Professional Documents

Culture Documents

Power Screws: Version 2 ME, IIT Kharagpur

Power Screws: Version 2 ME, IIT Kharagpur

Uploaded by

Alok RkmvCopyright:

Available Formats

You might also like

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- Assignment 1Document2 pagesAssignment 1Diganta Hatibaruah50% (2)

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- PSC GirderDocument73 pagesPSC GirderHegdeVenugopal100% (1)

- Hydrostatic Strength of HDPE Pipes - Test ProcedureDocument5 pagesHydrostatic Strength of HDPE Pipes - Test ProceduremuhamedzNo ratings yet

- 7DEFLECTIONDocument19 pages7DEFLECTIONJayson Mari0% (1)

- Critical AppraisalDocument11 pagesCritical AppraisalVaishnavi ChandranNo ratings yet

- 2 (B) Design of Knuckle JointDocument16 pages2 (B) Design of Knuckle JointOppo A7No ratings yet

- KDM 6Document54 pagesKDM 6KarthikeyanRamanujamNo ratings yet

- Screw Jacks CalculationDocument27 pagesScrew Jacks CalculationTarmana Antt0% (1)

- Machine Design Final ReportDocument23 pagesMachine Design Final ReportAvk Sanjeevan100% (2)

- Design of Screw Jack Report FinalDocument10 pagesDesign of Screw Jack Report Finaladitya kshirsagarNo ratings yet

- Solution: Fig. 6.27 Differential Screw JackDocument6 pagesSolution: Fig. 6.27 Differential Screw JackWahyu AwaludinNo ratings yet

- Design of The Toggle JackDocument30 pagesDesign of The Toggle Jackkoanakist91% (11)

- Design and Fabrication of Screw JackDocument18 pagesDesign and Fabrication of Screw JackPawan Seethepalli100% (2)

- General Description: Magnet Selection Guide Application NoteDocument15 pagesGeneral Description: Magnet Selection Guide Application NotesekoNo ratings yet

- Machine Design Report 1Document15 pagesMachine Design Report 1WaqasNo ratings yet

- Machine Design Assignment-1Document2 pagesMachine Design Assignment-1RAJAT RAJNo ratings yet

- Design of Keys and CouplingsDocument37 pagesDesign of Keys and Couplingskeval patel100% (1)

- Stresses in Machine MemberDocument18 pagesStresses in Machine MemberK ULAGANATHANNo ratings yet

- Tensile Testing of Ferrous and Non-Ferrous AlloyDocument7 pagesTensile Testing of Ferrous and Non-Ferrous Alloyrama100% (1)

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- FLYWHEEELSDocument22 pagesFLYWHEEELSRex OabelNo ratings yet

- Design Ofscrew JackDocument10 pagesDesign Ofscrew JacksbkulkNo ratings yet

- Design of Cylinder CoversDocument4 pagesDesign of Cylinder Coversjaison jacobNo ratings yet

- Jack DesignDocument24 pagesJack DesignWaseneh MuluNo ratings yet

- Design of Machine Elements2Document14 pagesDesign of Machine Elements2Satwik PriyadarshiNo ratings yet

- Bottle Jack - NewDocument9 pagesBottle Jack - NewWaseneh MuluNo ratings yet

- Chapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Document80 pagesChapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Dr. Aung Ko LattNo ratings yet

- Castigliano S TheoremDocument19 pagesCastigliano S TheoremAhver ChaudharyNo ratings yet

- Spring DesignDocument26 pagesSpring DesignNeelkanth BenadeNo ratings yet

- Pneumatic Sheet Metal Shearing MachineDocument21 pagesPneumatic Sheet Metal Shearing MachineGamerNo ratings yet

- Cotter JointDocument18 pagesCotter JointritNo ratings yet

- Electrical Carjack PDFDocument60 pagesElectrical Carjack PDFAj KNo ratings yet

- Engg Sol ManualDocument133 pagesEngg Sol Manualmiddieman147100% (6)

- CC2 Topic 6 Keys and Couplings - Lecture NoteDocument34 pagesCC2 Topic 6 Keys and Couplings - Lecture NoteChristian Breth BurgosNo ratings yet

- KOM Important QuestionsDocument12 pagesKOM Important QuestionsJithin KNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Me6503 Dme Unit 5 Study Notes 2015Document25 pagesMe6503 Dme Unit 5 Study Notes 2015Bala MuruganNo ratings yet

- Mdid Lab ManualDocument48 pagesMdid Lab Manualjaimin777No ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- BISRAT GIRMA Gearbox DesignDocument92 pagesBISRAT GIRMA Gearbox DesignŠmřű Žăm Ğ Bøýž0% (1)

- DME Lesson Plan As Per NBADocument3 pagesDME Lesson Plan As Per NBASabareesan Subramanian0% (1)

- Gearbox DesignDocument94 pagesGearbox DesignHema KumarNo ratings yet

- TurbomachineryDocument53 pagesTurbomachineryasp9924No ratings yet

- CH 19Document21 pagesCH 19Sanjay Kumar100% (1)

- Design Considerations For A Gear DriveDocument17 pagesDesign Considerations For A Gear Driveمحمدفیضان چوہدریNo ratings yet

- Keys, Shafts and CouplingsDocument26 pagesKeys, Shafts and CouplingsNauman KhanNo ratings yet

- Flange Coupling Lab PDFDocument25 pagesFlange Coupling Lab PDFAli Raza MalikNo ratings yet

- 7structural Analysis of Crane Hook PDFDocument4 pages7structural Analysis of Crane Hook PDFMohankumarNo ratings yet

- Unit 1. Fundamentals of Design Master b5Document20 pagesUnit 1. Fundamentals of Design Master b5S VNo ratings yet

- 76-3-Bevel GearDocument12 pages76-3-Bevel Gearrip111176No ratings yet

- Design of SpringsDocument7 pagesDesign of SpringsGAMUCHIRAI MUGADZANo ratings yet

- Design Procedures For Rigid and FlexibleDocument13 pagesDesign Procedures For Rigid and FlexibleParv JainNo ratings yet

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- Homework 2Document2 pagesHomework 2Mostafa RoozbahanNo ratings yet

- C Programming, Design A Spring (Helical) Under Given Static and Fluctuating Load For A Given Spring Index So That The Spring Design Lie Within Safe Limit.Document12 pagesC Programming, Design A Spring (Helical) Under Given Static and Fluctuating Load For A Given Spring Index So That The Spring Design Lie Within Safe Limit.Manoj Kumar GangwarNo ratings yet

- CIE3150 2017 Case Study Beam V 03-2Document19 pagesCIE3150 2017 Case Study Beam V 03-2FerdiVKNo ratings yet

- Thin CylinderDocument10 pagesThin Cylinderarunnical100% (3)

- Test Exams PDFDocument7 pagesTest Exams PDFShaheer Ahmed KhanNo ratings yet

- Design of Knuckle JointDocument26 pagesDesign of Knuckle Jointvikasporwal2605100% (2)

- Design of Welded JointsDocument7 pagesDesign of Welded JointsmohammadNo ratings yet

- (Meng) Mechanical Design of Rocket MotorsDocument31 pages(Meng) Mechanical Design of Rocket MotorsYudi RahmanNo ratings yet

- 41 Rolling Contact BearingsDocument11 pages41 Rolling Contact BearingsPRASAD326100% (3)

- 17 Power Screw Drives and Their EfficiencyDocument15 pages17 Power Screw Drives and Their EfficiencyPRASAD326100% (2)

- Block Diagram of Intel 8086Document5 pagesBlock Diagram of Intel 8086Ritesh SinghNo ratings yet

- 38 Design of Flat Belt DrivesDocument9 pages38 Design of Flat Belt DrivesPRASAD326100% (1)

- Bearing-Study Material Mechanical Engg-1Document14 pagesBearing-Study Material Mechanical Engg-1anishiitdNo ratings yet

- 39 Design of V - Belt DrivesDocument10 pages39 Design of V - Belt DrivesPRASAD326100% (6)

- 34 Design of Joints With Variable LoadingDocument8 pages34 Design of Joints With Variable LoadingPRASAD326100% (1)

- 35 Design of Shoe BrakesDocument10 pages35 Design of Shoe BrakesPRASAD326100% (1)

- 37 Introduction To Belt DrivesDocument12 pages37 Introduction To Belt DrivesPRASAD326100% (11)

- 36 Design of Band and Disc BrakesDocument10 pages36 Design of Band and Disc BrakesPRASAD326100% (2)

- 29 Welded Joints Types and UsesDocument10 pages29 Welded Joints Types and UsesPRASAD326100% (1)

- 21 Design of Leaf SpringsDocument10 pages21 Design of Leaf SpringsPRASAD326100% (1)

- 25 Thick Cylinders Stresses Due To Internal and External PressuresDocument14 pages25 Thick Cylinders Stresses Due To Internal and External PressuresPRASAD326100% (4)

- 33 Design of Eccentrically Loaded Welded JointsDocument10 pages33 Design of Eccentrically Loaded Welded JointsPRASAD326No ratings yet

- 23 Shaft and Its Design Based On StrengthDocument9 pages23 Shaft and Its Design Based On StrengthPRASAD326No ratings yet

- 30 Design of Welded JointsDocument8 pages30 Design of Welded JointsPRASAD326No ratings yet

- 32 Design of Eccentrically Loaded Bolted or Riveted JointsDocument10 pages32 Design of Eccentrically Loaded Bolted or Riveted JointsPRASAD326100% (3)

- 11 Types of Fasteners Pins and KeysDocument12 pages11 Types of Fasteners Pins and KeysPRASAD326100% (2)

- Thin CylinderDocument10 pagesThin Cylinderarunnical100% (3)

- 28 Design of Riveted JointsDocument9 pages28 Design of Riveted JointsPRASAD326100% (1)

- 20 Design of Helical Springs For Variable LoadDocument16 pages20 Design of Helical Springs For Variable LoadPRASAD326No ratings yet

- 27 Riveted Joints Types and UsesDocument11 pages27 Riveted Joints Types and UsesPRASAD326100% (1)

- Pin Bush Coupling DesignDocument15 pagesPin Bush Coupling Designyogwani79No ratings yet

- 22 Shaft and Its Design Based On StrengthDocument11 pages22 Shaft and Its Design Based On StrengthPRASAD326100% (4)

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- 12 Cotter and Knuckle JointDocument16 pages12 Cotter and Knuckle JointPRASAD326100% (3)

- 8 Stress ConcentrationDocument15 pages8 Stress ConcentrationPRASAD326100% (3)

- 10 Low and High Cycle FatigueDocument14 pages10 Low and High Cycle FatiguePRASAD326100% (1)

- 7 Design For Static LoadingDocument21 pages7 Design For Static LoadingPRASAD326100% (1)

- A. Boq For Hangar Foundation For Private Terminal & Hangar @mmia, Lagos.Document2 pagesA. Boq For Hangar Foundation For Private Terminal & Hangar @mmia, Lagos.uchennaNo ratings yet

- Eaton Fuller RTLO 16918B As Transmission Parts ManualDocument34 pagesEaton Fuller RTLO 16918B As Transmission Parts ManualRoy Hernandez100% (1)

- Chemrite Descaler A-28Document2 pagesChemrite Descaler A-28ghazanfarNo ratings yet

- Ca La Building Vol2 PDFDocument324 pagesCa La Building Vol2 PDFaa100200No ratings yet

- Compression Design Section1Document10 pagesCompression Design Section1Anonymous sfkedkymNo ratings yet

- Frank GehryDocument35 pagesFrank GehryPratyush DajuNo ratings yet

- RC (Doubly Reinforced) Beam06Document1 pageRC (Doubly Reinforced) Beam06Ral GLNo ratings yet

- Tatad v. Garcia, JRDocument9 pagesTatad v. Garcia, JRsophiaNo ratings yet

- Condition Survey of Old Houses (Pol) in AhmedabadDocument30 pagesCondition Survey of Old Houses (Pol) in Ahmedabadmaurya parkaraNo ratings yet

- Terrace Houses MalaysiaDocument4 pagesTerrace Houses MalaysiaRamandeep SinghNo ratings yet

- Old RTA NOC For Fense NOC-04122018-2204-NOCCertificate-25-03-2019-0713281554313640148Document8 pagesOld RTA NOC For Fense NOC-04122018-2204-NOCCertificate-25-03-2019-0713281554313640148albfaragNo ratings yet

- Stiffened RoundDocument16 pagesStiffened RoundIoannis Mitsis100% (1)

- Design Recommendation For Propeller PumpsDocument24 pagesDesign Recommendation For Propeller PumpsSamir SalimNo ratings yet

- Masonry Cement: Standard Specification ForDocument4 pagesMasonry Cement: Standard Specification ForLupita RamirezNo ratings yet

- Project Management Report For Tank FarmDocument12 pagesProject Management Report For Tank FarmsandycrackjackNo ratings yet

- Cognition PracticeDocument22 pagesCognition PracticeKhaoula BouhaimiNo ratings yet

- Polycab Price List - March - 2021Document13 pagesPolycab Price List - March - 2021Kevin MaldeNo ratings yet

- SIA 269-6-1 - en - 160114Document40 pagesSIA 269-6-1 - en - 160114Ricardo PimentelNo ratings yet

- Civil Engineer Resume-FinalDocument5 pagesCivil Engineer Resume-FinalNikhilNo ratings yet

- K08798 Wood Plastic Fusabond Brochure 0408Document4 pagesK08798 Wood Plastic Fusabond Brochure 0408anon_850523309No ratings yet

- Polyethylene Corrugated Duct (PEC) and HDPE Ducts: For Power & TelecommunicationDocument20 pagesPolyethylene Corrugated Duct (PEC) and HDPE Ducts: For Power & TelecommunicationthoufiqNo ratings yet

- Rate of Shedule M - P - 2009Document393 pagesRate of Shedule M - P - 2009Er Tarun PalNo ratings yet

- Architectural Design 05: Pangasinan State UniversityDocument13 pagesArchitectural Design 05: Pangasinan State UniversityKhalid Ali Saif Al-ShamsiNo ratings yet

- The Law and Jurisprudence OnDocument39 pagesThe Law and Jurisprudence OnRowan O'mearaNo ratings yet

- Plastiment VZ PDFDocument2 pagesPlastiment VZ PDFDarwin SyahputraNo ratings yet

- Design of Retaning Wall-1.0 To 1.5Mtr Above Ground LVLDocument8 pagesDesign of Retaning Wall-1.0 To 1.5Mtr Above Ground LVLAmarjit KulkarniNo ratings yet

Power Screws: Version 2 ME, IIT Kharagpur

Power Screws: Version 2 ME, IIT Kharagpur

Uploaded by

Alok RkmvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Screws: Version 2 ME, IIT Kharagpur

Power Screws: Version 2 ME, IIT Kharagpur

Uploaded by

Alok RkmvCopyright:

Available Formats

Module

6

Power Screws

Version 2 ME, IIT Kharagpur

Lesson

2

Design of power screws

Version 2 ME, IIT Kharagpur

Instructional Objectives

At the end of this lesson, the students should have the knowledge of

Stresses in power screw.

Design procedure of a power screw.

6.2.1 Stresses in power screws

Design of a power screw must be based on the stresses developed in the

constituent parts. A power screw is subjected to an axial load and a turning

moment. The following stresses would be developed due to the loading:

a) Compressive stress is developed in a power screw due to axial load.

Depending on the slenderness ratio it may be necessary to analyze for

buckling. The compressive stress

c

is given by

c

=

2

c

P

d

where d

c

is the

core diameter and if slenderness ratio is more than 100 or so buckling

criterion must be used. is defined as =

L

k

where I=Ak

2

and L is the

length of the screw. Buckling analysis yields a critical load P

c

and if

both

ends are assumed to be hinged critical load is given by P

C

=

2

2

EI

L

. In

general the equation may be written as P

C

=

2

2

EI

n

L

where n is a constant

that depends on end conditions.

b) Torsional shear stress is developed in the screw due to the turning

moment and this is given by =

3

c

16T

d

where T is the torque applied.

Version 2 ME, IIT Kharagpur

c) Bending stresses are developed in the screw thread and this is illustrated

in figure-6.2.1.1. The bending moment M=

'

Fh

2

and the bending stress on

a single thread is given by

b

=

My

I

. Here y =

t

2

, I =

3

m

d t

12

and F

is the load

on a single thread. Figure-6.2.1.2 shows a developed thread and figure-

6.2.1.3 shows a nut and screw assembly. This gives the bending stress at

the thread root to be

b

=

'

2

m

3Fh

d t

. This is clearly the most probable place

for failure.

Assuming that the load is equally shared by the nut threads

d) Bearing stress

br

at the threads is given by

br

=

'

m

F / n

d h

e) Again on similar assumption shear stress at the root diameter is given by

=

'

c

F / n

d t

Here n

/

is the number of threads in the nut. Since the screw is subjected to

torsional shear stress in addition to direct or transverse stress combined

effect of bending, torsion and tension or compression should be considered in

the design criterion.

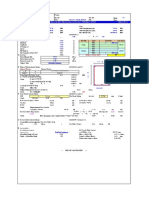

6.2.2 Design procedure of a Screw J ack

A typical screw jack is shown in figure-6.2.2.1 . It is probably more

informative to consider the design of a jack for a given load and lift. We

consider a reasonable value of the load to be 100KN and lifting height to be

500mm. The design will be considered in the following steps:

Version 2 ME, IIT Kharagpur

1. Design of the screw

A typical screw for this purpose is shown in figure-6.2.2.2.

Let us consider a mild steel screw for which the tensile and shear strengths

may be taken to be approximately 448MPa and 224 MPa respectively. Mild

steel being a ductile material we may take the compressive yield strength to

be also close to 448MPa. Taking a very high factor of safety of 10 due to the

nature of the application and considering the axial compression the core

diameter of the screw d

c

is given by

3

c

6

100x10

d

448x10

4 10

=

which gives d

c

54

mm.

From the chart of normal series square threads in table- 6.1.1.1 the nearest

standard nominal diameter of 70 mm is chosen, with pitch p =10 mm.

Therefore, core diameter d

c

=60 mm , Major diameter d

maj

=70mm , Mean

diameter d

m

=65 mm , Nominal diameter d

n

=70mm.

The torque required to raise the load is given by

T =

m m

m

Fd d

2 d

+

l

l

Where l =np, n being the number of starts. Here we have a single start screw

and hence l =p =10mm, d

m

=65mm, F =100X10

3

N

Taking a safe value of for this purpose to be 0.26 and substituting the

values we get

T =1027 Nm.

Check for combined stress

The screw is subjected to a direct compressive stress

c

and a torsional

shear stress . The stresses are given by

c

=

3

2 2

c

4F 4x100x10

35.3MPa

d x(0.06)

= =

Version 2 ME, IIT Kharagpur

3 3

c

16T 16x1027

24.22MPa

d x(0.060)

= = =

The principal stress can be given by

( )

2

2 35.3 35.3

24.22 47.6MPa

2 2

1,2

= + =

and 12.31 MPa

and maximum shear stress

max

=29.96 MPa.

The factor of safety in compression =

448

36.4

12.31

= and in shear =

224

7.48

29.96

= . Therefore the screw dimensions are safe. Check for buckling

and thread stress are also necessary. However this can be done after

designing the nut whose height and number of threads in contact is needed to

determine the free length of the screw.

2. Design of the nut

A suitable material for the nut, as shown in figure- 6.2.2.3, is phosphor

bronze which is a Cu-Zn alloy with small percentage of Pb and the yield

stresses may be taken as

Yield stress in tension

ty

=125MPa

Yield stress in compression

cy

=150MPa

Yield stress in shear

y

=105MPa

Safe bearing pressure P

b

=15MPa.

Considering that the load is shared equally by all threads bearing failure may

be avoided if

( )

2 2

maj c b

F d d P

4

=

/

n

where n

/

is the number of threads in contact. Substituting values in the above

equation we have n

/

=6.52. Let n

/

=8. Therefore H =n

/

p =8X10 =80mm.

The nut threads are also subjected to crushing and shear. Considering

crushing failure we have

Version 2 ME, IIT Kharagpur

( )

/ 2

maj c

F n d d

4

=

2

c

This gives

c

=12.24 MPa which is adequately safe since

cy

=150 MPa and

therefore crushing is not expected. To avoid shearing of the threads on the

nut we may write F =d

maj

t n

/

where t is the thread thickness which for the

square thread is

p

2

ie 5. This gives =11.37 MPa and since

y

=105MPa

shear failure of teeth is not expected. Due to the screw loading the nut needs

to be checked for tension also and we may write

CF =

( )

2 2

1 c

D d

4

ty

A correlation factor C for the load is used to account for the twisting moment.

With C=1.3 and on substitution of values in the equation D

1

works out to be

70mm. But D

1

needs to be larger than d

maj

and we take D

1

=100mm.

We may also consider crushing of the collar of the nut and to avoid this we

may write F =

( )

2 2

2 1

D D

4

cy

Substituting values we have D

2

=110 mm. To allow for the collar margin we

take D

2

=120mm. Considering shearing of the nut collar D

1

a

y

= F .

Substituting values we have a =4mm Let a =15mm

3. Buckling of the Screw.

Length L of the screw =Lifting height +H.

This gives L=500+80 =580 mm

With the nominal screw diameter of 70mm , I =

4

6

(0.07)

1.178X10

64

=

and K =

6

2

I 1.178X10

0.0175mm.

A

(0.07)

4

= =

The slenderness ration =

L 0.58

33

K 0.0175

=

Version 2 ME, IIT Kharagpur

This value of slenderness ratio is small (< 40) and the screw may be treated

as a short column . No buckling of the screw is therefore expected.

4. Tommy bar

A typical tommy bar for the purpose is shown in figure-6.2.2.4.a.

Total torsional moment without the collar friction is calculated in section

6.2.2.1 and T =1027 Nm. The collar friction in this case ( see figure-6.2.2.1)

occurs at the interface I. However in order to avoid rotation of the load when

the screw rotates a loose fitting of the cup is maintained.

Length l

/

of the tommy bar =l

1

+ and we may write the torque T as

3

D

T=F

1

l

/

Where F

1

is the maximum force applied at the tommy bar end and this

may be taken as approximately 400 N . This gives l

/

=

1027

400

=2.56m. This

length of the tommy bar is too large and one alternative is to place the tommy

bar centrally and apply force at both the ends. This alternative design of the

tommy bar is also shown in figure-6.2.2.4.b The bar is subjected to a bending

moment and its maximum value may be taken as1027 Nm. This means to

avoid bending we may write

3

1

d

32

ty

=1027 where d

1

is the tommy bar

diameter as shown in figure- 6.2.2.4.b If we choose a M.S bar of

ty

=

448MPa the tommy bar diameter d

1

works out to be d

1

=0.0285m.

Let d

1

=30 mm and we choose d

2

=40mm

5. Other dimensions

D

3

=(1.5 to 1.7 ) d Let D

3

=112 mm

D

4

=

3

D

2

=56 mm

Let L

1

=100 mm and t

4

=10 mm

Frame

Version 2 ME, IIT Kharagpur

t

1

=0.25 d

n

18 mm , D

5

2.25 D

2

=270 mm, D

6

=1.75 D

5

=473 mm,

t

3

=t

1

/2 =9 mm.

h/2

h/2

t

d

c

/2

d

m

/2

F

t

d

m

6.2.1.2 F- Dimensions of a developed

thread

6.2.1.1 F- Loading and bending stresses in screw threads

Version 2 ME, IIT Kharagpur

6.2.1.3 F- A screw and nut assembly

Version 2 ME, IIT Kharagpur

D

6

D

5

H

'

t

2

t

1

D

2

D

1

d

c

d

maj

t

3

D

3

D

4

Interface I

6.2.2.1F- A typical screw jack

Version 2 ME, IIT Kharagpur

6.2.2.3F- A phosphor bronze nut for the

screw jack

D

3

D

4

t

4

t

4

L

1

L

d

1

d

n

D

1

d

n

D

2

H

a

6.2.2.2F- The screw with the provision for tommy

bar attachment

Version 2 ME, IIT Kharagpur

l

1

l

'

l

2

d

2

D

3

d

1

6.2.2.4.a F- A typical tommy bar with a holding end.

d

1

l

'

6.2.2.4.b F- A typical centrally located tommy bar

Version 2 ME, IIT Kharagpur

6.2.3 Summary of this Lesson

In this lesson firstly the stresses developed in a power screw are discussed.

Design procedure of a screw jack is then considered and the components such

as the screw, the nut and the tommy bar are designed for strength. Finally the

assembled screw jack along with the components are shown in the dimensioned

figures.

6.2.4 Reference for Module-6

1) A textbook of machine design by P.C.Sharma and D.K.Agarwal,

S.K.Kataria and sons, 1998.

2) The elements of machine design by S.J .Berard and E.O.Waters, D.Van

Nostrand Company, 1927.

3) Design of machine elements by M.F.Spotts, Prentice hall of India, 1991.

4) Mechanical engineering design by J oseph E. Shigley, McGraw Hill,

1986.

5) A text book of machine drawing by R. K. Dhawan, S. Chand and Co.

Ltd., 1996.

Version 2 ME, IIT Kharagpur

You might also like

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- Assignment 1Document2 pagesAssignment 1Diganta Hatibaruah50% (2)

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- PSC GirderDocument73 pagesPSC GirderHegdeVenugopal100% (1)

- Hydrostatic Strength of HDPE Pipes - Test ProcedureDocument5 pagesHydrostatic Strength of HDPE Pipes - Test ProceduremuhamedzNo ratings yet

- 7DEFLECTIONDocument19 pages7DEFLECTIONJayson Mari0% (1)

- Critical AppraisalDocument11 pagesCritical AppraisalVaishnavi ChandranNo ratings yet

- 2 (B) Design of Knuckle JointDocument16 pages2 (B) Design of Knuckle JointOppo A7No ratings yet

- KDM 6Document54 pagesKDM 6KarthikeyanRamanujamNo ratings yet

- Screw Jacks CalculationDocument27 pagesScrew Jacks CalculationTarmana Antt0% (1)

- Machine Design Final ReportDocument23 pagesMachine Design Final ReportAvk Sanjeevan100% (2)

- Design of Screw Jack Report FinalDocument10 pagesDesign of Screw Jack Report Finaladitya kshirsagarNo ratings yet

- Solution: Fig. 6.27 Differential Screw JackDocument6 pagesSolution: Fig. 6.27 Differential Screw JackWahyu AwaludinNo ratings yet

- Design of The Toggle JackDocument30 pagesDesign of The Toggle Jackkoanakist91% (11)

- Design and Fabrication of Screw JackDocument18 pagesDesign and Fabrication of Screw JackPawan Seethepalli100% (2)

- General Description: Magnet Selection Guide Application NoteDocument15 pagesGeneral Description: Magnet Selection Guide Application NotesekoNo ratings yet

- Machine Design Report 1Document15 pagesMachine Design Report 1WaqasNo ratings yet

- Machine Design Assignment-1Document2 pagesMachine Design Assignment-1RAJAT RAJNo ratings yet

- Design of Keys and CouplingsDocument37 pagesDesign of Keys and Couplingskeval patel100% (1)

- Stresses in Machine MemberDocument18 pagesStresses in Machine MemberK ULAGANATHANNo ratings yet

- Tensile Testing of Ferrous and Non-Ferrous AlloyDocument7 pagesTensile Testing of Ferrous and Non-Ferrous Alloyrama100% (1)

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- FLYWHEEELSDocument22 pagesFLYWHEEELSRex OabelNo ratings yet

- Design Ofscrew JackDocument10 pagesDesign Ofscrew JacksbkulkNo ratings yet

- Design of Cylinder CoversDocument4 pagesDesign of Cylinder Coversjaison jacobNo ratings yet

- Jack DesignDocument24 pagesJack DesignWaseneh MuluNo ratings yet

- Design of Machine Elements2Document14 pagesDesign of Machine Elements2Satwik PriyadarshiNo ratings yet

- Bottle Jack - NewDocument9 pagesBottle Jack - NewWaseneh MuluNo ratings yet

- Chapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Document80 pagesChapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Dr. Aung Ko LattNo ratings yet

- Castigliano S TheoremDocument19 pagesCastigliano S TheoremAhver ChaudharyNo ratings yet

- Spring DesignDocument26 pagesSpring DesignNeelkanth BenadeNo ratings yet

- Pneumatic Sheet Metal Shearing MachineDocument21 pagesPneumatic Sheet Metal Shearing MachineGamerNo ratings yet

- Cotter JointDocument18 pagesCotter JointritNo ratings yet

- Electrical Carjack PDFDocument60 pagesElectrical Carjack PDFAj KNo ratings yet

- Engg Sol ManualDocument133 pagesEngg Sol Manualmiddieman147100% (6)

- CC2 Topic 6 Keys and Couplings - Lecture NoteDocument34 pagesCC2 Topic 6 Keys and Couplings - Lecture NoteChristian Breth BurgosNo ratings yet

- KOM Important QuestionsDocument12 pagesKOM Important QuestionsJithin KNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- Me6503 Dme Unit 5 Study Notes 2015Document25 pagesMe6503 Dme Unit 5 Study Notes 2015Bala MuruganNo ratings yet

- Mdid Lab ManualDocument48 pagesMdid Lab Manualjaimin777No ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- BISRAT GIRMA Gearbox DesignDocument92 pagesBISRAT GIRMA Gearbox DesignŠmřű Žăm Ğ Bøýž0% (1)

- DME Lesson Plan As Per NBADocument3 pagesDME Lesson Plan As Per NBASabareesan Subramanian0% (1)

- Gearbox DesignDocument94 pagesGearbox DesignHema KumarNo ratings yet

- TurbomachineryDocument53 pagesTurbomachineryasp9924No ratings yet

- CH 19Document21 pagesCH 19Sanjay Kumar100% (1)

- Design Considerations For A Gear DriveDocument17 pagesDesign Considerations For A Gear Driveمحمدفیضان چوہدریNo ratings yet

- Keys, Shafts and CouplingsDocument26 pagesKeys, Shafts and CouplingsNauman KhanNo ratings yet

- Flange Coupling Lab PDFDocument25 pagesFlange Coupling Lab PDFAli Raza MalikNo ratings yet

- 7structural Analysis of Crane Hook PDFDocument4 pages7structural Analysis of Crane Hook PDFMohankumarNo ratings yet

- Unit 1. Fundamentals of Design Master b5Document20 pagesUnit 1. Fundamentals of Design Master b5S VNo ratings yet

- 76-3-Bevel GearDocument12 pages76-3-Bevel Gearrip111176No ratings yet

- Design of SpringsDocument7 pagesDesign of SpringsGAMUCHIRAI MUGADZANo ratings yet

- Design Procedures For Rigid and FlexibleDocument13 pagesDesign Procedures For Rigid and FlexibleParv JainNo ratings yet

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- Homework 2Document2 pagesHomework 2Mostafa RoozbahanNo ratings yet

- C Programming, Design A Spring (Helical) Under Given Static and Fluctuating Load For A Given Spring Index So That The Spring Design Lie Within Safe Limit.Document12 pagesC Programming, Design A Spring (Helical) Under Given Static and Fluctuating Load For A Given Spring Index So That The Spring Design Lie Within Safe Limit.Manoj Kumar GangwarNo ratings yet

- CIE3150 2017 Case Study Beam V 03-2Document19 pagesCIE3150 2017 Case Study Beam V 03-2FerdiVKNo ratings yet

- Thin CylinderDocument10 pagesThin Cylinderarunnical100% (3)

- Test Exams PDFDocument7 pagesTest Exams PDFShaheer Ahmed KhanNo ratings yet

- Design of Knuckle JointDocument26 pagesDesign of Knuckle Jointvikasporwal2605100% (2)

- Design of Welded JointsDocument7 pagesDesign of Welded JointsmohammadNo ratings yet

- (Meng) Mechanical Design of Rocket MotorsDocument31 pages(Meng) Mechanical Design of Rocket MotorsYudi RahmanNo ratings yet

- 41 Rolling Contact BearingsDocument11 pages41 Rolling Contact BearingsPRASAD326100% (3)

- 17 Power Screw Drives and Their EfficiencyDocument15 pages17 Power Screw Drives and Their EfficiencyPRASAD326100% (2)

- Block Diagram of Intel 8086Document5 pagesBlock Diagram of Intel 8086Ritesh SinghNo ratings yet

- 38 Design of Flat Belt DrivesDocument9 pages38 Design of Flat Belt DrivesPRASAD326100% (1)

- Bearing-Study Material Mechanical Engg-1Document14 pagesBearing-Study Material Mechanical Engg-1anishiitdNo ratings yet

- 39 Design of V - Belt DrivesDocument10 pages39 Design of V - Belt DrivesPRASAD326100% (6)

- 34 Design of Joints With Variable LoadingDocument8 pages34 Design of Joints With Variable LoadingPRASAD326100% (1)

- 35 Design of Shoe BrakesDocument10 pages35 Design of Shoe BrakesPRASAD326100% (1)

- 37 Introduction To Belt DrivesDocument12 pages37 Introduction To Belt DrivesPRASAD326100% (11)

- 36 Design of Band and Disc BrakesDocument10 pages36 Design of Band and Disc BrakesPRASAD326100% (2)

- 29 Welded Joints Types and UsesDocument10 pages29 Welded Joints Types and UsesPRASAD326100% (1)

- 21 Design of Leaf SpringsDocument10 pages21 Design of Leaf SpringsPRASAD326100% (1)

- 25 Thick Cylinders Stresses Due To Internal and External PressuresDocument14 pages25 Thick Cylinders Stresses Due To Internal and External PressuresPRASAD326100% (4)

- 33 Design of Eccentrically Loaded Welded JointsDocument10 pages33 Design of Eccentrically Loaded Welded JointsPRASAD326No ratings yet

- 23 Shaft and Its Design Based On StrengthDocument9 pages23 Shaft and Its Design Based On StrengthPRASAD326No ratings yet

- 30 Design of Welded JointsDocument8 pages30 Design of Welded JointsPRASAD326No ratings yet

- 32 Design of Eccentrically Loaded Bolted or Riveted JointsDocument10 pages32 Design of Eccentrically Loaded Bolted or Riveted JointsPRASAD326100% (3)

- 11 Types of Fasteners Pins and KeysDocument12 pages11 Types of Fasteners Pins and KeysPRASAD326100% (2)

- Thin CylinderDocument10 pagesThin Cylinderarunnical100% (3)

- 28 Design of Riveted JointsDocument9 pages28 Design of Riveted JointsPRASAD326100% (1)

- 20 Design of Helical Springs For Variable LoadDocument16 pages20 Design of Helical Springs For Variable LoadPRASAD326No ratings yet

- 27 Riveted Joints Types and UsesDocument11 pages27 Riveted Joints Types and UsesPRASAD326100% (1)

- Pin Bush Coupling DesignDocument15 pagesPin Bush Coupling Designyogwani79No ratings yet

- 22 Shaft and Its Design Based On StrengthDocument11 pages22 Shaft and Its Design Based On StrengthPRASAD326100% (4)

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- 12 Cotter and Knuckle JointDocument16 pages12 Cotter and Knuckle JointPRASAD326100% (3)

- 8 Stress ConcentrationDocument15 pages8 Stress ConcentrationPRASAD326100% (3)

- 10 Low and High Cycle FatigueDocument14 pages10 Low and High Cycle FatiguePRASAD326100% (1)

- 7 Design For Static LoadingDocument21 pages7 Design For Static LoadingPRASAD326100% (1)

- A. Boq For Hangar Foundation For Private Terminal & Hangar @mmia, Lagos.Document2 pagesA. Boq For Hangar Foundation For Private Terminal & Hangar @mmia, Lagos.uchennaNo ratings yet

- Eaton Fuller RTLO 16918B As Transmission Parts ManualDocument34 pagesEaton Fuller RTLO 16918B As Transmission Parts ManualRoy Hernandez100% (1)

- Chemrite Descaler A-28Document2 pagesChemrite Descaler A-28ghazanfarNo ratings yet

- Ca La Building Vol2 PDFDocument324 pagesCa La Building Vol2 PDFaa100200No ratings yet

- Compression Design Section1Document10 pagesCompression Design Section1Anonymous sfkedkymNo ratings yet

- Frank GehryDocument35 pagesFrank GehryPratyush DajuNo ratings yet

- RC (Doubly Reinforced) Beam06Document1 pageRC (Doubly Reinforced) Beam06Ral GLNo ratings yet

- Tatad v. Garcia, JRDocument9 pagesTatad v. Garcia, JRsophiaNo ratings yet

- Condition Survey of Old Houses (Pol) in AhmedabadDocument30 pagesCondition Survey of Old Houses (Pol) in Ahmedabadmaurya parkaraNo ratings yet

- Terrace Houses MalaysiaDocument4 pagesTerrace Houses MalaysiaRamandeep SinghNo ratings yet

- Old RTA NOC For Fense NOC-04122018-2204-NOCCertificate-25-03-2019-0713281554313640148Document8 pagesOld RTA NOC For Fense NOC-04122018-2204-NOCCertificate-25-03-2019-0713281554313640148albfaragNo ratings yet

- Stiffened RoundDocument16 pagesStiffened RoundIoannis Mitsis100% (1)

- Design Recommendation For Propeller PumpsDocument24 pagesDesign Recommendation For Propeller PumpsSamir SalimNo ratings yet

- Masonry Cement: Standard Specification ForDocument4 pagesMasonry Cement: Standard Specification ForLupita RamirezNo ratings yet

- Project Management Report For Tank FarmDocument12 pagesProject Management Report For Tank FarmsandycrackjackNo ratings yet

- Cognition PracticeDocument22 pagesCognition PracticeKhaoula BouhaimiNo ratings yet

- Polycab Price List - March - 2021Document13 pagesPolycab Price List - March - 2021Kevin MaldeNo ratings yet

- SIA 269-6-1 - en - 160114Document40 pagesSIA 269-6-1 - en - 160114Ricardo PimentelNo ratings yet

- Civil Engineer Resume-FinalDocument5 pagesCivil Engineer Resume-FinalNikhilNo ratings yet

- K08798 Wood Plastic Fusabond Brochure 0408Document4 pagesK08798 Wood Plastic Fusabond Brochure 0408anon_850523309No ratings yet

- Polyethylene Corrugated Duct (PEC) and HDPE Ducts: For Power & TelecommunicationDocument20 pagesPolyethylene Corrugated Duct (PEC) and HDPE Ducts: For Power & TelecommunicationthoufiqNo ratings yet

- Rate of Shedule M - P - 2009Document393 pagesRate of Shedule M - P - 2009Er Tarun PalNo ratings yet

- Architectural Design 05: Pangasinan State UniversityDocument13 pagesArchitectural Design 05: Pangasinan State UniversityKhalid Ali Saif Al-ShamsiNo ratings yet

- The Law and Jurisprudence OnDocument39 pagesThe Law and Jurisprudence OnRowan O'mearaNo ratings yet

- Plastiment VZ PDFDocument2 pagesPlastiment VZ PDFDarwin SyahputraNo ratings yet

- Design of Retaning Wall-1.0 To 1.5Mtr Above Ground LVLDocument8 pagesDesign of Retaning Wall-1.0 To 1.5Mtr Above Ground LVLAmarjit KulkarniNo ratings yet