Professional Documents

Culture Documents

Mech 203 Term Project Automobile Differential and Transmission

Mech 203 Term Project Automobile Differential and Transmission

Uploaded by

venkateshyadav21160 ratings0% found this document useful (0 votes)

7 views29 pagesmech 203 term proj

Original Title

Mech 203 Term Project

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmech 203 term proj

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

7 views29 pagesMech 203 Term Project Automobile Differential and Transmission

Mech 203 Term Project Automobile Differential and Transmission

Uploaded by

venkateshyadav2116mech 203 term proj

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 29

Mech 203 Term Project

Automobile Differential and

Transmission

Hakan Uzuner

mm Ko

mer Fidan

What is a differential?

Differential is a device capable of

transmitting torque and rotation through

three shafts, almost always used in one of

two ways. In one of these, it receives one

input and provides two outputs; this is

found in most automobiles. In an

automobile and other wheeled vehicles,

the differential allows each of the driving

wheels to rotate at different speeds, while

supplying equal torque to each of them.

Purpose of a differential

The differential is found on all modern cars

and trucks, and also in many all-wheel-

drive vehicles. These all-wheel-drive

vehicles need a differential between each

set of drive wheels, and they need one

between the front and the back wheels as

well, because the front wheels travel a

different distance through a turn than the

rear wheels.

Differential Gear Train on a Turning Car

Differential Gear Train on a Turning Car

The outer wheel traverses an arc with radius

r

o

and the inner wheel traverses an arc with

radius r

i

. As illustrated, the lengths of the

arcs traversed are s

o

, s

n

, and s

i

. The outer

arc s

o

is obviously larger than the inner arc

s

i

for a given traversed angle theta. Some

way of ensuring that the outer wheel is

able to turn slightly faster than the inner

wheel must be ensured in order to prevent

binding and slippage of the tires on the

road.

Differential Gear Train on a Turning Car

Fortunately, the automobile

differential solves this problem with

only one transmission and one drive

shaft for both driven wheels.

Differential Gear Train on a Turning Car

Since s=r(THETA), the length of the arc traversed

for a given theta is proportional to the radius. Since

r

o

is greater than r

n

by the same amount that r

i

is

less than r

n

, the right wheel center must travel

further than the car center by the same amount that

the left wheel center must travel less further than

the car center. As its name implies, a differential

allows the left and right drive wheels to turn

differentially with respect to each other. As can be

seen by turning the drive wheels of a car on a

mechanic's lift, turning one drive wheel results in

the opposite wheel turning at the same rate in the

opposite direction.

Automobile Differential Animation

http://auto.howstuffworks.com/diffe

rential2.htm

Parts of a differential

Differential

Automobile Differential in Unigraphics

Before we started our project, we

researched the dimensions and overall

shape of a differential system on internet

and by visiting a car mechanic shop. After

we acquired the necessary data, we

started to construct our differential

system by using Unigraphics. We reduced

and normalized the dimensions that we

collected for easier application to

unigraphics.

Automobile Differential in Unigraphics

We scaled and normalized the

dimensions we have gathered

for easier drawing experience in

Unigraphics.

Autmobile Differential in Unigraphics

Our differential system consisted of

eight unique parts. Six of these

were used to construct the

differential. These included crown

gear, sungear, planet pinion, drive

shaft and half shafts, which connect

to the wheels. Two remaining parts

made up our wheels.

Autmobile Differential in Unigraphics

Autmobile Differential in Unigraphics

Automobile Transmission

Using the principle of mechanical

advantage, transmissions provide a

speed-torque conversion

(commonly known as "gear

reduction" or "speed reduction")

from a higher speed motor to a

slower but more forceful output or

vice-versa.

Autmobile Transmission

Most modern gearboxes either

reduce an unsuitable high speed

and low torque of the prime mover

output shaft to a more stable lower

speed with higher torque, or do the

opposite and provide a mechanical

advantage (i.e increase in torque) to

allow higher forces to be generated.

Autmobile Transmission

Manual transmission come in two

basic types:

Sliding-mesh

Constant-mesh

Automobile Transmission

Sliding-mesh or unsynchronized /

non-synchronous system, where

straight-cut spur gear sets are

spinning freely, and must be

synchronized by the operator

matching engine revs to road

speed, to avoid noisy and damaging

"gear clash"

Automobile Transmission

Constant-mesh gearboxes which

can include non-synchronised, or

synchronized/synchromesh systems,

where diagonal cut helical (and

sometimes double-helical) gear sets

are constantly "meshed" together,

and a dog clutch is used for changing

gears. On synchromesh boxes,

friction cones or "synchro-rings" are

used in addition to the dog clutch.

Automobile transmission

Automobile transmission in Unigraphics

The challenging part of designing a

transmission in unigraphics was the

amount of gears we had to draw. Gear

drawing is hard due to the fact that each

gear has to be perfect since they have to

fit with the adjacent gears. We used the

dimensions acquired from machine

shops and internet to design an accurate

transmission.

Automobile transmission in Unigraphics

We designed fifteen gears for our

trasmission (5 gears and reverse). We

also included the synchronizers

between the gears.

Automobile transmission in Unigraphics

Automobile transmission in Unigraphics

Automobile transmission in Unigraphics

Automobile transmission in Unigraphics

Automobile transmission in Unigraphics

Automobile transmission in Unigraphics

You might also like

- The Perfect Corner 2: A Driver's Step-by-Step Guide to Optimizing Complex Sections Through the Physics of RacingFrom EverandThe Perfect Corner 2: A Driver's Step-by-Step Guide to Optimizing Complex Sections Through the Physics of RacingNo ratings yet

- CPC KersDocument13 pagesCPC KersandrewgeorgecherianNo ratings yet

- Automobile Transmission System and Its ComponentsDocument5 pagesAutomobile Transmission System and Its ComponentsSelvakumar JayarajNo ratings yet

- Final ReportDocument37 pagesFinal ReportAliNo ratings yet

- Semi Automatic Transmission ReportDocument52 pagesSemi Automatic Transmission ReportPranav EkhandeNo ratings yet

- Module 3 - Lesson 1 - MEEC 101A PDFDocument8 pagesModule 3 - Lesson 1 - MEEC 101A PDFErica May MundinaNo ratings yet

- Good Morning .?: Presentation On Vehicle Steering Systems by Pari, D.J & K.CDocument29 pagesGood Morning .?: Presentation On Vehicle Steering Systems by Pari, D.J & K.CSrikar ChinmayaNo ratings yet

- Second ReportDocument14 pagesSecond ReportMy ProNo ratings yet

- TO Automotive Steering SystemDocument22 pagesTO Automotive Steering SystemJ Naveen KumarNo ratings yet

- Automotive (2) Lab: EXP2: Manual Transmission and TransaxlesDocument10 pagesAutomotive (2) Lab: EXP2: Manual Transmission and TransaxlesMohammad YahyaNo ratings yet

- Kassahun Tadess GeerboxDocument16 pagesKassahun Tadess Geerboxabubekery61No ratings yet

- Geer box-WPS OfficeDocument6 pagesGeer box-WPS OfficeYosef EphremNo ratings yet

- Title: Automotive Powertrain Date: Objective: To Understand The Power Train Components of Automobiles Both Observation/TheoryDocument17 pagesTitle: Automotive Powertrain Date: Objective: To Understand The Power Train Components of Automobiles Both Observation/TheorybroNo ratings yet

- Chapter 2 - Manual Transmission P2Document36 pagesChapter 2 - Manual Transmission P2ahmad kamalNo ratings yet

- Automotive Driveline Overview PDFDocument8 pagesAutomotive Driveline Overview PDFKarniNo ratings yet

- Steering: Essential To Driving: Latest Blog EntryDocument8 pagesSteering: Essential To Driving: Latest Blog EntrySoham DeNo ratings yet

- 1.conventional SteeringDocument11 pages1.conventional SteeringRaghu Ram Bura100% (1)

- Chemical SensorsDocument10 pagesChemical Sensorsmos3ad2006No ratings yet

- " Transmission System of An Automobile Vehicle ": Mr. V. M. BarethiyeDocument15 pages" Transmission System of An Automobile Vehicle ": Mr. V. M. BarethiyevbarethiyaNo ratings yet

- Seminar FinalDocument21 pagesSeminar FinalLOKENDRA91No ratings yet

- Lecture 7 Notes Manual TransmissionsDocument22 pagesLecture 7 Notes Manual TransmissionsMatthew JumaNo ratings yet

- Advanced Four Wheel Steering SystemDocument5 pagesAdvanced Four Wheel Steering SystemSyedAbuBakar'sAlkaffNo ratings yet

- Differential GearDocument20 pagesDifferential GearSalman SaifuddinNo ratings yet

- Gearboxes ClassDocument35 pagesGearboxes ClassNaveen Vachipalli100% (1)

- Steering: BallDocument7 pagesSteering: BallLokesh Kumar GuptaNo ratings yet

- Transmission SystemDocument29 pagesTransmission SystemSaicharan VelpulaNo ratings yet

- Why Wheels Don't Point in The Same Direction?Document14 pagesWhy Wheels Don't Point in The Same Direction?BrijNo ratings yet

- GearboxDocument15 pagesGearboxRaduNo ratings yet

- Gear Box TypesDocument4 pagesGear Box TypespenihaniNo ratings yet

- Senior Project ReportDocument6 pagesSenior Project ReportRoss Bunnell100% (1)

- The Steering Bible: Steering: Essential To DrivingDocument10 pagesThe Steering Bible: Steering: Essential To DrivingAlykNo ratings yet

- Assignment 3 AutomobileDocument11 pagesAssignment 3 Automobilepawan sharmaNo ratings yet

- Title: Automotive Powertrain Date: Objective: To Understand The Power Train Components of Automobiles BothDocument6 pagesTitle: Automotive Powertrain Date: Objective: To Understand The Power Train Components of Automobiles BothbroNo ratings yet

- Car BibleDocument3 pagesCar BibleSoheil YadNo ratings yet

- Automotive Transmission SystemDocument94 pagesAutomotive Transmission SystemTanzim Rafat AyonNo ratings yet

- Indian Institute of Technology PatnaDocument14 pagesIndian Institute of Technology PatnaAnkit SahNo ratings yet

- Table of ContentDocument19 pagesTable of ContentAmrit singhNo ratings yet

- DIFFERENTIALSDocument10 pagesDIFFERENTIALSAyodeji AdeyemiNo ratings yet

- Design Progress 123Document24 pagesDesign Progress 123a61812344No ratings yet

- Unit-Iv Steering SystemDocument20 pagesUnit-Iv Steering SystemMark MubiruNo ratings yet

- Design of The Differential For A Truck Brand Ford Model Ranger 1998Document22 pagesDesign of The Differential For A Truck Brand Ford Model Ranger 1998Mishu MalesNo ratings yet

- How Steering Wheel WorkDocument4 pagesHow Steering Wheel Workbashiradd@yahoo.comNo ratings yet

- Actr Mod 2Document18 pagesActr Mod 2jithinkumar22103No ratings yet

- Hotchkiss Drive RearDocument17 pagesHotchkiss Drive RearravivpsNo ratings yet

- Ch-10-Steering and Front AxleDocument45 pagesCh-10-Steering and Front Axlekeval patel100% (2)

- What We Are Going To UseDocument8 pagesWhat We Are Going To UseSukhmandeep SinghNo ratings yet

- MCT 311 Lesson 5Document16 pagesMCT 311 Lesson 5Moussa SaidNo ratings yet

- How Does A Car Steering WorkDocument8 pagesHow Does A Car Steering WorkJ Naveen KumarNo ratings yet

- ThessisDocument43 pagesThessisManjeet SinghNo ratings yet

- What Is A Gearbox? (Transmission) - Types, Parts, Function & DiagramDocument14 pagesWhat Is A Gearbox? (Transmission) - Types, Parts, Function & DiagramTisha GaikwadNo ratings yet

- Ninty Degree SteeringDocument48 pagesNinty Degree Steeringparas bhogulkarNo ratings yet

- Why Do We Need Epicyclic Transmission?Document4 pagesWhy Do We Need Epicyclic Transmission?Md Faisal HussainNo ratings yet

- Design and Manufacturing of Differential Locking SystemDocument6 pagesDesign and Manufacturing of Differential Locking SystemShashank VaidyaNo ratings yet

- Suspension: 1) Wheelbase and TrackwidthDocument8 pagesSuspension: 1) Wheelbase and TrackwidthRaneem khaledNo ratings yet

- Chapter 2Document22 pagesChapter 2avinashNo ratings yet

- Internship ReportDocument15 pagesInternship ReportEshwar Krishna50% (2)

- Jaipur National University: Shivam Hyundai Ajmer Training ReportDocument26 pagesJaipur National University: Shivam Hyundai Ajmer Training ReportvivekNo ratings yet

- AUTOMOTIVEpower Drive Train MODULE 2Document17 pagesAUTOMOTIVEpower Drive Train MODULE 2Selazinap LptNo ratings yet

- Car Steering MechanismDocument9 pagesCar Steering MechanismJanak AnandNo ratings yet

- The Slot Car Handbook: The definitive guide to setting-up and running Scalextric sytle 1/32 scale ready-to-race slot carsFrom EverandThe Slot Car Handbook: The definitive guide to setting-up and running Scalextric sytle 1/32 scale ready-to-race slot carsRating: 3 out of 5 stars3/5 (1)

- Activity Relationship Chart 2Document2 pagesActivity Relationship Chart 2Yugi SupriatnaNo ratings yet

- IELTS Writing Lesson Plan 1 PDFDocument10 pagesIELTS Writing Lesson Plan 1 PDFYugi SupriatnaNo ratings yet

- Clause (Adjective+Adverb)Document13 pagesClause (Adjective+Adverb)Yugi Supriatna100% (1)

- IELTS Writing Lesson Plan 2 PDFDocument12 pagesIELTS Writing Lesson Plan 2 PDFYugi Supriatna0% (1)

- Differential DiagnosisDocument31 pagesDifferential DiagnosisYugi Supriatna100% (1)

- Eaton Fs 6309Document2 pagesEaton Fs 6309atendimento.dcdNo ratings yet

- Report On GearDocument18 pagesReport On GearShubham KhannaNo ratings yet

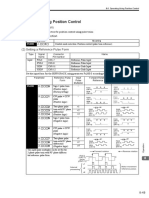

- YASKAWA - SGDMs80000015d - 8 - 1 - Setting in Position Mode ControlDocument5 pagesYASKAWA - SGDMs80000015d - 8 - 1 - Setting in Position Mode ControldangkhuyenmaiNo ratings yet

- Lesson Plan GR 9 Technology T3 W6Document7 pagesLesson Plan GR 9 Technology T3 W6sibiyazukiswa27No ratings yet

- Geometry Design of An Elementary Planetary Gear Trainwith Cylindrical Tooth-ProfilesDocument11 pagesGeometry Design of An Elementary Planetary Gear Trainwith Cylindrical Tooth-ProfilesAlejandro ChavezNo ratings yet

- Grua Electircaribe T-2844Document2 pagesGrua Electircaribe T-2844davidsierraNo ratings yet

- Designand Analysisofan Integrated Coconut Gratingand Milk Extracting Machine Journal FormatDocument17 pagesDesignand Analysisofan Integrated Coconut Gratingand Milk Extracting Machine Journal FormatJenny AtienzaNo ratings yet

- Theory of Machine (9050)Document7 pagesTheory of Machine (9050)Candice Andrews25% (4)

- QB For KomDocument19 pagesQB For KomNoor KNo ratings yet

- Chapter 9 - Solved ProblemsDocument11 pagesChapter 9 - Solved Problemshanihamoud05No ratings yet

- 2020 DentalDocument25 pages2020 DentalJuanjo CascoNo ratings yet

- Jeep Willy MB GPW ManualDocument242 pagesJeep Willy MB GPW Manualpunjaa83% (6)

- pk2 Catalogue enDocument100 pagespk2 Catalogue engabictbNo ratings yet

- Gears: Gear Types 1.2 Gear Nomenclature and FormulasDocument17 pagesGears: Gear Types 1.2 Gear Nomenclature and FormulasDarwin LimNo ratings yet

- Machine Design Problem SetsDocument23 pagesMachine Design Problem SetsMAX LAPINGCAO100% (1)

- Ab 01023Document24 pagesAb 01023ANWARNo ratings yet

- 3054 Idler Gear - Remove and Install - Delphi DP210 Fuel InjectionDocument8 pages3054 Idler Gear - Remove and Install - Delphi DP210 Fuel Injectionhenry lavieraNo ratings yet

- 04 Power TransmissionDocument16 pages04 Power TransmissionVasudev Gupta100% (1)

- Motor Selection ExampleDocument11 pagesMotor Selection ExampleMorena MoremoholoNo ratings yet

- English 3578049401Document447 pagesEnglish 3578049401jhonatan_silveira_8100% (1)

- Kom Assignments PDFDocument6 pagesKom Assignments PDFapi-263237278No ratings yet

- Modelling, Simulations, and Optimisation of Electric Vehicles For Analysis of Transmission Ratio SelectionDocument15 pagesModelling, Simulations, and Optimisation of Electric Vehicles For Analysis of Transmission Ratio SelectionKyla WindartaNo ratings yet

- SSS Syllabus RoboticsDocument25 pagesSSS Syllabus RoboticsIsaiah sesayNo ratings yet

- Siemens SQM331Document8 pagesSiemens SQM331WitbaasNo ratings yet

- Maruti Swif DZire ZDi BSIV-201188646Document7 pagesMaruti Swif DZire ZDi BSIV-201188646Sayed AsifNo ratings yet

- Examples of GearDocument3 pagesExamples of GearShailesh Patel100% (1)

- Puestatiempo3064 PDFDocument5 pagesPuestatiempo3064 PDFRaul RodriguezNo ratings yet

- Four Gear TransmissionDocument7 pagesFour Gear Transmissionshaan punekarNo ratings yet