Professional Documents

Culture Documents

Flame Seal - TB

Flame Seal - TB

Uploaded by

littlepao0 ratings0% found this document useful (0 votes)

97 views1 pageFLAME SEAL-TB(tm) is the first thin film paint-on 15minute thermal barrier to pass the UL-1715 room corner fire test. The fire protective coating provides a highly protective thermal and ignition barrier for spray on Polyurethane foam insulation.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFLAME SEAL-TB(tm) is the first thin film paint-on 15minute thermal barrier to pass the UL-1715 room corner fire test. The fire protective coating provides a highly protective thermal and ignition barrier for spray on Polyurethane foam insulation.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

97 views1 pageFlame Seal - TB

Flame Seal - TB

Uploaded by

littlepaoFLAME SEAL-TB(tm) is the first thin film paint-on 15minute thermal barrier to pass the UL-1715 room corner fire test. The fire protective coating provides a highly protective thermal and ignition barrier for spray on Polyurethane foam insulation.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

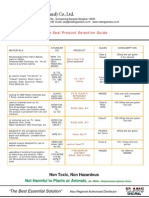

ROBERGE & CO. (Thailand) Co.,Ltd.

SSP Tower3, 14 Fl. Unit A3, 88 Silom Rd., Suriyawong Bangrak Bangkok 10500

Tel: 662-863-3200 Fax: 662-863-4955 E-mail: sales@robergeandco.co.th www.robergeandco.co.th

FLAME SEAL-TB™ - THERMAL BARRIER FOAM COATING

Coating Passed UL-1715 test specifications at Intertek Laboratory

on Polyurethane Foam (Less than 18 mils...Thin Film "Paint-On" Coating)

Total Solids: 61% - 66%

FLAME SEAL – TB™ is the first thin film paint-on 15minute thermal

barrier to pass the UL-1715 room corner fire test. The fire protective

Weight per

10.8 lbs.- 11.2 lbs.

coating provides a highly protective thermal and ignition barrier for

spray on Polyurethane foam insulation. At flame temperatures over Gallon:

600F/315C FLAME SEAL-TB™ will resist flame spread to substrate Specific

1.3 - 1.4

of wall and ceiling treated with the product. Gravity:

pH: 2.5 - 3.5

RECOMMENDED USE: Flash Point: None

Color: White

"FLAME SEAL-TB™ FIRE BARRIER COATING" - CLASS A:

thermal barrier intumescent coating, designed for use over Coverage: 65 Square Feet-Gallon

Volatility: Non-volatile

Polyurethane Foam Insulation. Application may be accomplished by

either brush, roller, or spray methods. Blend well in original

Water (Contains no

container before use, as some solids may settle on the bottom of the Solvents:

container. Mix with T50-TB™ curing agent at a mix ratio of 4:1 (4 petroleum derivatives)

parts FLAME SEAL-TB™ resin to 1 part T50-TB™ by volume. Ex: Toxicity: Non-toxic

4 gallons FLAME SEAL-TB™ + 1 gallon T50-TB™) Mix thoroughly

Fungus

with low-medium speed mixer for 5 minutes. The coverage rate Good

should be 65 square feet per gallon. (See Intertek UL-1715 Test Resistance:

Mold

Good

Report) This product recommended for Interior use only.

Resistance:

Bacteria

Mildly resistant

Compliant with FDA/USDA for incidental food Resistance

contact. Linear

None

This product complies with U.S. Federal Regulations Shrinkage:

concerning the use of lead in paint AND hydrocarbon Moisture

None

emissions. Absorption:

Corrosive: Mildly, none when dry

FLAME SEAL-TB™ COATING is mixed with T50-TB™ CURING AGENT (both arrive in

correct mixture ratios)

Non Toxic, Non Hazardous

Not Harmful to Plants or Animals, (No PBDEs - Polybrominated diphenyl ethers)

“The Best Essential Solution” Asia Regional Authorized Distributor

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Press Release TemplateDocument2 pagesPress Release TemplateJocelyn MartensonNo ratings yet

- Tirupati Telecom Primary Account Holder Name: Your A/C StatusDocument12 pagesTirupati Telecom Primary Account Holder Name: Your A/C StatusMy PhotosNo ratings yet

- Innovatum DLP WPDocument9 pagesInnovatum DLP WPlittlepaoNo ratings yet

- FX-100 Application Method Catalog1Document1 pageFX-100 Application Method Catalog1littlepao100% (2)

- Paper SealDocument1 pagePaper SeallittlepaoNo ratings yet

- FX-100 Fire Retardant CoatingDocument1 pageFX-100 Fire Retardant CoatinglittlepaoNo ratings yet

- FX-100 Fire Retardant Coating CatalogDocument1 pageFX-100 Fire Retardant Coating Cataloglittlepao100% (2)

- FS Paper SealDocument1 pageFS Paper Seallittlepao100% (2)

- FX-100 Application Method Catalog1Document1 pageFX-100 Application Method Catalog1littlepao100% (2)

- FS-Fabric N CatalogDocument1 pageFS-Fabric N CataloglittlepaoNo ratings yet

- FS-Fabric Application CON DILUTIONDocument1 pageFS-Fabric Application CON DILUTIONlittlepaoNo ratings yet

- Fs ConcentrateDocument1 pageFs ConcentratelittlepaoNo ratings yet

- Flame Seal Product Selection GuideDocument1 pageFlame Seal Product Selection GuidelittlepaoNo ratings yet

- Bar Bending Schedule (Service BLDG)Document20 pagesBar Bending Schedule (Service BLDG)Rania SaiedNo ratings yet

- Sungrow-SG3 0RT-SG4 0RTDocument2 pagesSungrow-SG3 0RT-SG4 0RTchris dascalopoulosNo ratings yet

- C#Document42 pagesC#Shreyansh SharmaNo ratings yet

- What Is Pesonet?: Frequently Asked Questions OnDocument4 pagesWhat Is Pesonet?: Frequently Asked Questions OnJackNo ratings yet

- Personal Report Rajiv Patil: Focus StylesDocument3 pagesPersonal Report Rajiv Patil: Focus Stylesrajivpatil11No ratings yet

- Value Maximization, Stakeholder Theory, and The Corporate Objective FunctionDocument2 pagesValue Maximization, Stakeholder Theory, and The Corporate Objective FunctionramdaneNo ratings yet

- Handout - 20475 - AU 2016 Class Handout - Revit and Dynamo For Landscape ArchitectureDocument58 pagesHandout - 20475 - AU 2016 Class Handout - Revit and Dynamo For Landscape ArchitectureKelvinatorNo ratings yet

- Feeling Comfortable With Logic Analyzers PDFDocument24 pagesFeeling Comfortable With Logic Analyzers PDFJ dosherNo ratings yet

- Paper Format ResearchDocument55 pagesPaper Format ResearchJezryl PelayoNo ratings yet

- Wings of FireDocument5 pagesWings of FireJitendra AsawaNo ratings yet

- Meeting Minutes of 17th Departmental MeetingDocument3 pagesMeeting Minutes of 17th Departmental Meetingmyousafzai67No ratings yet

- IDOCs For IntroDocument62 pagesIDOCs For IntroGeetikaNo ratings yet

- Jawapan Topikal Kertas 1 Tingkatan 4Document16 pagesJawapan Topikal Kertas 1 Tingkatan 4qistinaunie07No ratings yet

- Beta-4 Manual SupplementDocument10 pagesBeta-4 Manual SupplementDAVI VIANANo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetFahad NaveedNo ratings yet

- MGT410 Take Home Final 1 - Fall2010Document10 pagesMGT410 Take Home Final 1 - Fall2010Belinda Elois ToNo ratings yet

- Metal Forming ProcessDocument19 pagesMetal Forming ProcessragulnarayanNo ratings yet

- CS 123 I2P Assignment 2Document3 pagesCS 123 I2P Assignment 2Hafiz AbdullahNo ratings yet

- (Adi Kuntsman (Eds.) ) Selfie CitizenshipDocument169 pages(Adi Kuntsman (Eds.) ) Selfie CitizenshipUğur GündüzNo ratings yet

- ABCACBADocument3 pagesABCACBAJohn Clement HusainNo ratings yet

- Corrigendum 18.10.2011Document4 pagesCorrigendum 18.10.2011Ravi KalesNo ratings yet

- IELTS Essay 1 With AnswerDocument1 pageIELTS Essay 1 With AnsweraazizmajidNo ratings yet

- Article WritingDocument10 pagesArticle WritingMosteroidNo ratings yet

- Microprocessor Book PDFDocument4 pagesMicroprocessor Book PDFJagan Eashwar0% (4)

- Students' Attitude Towards English Language Learning: February 2021Document10 pagesStudents' Attitude Towards English Language Learning: February 2021Muhammad RizwanNo ratings yet

- Art Meta-Analyses of Experimental Data in An PDFDocument12 pagesArt Meta-Analyses of Experimental Data in An PDFIonela HoteaNo ratings yet

- TDB-E-CM 725-Technisches DatenblattDocument2 pagesTDB-E-CM 725-Technisches DatenblattNarimane Benty100% (1)

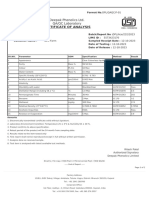

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet