Professional Documents

Culture Documents

Eficiencia de Energia PDF

Eficiencia de Energia PDF

Uploaded by

Clau MontesCopyright:

Available Formats

You might also like

- Modelling & Simulation of Binary Distillation ColumnDocument53 pagesModelling & Simulation of Binary Distillation Columnpriyankthada100% (6)

- Resid Hydrocracking Better Than Delayed Coking in Case Studies - Oil & Gas JournalDocument4 pagesResid Hydrocracking Better Than Delayed Coking in Case Studies - Oil & Gas Journalcool_ddNo ratings yet

- Bar Screen DesignDocument5 pagesBar Screen Designuemaapl100% (1)

- Absorber Design FinalDocument27 pagesAbsorber Design FinalTamara NwaserNo ratings yet

- Performance Analysis of Shell and Tube Heat ExchangersDocument5 pagesPerformance Analysis of Shell and Tube Heat ExchangersMichał KisielewskiNo ratings yet

- Boiler and Steam SystemDocument33 pagesBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Steam Efficiency Guide For Energy ManagersDocument38 pagesSteam Efficiency Guide For Energy ManagersUm TiagoNo ratings yet

- Boiler Start UpDocument6 pagesBoiler Start UpAnonymous 0vtkoS155100% (2)

- Boiler NotesDocument34 pagesBoiler NotesRakesh Singh BhadoriyaNo ratings yet

- Buffer & Barrier Fluids Plan 52Document4 pagesBuffer & Barrier Fluids Plan 52gatita_salemNo ratings yet

- Troubleshoot in Heat Exchangers HP 1996Document5 pagesTroubleshoot in Heat Exchangers HP 1996piolinwalls100% (1)

- Basic Parts of A BoilerDocument9 pagesBasic Parts of A Boilermessi107No ratings yet

- Incinerator CDocument12 pagesIncinerator CArjun Shantaram ZopeNo ratings yet

- Properties of Steam Numericals v2Document32 pagesProperties of Steam Numericals v2Saurabh R Shah100% (4)

- Strategy For DistillationColumn ControlDocument529 pagesStrategy For DistillationColumn ControlLisandro Mangini100% (2)

- Condenser CondenserDocument47 pagesCondenser CondenserPrashant Puri100% (1)

- Steam Turbine PerformanceDocument16 pagesSteam Turbine PerformanceVILLANUEVA_DANIEL2064100% (3)

- 21 Surface CondensersDocument12 pages21 Surface CondensersMohsin EhsanNo ratings yet

- Steam HandbookDocument64 pagesSteam Handbookmsavidge50No ratings yet

- Flue Gas Heat Recovery in Power Plants, Part IIIDocument6 pagesFlue Gas Heat Recovery in Power Plants, Part IIIknsaravanaNo ratings yet

- Steam and Energy SystemsDocument264 pagesSteam and Energy SystemsdeepNo ratings yet

- 1 Reboilers TypesDocument5 pages1 Reboilers TypesIvan Ruben Capuñay IzquierdoNo ratings yet

- Steam Generator PerformanceDocument7 pagesSteam Generator Performancervkumar61No ratings yet

- Boiler EfficiencyDocument28 pagesBoiler EfficiencyRintu BiswasNo ratings yet

- Daily Maintenance BoilerDocument3 pagesDaily Maintenance BoilerAppleuk SudarNo ratings yet

- Furnace Flooding, 011107Document11 pagesFurnace Flooding, 011107Arief HidayatNo ratings yet

- Chapter 21: Evaporation - Principles, Types of EvaporatorsDocument7 pagesChapter 21: Evaporation - Principles, Types of EvaporatorssdfaNo ratings yet

- Ethylene Refrigeration CompressorDocument17 pagesEthylene Refrigeration CompressorfvaefaNo ratings yet

- Process Calculations Sample ChaptersDocument21 pagesProcess Calculations Sample ChaptersGurunath Epili50% (2)

- Types of EvaporatorsDocument12 pagesTypes of Evaporatorsapi-377437388% (8)

- Refining Process (ARCHANA COMPLETE REFINING STUFF)Document96 pagesRefining Process (ARCHANA COMPLETE REFINING STUFF)Mahesh sinhaNo ratings yet

- Reducing Steam Header PressureDocument1 pageReducing Steam Header Pressuresj_scribdNo ratings yet

- Steam Turbines FundamentalsDocument51 pagesSteam Turbines Fundamentalssevero97100% (2)

- Reciprocating CompressorDocument24 pagesReciprocating CompressorSANTHOSH NAGARAJA0% (1)

- Cog en Era Ti OnDocument12 pagesCog en Era Ti OnMayank DubeyNo ratings yet

- Fired Heater SimulatorDocument11 pagesFired Heater SimulatorNimeshKamatNo ratings yet

- Boiler Controls and Boiler InterlocksDocument24 pagesBoiler Controls and Boiler InterlocksMohamed ShameemNo ratings yet

- Fuel Ethanol Distillation - Fundamentals - KatzenDocument18 pagesFuel Ethanol Distillation - Fundamentals - Katzenaseptman1No ratings yet

- IEEE BoilerDocument9 pagesIEEE Boiler4nagNo ratings yet

- Vaccum DistillationDocument36 pagesVaccum Distillationquangquy91No ratings yet

- Boilers: Eng. W.M. Sathyajith KandegamaDocument67 pagesBoilers: Eng. W.M. Sathyajith Kandegamakmas1612No ratings yet

- Steam BoilerDocument41 pagesSteam BoilerRhydham PNo ratings yet

- WEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaDocument10 pagesWEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaMisge ChekoleNo ratings yet

- Steam Generation & Distribution PDFDocument34 pagesSteam Generation & Distribution PDFPopescu Andrei-Mihai50% (2)

- Single and Multistage Steam Jet Ejectors: TorinoDocument12 pagesSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiNo ratings yet

- FCC Troubleshooting - Catalyst LossesDocument36 pagesFCC Troubleshooting - Catalyst LossesLee860531No ratings yet

- Boiler EconomyDocument64 pagesBoiler EconomyKhurram ShahzadNo ratings yet

- Management of Spent Catalysts in Petroleum RefineriesDocument11 pagesManagement of Spent Catalysts in Petroleum Refineriesapi-3775048100% (5)

- Diagnosis of Boiler PerformanceDocument36 pagesDiagnosis of Boiler PerformanceAnsuman Sen SharmaNo ratings yet

- Boiler Seminar - Taylor PDFDocument140 pagesBoiler Seminar - Taylor PDFhercuhattyNo ratings yet

- BoilersDocument39 pagesBoilersVinay Balineni100% (1)

- Principles of Boiler OperationsDocument35 pagesPrinciples of Boiler Operationseblees100No ratings yet

- PTQ Q2 - Spirax PT 1Document6 pagesPTQ Q2 - Spirax PT 1Pop-Coman Simion100% (1)

- OJT 6 - Boiler Water TreatmentDocument26 pagesOJT 6 - Boiler Water TreatmentAzizul Ishak100% (1)

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- GF Type 546 BallDocument10 pagesGF Type 546 Ballbabis1980No ratings yet

- 1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013Document2 pages1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013babis1980No ratings yet

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsDocument70 pagesThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- P&IDDocument18 pagesP&IDhectornicolau100% (1)

- Tech Manual Electrical Power Plant DesignDocument135 pagesTech Manual Electrical Power Plant Designd_kabulpuriaNo ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Sa 312Document1 pageSa 312babis1980No ratings yet

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980No ratings yet

- Flanged Immersion Heaters: Operating ConditionsDocument1 pageFlanged Immersion Heaters: Operating Conditionsbabis1980No ratings yet

- ATEX Reference GuideDocument2 pagesATEX Reference Guidebabis1980No ratings yet

- 4.24 Drains Systems Design PhilosophyDocument8 pages4.24 Drains Systems Design Philosophybabis1980No ratings yet

- Brochure ACCDocument8 pagesBrochure ACCbabis1980No ratings yet

- DS FL1001 GB 50631Document10 pagesDS FL1001 GB 50631Rafael IbelliNo ratings yet

- CEMS Guidelines Volume I Full VersionDocument28 pagesCEMS Guidelines Volume I Full Versionbabis1980100% (1)

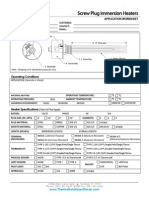

- Screw Plug Immersion Heaters: Operating ConditionsDocument1 pageScrew Plug Immersion Heaters: Operating Conditionsbabis1980No ratings yet

- Face-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Classes 150, 300, 600, 900, 1500, and 2500)Document18 pagesFace-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Classes 150, 300, 600, 900, 1500, and 2500)babis1980No ratings yet

- Furnaces and Furnace ReactorsDocument33 pagesFurnaces and Furnace ReactorsSamyak JainNo ratings yet

- Lecture 4 PumpsDocument38 pagesLecture 4 PumpsArvin BhurtunNo ratings yet

- Wmo 364-V1p1 Dynamic AtmosphericDocument345 pagesWmo 364-V1p1 Dynamic AtmosphericwalterdryNo ratings yet

- Service Manual Hsu-09 (12) Ha Hva Rha103r2 (DB) - TD (071230)Document79 pagesService Manual Hsu-09 (12) Ha Hva Rha103r2 (DB) - TD (071230)ronson72No ratings yet

- Teh 908a PDFDocument30 pagesTeh 908a PDFAnonymous 73gEYyEtLNo ratings yet

- API 6A ValveDocument12 pagesAPI 6A Valveedo_tapia_ur100% (1)

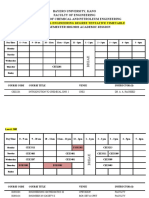

- 1st Sem Timetable CPE 21-22Document5 pages1st Sem Timetable CPE 21-22EmmanuelNo ratings yet

- Properties of Pure Substance and Steam Power Cycle Pure SubstanceDocument43 pagesProperties of Pure Substance and Steam Power Cycle Pure SubstanceSachin SinghNo ratings yet

- Study Plan...Document3 pagesStudy Plan...mustafakamal35302100% (1)

- Pengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDocument7 pagesPengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDwi BintangNo ratings yet

- (Rev. A) LVSL& Merlin Valve AdapterDocument3 pages(Rev. A) LVSL& Merlin Valve AdapterLost LionNo ratings yet

- Cornell MANURE 2016Document8 pagesCornell MANURE 2016MatoNo ratings yet

- Sulfinol D Evaluation.Document24 pagesSulfinol D Evaluation.Clibert RodríguezNo ratings yet

- J-SF24 Sand FilterDocument8 pagesJ-SF24 Sand Filterelle diemNo ratings yet

- Calculations Tank S6Document19 pagesCalculations Tank S6Joshue Adele100% (1)

- MANOMETER Power PointDocument16 pagesMANOMETER Power PointErwin Bolamino BlasNo ratings yet

- Zohr Onshore Project Facilities Rup System & Sub-System Breakdown ListDocument7 pagesZohr Onshore Project Facilities Rup System & Sub-System Breakdown ListMohamedNo ratings yet

- Mass Balance Tutorial 2 - 2021 Fin-StuDocument2 pagesMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanNo ratings yet

- Experimental Aerodynamic Analysis of Delta WingDocument9 pagesExperimental Aerodynamic Analysis of Delta WingSharan Teja ElagandulaNo ratings yet

- BowTie Poster Loss of ContainmentDocument1 pageBowTie Poster Loss of ContainmentRoberto Burgos0% (1)

- Fabrication & Installation of Thorp T-211 WingDocument102 pagesFabrication & Installation of Thorp T-211 WingSudharSanNo ratings yet

- Theory Book Compaction DdpandaDocument7 pagesTheory Book Compaction Ddpandapratik gamaraNo ratings yet

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Document2 pagesProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomNo ratings yet

- AIAA-Prediction of Average DownwashDocument21 pagesAIAA-Prediction of Average DownwashChan Teng YanNo ratings yet

- Agitation and MixingDocument77 pagesAgitation and MixingKolliparaDeepak100% (1)

- Tank Venting API STD 2000 Nov 2009 RevisDocument3 pagesTank Venting API STD 2000 Nov 2009 RevisCarlos Arias50% (2)

- 460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolandDocument8 pages460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolanddhmbasNo ratings yet

- t2 S 686 Separating Mixtures Powerpoint Ver 1Document8 pagest2 S 686 Separating Mixtures Powerpoint Ver 1Misbah HashmiNo ratings yet

Eficiencia de Energia PDF

Eficiencia de Energia PDF

Uploaded by

Clau MontesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eficiencia de Energia PDF

Eficiencia de Energia PDF

Uploaded by

Clau MontesCopyright:

Available Formats

Energy saving in steam systems.

Dr.G.G.Rajan / Cochin / India

Substantial quantity of savings in steam is possible by adopting the following

thumb rules. Most important operating parameters to minimize steam consumption

include using dry saturated steam having saturation temperature equal or very nearly

equal to the required process temperature in steam consuming devices such as

Steam heaters

Steam heated reboilers

Steam tracers etc.

On the contrary, superheated steam must be used in

Back pressure turbines

Extraction turbines and

Total condensing turbines.

Steam temperature or degree of super heat is an important factor that minimizes

steam consumption. Since steam temperature is related to steam pressure,

temperature parameter automatically sets the steam pressure. This would mean that

various steam heated devices require various steam pressures and super heats, depending

on the process configuration. Following table shows, how steam temperature plays an

important role in controlling steam consumption in various heating devices.

Process

temperature

required oC

Steam

temperature

oC

Corresponding

steam pressure

.in bar (on

process temp)

Steam

enthalpy

Kcal/kgm

Latent

heat

Kcal/kgm

100 130 1.03 650.8 516.7

150 180 5.00 671.2 503.4

200 230 15.0 676.3 464.7

250 280 40.0 680.8 409.1

300 330 85.0 667.0 336.0

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Steam temperature is selected 30 oC higher than the required process temperature.

The best steam for industrial process heating is dry saturated steam, which is

neither wet not highly super heated. Wet steam reduces heat transfer while super heated

steam is not desirable for process heating because of the problems in temperature

control of the process fluids and the low heat transfer coefficient. Condensation heat

transfer is best suited for process heating applications. Available enthalpy in wet steam is

reduced depending on the moisture content present in the steam. For example, latent

heat available in a 95% dry steam, with 5% moisture shall have a latent heat of 478.2

kcal/kgm against the value of 503.4.

It is only the latent heat of steam that takes part in the process heating. Hence

it is essential that the latent heat of steam used for process heating is as high as possible.

From the above table it is obvious that lower the steam pressure, the higher is the latent

heat of steam. It may also be noted from the above table that as the steam pressure comes

down, the saturation temperature also comes down. The steam pressure for process

heating must therefore, be selected based on the required process temperature. The

saturation temperature may be selected a few degrees higher ( 10 to 20 oC) and the steam

pressure fixed accordingly.

For example, when the process temperature to be maintained is between 100 to

200 oC, it is economical to select steam pressure whose saturation temperature just

matches the process temperature plus 5 to 10 oC. Using dry saturated steam for process

heating is efficient due to its film heat transfer coefficient which is comparatively

higher than highly super heated steam.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Example : Furnace oil is used as a fuel in a fired heater. The furnace oil is stored in a

tank and maintained at 70 oC. The oil is heated in a steam heated exchanger to 110 oC

using a steam heater. The flow rate of furnace oil is 10 tons /hr. the specific heat of FO is

0.68. Determine the optimum steam pressure for this system and calculate the steam

rate?

Following figure shows the arrangement for heating the furnace oil. There are two

reasons for heating the furnace oil, before it goes to the burner. The primary reason is to

reduce the viscosity of the furnace oil at burner tip, so that it is atomized easily and the

secondary reason is to increase the burner efficiency and accelerate ease of combustion.

Heat required to increase FO temperature from 70 to 110 oC is given by

= Mass x Sp.heat x t

= 10 x 1000 x 0.68 x ( 110-70) kcal/hr

= 272000 kcal/hr.

Steam in

Condensate

FO Tank

FO pump

Hot FO @ 110

oC to heater

70 oC

FO

return

Furnace Oil Heating using dry

saturated steam

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Steam data:

Since the FO to be heated is from 70 oC to 110 oC, the driving force for the last three

cases in terms of average temperature is calculated as shown below. The first case is

neglected, as the driving force is too low.

Taking an average overall heat transfer coefficient of 220, 225 & 230 kcal/hr/m2/oC

respectively for the above three cases, the heat transfer area requirement for the above

cases works out to 41.77, 32.85, 27.57 m2 respectively. Steam requirement for the above

process heating is given in the last column.

It may be noted from the last column that the steam requirement in the above

cases increase with increasing steam pressure.

Steam pressure

kg/cm2a

Saturation

temp oC

Latent heat

kcal/kg

Enthalpy

in kcal/kg

1.5 110.8 532.1 643.1

2.0 119.6 526.4 646.3

2.5 126.8 521.4 648.7

3.0 132.9 517.3 650.8

Steam pressure

kg/cm2a

Saturation

temp oC

t1 t2 t=(t1+t)

/2

Steam

required in

kg/hr

2.0 119.6 49.6 9.6 29.6 516.7

2.5 126.8 56.8 16.8 36.8 521.6

3.0 132.9 62.9 22.9 42.9 525.8

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Based on 8000 operating hours per year, the steam consumption works out to

4133.6, 4172.8 & 4206.4 tons respectively. While the above example refers to a single

steam heater, there will be substantial savings in steam in major process industries

comprising a number of such steam devices.

Using exhaust steam in LP service : For the LP (low pressure) process steam service,

it is economical to use exhaust steam from back pressure turbines, extraction turbines,

extraction cum condensing turbines, steam de super heaters, pressure reducers etc as

direct production of LP steam is not energy efficient. By using turbine exhaust steam,

overall thermal efficiency of the system will be high as shown in the figure1 below.

HP Steam. 100 t/hr ,

40 bar , 320 oC

MP Steam, 50 t/hr, 10 bar,

220 oC

20 t/hr, 5 mmhg, ,60 0C

LP Steam 30 t/hr, 5 bar,

160 oC

~

Fig 1. Extraction turbine lay out.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Theoretical Carnot cycle efficiency of the turbine in Stage I, II & III are 16.86,

12.17 and 23.09 respectively. This is calculated by the relationship

carnot

= (T

1

T

2

) x100 /T

1

where T

1

& T

2

are steam inlet and outlet temperatures absolute (oK) at each stage.

Theoretical power generation for the above parameters may be calculated by

enthalpy values at inlet and outlet conditions at each stage.

Though the turbine efficiency is less than 25%, the integrated overall plant

efficiency will be high, when the two extraction steam flows are used in the plant. This is

because of the fact that the entire latent heat available in these steams will be utilized for

process heating and only the condensate will be returned to the condensate recovery

system. A typical break up of energy is shown in the following table.

Energy Utilized in Turbine alone

Steam Enthalpy

Kcal/kg

Flow

in

kg/hr

Energy

input

000Kcal/hr

Energy

output

000kcal/hr

Energy

used

000kcal/hr

%

utilized

on input

HP (40

bar, 320

oC

720.6 100000 72060

MP (10

bar,220

oC

685.3 50000 36030 34265 1765 2.45

LP ( 5 bar

,160 oC)

658.6 30000 21618 19758 1860 2.58

Vac

25mmhg

608.63 20000 14412 12172.6 2239.4 3.11

Total 5864.4 8.14

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Energy utilization in total process

Steam Enthalpy

/ Latent

heat in

Kcal/kg

Flow

in

kg/hr

Energy

input

000Kcal/hr

Energy

output

000kcal/hr

Energy

used

000kcal/hr

%

utilized

on input

HP (40

bar, 320

oC

720.6

100000 72060

MP (10

bar,220

oC

685.3 /

480.3

50000 36030 10250 25780 35.78

LP ( 5 bar

,160 oC)

658.6 /

500.0

30000 21618 4758 16860 23.40

Total in

process

42640 59.18

Total in

tutbine

section

5864.4 8.14

Overall

plant

48504.4 67.32

As could be seen from the above tables, energy utilization is the highest, when the

MP and LP steams are used in the process units. The balance of 32.68 % include hot

condensate at each pressure level plus the loss of steam / condensate due to leaks,

draining etc.

Following figure2 shows the energy consumption break-up in a two stage

extraction steam turbine.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Energy Utilization Level for two stage extraction turbine

35.78

23.4

8.14

32.68

MP LP tutbine losses

Fig 2. Energy Utilization level for two stage extraction turbine

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Economizing Steam consumption in typical back pressure

/ condensing steam turbines.

Steam turbines may be operated in different ways to meet the power demand. For

example, the turbine may be operated in total condensing mode or back pressure mode

depending on the steam and power demand of the process. Steam turbines used in the

process are major energy consumers. Optimizing process operating conditions can

considerably improve turbine efficiency , which in turn will significantly reduce energy

requirement. Various operating parameters affect condensing and back pressure turbine

steam consumption and efficiency.

Turbine efficiency Significance.

The industrial sector is the largest energy consumer, accounting for about 30 % of

total energy used. With the present trend of energy prices and scarcity of hydrocarbon

resources, lowering energy requirement is a top priority. Energy conservation benefits

depend on applying certain minor or major modifications and using the modern

operational features. Energy conservation does not mean curtailing energy use alone at

the cost of industrial and economic growth. In major / mega process industries, steam

turbines are the main energy consumers. Savings achieved here will be significant, with a

better return on investment than for most other equipment.

Effect of operating conditions on steam turbines

A condensing turbine system is shown in figure 3. Turbine exhaust operating

below atmosphere, is condensed in a shell and tube exchanger called surface condenser

as shown in fig 3a.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Refer to fig 3a. Condensate flows in the shell side of the condenser and steam is

condensed by the cooling water. Vacuum in the surface condenser i.e. turbine exhaust

vacuum is controlled / maintained by vacuum ejector system of the surface condenser.

Figure 3a shows the layout of a typical surface condenser used in steam turbines.

Fig 3. Diagrammatic details of a condensing type turbine.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Fig 3a. Layout of surface Condenser

Turbines are designed for a particular operating conditions like steam inlet

pressure, steam inlet temperature and turbine exhaust pressure/ exhaust vacuum, which

affects the performance of the turbines in a significant way. Variations in these

parameters affects the steam consumption in the turbines and also the turbine efficiency.

Theoretical turbine efficiency is calculated as work done by the turbine to the

heat supplied to generate the steam.

Impact of various operating conditions on turbine performance is shown in the

table below, considering the steam conditions used in the turbine.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

TABLE : Steam Consumption comparison for constant BHP

In the above referred turbines, 1 % reduction in steam consumption saves around

$ 47000 annually for condensing turbines and around $ 84000 annually in back pressure

turbine. LHV of the fuel for generating steam is considered as 10500 kcal/kg and boiler

efficiency is taken as 87 %.

Energy Balance:

Case : Condensing Turbine

Enthalpy of input steam at 40 kg/cm2a & 350 oC = 737.9 kcal / kg

Saturation temperature = 249.0 oC : Enthalpy : 669.0 kcal/kg @ saturation temperature.

Enthalpy @ outlet conditions : 647 mmhg vacuum = 113 mmhg pressure absolute

= 620.5 kcal/kgm

Saturation temperature = 53.5 oC

Net energy input = steam rate ( kg/hr) * Enthalpy kcal /hr

= 27785 * (737.9 620.5) = 27785 * 117.4

= 3261959 kcal /hr

Carnot cycle efficiency = (350 53.5) x 100 /(350+273) = 47.59 %

Energy equivalent power generated = 2000 * 0.746 * 860 = 1283120 kcal /hr

Actual efficiency on energy input = 39.33 %

Condensing Type Turbine Back pressure type turbine

Steam Inlet Pressure 40 kg/cm2a Steam inlet pressure 40 kg/cm2a

Steam inlet temperature 350 oC Steam inlet temperature 350 oC

Exhaust Vacuum 657 mmhg Exhaust Pressure 4.5 kg/cm2a

Turbine rated BHP 2000 HP Turbine rated BHP 2000 HP

Steam consumption 27785 Kg Steam consumption 57960 Kg

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Case : Back pressure Turbine

Enthalpy of input steam at 40 kg/cm2a & 350 oC = 737.9 kcal / kg

Enthalpy @ outlet conditions : 4.5 kg/cm2a & 148 oC = 655.2 kcal/kgm

Saturation temperature = 147.2oC

Net energy input = steam rate ( kg/hr) * Enthalpy kcal /hr

= 57960 * (737.9 655.2) = 57960 *82.7

= 4793292 kcal /hr

Carnot cycle efficiency = (350 147.2) x 100 /(350+273) = 32.55 %

Energy equivalent power generated = 2000 * 0.746 * 860 = 1283120 kcal /hr

Actual efficiency on energy input = 26.77

Case : Back pressure Turbine with exhaust steam to process.

Latent heat of steam consumed in

process = Steam rate x Latent heat (@4.5 kg/cm2a, 147.2 oC)

= 57960 x 507.1 = 29391516

Total Energy utilized = 1283120 + 29391516 = 30674636

(power) (Heat)

Overall system efficiency = 71.72 %

This example shows the practical energy efficiency improvement which may be achieved

by using the combined heat power cycle as shown above.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Steam system efficiency.

In conventional process plants, steam boilers are used to generate steam for the

process and generate power required by the process using steam turbine. The demand

scenario of power and steam (heat) is always dynamic and depends on a number of

process parameters such as through put ( capacity utilization ), feed quality, operating

severity, down stream operations etc.

A critical analysis of the process shall reveal that the overall steam system

efficiency is a function of

Boiler efficiency

Turbine efficiency

Steam transmission efficiency

Individual steam consuming device efficiency

Specific consumption of process steam in processes.

Steam losses due to leaks, blow downs, flashing venting etc.

For maintaining steam system efficiency, it is imperative to monitor all the above

factors meticulously. Boiler efficiency is a function of excess air, burner efficiency, type

of fuel used , convection and radiation losses and blow down losses.

Boiler feed water quality also plays an important role in heat transfer in the boiler

water tubes, economizer section and super heating section. Hence boiler efficiency is a

function of economizer efficiency, water evaporation efficiency in the boiler and super

heater efficiency. A simple method of determining boiler efficiency is by indirect

method in which the sum of energy losses is determined from boiler operating data as %

of energy input and subtracted from 100 to get the boiler efficiency. This method is good

enough for monitoring purposes. Figure 4 shows the various losses associated with

boiler efficiency and the table shows a typical boiler efficiency program output.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Fig 4. Energy Input / Output Diagram - Boiler

A heat balance of boiler indicates the type of heat losses which could be used

for identifying areas of improvement . A number of parameters affect the thermal

efficiency of the boiler. They are

Sensible heat in flue gases

Convection and Radiation losses.

Unburnt Combustibles in flue gases.

Unburnt combustibles in refuse

Blow Down losses etc

Sensible heat loss in flue gases:

This loss is the largest in a boiler and represents the heat carried away by the

flue gases and released to the atmosphere without doing any useful work . Hence it is

Boiler

Energy In Energy Out

Fuel

Air

BFW

Flue Gas

Conv &

Rad loss

Steam

Blow down

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

obvious that if more than the required quantity of air is used in a boiler , more will be

the loss in flue gases and the thermal efficiency of the boiler will be reduced

correspondingly.

Convection and Radiation losses :

This depends on the temperature of boiler's external surface . Quantity of heat

lost by convection and radiation is a function of shell temperature and wind velocity.

This loss occurs basically due to poor insulation and poor design characteristics .

If the refractory lining and other insulating materials are not in good condition ,

these losses will tend to increase and reduce the thermal efficiency of the boiler. Hence

it is imperative that the surface temperature at various sections should be monitored

periodically and corrective actions taken to minimize this loss.

Unburnt matter in flue gas:

When combustion is incomplete , part of the carbon present in the hydro

carbon fuel may be converted into carbon monoxide instead of carbon-di-oxide. When

the carbon content of the fuel is not fully burnt to carbon-di-oxide, there will be

substantial energy loss to the atmosphere from the flue gases ( besides atmospheric

pollution) , the loss being proportional to the amount of carbon monoxide produced .

This could be estimated by a carbon balance across the boiler taking into

consideration carbon content in fuel , carbon-di-oxide and carbon monoxide in the flue

gases and carbon content in the refuse.

Unburnt matter may show itself in the flue gas in the form of black smoke

which represents presence of carbon particles in the flue gas. It may also show itself

as Carbon monoxide in the flue gas While every kg of carbon present in the flue gas

represents a loss of 8084 kcals , every kg of Carbon partially oxidized to CO results

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

in a loss of 5654 kcals . This situation could be controlled with optimum excess air

input to the boiler.

Blow Down Losses:

Dissolved salts find entry to the boiler through make-up water which is

continuously fed by the Boiler Feed Water pump ( bfw) . In the boiler , there is

continuous evaporation of water into steam . This leaves behind the salts in the boiler.

Concentration of these salts , tend to increase in the boiler drum and starts precipitation

after certain concentration level .

Water from the drum should be blown down to prevent concentration of salts

beyond certain limits . Since the water in the boiler drum is at a high temperature (

equivalent to it's saturation temperature at boiler drum pressure ) , excess blow-down

will lead to loss of energy known as 'blow-down losses ' . Blow-down rate reduces the

boiler efficiency considerably as could be seen from the figure 3. Hence it is imperative

that blow-down rates are optimized ,based on the hardness levels of boiler drum water

which is a function of the operating pressure.

The program output given in the Annexure 1 shows, how various losses are

calculated for the boiler. Basis for the energy evaluation is unit weight of fuel. For

determining the quantity of energy lost in flue gas, air input quantity is calculated by the

excess oxygen leaving the stack as given by O2 monitor readings or flue gas analysis

(Orsat Analysis ).

Typical energy losses in a boiler plant is shown in fig 5. These losses are

1.Dry gas loss

2.Air moisture loss

3. Combustion moisture loss.

4.Fuel moisture loss

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

5.Convection and Radiation losses

6.Blow down loss.

7. Loss due to incomplete combustion of fule.

5.53

0.22 6.65

0.00

1.85

0.55

0.00

1 2 3 4 5 6 7

Dry gas loss is controlled by the excess air used in the combustion of boiler fuel.

This is the energy picked up by CO2, excess O2 and N2 from ambient temperature to

stack temperature.

Fig 5. Energy losses in steam generation using liquid fuel

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Combustion moisture is controlled by the type of fuel used. High Carbon /

Hydrogen ratio of the fuel minimizes combustion moisture. But the calorific value of

high carbon fuel will be lower than lower Carbon fuel. Hence type of fuel used in the

boiler determines this loss. An optimum fuel mix (considering the cost) may be used to

minimize this loss.

In case of solid fuels, Ash content in the fuel reduces the boiler efficiency for the

same steam generation as shown in fig 6.

FIG 6. Ash content in Coal vs Efficiency (LHV)

Since the cost of coal is determined by the ash and sulfur content present in the

coal, it is possible to optimize the coal blend that will minimize the fuel cost for the same

steam generating capacity.

82

83

84

85

86

87

88

' 16 % ' ' 21 %' ' 30 %' ' 35 %'

% ef f bl r

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Other two controllable losses are Convection and Radiation Loss and Blow down

losses. Convection and Radiation losses may be controlled by periodic Boiler Shell

temperature survey.

Convection and Radiation losses .

For this purpose, the entire boiler shell may be divided into a number of sections

and the average temperature physically measured using a digital thermo meter or contact

thermometer. During the survey, wind velocity in the vicinity of the section may be

measured using an anemometer. Area of the section surveyed is also measured

From the shell temperature and the wind velocity, heat loss from the section is

give by standard programs in kcal / hr / m2 / oC. Multiplying this coefficient by the area

and the measured temperature, the convection and radiation loss is obtained as kcal /hr.

The sum of these values will represent total heat loss from the boiler shell due to

convection and radiation.

Annexure II gives the output of the program used to calculate the convection and

radiation loss from a boiler. Periodic monitoring of the convection and radiation loss

from boiler shall reveal the boiler refractory / shell condition.

When any hot spot develops in the boiler shell, heat loss will be more and boiler

efficiency will start dropping down. Using convection and radiation loss historic data , it

is possible to estimate the boiler efficiency deterioration as a function of time for taking

corrective action.

Fig 7 shows how the convection and radiation loss survey results are used for

developing a time dependant model.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Fig 7. Heat Loss from Boiler Sections

30.0

50.0

70.0

90.0

110.0

130.0

150.0

100 130 160 180 210 240 270 300

stream dat

h

e

a

t

l

o

s

s

k

c

a

l

/

h

r

section 1 section 2 section 3 section 4

It may be noted from the figure that convection and radiation loss from the sections 1 and

2 show an increasing tendency, while other sections are in tact. Hence necessary

corrective action may be taken at the appropriate time to restore the heat loss to the base

level.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Blow down losses :

Dissolved salts find entry to the boiler through make-up water which is

continuously fed by the Boiler Feed Water pump ( bfw) . In the boiler , there is

continuous evaporation of water into steam . This leaves behind the salts in the boiler.

Concentration of these salts , tend to increase in the boiler drum and starts precipitation

after certain concentration level .

Water from the drum should be blown down to prevent concentration of salts

beyond certain limits . Since the water in the boiler drum is at a high temperature (

equivalent to it's saturation temperature at boiler drum pressure ) , excess blow-down

will lead to loss of energy known as 'blow-down losses ' .

Blow-down rate reduces the boiler efficiency considerably as could be seen

from the figure 8. Hence it is imperative that blow-down rates are optimized, based on

the hardness levels of boiler drum water which is a function of the operating pressure.

In boiler operation practice, rate of blow down increases with steam pressure as

the scaling tendency increases with high temperature because the hardness limits are

very stringent .While figure 8 gives an estimate of % blow down on losses ,the same

may be calculated from the hardness levels of make-up water , flow rate ,steam

generation rate and the hardness level of drum water ( observed).

Model given below could be used to determine the maximum limits of TDS

(total dissolved solids) that could be tolerated in the boiler drum operating at various

pressures . The correlation developed by the author is based on American Boiler

Manufacturers' Association code of practice.

However, if the limits stipulated by the Boiler Designer is less than this value ,

the lower of the two must be taken as the tolerance limit.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Where TDS is the permissible Total Dissolved Solids in ppm at the boiler drum

and Pr is the drum pressure in psig.

Fig 8. Impact of Blow Down Rate of fuel loss.

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

0 2 4 6 8 10 12

% blow down

%

f

u

e

l

w

a

s

t

e

d

14.1 kg/cm2g 10.5 kg/cm2g 7 kg/cm2g 3.5 kg/cm2g

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

The quantity of blow down to maintain the given status of boiler water in terms of

TDS is determined by the material balance of solids across the boiler drum as given in

the figure below.

Blow Down Rate Estimation :

For estimating the boiler drum blow down rates, we will use following

nomenclatures are used.

Let

F = feed water in t/hr

C

m

= Concentration of TDS in make-up water in ppm

C

f

= Concentration of TDS in feed water in ppm.

C

b

= Concentration of TDS in blow-down water

m = weight fraction of make-up water in feed water.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

For establishing the blow-down rate, a material balance on TDS is developed as

shown.

TDS balance:

W

bd

* C

b

= F * m * C

m

-------------------i

F = W

s

+ W

bd

---------------------ii

Therefore equation i may be written as

W

bd

* C

b

= ( W

s

+ W

bd

) * m * C

m

-----iii

If C

f

is the TDS present in the combined feed water to the boiler, above

equation may be written as

W

bd

* C

b

= ( Ws + W

bd

) * C

f

-----iv

If more than the required quantity ( i.e W

bd

t/hr ) is blown down, the excess

quantity will result in lower boiler efficiency . Hence, it is imperative that boiler blow

down rate is monitored continuously for achieving high boiler efficiency. An optimal

blow down rate may be calculated taking into consideration the impact of high TDS on

poor heat transfer vs boiler efficiency.

In this section practical methods of improving the boiler efficiency was discussed

with examples. Program outputs are shown in the Annexure I & II.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Improving steam system efficiency:

Steam system efficiency may be improved by

Minimizing steam transmission losses from the steam generating plant to the

consuming sections

Minimizing steam leaks in the plant area and periodic monitoring and control of

steam leaks

Condensate recovery and

Flash steam recovery.

Steam transmission losses can be minimized by using adequate steam insulation

thickness in the steam lines and periodic monitoring of insulation efficiency by surveys.

Slightly super heated steam must be used while transferring steam to far off distances, to

minimize steam condensation in the steam line itself.

One practical way of determining the line losses is to take the steam temperature

readings at various plant battery limits and calculating the energy loss from enthalpy data,

Stefan Boltzmann and Langmuir equations. A detailed steam line insulation survey is

imperative in steam intensive sections to identify critical areas for corrective action.

Typical steam line audit survey data and observation is given in Annexure III.

Steam leak survey.

There are many methods of evaluating steal leaks from pin holes whose diameter

is known. Following table shows the steam leak from a known hole diameter and

pressure.

As the hole diameter increases, the issue of steam to atmosphere is proportional to

the square of the hole diameter, for the same header pressure. Similarly, when the

pressure inside the header increases, steam loss also tends to increase.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Steam Loss Chart

Monetary loss due to blowing traps in the system can have a dramatic effect on the

bottom line. The chart below is based a steam cost of $ 8.00/1,000 lbs. of steam

produced.

Orifice

Size

5 PSI 15 PSI 30 PSI 50 PSI 75 PSI 100 PSI 125 PSI

.03 130.66 197.74 296.62 431.32 594.56 62.44 928.33

.125 520.24 790.98 1,186.46 1725.27 2,378.23 3,049.77 3,713.34

.25 2,080.96 4,745.85 3,163.90 6,901.13 9,512.94 12,199.07 14,855.30

To compute steam loss through an orifice:

24.24 x PSIA x (diameter of orifice in inches)

To convert psi to PSIA: add 14.7. Therefore, 100 PSI steam is 114.7 PSIA (absolute)

Example: Compute steam loss through a 1/8" orifice at 100 PSI steam?

24.24 x 114.7 x (.125 x .125) = 43.44

To estimate total cost of system-wide loss: Multiply the steam loss by hours of

operation, steam cost (usually between $4.00 and $14.00 per 1,000 lbs.) and by the

number of faulty traps.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Another method of identifying steam leak is to measure the plume length of the

steam length, leaking from a spot and use the following equation to assess the

approximate quantity of steam leak.

Steam Leaks are categorized into 5 types as given below.

Figure given in the next page shows the layout of a pipe line carrying steam.

Whenever any hole develops on the surface, steam will start leaking through it. The

height of plume may be measured by a steel tape or a metre scale as accurate as possible.

Another method of measuring the plume height is to hold a light metal plate

perpendicular to the direction of leak and measure the height at which the leaking steam

hits the surface with least force.

category type of leak.

a valve/trap flange leak

b valve gland leak.

c pin hole leak

d trap blowing

e Venting from vents / Desuper

Heating/Depressurizing

Stations.

stmleak = 2.5678 * EXP(1.845 * plume)

where

plume is the height of plume in meters and

stmleak is the steam leak from the measured section in kg/hr.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Steam flow

A detailed survey carried out in the plant shall reveal the type of steam leak that is

dominant over others. Quality of gasket and valve gland materials play an important role

in flange gasket and valve gland leaks.

Besides, workmanship related to proper alignment, tightening etc also tend to

increase the leak from these sections. Corrective actions may be taken to avert steam loss

due to leaks using the steam loss survey data. Annexure III shows the output of a steal

leak survey with minimum readings. A critical analysis of the type of steam leaks may be

used for improving material quality or workmanship or both based on the survey results.

H

Plume

H = plume height in metres

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Conclusion :

In this paper a number of methods related to steam system management and

energy efficiency improvements have been high lighted. A number of practical examples

and cases have been covered. Since this is an area of continuous improvement and the

controlling techniques vary with cost of energy from time to time, it is imperative to

adapt to the changes as and when called for. Only by this approach , Steam system

efficiency shall be maintained at the peak.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

RESULTS - BOILER EFFICIENCY

I.Fuel Data

Carbon 0.870

Hydrogen 0.125

Moisture 0.000

Oxygen 0.000

Sulfur 0.005

Nitrogen 0.000

Ash 0.000

II.Observed Process parameters

Boiler Duty mmkcal/h 60

% Unburnt matter in refuse 0

Amb.Temperature oC 30

Flue Gas Temp oC 180

Relative Humidity 78

Excess Air 20

High Heating Value kcal/kgm 11325

Low Heating Value kcal/kgm 10650

III.Energy Losses

a.Dry Gas Loss 5.53

b.Air Moisture loss 0.22

c.Combustion Moisture Loss 6.65

d.Fuel Moisture Loss 0.00

e.Radiation Loss 1.85

f.Blow down Losses 0.55

g.Loss due to combustib 0.00

Total Loss % ( dry basis) 14.58

IV.Boiler Efficiency

a.EFFICIENCY HHV basis 85.42

b.EFFICIENCY LHV basis 90.84

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

NOTE:

a.Air misture loss is due to moisture present in combustion air.

b.Combustion moisture is due to combustion of H2 in fuel to water.

c.Fuel moisture is due to presence of water in the fuel fired.

d.Radiation loss is due to heat loss from the exposed boiler surface.

e.Calorific Value of combustibles in refuse is taken as 7800 BTU/Lb.

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Annexure II

HEAT LOSSES FROM HOT PRODUCT AND STEAM LINES

USING STEFAN BOLTZMANN & LANDMUIR EQUATIONS.

Conv. Rad. Total Surface

Unit pipe_no/ length dia in Surface insuln fluid temp Loss kcal/ Loss kcal Losses temp oC

Name code metres mm Temp oC in mm in oC /hr/m2 /hr/m2 '000 kcal/hr temp oC

crude FSS401 300 250 75 50 150.0 514.4 217.0 248.6 75.0

crude2 FSS403 350 150 65 50 130.0 375.7 160.8 152.0 65.0

Vacuum FSS401 300 100 70 60 200.0 443.9 188.3 135.1 70.0

Vac FSS401 300 200 75 80 250.0 514.4 217.0 255.7 75.0

DC 1 FSS401 300 180 80 90 300.0 586.8 246.9 291.5 80.0

DC 3 FSS401 300 200 85 90 340.0 661.0 278.2 346.6 85.0

ARU FSS401 300 190 65 80 250.0 375.7 160.8 182.4 65.0

WHB FSS401 300 180 65 80 265.0 375.7 160.8 177.2 65.0

OMS LSHS 1000 200 85 100 130.0 661.0 278.2 1216.1 85.0

OMS Bit 200 1000 150 85 100 140.0 661.0 278.2 1064.1 85.0

UTIL ut4001 2000 150 80 25 230.0 586.8 246.9 1079.5 80.0

Total Energy Loss from system '000 kcal/hr 5148.6

Note:

1.Ambient Temperature used in the program in oC : 30

2.Wind velocity for the program in km/h : 7.5

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

Annexure III

S T E A M L E A K S U R V E Y

UNIT TAG LEAKAGE PLUME ht STM Loss Remarks

CODE NO CATEGORY (metre) kg/h

I 1 a 2.00 102.83

I 2 a 1.50 40.88

I 3 c 0.67 8.84

I 4 b 2.67 353.97

I 5 d 1.20 23.50

I 6 a 0.96 15.09

I 7 a 0.65 8.52

I 8 b 1.12 20.28

II 9 b 1.21 23.94

II 10 c 0.76 10.44

II 11 a 0.32 4.63

II 12 a 0.21 3.78

II 13 b 1.11 19.91

III 14 b 0.32 4.63

III 15 c 0.54 6.95

III 16 a 0.96 15.09

III 17 a 1.23 24.84

III 18 a 1.08 18.83

III 19 b 0.45 5.89

III 20 b 0.23 3.93

III 21 b 0.98 15.66

III 22 a 1.05 17.82

III 23 a 0.99 15.95

IV 24 a 1.21 23.94

IV 25 b 0.91 13.76

IV 26 c 0.45 5.89

IV 27 b 0.99 15.95

IV 28 a 1.25 25.77

IV 29 a 1.99 100.95

Total Steam Leaks in kg/h 952.4613

Equivalent Fuel in kg/h 68.57722

Note : Steam Enthalpy for estimation (kcal/kg) : 720

Fuel Calorific Value in kcal/kg : 10000

Kolmetz.Com is a chemical engineering web site that publishes

articles on distillation, process optimization, operations training,

personal improvement, process unit safety and environmental concerns.

You might also like

- Modelling & Simulation of Binary Distillation ColumnDocument53 pagesModelling & Simulation of Binary Distillation Columnpriyankthada100% (6)

- Resid Hydrocracking Better Than Delayed Coking in Case Studies - Oil & Gas JournalDocument4 pagesResid Hydrocracking Better Than Delayed Coking in Case Studies - Oil & Gas Journalcool_ddNo ratings yet

- Bar Screen DesignDocument5 pagesBar Screen Designuemaapl100% (1)

- Absorber Design FinalDocument27 pagesAbsorber Design FinalTamara NwaserNo ratings yet

- Performance Analysis of Shell and Tube Heat ExchangersDocument5 pagesPerformance Analysis of Shell and Tube Heat ExchangersMichał KisielewskiNo ratings yet

- Boiler and Steam SystemDocument33 pagesBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Steam Efficiency Guide For Energy ManagersDocument38 pagesSteam Efficiency Guide For Energy ManagersUm TiagoNo ratings yet

- Boiler Start UpDocument6 pagesBoiler Start UpAnonymous 0vtkoS155100% (2)

- Boiler NotesDocument34 pagesBoiler NotesRakesh Singh BhadoriyaNo ratings yet

- Buffer & Barrier Fluids Plan 52Document4 pagesBuffer & Barrier Fluids Plan 52gatita_salemNo ratings yet

- Troubleshoot in Heat Exchangers HP 1996Document5 pagesTroubleshoot in Heat Exchangers HP 1996piolinwalls100% (1)

- Basic Parts of A BoilerDocument9 pagesBasic Parts of A Boilermessi107No ratings yet

- Incinerator CDocument12 pagesIncinerator CArjun Shantaram ZopeNo ratings yet

- Properties of Steam Numericals v2Document32 pagesProperties of Steam Numericals v2Saurabh R Shah100% (4)

- Strategy For DistillationColumn ControlDocument529 pagesStrategy For DistillationColumn ControlLisandro Mangini100% (2)

- Condenser CondenserDocument47 pagesCondenser CondenserPrashant Puri100% (1)

- Steam Turbine PerformanceDocument16 pagesSteam Turbine PerformanceVILLANUEVA_DANIEL2064100% (3)

- 21 Surface CondensersDocument12 pages21 Surface CondensersMohsin EhsanNo ratings yet

- Steam HandbookDocument64 pagesSteam Handbookmsavidge50No ratings yet

- Flue Gas Heat Recovery in Power Plants, Part IIIDocument6 pagesFlue Gas Heat Recovery in Power Plants, Part IIIknsaravanaNo ratings yet

- Steam and Energy SystemsDocument264 pagesSteam and Energy SystemsdeepNo ratings yet

- 1 Reboilers TypesDocument5 pages1 Reboilers TypesIvan Ruben Capuñay IzquierdoNo ratings yet

- Steam Generator PerformanceDocument7 pagesSteam Generator Performancervkumar61No ratings yet

- Boiler EfficiencyDocument28 pagesBoiler EfficiencyRintu BiswasNo ratings yet

- Daily Maintenance BoilerDocument3 pagesDaily Maintenance BoilerAppleuk SudarNo ratings yet

- Furnace Flooding, 011107Document11 pagesFurnace Flooding, 011107Arief HidayatNo ratings yet

- Chapter 21: Evaporation - Principles, Types of EvaporatorsDocument7 pagesChapter 21: Evaporation - Principles, Types of EvaporatorssdfaNo ratings yet

- Ethylene Refrigeration CompressorDocument17 pagesEthylene Refrigeration CompressorfvaefaNo ratings yet

- Process Calculations Sample ChaptersDocument21 pagesProcess Calculations Sample ChaptersGurunath Epili50% (2)

- Types of EvaporatorsDocument12 pagesTypes of Evaporatorsapi-377437388% (8)

- Refining Process (ARCHANA COMPLETE REFINING STUFF)Document96 pagesRefining Process (ARCHANA COMPLETE REFINING STUFF)Mahesh sinhaNo ratings yet

- Reducing Steam Header PressureDocument1 pageReducing Steam Header Pressuresj_scribdNo ratings yet

- Steam Turbines FundamentalsDocument51 pagesSteam Turbines Fundamentalssevero97100% (2)

- Reciprocating CompressorDocument24 pagesReciprocating CompressorSANTHOSH NAGARAJA0% (1)

- Cog en Era Ti OnDocument12 pagesCog en Era Ti OnMayank DubeyNo ratings yet

- Fired Heater SimulatorDocument11 pagesFired Heater SimulatorNimeshKamatNo ratings yet

- Boiler Controls and Boiler InterlocksDocument24 pagesBoiler Controls and Boiler InterlocksMohamed ShameemNo ratings yet

- Fuel Ethanol Distillation - Fundamentals - KatzenDocument18 pagesFuel Ethanol Distillation - Fundamentals - Katzenaseptman1No ratings yet

- IEEE BoilerDocument9 pagesIEEE Boiler4nagNo ratings yet

- Vaccum DistillationDocument36 pagesVaccum Distillationquangquy91No ratings yet

- Boilers: Eng. W.M. Sathyajith KandegamaDocument67 pagesBoilers: Eng. W.M. Sathyajith Kandegamakmas1612No ratings yet

- Steam BoilerDocument41 pagesSteam BoilerRhydham PNo ratings yet

- WEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaDocument10 pagesWEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaMisge ChekoleNo ratings yet

- Steam Generation & Distribution PDFDocument34 pagesSteam Generation & Distribution PDFPopescu Andrei-Mihai50% (2)

- Single and Multistage Steam Jet Ejectors: TorinoDocument12 pagesSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiNo ratings yet

- FCC Troubleshooting - Catalyst LossesDocument36 pagesFCC Troubleshooting - Catalyst LossesLee860531No ratings yet

- Boiler EconomyDocument64 pagesBoiler EconomyKhurram ShahzadNo ratings yet

- Management of Spent Catalysts in Petroleum RefineriesDocument11 pagesManagement of Spent Catalysts in Petroleum Refineriesapi-3775048100% (5)

- Diagnosis of Boiler PerformanceDocument36 pagesDiagnosis of Boiler PerformanceAnsuman Sen SharmaNo ratings yet

- Boiler Seminar - Taylor PDFDocument140 pagesBoiler Seminar - Taylor PDFhercuhattyNo ratings yet

- BoilersDocument39 pagesBoilersVinay Balineni100% (1)

- Principles of Boiler OperationsDocument35 pagesPrinciples of Boiler Operationseblees100No ratings yet

- PTQ Q2 - Spirax PT 1Document6 pagesPTQ Q2 - Spirax PT 1Pop-Coman Simion100% (1)

- OJT 6 - Boiler Water TreatmentDocument26 pagesOJT 6 - Boiler Water TreatmentAzizul Ishak100% (1)

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- GF Type 546 BallDocument10 pagesGF Type 546 Ballbabis1980No ratings yet

- 1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013Document2 pages1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013babis1980No ratings yet

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsDocument70 pagesThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- P&IDDocument18 pagesP&IDhectornicolau100% (1)

- Tech Manual Electrical Power Plant DesignDocument135 pagesTech Manual Electrical Power Plant Designd_kabulpuriaNo ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Sa 312Document1 pageSa 312babis1980No ratings yet

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980No ratings yet

- Flanged Immersion Heaters: Operating ConditionsDocument1 pageFlanged Immersion Heaters: Operating Conditionsbabis1980No ratings yet

- ATEX Reference GuideDocument2 pagesATEX Reference Guidebabis1980No ratings yet

- 4.24 Drains Systems Design PhilosophyDocument8 pages4.24 Drains Systems Design Philosophybabis1980No ratings yet

- Brochure ACCDocument8 pagesBrochure ACCbabis1980No ratings yet

- DS FL1001 GB 50631Document10 pagesDS FL1001 GB 50631Rafael IbelliNo ratings yet

- CEMS Guidelines Volume I Full VersionDocument28 pagesCEMS Guidelines Volume I Full Versionbabis1980100% (1)

- Screw Plug Immersion Heaters: Operating ConditionsDocument1 pageScrew Plug Immersion Heaters: Operating Conditionsbabis1980No ratings yet

- Face-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Classes 150, 300, 600, 900, 1500, and 2500)Document18 pagesFace-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Classes 150, 300, 600, 900, 1500, and 2500)babis1980No ratings yet

- Furnaces and Furnace ReactorsDocument33 pagesFurnaces and Furnace ReactorsSamyak JainNo ratings yet

- Lecture 4 PumpsDocument38 pagesLecture 4 PumpsArvin BhurtunNo ratings yet

- Wmo 364-V1p1 Dynamic AtmosphericDocument345 pagesWmo 364-V1p1 Dynamic AtmosphericwalterdryNo ratings yet

- Service Manual Hsu-09 (12) Ha Hva Rha103r2 (DB) - TD (071230)Document79 pagesService Manual Hsu-09 (12) Ha Hva Rha103r2 (DB) - TD (071230)ronson72No ratings yet

- Teh 908a PDFDocument30 pagesTeh 908a PDFAnonymous 73gEYyEtLNo ratings yet

- API 6A ValveDocument12 pagesAPI 6A Valveedo_tapia_ur100% (1)

- 1st Sem Timetable CPE 21-22Document5 pages1st Sem Timetable CPE 21-22EmmanuelNo ratings yet

- Properties of Pure Substance and Steam Power Cycle Pure SubstanceDocument43 pagesProperties of Pure Substance and Steam Power Cycle Pure SubstanceSachin SinghNo ratings yet

- Study Plan...Document3 pagesStudy Plan...mustafakamal35302100% (1)

- Pengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDocument7 pagesPengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDwi BintangNo ratings yet

- (Rev. A) LVSL& Merlin Valve AdapterDocument3 pages(Rev. A) LVSL& Merlin Valve AdapterLost LionNo ratings yet

- Cornell MANURE 2016Document8 pagesCornell MANURE 2016MatoNo ratings yet

- Sulfinol D Evaluation.Document24 pagesSulfinol D Evaluation.Clibert RodríguezNo ratings yet

- J-SF24 Sand FilterDocument8 pagesJ-SF24 Sand Filterelle diemNo ratings yet

- Calculations Tank S6Document19 pagesCalculations Tank S6Joshue Adele100% (1)

- MANOMETER Power PointDocument16 pagesMANOMETER Power PointErwin Bolamino BlasNo ratings yet

- Zohr Onshore Project Facilities Rup System & Sub-System Breakdown ListDocument7 pagesZohr Onshore Project Facilities Rup System & Sub-System Breakdown ListMohamedNo ratings yet

- Mass Balance Tutorial 2 - 2021 Fin-StuDocument2 pagesMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanNo ratings yet

- Experimental Aerodynamic Analysis of Delta WingDocument9 pagesExperimental Aerodynamic Analysis of Delta WingSharan Teja ElagandulaNo ratings yet

- BowTie Poster Loss of ContainmentDocument1 pageBowTie Poster Loss of ContainmentRoberto Burgos0% (1)

- Fabrication & Installation of Thorp T-211 WingDocument102 pagesFabrication & Installation of Thorp T-211 WingSudharSanNo ratings yet

- Theory Book Compaction DdpandaDocument7 pagesTheory Book Compaction Ddpandapratik gamaraNo ratings yet

- Proposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)Document2 pagesProposed Sewage Treatment Plant of Piggery Farm 50CmD (Design and Build)John Axl LajomNo ratings yet

- AIAA-Prediction of Average DownwashDocument21 pagesAIAA-Prediction of Average DownwashChan Teng YanNo ratings yet

- Agitation and MixingDocument77 pagesAgitation and MixingKolliparaDeepak100% (1)

- Tank Venting API STD 2000 Nov 2009 RevisDocument3 pagesTank Venting API STD 2000 Nov 2009 RevisCarlos Arias50% (2)

- 460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolandDocument8 pages460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolanddhmbasNo ratings yet

- t2 S 686 Separating Mixtures Powerpoint Ver 1Document8 pagest2 S 686 Separating Mixtures Powerpoint Ver 1Misbah HashmiNo ratings yet