005 Clause 5.9 & SADCAS Requirements (Issue 2)tomychalilNo ratings yet

- 84876283Document4 pages84876283homaNo ratings yet

- Catalouge Coremetal 1Document16 pagesCatalouge Coremetal 1220479No ratings yet

- Oxidation ReactionDocument32 pagesOxidation ReactionDeepak PradhanNo ratings yet

- Medical Electrical Equipment - Part 2-41: Particular Requirements For Basic Safety and Essential Performance of Surgical Luminaires and Luminaires For DiagnosisDocument23 pagesMedical Electrical Equipment - Part 2-41: Particular Requirements For Basic Safety and Essential Performance of Surgical Luminaires and Luminaires For Diagnosisguezaki6636No ratings yet

- F 35 Sar 2018 PDFDocument100 pagesF 35 Sar 2018 PDFVietVetSteveNo ratings yet

- INTERACTION and SQUATDocument48 pagesINTERACTION and SQUATمرتضى جبار السودانيNo ratings yet

- Lec Room PDFDocument70 pagesLec Room PDFKhairul IzuwanNo ratings yet

- Ficha Tecnica Megum 128Document2 pagesFicha Tecnica Megum 128Pedro CasillaNo ratings yet

- Marine Smart Trash (New)Document5 pagesMarine Smart Trash (New)king syNo ratings yet